In this article, we will talk about Shining 3D — a company that made a name for itself as a manufacturer of high-end 3D scanners, additionally producing 3D printers along with other equipment for additive and digital production.

Shining3D offers a wide range of 3D digitization and printing solutions, including scanners, printers, additive manufacturing consumables, design services, and a fully-formed networked cloud platform.

Founded in 2004, Shining3D is a recognized leader in independent research, development of additive technologies and innovations in 3D scanning. Shining3D owns over 300 patents and 100 copyrights. The company manufactures 3D products on a large scale, offering powerful technologies and providing solid support around the world.

The goals of Shining3D encompass increasing the efficiency of high-quality 3D modeling, providing flexible production of complex design parts, and making 3D digitization and additive manufacturing technologies available to everyone — from transnational corporations to ordinary users.

Shining3D provides solutions in 3D digitization, intellectual design and additive technologies for industrial production, healthcare and biological sciences, the creation of personalized products and training; offers comprehensive, easy-to-use and profitable products; contributes to the development of 3D technologies.

Headquartered in Hangzhou (China), Shining3D has gained a significant presence in North America and Europe, owns and manages subsidiaries in Stuttgart (Germany) and San Francisco (USA), demonstrates its influence in more than 70 countries in Asia and the Pacific, North and South America, Europe, the Middle East and Africa. One of the official partners and integrators of Shining3D is our company, Top 3D Shop. For many years of fruitful and successful work, we won the Marketing Award.

Ivan Mosunov, COO of Top 3D Shop at the Marketing Award ceremony.

Shining3D factories located in the cities of Hangzhou, Beijing and Tianjin are engaged in the mass production of 3D scanners and 3D printers of various types. The facilities equipped with advanced production and control systems offer customers innovative equipment of high quality and reliability.

Shining3D production systems are based on the strict standards of ISO 9001, ISO 14001, ISO 13485, OHSAS 18001. Most products are certified by CE, FDA, UL, FCC and RoHS, which guarantees consistency in standard and large-scale production, a safeguards system, stable quality and efficiency of production. Applying the criteria for performance excellence (GB/T 19580-2012), the company received the Hangzhou Quality Award, Xiaoshan District, in 2018.

Shining3D develops, manufactures and commercializes a wide range of 3D technologies, including 3D scanners for different industries and applications, a variety of 3D printers, professional software, as well as computer-aided design and 3D control systems.

With the development of science and technology and the improvement of production, there appeared many Class-A curved surfaces in the parts of household appliances, airplanes and vehicles, which require high accuracy, but complex curved surfaces are difficult to inspect using conventional measuring tools. Even if you do employ such an opportunity, the accuracy of checking will be low, especially in the context of curved dimensions, which does not meet time requirements and deal with operational difficulties.

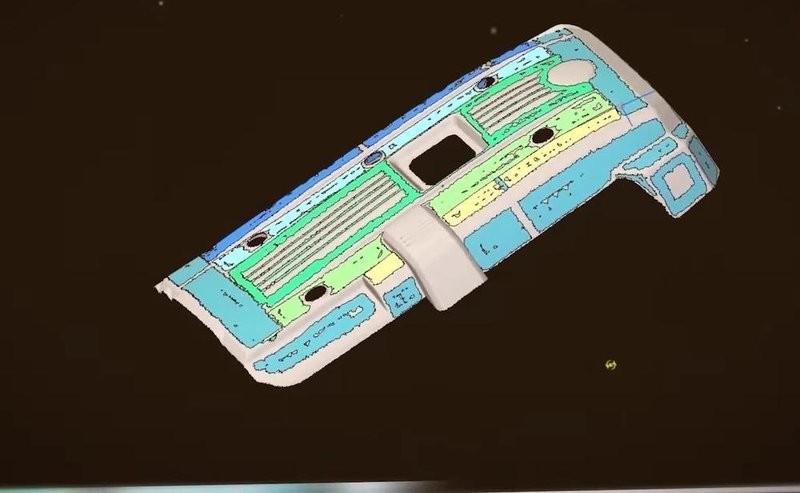

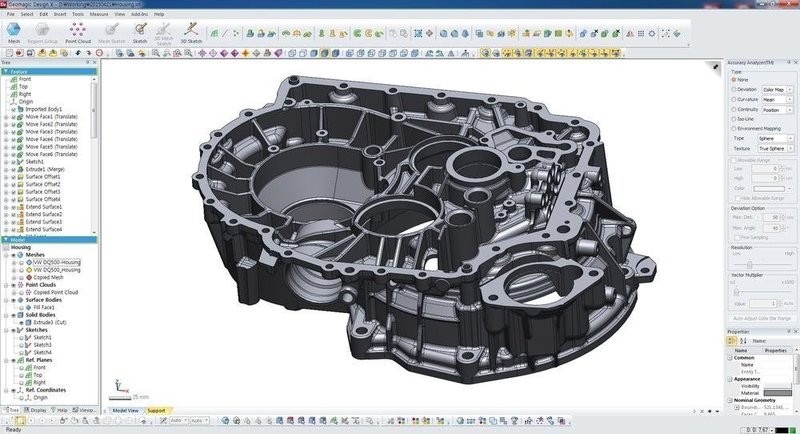

Considering that there are a variety of materials used in the modern manufacturing industry, including soft and easily deformable ones, it seems impossible to inspect them by contact measurement. So, an alternative checking method is needed. The technology of 3D scanning is that of a full-size inspection. The method consists of scanning a local or a whole part of objects to be inspected. Data obtained from point clouds is compared with computer-aided design graphics; a color image of the error code is created as an easily understandable inspection report. Today, 3D scanning technology is widely used in industrial production.

OptimScan-3M is a standard 3D scanner model. High speed and accuracy of scanning are carried out due to 3 MP cameras and Blue Light technology allowing you to scan models of different sizes, various structures and shapes, as well as dark metal objects.

Shining3D OptimScan-5M is the latest 3D scanner with special features, structure, components, and configuration. 5 MP cameras and scanning with the help of Blue Light technology provide amazing speed and accuracy suitable for being used in the defense, aerospace, foundry, and other industries.

The Shining3D high-precision 3D scanner and photogrammetry system can work with professional CAV software. It is used in scanning and full-scale measuring control for most industrial parts, such as molds, turbine blades, part prototypes, plastic parts, castings, and so on.

Shining3D provides plenty of professional 3D scanning software that can automatically compare and analyze errors between CAD models and real parts.

Scan data is processed in batch mode in the inspection report in which:

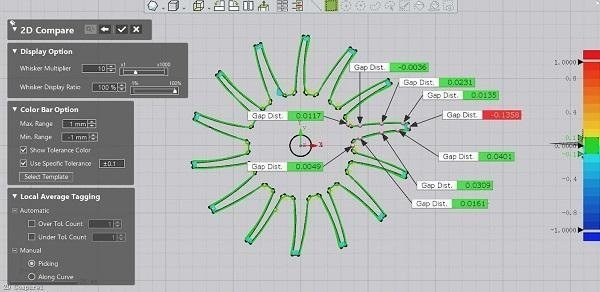

separation lines, characteristic lines, thickness, shape line, profile deviation, residual deviation and cross-section can be indicated;

a detailed comparison with the indicated points on the CAD drawing is available along with the analysis of a continuous curved surface and curvature flow, which ensures fitting of parts and is suitable for setting geometric characteristics and tolerances.

Such a solution minimizes difference errors and drastically saves time, increasing the efficiency of the checking process and therefore production.

The professional software records all stages and parameters. Batch processing is as simple as a single-stage sampling inspection because the software automatically repeats the checking process. It is enough for the user to press one key. Any stage of the process can be changed, the software will automatically update all the aspects related to it.

Shining3D equipment provides high repeatability and dimensional stability in a batch, which is important to ensure the quality level.

3D scanning of large objects with high accuracy appears to be a challenge. Data harmonization is a problem; during the scanning process, you may encounter the so-called cumulative error. It leads to the displacement of scanning, which, in turn, makes the scan data incorrect and useless.

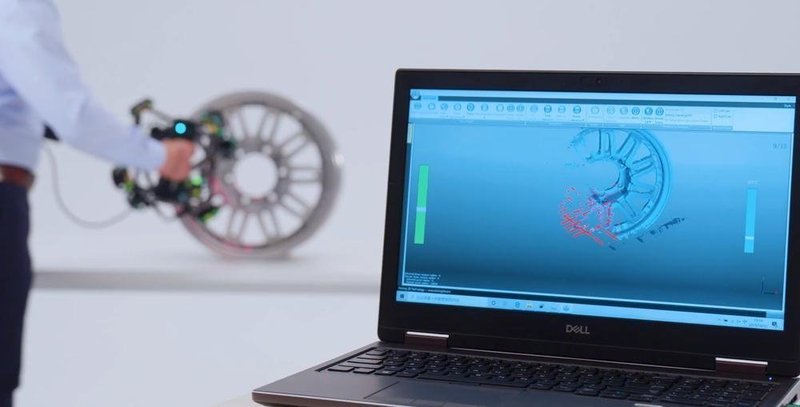

On the other hand, there is photogrammetry, the principle of which is that it is easy to apply to large objects. Of course, the data will not be accurate enough for reverse engineering, not to mention control at the industrial level. But the problem is solvable. Shining3D digital photogrammetry, with the FreeScan line of handheld laser scanners, combines the accuracy of measuring large-scale objects by means of photogrammetry and the high resolution of handheld laser scanning.

The digital photogrammetric system uses a camera and markers to create a three-dimensional standard of the object. Data is imported directly into the FreeScan Shining3D software and downloaded as a global help file. The standard created in the software transmits to FreeScan the shape and size of the object scanned.

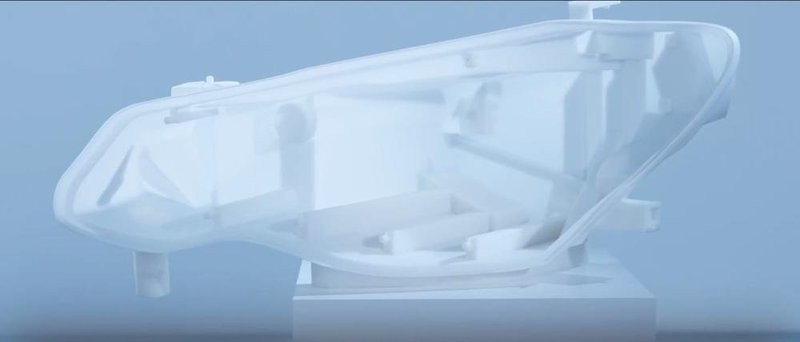

Reverse engineering is a powerful tool for additive manufacturing, which provides methods for generating the necessary three-dimensional data. The combination of additive technology and reverse engineering considerably improves product design and shortens the development cycle. If it is necessary to manufacture an obsolete part that does not have a digital model, a spare part for replacement, reverse engineering offers numerous advantages. A number of industries, including aerospace, automotive and medical, use these benefits, significantly saving time and money.

When designing an object from scratch, a design engineer, as a rule, creates drawings detailing how the object should be built. Reverse engineering presupposes the opposite approach: the design engineer starts with the finished product, working in the opposite direction to get the initial design information.

The reverse engineering process begins with measuring the size and shape of the object. This can be done manually, but 3D scanning is quite common in the industry. The data related to the design specifications of the object is converted to a digital CAD file. At this point, the digital model can be converted to STL, being optimized for 3D printing.

The traditional process of manual measurement of an object for the purpose of reverse engineering is very laborious, requiring a variety of devices, such as calipers and sliding sensors to measure and draw the shape and size of a component before it is replicated to the CAD program. Many objects are very complex and require a significant number of measurements and interpretations to obtain a well-defined three-dimensional model. Manual measurement of complex elements can lead to conflicting results, from part to part and from operator to operator. Needed is a more reliable and reproducible method for measuring parts. Fortunately, we are seeing impressive advances in reverse engineering technology allowing for a fast and precise solution: 3D scanning.

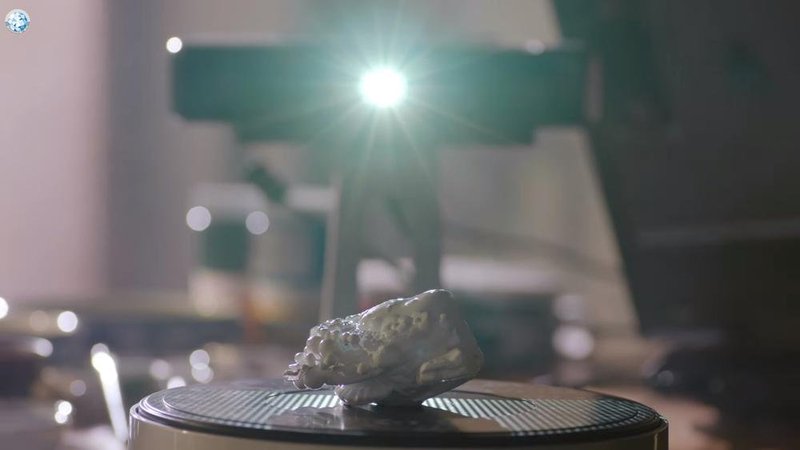

Shining3D scanners are devices used for three-dimensional measurements that allow you to quickly and accurately capture the data of a physical object for creating “point clouds”, which are then converted into a 3D image.

Einscan Pro + is a high-quality 3D scanner designed for professional use in areas such as healthcare, education, design, virtual reality, and engineering. Thanks to such devices, 3D scanning technology becomes easy to use, less expensive and, most importantly, capable of capturing high-quality 3D images.

The key to successful 3D scanning is measuring an object with a sufficient degree of accuracy. For this, there are several options of 3D scanning that help create a model ready for 3D printing:

photogrammetry method;

structured light 3D scanning;

computer tomography.

Technologies such as 3D scanning help integrate reverse engineering into the additive manufacturing workflow, providing producers in different industries with the right solution for specific engineering tasks.

One of the examples is the production of three-dimensional printed prototypes of obsolete parts when restoring discontinued equipment, vintage cars, or when duplicating parts which have never been mass-produced, as in the aerospace industry. In the medical sector, the integration of reverse engineering and additive manufacturing is crucial for complex cases, for instance, 3D scanning and 3D printing for ear reconstruction surgery, creating osteoprosthethic implants, and so on.

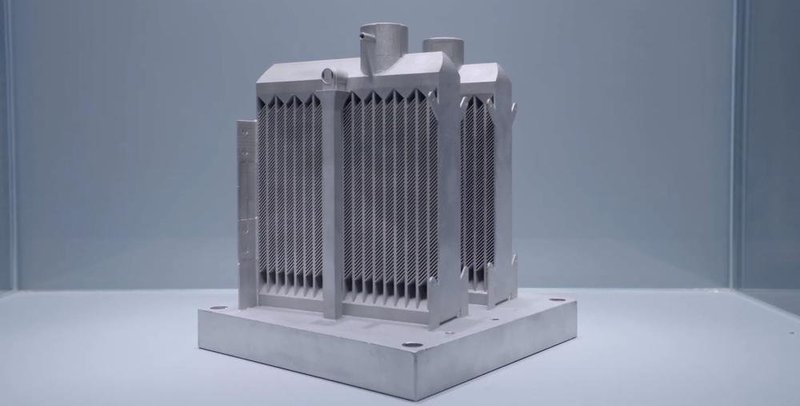

The production of metal additives in the aerospace industry allows for the manufacture of high-quality metal parts of lightweight structures, with an integrated design or complex topology. The solution for 3D digitization and metrology provides the non-contact measurement of aircraft parts, ensuring better quality control.

Through the sequential addition of metal and plastic, additive manufacturing technologies introduce a new method for the production of light components in automobile and machine building. They are perfect for rapid prototyping, speeding up the R&D process and reducing costs.

Solutions for 3D digitization and metrology allow checking large machines and industrial parts for compliance with the project requirements, controlling the wear and deformation of parts over a long period of operation.

Additive manufacturing is a great addition to casting and stamping. For example, metal parts with internal cooling channels, which are impossible or very difficult and expensive to produce using other technologies, significantly surpass their counterparts in quality and cost. The application of additive technologies also helps in machining, allowing you to create patterns and forms in a short time and at a reduced cost.

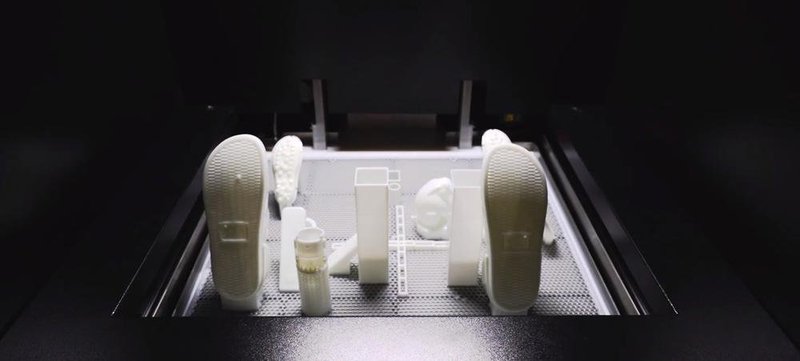

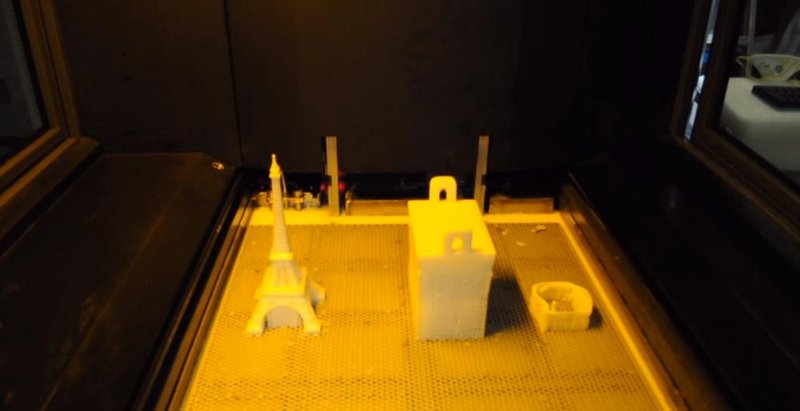

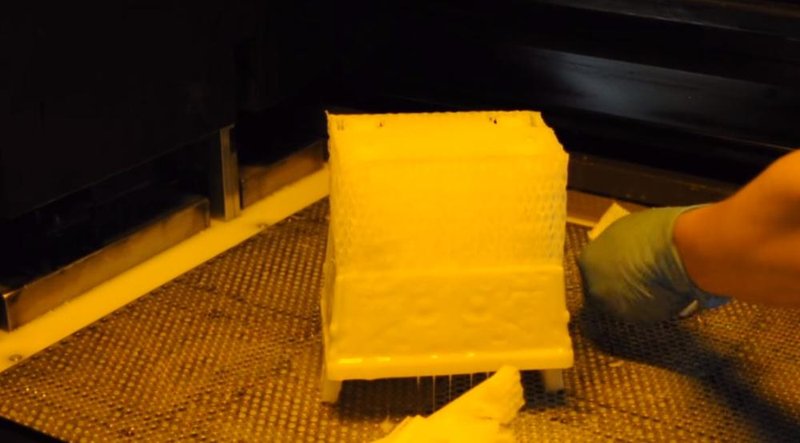

Shining3D offers the latest technologies for rapid prototyping and 3D printing, helping customers realize their product in 3D.

Stereolithography (SLA or SL) is an additive manufacturing technology, one of the several methods used to create models, prototypes, and manufacturing parts. It is the process by which a unique 3D printing machine called a stereolithography apparatus (SLA) turns liquid plastic into solid objects.

Laser stereolithography is a rapid prototyping technology suitable for the production of small and medium-sized parts directly from photopolymer resins, or for the creation of master models or molds for casting. It is mainly used for prototyping conceptual models, simple assembly testing and functionality checking.

There are many ways to 3D print an object. But nearly all of them use computer-aided design (CAD) files — digital images of the object. In 3D printing (or additive manufacturing), CAD files are to be converted to a format understandable to the 3D printer. The standard tessellation language (STL) is one of those file types and the language most commonly used for stereolithography, as well as in other additive manufacturing processes. Since additive manufacturing works by adding layer by layer, CAD models must be layered before 3D printing. STL files slice CAD models, providing the 3D printer with the information needed for printing each layer of the object.

Unlike a desktop printer, which is used to print documents, the SLA printer at startup contains in the print area a tank with resin, part of which polymerizes, forming a solid object.

The maintenance consists of the four main stages which involve:

a tank filled with liquid photopolymer resin cured by ultraviolet radiation;

a bad that lowers into the tank;

ultraviolet (UV) laser to create layers;

computer managing the bed and laser.

At the initial stage of the SLA process, a thin layer of the resin is exposed in contact with the bed, the laser beam “draws” on the bed a section of the object, under the influence of this light the resin is cured and the product layer forms.

Once the first layer of the object hardens, the bed moves away from the exposure window by a distance equal to the thickness of the next layer, and the laser produces the next exposure. The thickness is usually from 0.05 mm to 0.15 mm. The procedure is repeated until the object is finished.

After that, the object is removed, the excess resin is washed off, and the former is additionally UV-exposed in the special chamber. Objects created using stereolithography typically have very thin and gradual layers, their surface being smooth and high-quality.

Stereolithography is a perfect (relatively inexpensive) solution to create high-precision objects, saving a good deal of time:

functional parts can be manufactured in one day;

the prototyping accuracy is 0.1 mm;

it allows for high-resolution prototypes.

SLA machines can create objects of non-standard forms, which are difficult to manufacture by traditional prototyping methods.

The Shining3D iSLA-650 Pro printer for stereolithography is easy to use and features high stability along with excellent print results:

High accuracy, 0.05–0.2 mm; the ultraviolet laser focuses automatically, the beam diameter is less than 0.15 mm; auto-calibration.

Smooth surface (ra <0.1 μm); any complex components can be created (for example, hollow parts).

Adjustment with auto-alignment: automatic path planning; automatic fluid level control.

Many industries use stereolithography to create prototypes. Those can be tested to fit size and shape, serving as patterns for creating parts.

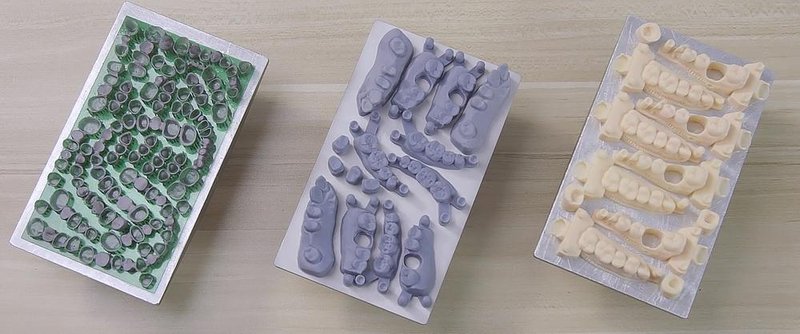

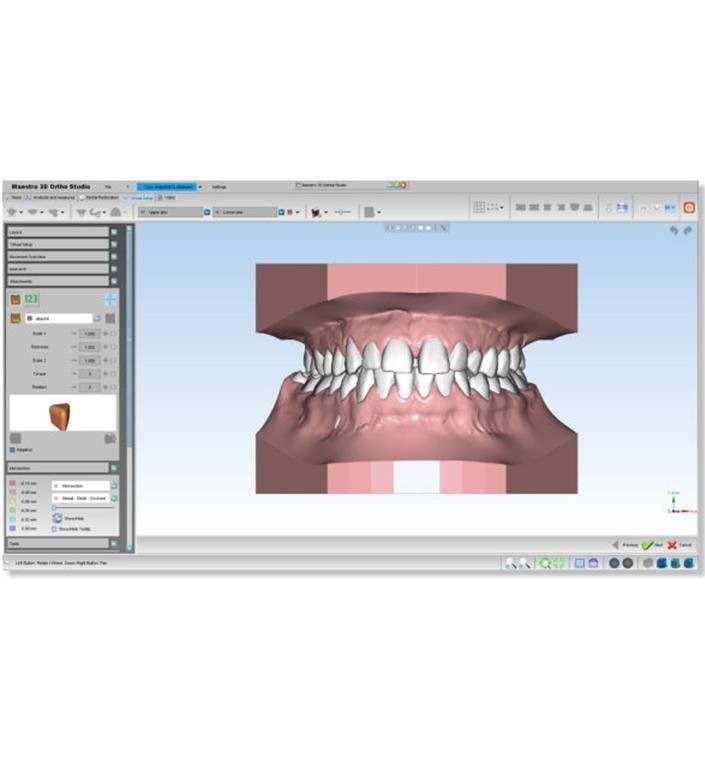

Shining3D supplies 3D technologies for dentistry, including equipment such as intraoral and desktop 3D scanners for scanning the patient's teeth and their casts. 3D printing is used for tooth restoration. The system provided by the company allows for the integration of third-party software and hardware.

Shining3D has technology that helps create an impeccable integrated solution for CAD/CAM dentistry.

Digital dentistry is one of the areas of application of advanced computer technologies and auxiliary equipment for diagnosing, design, treatment and restoration of functions, and obtaining diagnostic information. CAD/CAM technologies are widely used in restorative dentistry.

Shining3D digital dentistry includes CAD/CAM technology, equipment, and relevant materials for 3D printing. Shining3D also provides a range of digital solutions for the restoration and reconstruction of teeth.

With Shining3D dental solutions, it is possible to quickly and accurately produce dental crowns, bridges, gypsum models, and surgical guides using 3D scanning, CAD/CAM design, and 3D printing.

Digital technology in the dental industry helps doctors and dental laboratory staff get rid of hard manual work and eliminate manual modeling errors.

Shining3D methodically promotes the use of digital technologies in the dental industry, collaborating with dental laboratories, clinics, and famous international companies producing dental materials and equipment.

The company's products include an intraoral 3D scanner, software for fixed and flexible dentures, software for temperature control, equipment for 3D printing, and relevant materials for printing.

The AutoScan-DS-EX Pro scanner is notable for being compact and versatile. Advanced technology provides perfect accuracy at high scanning speed. With two projection lighting options that allow scanning black-and-white and color images, AutoScan-DS-EX Pro takes scanning capabilities to a high level. It is used in data collection for tooth reconstruction, orthodontics, and implantation.

Shining Aoralscan simplifies the process of intraoral scanning, making it easy for dentists and technicians to capture digital images. It is simple to operate, provides patients' comfort, and accurate scan results.

AccuFab-D1 is a desktop DLP 3D printer specifically designed for digital dentistry. It comes with its own optimized Shining3D software providing a convenient and intuitive workflow. AccuFab-D1 features high print resolution and high efficiency.

The digital model obtained with 3D scanning is distinguished by detailing and high accuracy. Compared to the conventional method, the digital model allows you to predict the clinical outcome, identifying problems with teeth invisible to the naked eye and even in X-rays. Such images are easy to enlarge and reorient, which allows accurately diagnosing diseases and making a treatment plan faster and more confidently than before.

STL is supported not only by 3D printers but also by many other software packages, including milling machines for the production of metal crowns and implants. Dentists and dental technicians can choose the optimal solution in each particular case.

CAD/CAM improves the quality of dentures and standardizes the production process, which allows working with new materials with a high accuracy level.

Due to the 3D printer, the denture manufacturing time is considerably reduced, while efficiency and productivity are increased.

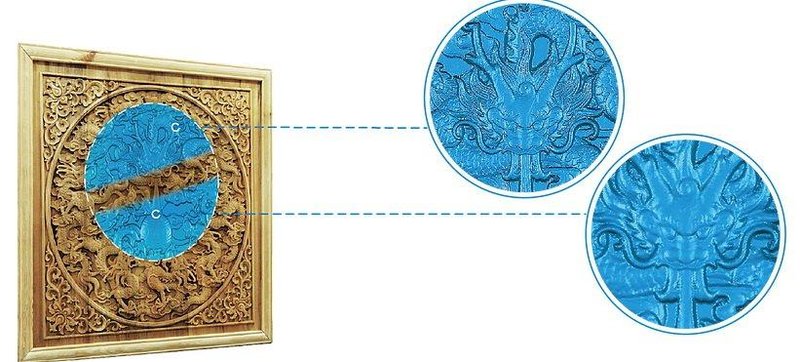

Jewelry art is increasingly turning to modern 3D printing and scanning technologies to improve the quality of jewelry and production processes. The main applications of 3D printing in the jewelry segment are creating prototypes, master models, molds for investment and lost-foam casting.

Shining3D offers integrated solutions for 3D digitization and 3D printing. Using the latest technology, a transition from the traditional manufacturing model to the fast digital solution is possible.

EinScan-SE is the best 3D scanner of 2019 — the "Elite" version of EinScan desktop scanners. This product is followed by the "Platinum" version EinScan-SP. Both models scan three-dimensional objects in color or black-and-white. They are equipped with easy-to-use EinScan software which acts as a simplified editing program for 3D scans, being able to export them as well.

For still more accurate 3D scans, there is an optional EinScan HD Prime Pack for the EinScan-Pro+ scanner, which allows you to further increase the detailing and accuracy of scans. Besides, the scanning speed increases by 30%.

Above is the result of scanning with HD Prime; below is one without it.

Prototyping: 3D printing enables professionals of the jewelry sector to save time and money. Jewelers can create economical thermoplastic wax patterns before sending the final design to production, which reduces design flaws.

Functional testing: understanding and implementing goals that improve the function and quality of a product, reducing its cost price.

Meeting the needs for personalized products: due to its high efficiency, 3D printing can be used to make jewelry from silver, gold or platinum using 3D devices printing metal. Metal 3D printing is still a very expensive technology, yet this is a secondary factor in the segment of custom jewelry.

Jewelry and parts created with 3D printing technology are becoming very popular. They are presented at international fashion weeks and make a strong impression on consumers.

Most often, it is SLA or DLP resin 3D printing that is used in the jewelry industry. These technologies allow you to create objects with a smooth surface and meticulous detailing, and these are the basic requirements for 3D printing of jewelry.

Cost-efficiency: prototyping jewelry with the help of 3D printing is cheaper than traditional manufacturing techniques.

Speed: the use of rapid prototyping and 3D printing significantly reduces the production cycle of a designed product. With 3D printing technology, it is possible to abandon complicated manual operations and speed up the production of wax models.

No design restrictions: 3D printing allows creating complex forms and intricate designs that would be incredibly difficult to implement using traditional technologies.

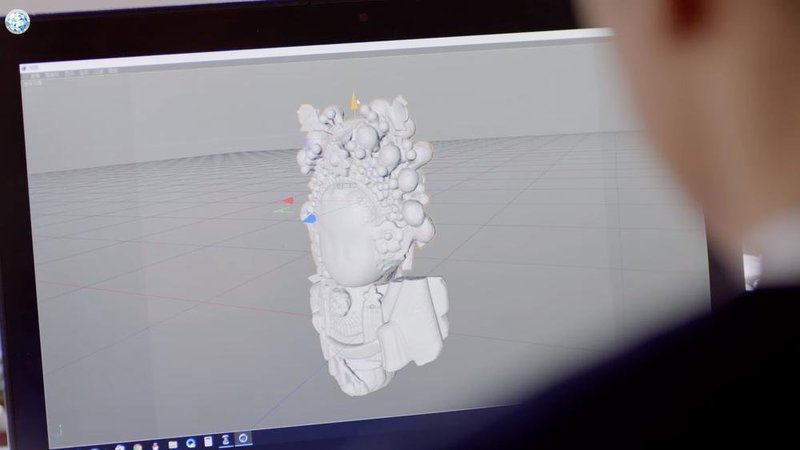

Ancient cities, such as Babylon, have for centuries been destroyed by time and people, turning into pale and fragmented copies of what they used to be. Babylon was repeatedly denied the status of a World Heritage property for the vaguely defined boundaries of the city and the lack of a comprehensive preservation plan.

The former splendor of places like the Hanging Gardens of Babylon has long been lost, but the Iraqi government and the World Monument Fund (WMF) are making new attempts to preserve them. According to WMF, the problems are numerous: for instance, restoration of damage caused by the military conflict, assessment of the impact of twentieth-century construction on ancient artifacts. The organization is faced with the task of helping the Iraqi authorities prepare this place for visitors to enjoy the “cradle of civilization."

Shining3D helps solve these problems with 3D scanning and 3D printing. The company's solutions have been successfully applied to preserve cultural values, such as sculptures, for scientific research, and professional education. Throughout the company's history, special attention has been paid to helping customers realize the value of additive manufacturing and its use for the restoration and preservation of ancient artifacts.

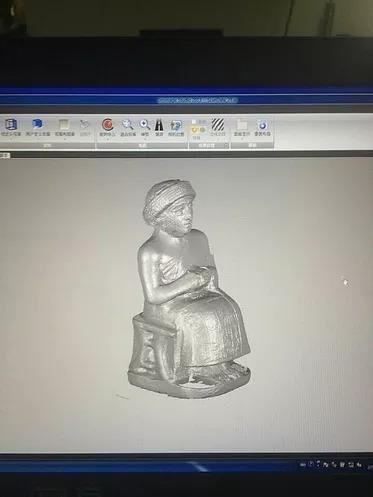

The software engineers Xinu Zhang and Hong Liang went to Babylon. Their mission was to present the EinScan 3D scanner and the EinStart-S 3D printer to the Government of Iraq. The purpose of the Shining3D donation was to support the preservation of cultural relics in Iraq.

Having achieved a significant breakthrough in 3D scanning technology, the company firmly believes in setting an international standard for digitizing and archiving cultural relics and archaeological sites. Unique scanning and printing technologies will have a huge impact on research in this important area.

During the visit, the Shining3D specialists conducted comprehensive training on various applications of 3D scanning and 3D printing, presenting valuable concepts for local officials to teach them how to preserve cultural relics in digital form.

Even if you devote your whole life to traveling to museums in different countries of the world, acquaintance with historical artifacts and works of art, there will still remain many wonderful objects that you will never be able to look at. The fact is that at any given time period, museums only display a small selection of their treasures.

Advancing 3D scanning technology, with the help of Save the World ART project, Shining3D stores museum collections around the world in digital form. Thanks to the EinScan-Pro professional portable scanner, the company, using its international client base, preserves priceless works of art and ancient relics.

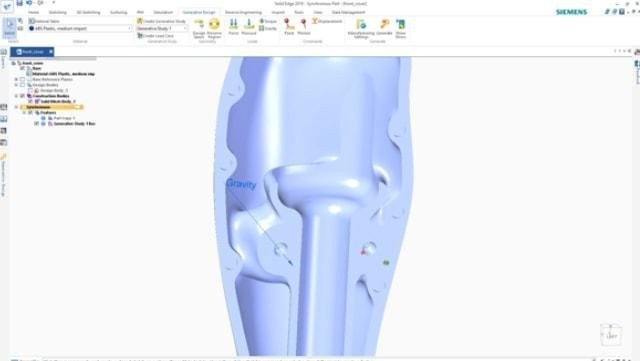

Reverse engineering is the most commonly used application of 3D scanning and 3D printing in many industries. The ability to 3D scan an object and create an individual product is an invaluable skill. 3D scanners allow digitizing both inanimate objects and living beings, which makes them an ideal tool in industries related to traditional CAD design methods. One of these industries is prosthetics and the creation of supporting devices.

Functionality is the main criterion for evaluating an artificial limb, but the fit and shape of the prosthesis are no less important for the patient. A correctly selected prosthesis adds confidence and provides comfort. 3D scanners paved the way for the individualization of the shape of these products, and personalized prostheses have become a reality for many people with disabilities. EinScan Pro portable 3D scanners and Shining3D industrial 3D printers make 3D scanning and 3D printing more available for healthcare.

The EinScan Pro and Pro 2X scanners are multifunctional. The portable capabilities of scanners make it easy to scan large objects, a human body, or its parts. The flagship scanner of the company, EinScan Pro 2X Plus, scans a person’s leg, and the received data can be processed, customized and printed in 3D very quickly.

Using the EinScan Pro + Handheld Rapid Scan mode, scanning is literally instant. The data collected is accurate enough for reverse engineering, which helps create individual prostheses.

A 3D scan of the patient’s healthy leg is taken as a pattern, which is then mirrored in the software and used as a model to make the prosthesis as close as possible to a real leg.

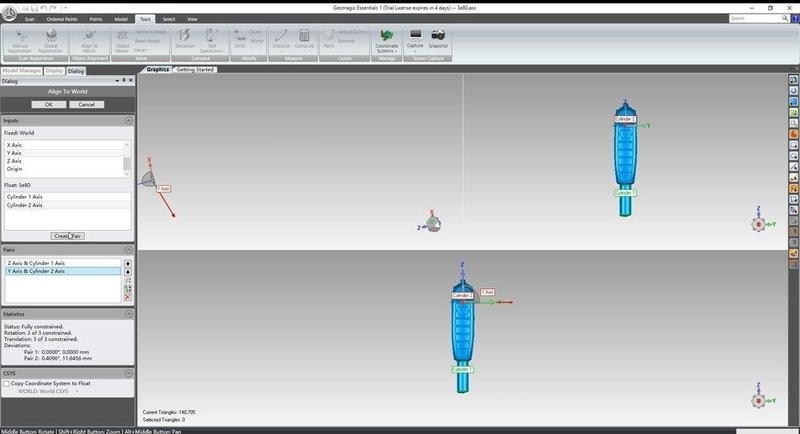

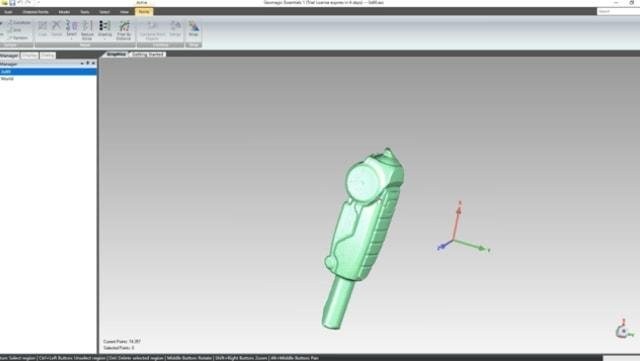

After collecting the data and completing the scan, the file is exported to Geomagic Essentials.

Working with organic forms in the context of CAD can be a difficult task even for the most experienced professionals, but the tools in Essentials provide a smooth transformation of 3D scans into a CAD model.

Coordinates are assigned to 3D models, which simplifies reverse engineering. The contours, general shape and geometry of the product are extracted and determined using available tools.

The second dataset of the patient's leg scanning is imported into Essentials. The process repeats, and the 3D model is prepared for reverse engineering.

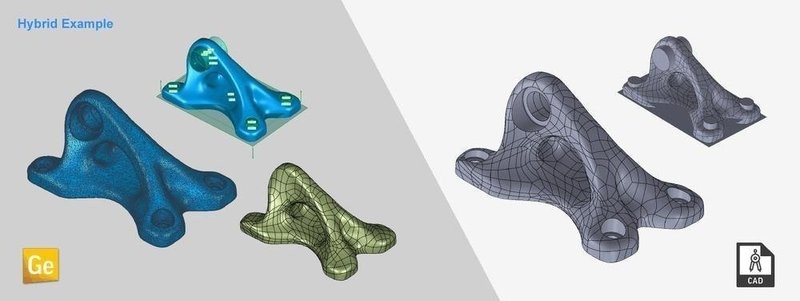

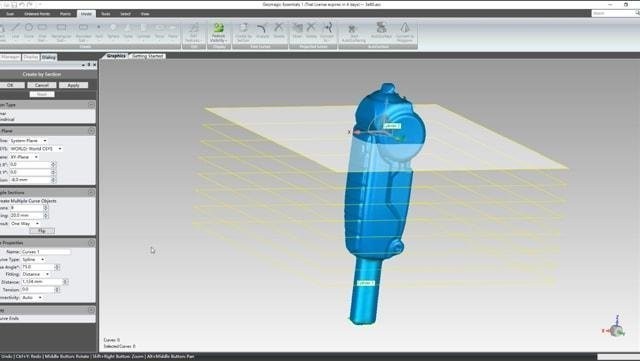

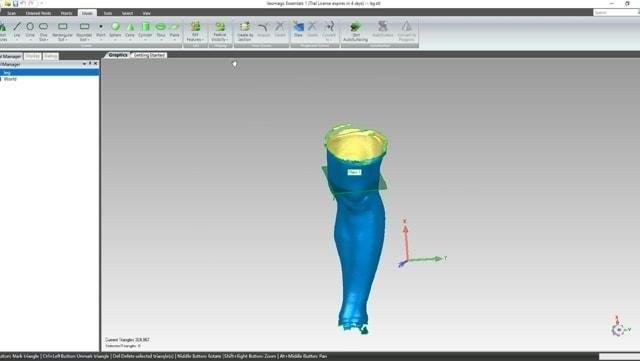

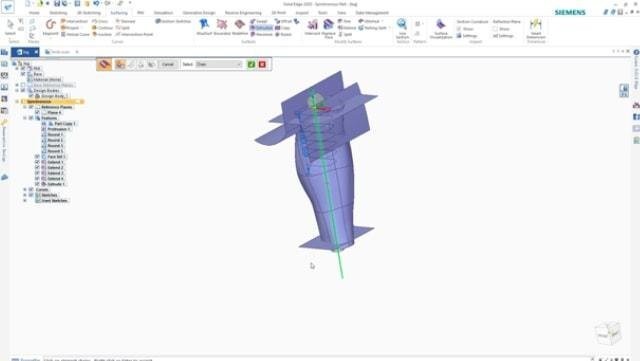

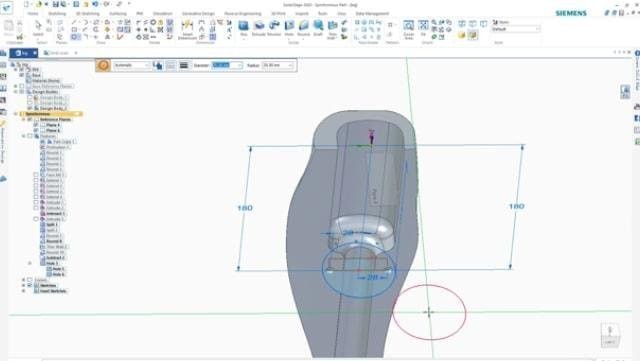

Once both datasets are processed, they are exported to Solid Edge Shining3D Edition. Solid Edge is a professional piece of CAD software that allows reverse engineering based on 3D scans.

The software imports both scans directly. Two models are developed individually. The prosthesis is used as the mechanical part of the CAD model, while the scan of the healthy leg is employed as a form to shape its appearance.

As soon as the overall design is complete, the Generative Design function is applied. The result is an absolutely functional prosthesis that takes into account the patient’s weight and the loads exerted on him when running, walking, and exercising.

The 3D model is saved and printed on the Shining3D EP-P3850 SLS 3D printer. The finished print is post-processed and prepared for the patient.

EinScan Pro scanners have made 3D scanning in the medical sector more available than ever.

Shining3D offers everything needed for 3D Scan to Design concept solutions, and industrial 3D printers such as EP-P3850 bring projects to life with amazing accuracy.

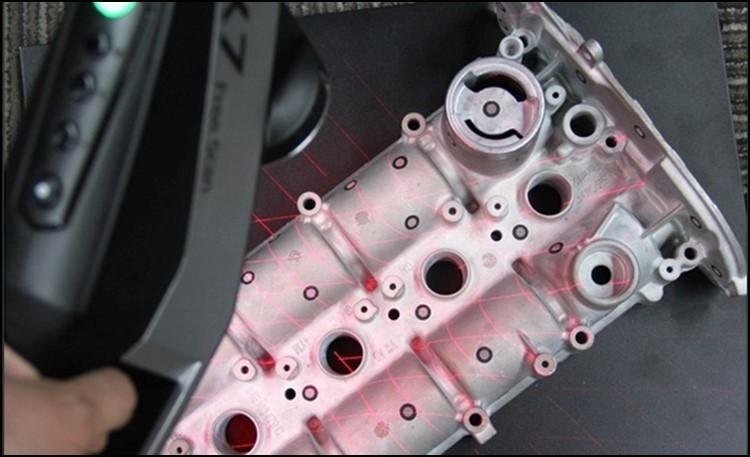

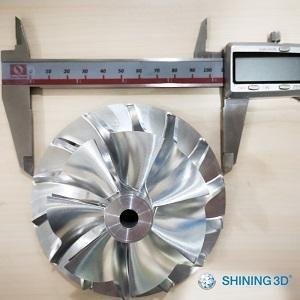

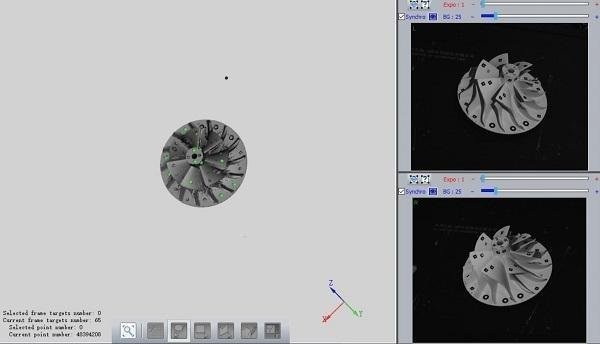

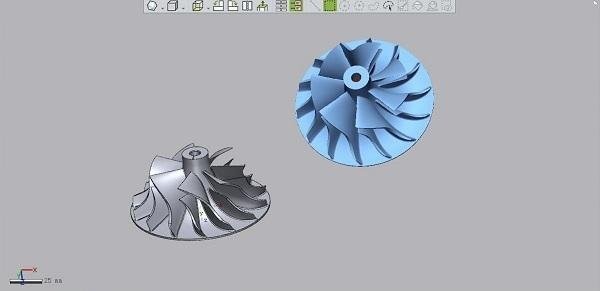

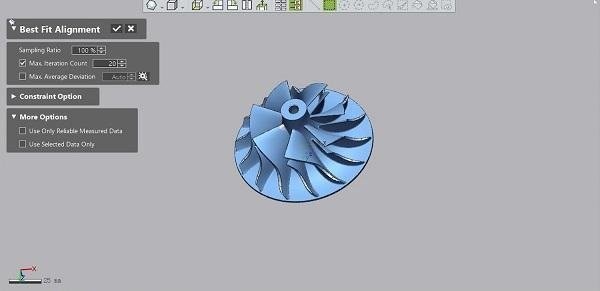

For the manufacture of turbine blades, an aerospace company used processing with CNC machine and high-temperature alloying materials. After the completion of the production process, it is necessary to check the finished part for compliance with the design dimensions — the deviation between the manufactured blade and the design data should not exceed 0.04 mm.

Until recently, the company used a three-coordinate measurement of certain given points of the object, which did not give a complete picture. A new measurement method was needed to inspect the entire surface. This led to the development and use of a metrology-grade 3D scanner.

Using the OptimScan 5M-Plus metrology-grade 3D scanner, it was possible to get three-dimensional data of the part. The process itself only takes a few minutes, and the 3D models obtained by scanning contain all the necessary information about the surfaces.

A three-dimensional scan consists of hundreds of thousands of points collected from the scanned part, which makes this form of measurement reliable when checking for deviations.

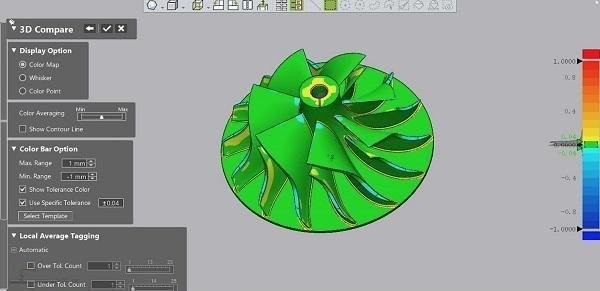

Deviations from the given dimensions are displayed with the help of a chromatographic scale. Thus, users learn about deviations, determine the source of errors, and adjust the processing method according to the results.

All of that can be done with the Geomagic Control X software, which is used to check the collected 3D scan data.

Products by Shining3D represent a full range of elements necessary for the implementation of digital production using additive technologies in enterprises, including small and medium-sized ones: jewelry, dental, auto-tuning; large engineering, medical, cultural and scientific facilities, etc. Despite the fairly young age of the 3D technologies, the company's equipment is already widespread, having proved its quality in numerous applications.

If you’re in need of a high-performance device from Shining3D, contact Top 3D Shop. Our experts will conduct a full cycle of implementation of new technologies into production, starting from assessing the need to use 3D technologies in different areas of the production line, continuing with the creation of a project, delivery and installation of equipment, and ending with maintenance during operation. Get in touch!

Update your browser to view this website correctly. Update my browser now

Write a comment