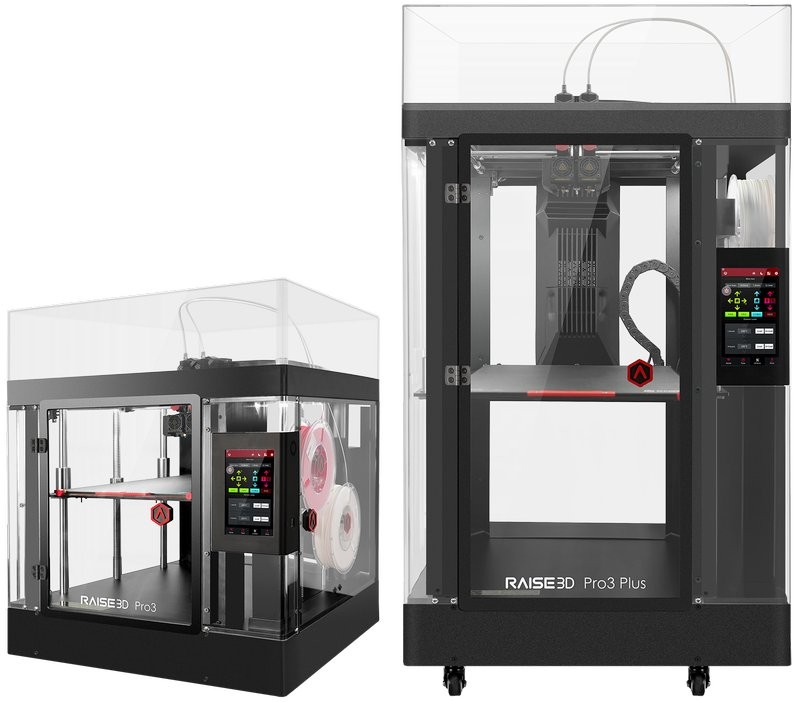

Three years after the launch of the extremely successful Pro2 series of printers, Raise3D has released a new lineup of its upgraded version called Pro3. Like its predecessor, it consists of two models: the Pro3 and the Pro3 Plus. According to the manufacturer, it is a more intelligent, modern 3D printer to meet the needs of small-scale production. Read on to find out what new features are offered by the devices.

At first glance, the series does not differ from the Raise3D Pro2. This is because the company decided not to change the design of its product, which is difficult to confuse with models from other manufacturers. Looking more closely, though, you can see significant differences which are aimed at increasing the stability of printer operation and improving the user experience.

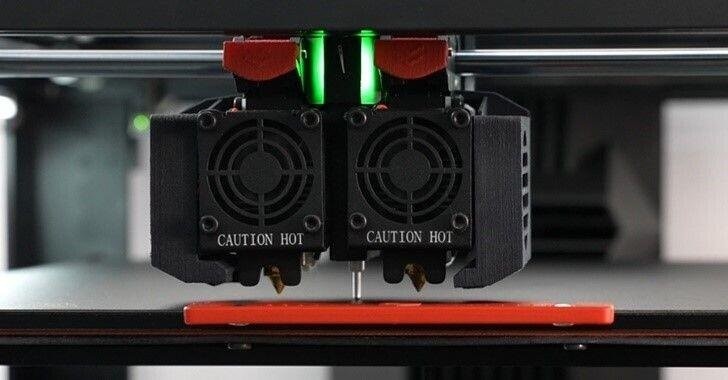

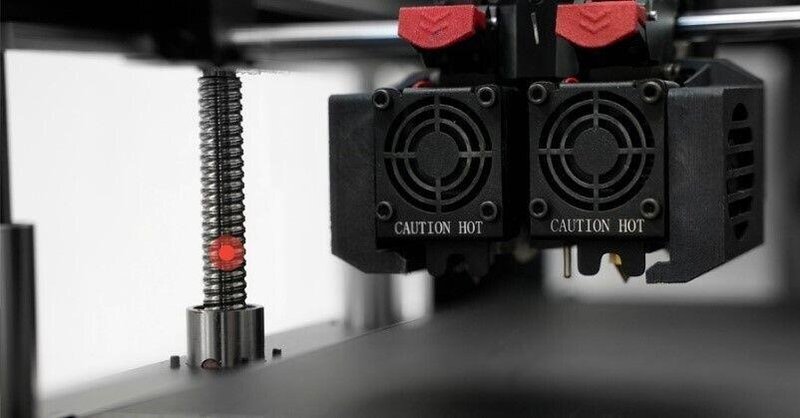

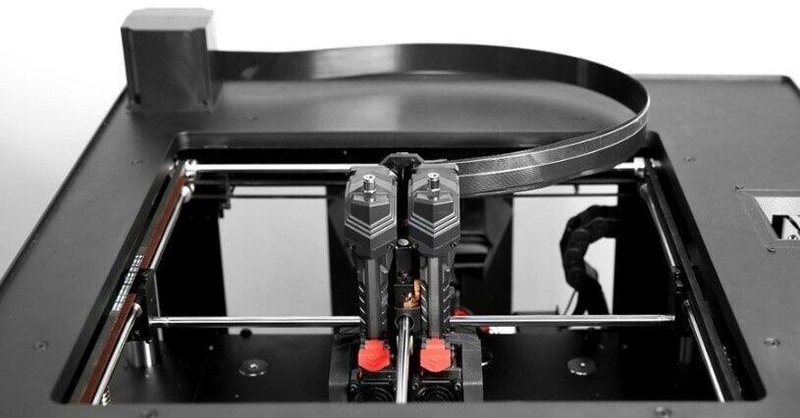

The heart of any 3D printer is the extruder, and here it has been completely redesigned to provide users with maximum convenience and reduce the possibility of downtime caused by maintenance or replacement. The main novelty of the device is the system of quick replacement of the extruder in case of need for repairs, maintenance, or changing the size or type of the nozzle used. The new system will increase the fault tolerance of the printer and accelerate the process of transition between different types of materials, for example, from abrasive to usual ones or vice versa.

Ultimately, the innovation enables the Pro3 printers to use a variety of filaments, reducing jams and allowing for easy disassembly and replacement of components. The new interchangeable hotend system is ideal for users who may require different types of nozzles or those who need to print at higher speeds, which will in turn require different nozzle sizes. They are engineered with a snap-and-lock mechanism, each of them uniquely identified to track and record nozzle usage.

While the Pro2 series comes factory calibrated, the Pro3 is equipped with an automatic bed leveling system similar to that in the E2 printer. This replaces the stiffer print bed used in the Pro2 series with a flexible one as in the E2, making it easy to remove printed models.

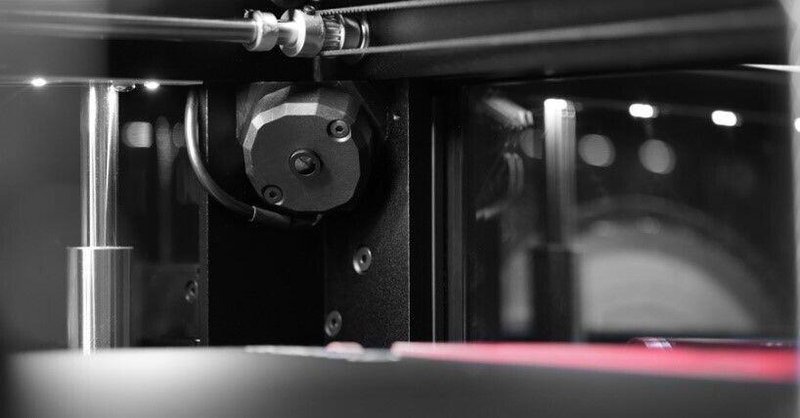

The calibration system uses a BLTouch contact sensor, and the printer display shows a 3D map of your build area. If the error in heights is higher than normal, you can easily assess this visually. As a result, you get a more predictable printing experience. It is especially important when printing models of the maximum size, where even a small variation in heights can lead to failure with enormous time losses.

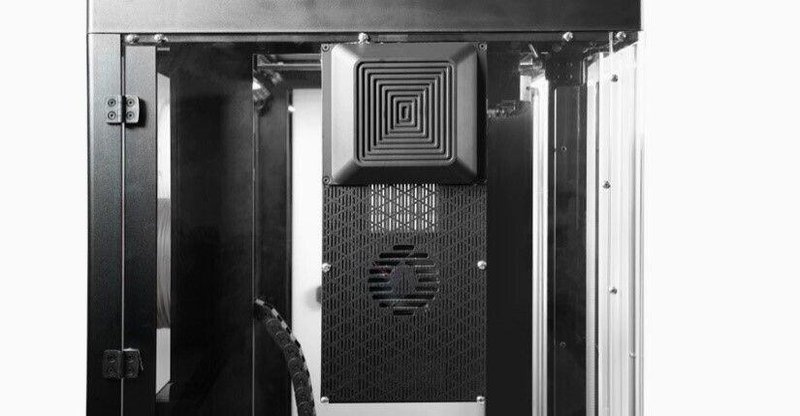

The new Air Flow Manager is located on the back of the printer, which improves heat dissipation and air circulation, creating a stable environment inside the print chamber. Equipped with a HEPA filter, this manager can also purify the air. As long as it operates within the recommended temperature range, airflow maintains a stable temperature inside the chamber, resulting in better repeatability of high-quality results regardless of external conditions. This improvement will be very important for those who print with technical filaments such as ABS, nylon, carbon, polycarbonate, and others. The solution enhances interlayer adhesion and prevents the model from sticking off the table.

Another innovation in the series is a built-in intelligent assistant called EVE, which can guide users to identify and eliminate issues that may affect the final print. It also has a function of analyzing printer usage and sending reminders of scheduled interventions to ensure that the printer is maintained in a timely manner. Raise3D is the first company in its segment to implement this feature, taking the usability of professional 3D printers to the next level. Such functionality is especially useful for beginners who, not knowing all the intricacies of operating the printer, will be getting prompt hints about possible current problems.

In addition to the main improvements, there are a few more points worth noting.

The Z-axis rod stiffness has been increased by 75% to deliver more stable performance.

The door sensor detects when the door is opened to immediately pause a print job and resume it after the door is closed.

The second-generation power loss recovery saves the progress in the event of a power outage and resumes printing from the same point after the power is restored.

The lightweight cable with digital temperature measurement reduces the extruder weight while keeping the center of gravity in the middle to ensure more stable print quality.

The built-in HD camera with improved image quality and exposure sensitivity enables you to keep a close eye on the printing process.

While significantly improving an array of technical characteristics in the new model, Raise3D managed to preserve all those features appreciated by users around the world: a large build volume, 7-inch color touchscreen, dual extruder heating up to 300 °C, and a transparent body that allows for a maximum overview of the 3D printing process.

Update your browser to view this website correctly. Update my browser now

Write a comment