Only a decade ago, 3D printing was much more expensive. Even the most basic machines producing simple models at a rather low quality were not exactly affordable. The times are changing, and nowadays you can buy a large-volume machine providing an industrial-grade print quality for a budget price. The Modix BIG-120X V4 is one such device. Its massive build volume, sturdy frame, and flexible construction are nicely accompanied by high-precision printing capabilities.

With its headquarters in Tel Aviv, Israel, Modix was founded in 2014. The company released its first 3D printer called Agam in the following year. After that, the brand changed its course to focus on the large-scale FDM 3D printers, which marked the beginning of the ‘BIG’ series extending over several generations.

Source: modix3d.com

Currently, it is about the Generation 4, which comes with all sorts of technical tweaks and modifications making the Modix devices even more precise, fast, reliable, and user-friendly. Apart from upgraded functionality and new components, the V4 machines come with improved supply kits including some previous add-ons that are now available by default. To find out more, check out the video below.

The Modix BIG-120X V4 is a supersized version of the BIG-60 model, upgraded edition of the BIG-120X V3 3D printer, and overall perfect addition to the company’s ‘BIG’ series with its impressive build volume of 1200 x 600 x 640 mm. Alongside this distinctive feature, the machine boasts an extremely sturdy frame made of high-quality aluminum profiles and featuring laser-cut powder-coated brackets, heated print bed with a fully automatic leveling, and a 7" LCD touchscreen that offers a great level of control.

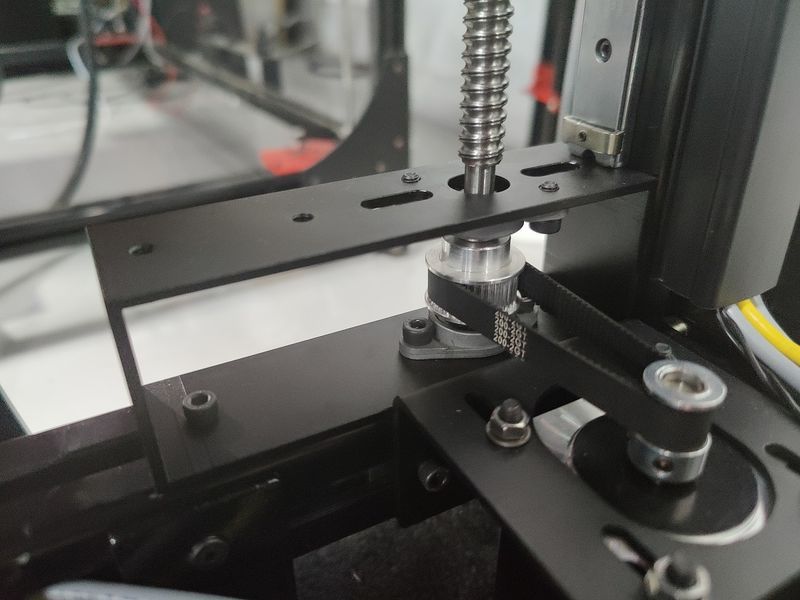

As a part of the Generation 4 lineup, the BIG-120X supports all the recent innovations introduced by Modix. These include strong Nema-23 motors for the Z-axis ensuring higher level of print accuracy, upgraded X-axis providing the accelerated print speed of up to 250 mm/s, and reliable CNC machined brackets for increased stability.

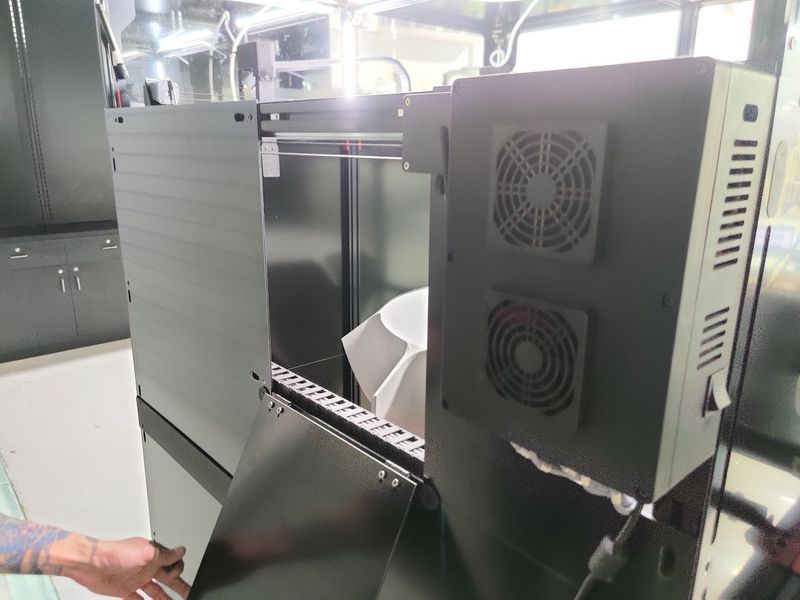

In addition, the V4 version is engineered with the electronic expansion board Duex 5 that offers a full set of automated calibration routines, upgraded Griffin printhead featuring high flow rate as well as increased reliability and longer service life, accurate optical switches with better repeatability and smoother print recovery after power outages, and general design changes for smooth and convenient usage. The latter include a pneumatic top lid, rear maintenance opening hatch, sturdy door hinges, door and lid sealing strips, improved internal LED lighting, convenient PTFE tube and wires management.

The Modix BIG-120X V4 comes as a DIY kit, which is easy to assemble due to standardized parts. The printer’s modular design allows for potential upgrades in both configuration and hardware with no need to buy a new machine in the future. Although the machine has an open construction, a dedicated enclosure for enhanced temperature control and stability is available as an option as well as some other add-ons, such as the IDEX (independent dual extruder) module, high-precision HIWIN rails, magnetic print bed, tilt screen, and casters. All these devices can be purchased separately to improve one’s user experience with the BIG-120X V4 3D printer.

For more specific information, check out the product page in our shop.

The machine comes as a DIY kit and needs to be assembled. It comes in several boxes, the contents of which include:

Modix does not provide any proprietary software for slicing, so the user is free to choose any free solution available on the market, from Cura to Simplify3D.

The BIG-120X V4 is compatible with the majority of file formats and can be connected to the PC via Wi-Fi or USB. With a web interface and mobile app available, it is possible to operate the machine remotely.

The Modix BIG-120X V4 is expected to be used by experienced makers with enough skills and patience that are able to achieve the best balance between print speed, detail, and quality. When it comes to large 3D models, printing them as a whole provides more reliable results and saves time on post-processing. Not to mention you can print multiple smaller items in one batch production.

Generally, the device can be successfully applied in prototyping, mold making, research and development, restoration for printing functional prototypes, end-use products, top-quality spare parts, art models, and more.

From the video below, you can see the whole printing process with the Modix BIG-120X V4:

Thus, the machine can easily print a 1.1 m long object with PLA in 48 hours.

Large-sized, relatively affordable and quite accurate, the Modix BIG-120X V4 is a powerful device that manages to pack a great number of technological features and combine it with an enormous build volume. The machine’s modular design offers several ways for upgrades, while its rigid frame allows producing big models of high quality. With the right set of parts and skills, you can get an industrial-level machine at a beneficial price.

Update your browser to view this website correctly. Update my browser now

Write a comment