How do you tell whether a 3D printer is big? For someone, big 3D printer is a machine with a build volume of 500 х 500 х 500 mm, for others it’s a room-sized device or even a machine that can print an airplane wing or a submarine hull. All these opinions are correct. In this article, we’ll tell you about the applications of such 3D printers.

For example, how do you like a functional 3D printed motorcycle?

Photo: Nera, e-motorcycle; Source: bigrep.com

BigRep, a leading German manufacturer of large format 3D printers presented Nera, an electric motorcycle prototype. The interesting thing about it is that it was printed on large format 3D printers. The motorcycle was designed by experts from BigRep’s NowLab, its dimensions are: 1900 х 900 х 550 mm. Almost all parts of the motorcycle (besides electronics, motor and battery) are 3D printed, including airless tires, rims and steering.

Photo: a frame from “Westworld”; Source: fsmedia.imgix.net

3D printing is more and more often used as a manufacturing technology for making split bearings, car parts, medical implants and sports shoes.

A common factor is that all manufactured products are rather small in size.

Large-scale 3D printing is believed to be a very narrow-focused technology that doesn't enjoy strong demand in the market. Nevertheless, three-dimensional large-format printing has enormous potential for solving many of the problems that manufacturers face during production of large objects.

Source: 3dnetprint.ru

The traditional process of manufacturing large parts, such as airplane wings, is long, painstaking and expensive, since it involves the use of large equipment, which still needs to be properly configured and prepared for work. Ultimately, it leads to the increase in production expenditures and in time of manufacture.

3D printing can help industrial companies produce large parts faster and at a lower cost. Given the speed and accuracy of printing offered by modern large-format machines, 3D printed parts have several advantages over parts made using traditional methods, for example, you can reduce weight while retaining strength properties.

Source: erectorbot.com

In modern production, many large components are manufactured in parts and then assembled into a single structure, which negatively affects delivery dates. Large 3D printers can build objects in a single print session, which also provides the benefit of reducing production and delivery time.

Source: tctmagazine.com

Some people new to 3D printing believe that a large-format 3D printer is just a machine that’s just slightly larger than others.

In reality, a large-format 3D printer is a robot capable of printing life-size objects, whether it’s furniture, an aircraft turbine or a prosthetic leg. For example, Erectorbot EB 2076 LX, often used in car industry and boat building, is capable of printing objects with dimensions of 7 x 2.1 x 1.8 m.

Source: erectorbot.com

HuaShang TengDa, a Chinese construction company prints prints two-story luxury cement villas, which usually takes just 45 days. The company uses its own printing equipment.

Source: all3dp.com

The main differences of large-format 3D printers:

High printing speed. Most of large-scale printers can print with a speed of up to 250 mm/sec and a travel speed of 400 mm/sec.

Print dimensions. Build volume limitation is the main weakness of most standard 3D printers. But large-format printers feature huge build platforms, which allows to print large models in just one go, rather than in small details for further assembly.

Printing accuracy. Large-format 3D printers offer a max layer height of 40 microns and the XY resolution of 20 microns, which allows for a great quality, even for large-scale prints.

Printing materials. Thanks to the wide range of operating temperatures and the ability to heat the platform up to several hundred degrees Celsius, large-format 3D printers can print with most of the available materials, whether it’s PLA, ABS, TPU, Nylon or even polycarbonate.

Fused Deposition Modeling or Fused Filament Fabrication (FDM/FFF) is an additive technology for creating 3D prints by sequentially depositing layers of material according to the digital model. The common materials are PLA and ABS plastics as well as Nylon, polycarbonate and polyethylene.

Selective laser sintering (SLS) is an additive manufacturing method, where the laser acts as an energy source for sintering of powdered material(usually nylon, polyamide, polystyrene, thermoplastic elastomers). The laser beam is directed to the points specified by the digital model and fuses the powder together to create a solid structure.

Stereolithography(SLA) is another method used in large-scale 3D printing. This technology allows to create prototypes, models and production parts layer by layer, using photochemical processes by which light causes chemical monomers to link together and form polymers.

3DCP or 3D Construction Printing is a construction printing method that allows to manufacture structural components or even entire buildings.

Large-format 3D printing provides great advantages to businesses. Let’s see how various branches of industry can use it to accelerate production, decrease times of delivery, reduce waste, and create new geometrical forms impossible to design using traditional technologies.

Source: trendhunterstatic.com

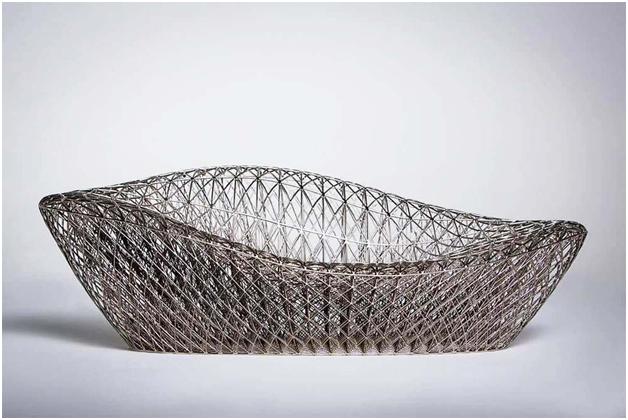

Large-format 3D printers can be used to create three-dimensional furniture models in just one go. Tables, chairs, sofas and even bathtubs - all of them and more can be 3D printed. Besides, 3D printing allows for creating complex furniture elements that would be difficult to make the traditional way. Industrial 3D printers will allow you to make unique pieces of furniture that you won’t find anywhere else.

Take, for example, a life-size hammock-chair that was printed on a 3D Systems ProX 950 printer using SLA technology. The print turned out to be so awesome that they called it Sofa So Good. The hammock-chair was made using only 2.5 litres of resin, and was coated with chrome and copper to increase rigidity and improve aesthetic properties. The dimensions of the furniture piece are 1.5 x 0.75 x 0.55 m. The weight is only 2.5 kg.

Source: jannekyttanen.com

Source: 3dprintingindustry.com

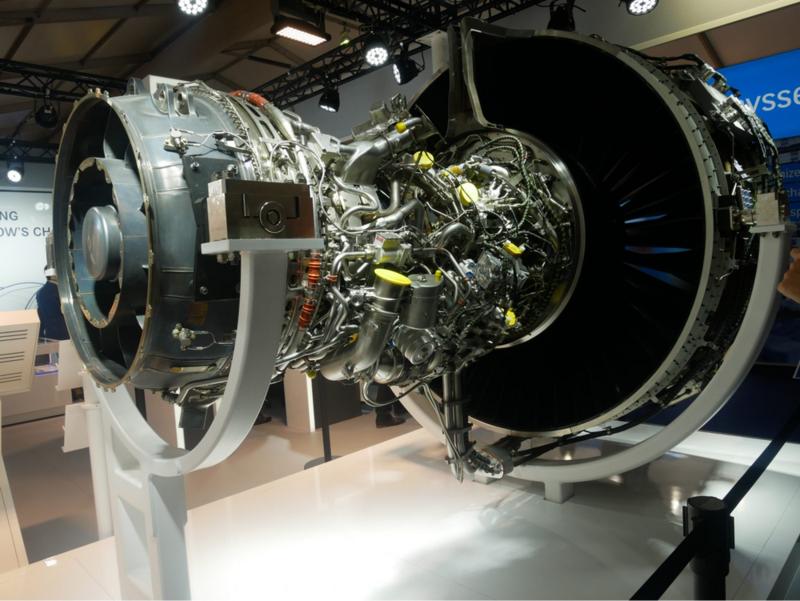

In aerospace industry, 3D printing is mostly used for production of small and medium-sized parts and tools. This allows manufacturers to cut the costs.

However, large-format 3D printing also has something to offer in this sector. Its advantages include reduced manufacturing time and optimized production waste.

It may take more than a year to manufacture certain large parts using traditional methods, such as forging or lathe tuning. Besides the production times, such methods are ineffective due to the fact that production waste can make up 80% of used material.

Many companies already implemented large-format 3D printing for commercial purposes.

For example, Lockheed Martin (an American global aerospace, defense, security and advanced technologies company) uses 3D printers to build giant titanium dome cameras with diameter of 116 cm. The cameras can be used as fuel tanks for the company’s satellites.

3D printed dome cameras were designed by the company as a part of a multi-year program for developing high-pressure tanks for transporting the fuel to satellites.

Source: amfg.ai

Source: designingbuildings.co.uk

In construction industry, 3D printing can be used to build load carrying structures or even “print” the whole houses.

3D printing in construction can provide faster and more accurate production of objects, as well as decrease labor costs and reduce waste. Three-dimensional printing also allows you to build objects in harsh or dangerous conditions that are not suitable for humans, such as in the desert.

For example, WASP, a young Italian company set out to print full-sized residential buildings at minimal cost, using local natural materials. The result is a Gaia eco-friendly home, printed by the Crane WASP industrial 3D printer. The printing material was a specifically developed mixture consisting of soil, rice husks and hydraulic lime.

Source: edilportale.com

The well-known Shanghai construction company Shanghai Mechanized Construction (SMC) decided to improve the infrastructure of their hometown by placing a beautiful pedestrian bridge downtown. It was made of plastic using 3D printing. The design weighs 5.8 tons and has a length of 15.25 meters, a width of 3 meters and a height of 1.2 meters.

Source: designboom.com

Acrylonitrile styrene acrylate (ASA) became the main material used for bridge construction, and 12.5% of the structure consists of fiberglass, which improves the mechanical properties of the object and helps reduce the likelihood of bridge deformation. The large-format printer was developed by specialists from the Shenyang Machine Group, and the extruder system and circuit board were made by Coin Robotic.

Source: vexmatech.com

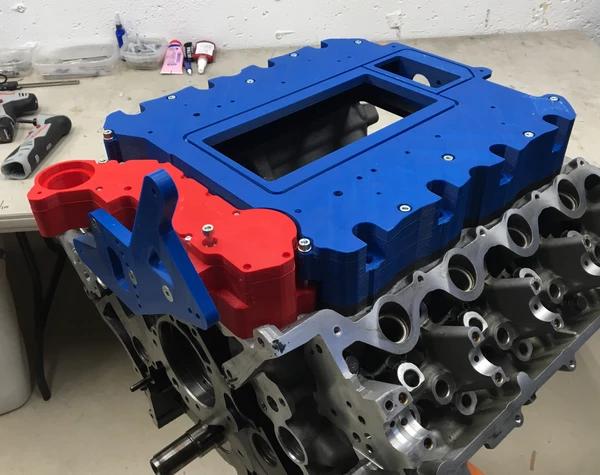

Additive manufacturing is widely used in the car industry, as it allows to create new designs, reduce delivery times and substantially reduce the cost of car manufacturing.

For example, Porsche takes advantage of large-scale 3D printing technology to ensure profitability when it comes to making spare parts for cars. The short production cycle of many Porsche Classic vehicles makes it financially impractical for a company to store a large number of components, but manufacturing spare parts after the production cycle is completed requires expensive specific tools.

Currently, the company is combining SLM 3D printing for the production of metal parts and the SLS technology for manufacturing of plastic parts and tools.

Source: cloudfront.net

Another German company, APWorks, 3D printed an electric motorcycle Light Rider. The bike was created on an SLS 3D printer using a unique aluminum alloy powder. The Light Rider weighs 77 pounds (35 kg) and has a top speed of 49.6 mph (80 km / h) thanks to a 6 kW electric motor. One of the reasons APWorks created the electric bike was to demonstrate the possibilities of additive manufacturing.

Source: all3dp.com

Source: 3dprintingindustry.com

Ships are often located far away from repair docks and parts warehouses, so the ability to produce spare parts directly on board using 3D printing can be extremely useful.

Advantages offered by additive manufacturing for shipbuilding include a better energy performance, reduced emissions, improved controllability of the structure, and shorter production times. Reducing the cost of storing inventories is another advantage, as shipbuilders can manufacture spare parts when needed, rather than storing them in a warehouse until they're required, and ship mechanics can create parts right on board without waiting to reach the port.

A great example of how large-format 3D printing can be used in shipbuilding is WAAMpeller, the world's first 3D printed ship's propeller. WAAMpeller is the result of a collaboration between Promarin, Autodesk, RAMLAB, Bureau Veritas and Damen.

Source: blog.iqb.ru

WAAM technology uses an electric arc to melt a metal wire, creating a structure by layer layer. The resulting propeller consists of 298 layers of nickel aluminium bronze alloy.

Autodesk's role was to support RAMLAB with powerful software, while Promarin provided the original screw design.

WAAMpeller was installed on a Damen Stan Tug 1606 working boat. Thanks to this project, additive manufacturing entered the naval sector.

Of course, all the aforementioned industries are only a small part of possible areas of application of large-format three-dimensional printing. Manufacture of full-size limb prostheses in medicine and veterinary medicine, production of growth mannequins in the fashion industry, printing of personal protective equipment in the sports goods industry, production of mobile house vans, printing of unique interior and decor items - it is impossible to list all the possibilities provided by large-scale 3D printers!

Now let's get to some specific cases.

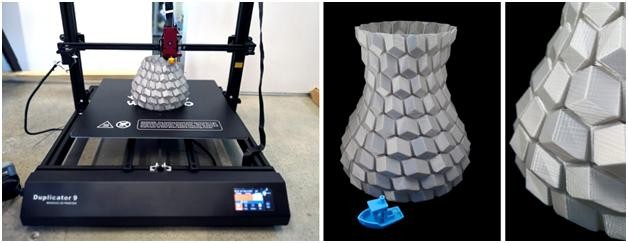

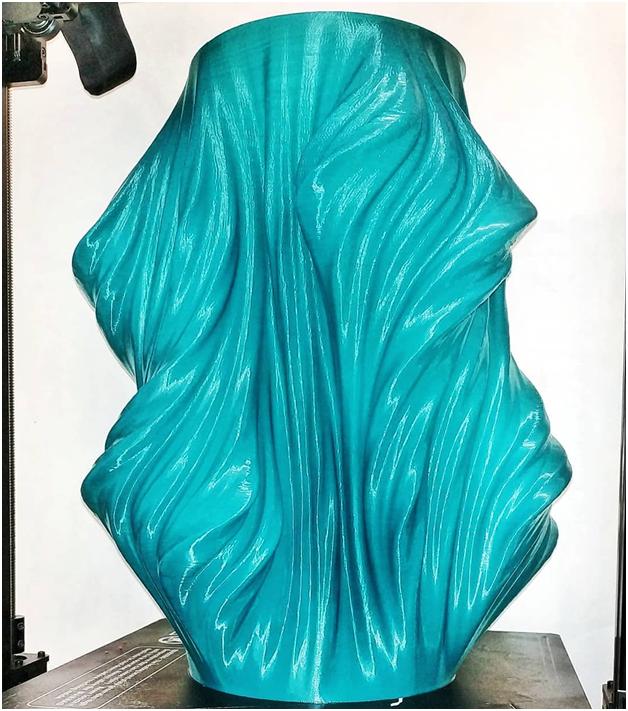

Tall 3D printed vases for your interior / Source: edditiveblog.files.wordpress.com

James Novak, a popular Internet blogger is an ardent fan of 3D printing and often tests all sorts of new devices in the field of additive manufacturing. As soon as the consumer printer Wanhao Duplicator D9 / 500 Mark II entered the market, the enthusiast immediately decided to test it in action, and at the same time refine the interior of his home. It's not suprising that the result was astonishing, since this machine offers a build area of 500 x 500 x 500 mm.

Source: thingiverse.com

Source: alicdn.com

Source: cdninstagram.com

Wanhao Duplicator D9 / 500 Mark II is a large consumer 3D Printer that uses the FDM technology. It is features a touch screen, MK10 extruder with an all-metal body, platform heating and anti-backlash system. The printer is made from machined metal brackets and extruded aluminum. An ideal printer for teachers who teach technical students, also a great solution for 3D printing enthusiasts.

Wanhao Duplicator D9/500 Mark II

Creatbot D600

Source: creatbot.com

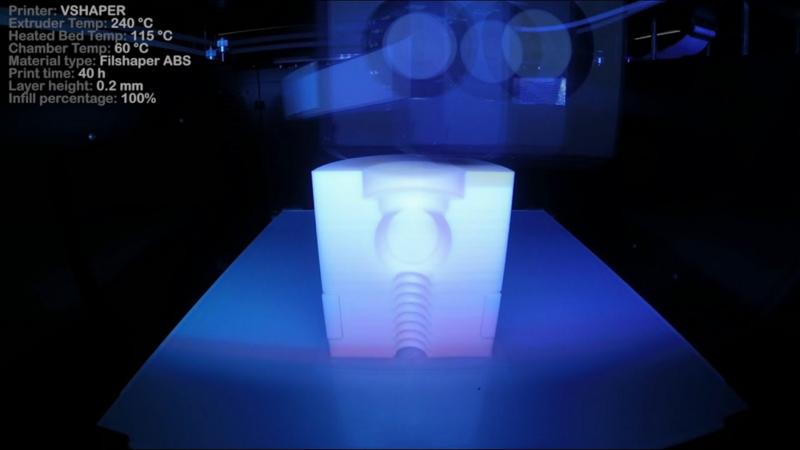

CreatBot D600 is a truly impressive production machine. It's an industrial high temperature FDM 3D printer with two extruders. An enclosed chamber with a build area of 600 x 600 x 600 mm blocks all external interference and at the same time maintains a constant temperature inside the chamber, thereby preventing deformation of the product.

Source: v3dprinters.com

The dual-extrusion system provides a high melting point of up to 420 ° C and is able to work with such materials as PLA, ABS, PC, nylon, carbon fiber and many other materials with similar thermal properties.

The CreatBot D600 3D printer is characterized by increased accuracy and print speed: accuracy up to 0.05 mm, speed up to 200 mm / s.

Source: creatbot.com

The single piece steel case not only provides stability during the printing process, but also significantly extends the usage periode. The first batch of CreatBot 3D printers lasted 5 years and worked for more than 8000 hours.

The printer automatically remembers the current position and saves print data, lowers the working platform and removes the filament in case of a sudden power loss.

Source: ytimg.com

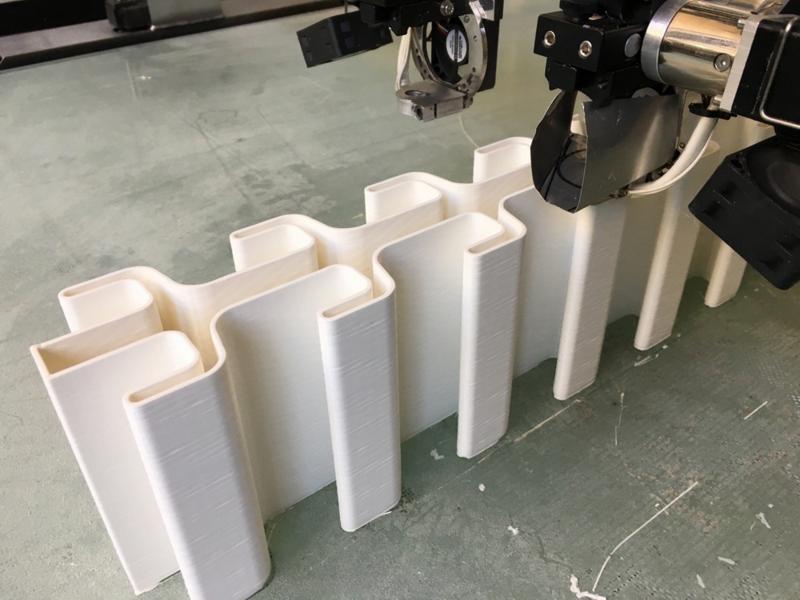

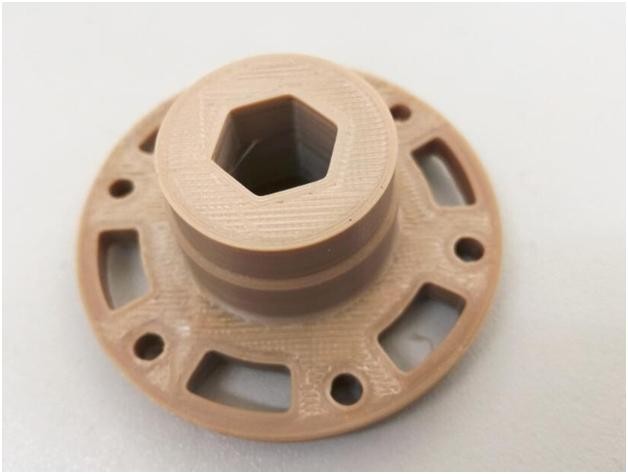

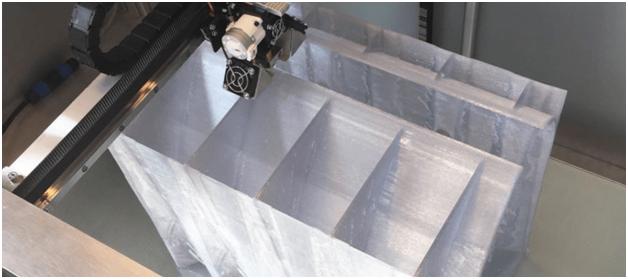

BGM is a Krakow-based company specializing in the production of industrial machines, production assembly lines and measuring systems adapted to specific needs of businesses. For quite some time now, BGM manufacturing processes have been supported by VSHAPER 3D printers.

“By investing in 3D Printing technology, we strived to increase the efficiency of our work. The 3D Printer turned out to be a great alternative to expensive, more complex and advanced machines such as CNC milling machines”, said Tomasz Bobek, the CEO of BGM.

BGM uses VSHAPER 3D printers to create high-strength and structurally complex machines parts. One such industrial 3D printer is the VSHAPER 500.

VSHAPER 500 is ideal for additive manufacturing as it offers a build volume of 430x430x450 mm. Featuring an extruder with two V-JET heads, this machine is capable of producing large-sized parts using FDM technology. An enclosed chamber, together with a heated platform, guarantee the highest quality prints. The device is suitable for industries where prototyping is used, as well as for small-scale production.

Source: 3printr.com

The V-PORT dual extruder is capable of printing with two materials at the same time, allowing you to create amazingly complex large-scale models with almost unrivaled precision.

VSHAPER 500 Industrial 3D Printer Specifications:

Source: intamsys.com

The knee is one of the most vulnerable and fragile joints in the human body, whose average life expectancy is 50 years. Many elderly people suffer from various knee joint problems, which affect a normal lifestyle and reduce mobility in old age.

Manufactured by Sichuan Ju An Hui Co. Ltd., BioNEEK is a bionic exoskeletal knee brace equipped with a magnetorheological damper.

With biomechanical assistance, BioNEEK enhances support, reduces impact, improves stability and maximizes the protection of the knee so that it can be constantly rehabilitated. The magnetorheological damper works just like a shock absorption system that reduces the impact on users’ knees while improving endurance and mobility.

BioNEEK was 3D printed on an industrial FUNMAT PRO HT printer, which is capable of efficiently printing large models with PEEK (polyetheretherketone).

Each BioNEEK user has individual needs in terms of size and shape of the knee brace, but that is the beauty of 3D printing - it allows to create objects according to specified parameters.

BioNEEK knee brace helps prevent injuries by providing users with an extra level of strength and protection when rehabilitating a damaged or weakened joint. The bandage has a soft lining so that wearing it is comfortable.

FUNMAT PRO HT is INTAMSYS' most advanced industrial 3D printer. It has a build volume of 450 x 450 x 600 mm.

The advanced design of the 3D printer features a camera with a constant temperature of 120 ° C, a heating platform with the temperature of up to 160 ° C, a high-temperature extruder 450 ° C and an all-metal body.

The machine is able to print with more than twenty types of high-strength engineering thermoplastic materials. It is possible to create large objects from such materials. Compatible materials include PEEK, PEKK, ULTEM, PPSU, PC, ABS and many more.

Intamsys FUNMAT PRO HT

Source: builder3dprinters.com

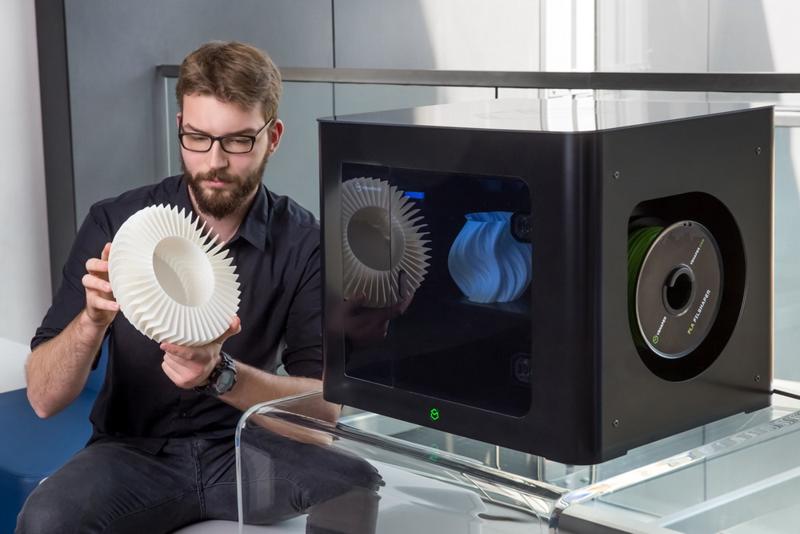

Field Factors is a Dutch company that provides complex solutions for urban water treatment. Inspired by the beauty of nature, the company designs and creates water treatment plants for public and industrial use.

Field Factors uses the Builder Extreme 1500 to build full-size models. Its build volume is 1100 x 850 x 550 mm - this is one of the largest FDM printers in the world, its use allows Field Factors to prototype large models of infrastructure components. It takes several days to create these highly detailed models.

In addition to printing full-scale component prototypes for infrastructure applications, the company also uses Builder Extreme 1500 to quickly make concrete molds. The ability to quickly create and test detailed models is essential when designing infrastructure elements.

Builder Extreme 1500 is an industrial large-format 3D printer featuring a build volume of 1100x500x820 mm (XYZ), an extruder with two printheads, a 7-inch touch screen and many other advanced features.

Builder Extreme 1500

Source: massportal.com

3D printing can be used to produce custom braces, splints, and other artificial external devices serving to support the limbs or spine. Three-dimensional printing allows to create lightweight and aesthetic assistive devices with more freedom in terms of customization and design compared to traditional assistive devices.

Comparison of traditional brace (left) and 3D printed back brace. Source: massportal.com

WiDE is a Latvian company producing orthopedic and prosthetic parts using 3D printing. The company uses the industrial 3D printer Mass Portal D1200 to make orthotics for scoliosis patients. The brace has a mesh pattern, which makes the construction easier to wear and more attractive for everyday use.

Mass Portal D1200

Source: stratasys.com

The rover you see in the picture has about 70 FDM parts printed on a Stratasys F900 printer, including flame-retardant vents and housings, camera mounts, large pod doors, a large part that functions as a front bumper, and many custom fixtures. The rover is now roaming the Arizona desert, maneuvering in extreme environmental conditions. NASA astronauts and engineers test rover's capability to move on rocks and sand, up and down hills in an environment that perfectly simulates the harsh conditions on Mars. This is a part of Nasa's next project, Desert RATS (Research and Technology Studies), a Hummer-sized rover equipped with a pressurized cabin to provide life support to astronauts in space. In the near future, such vehicles can help people explore near-Earth asteroids and nearby planets, including Mars.

To design such a specialized all-terrain vehicle, NASA engineers turned to large-format 3D printing technology. About 70 parts of this vehicle were digitally modeled and built inside the build chamber of the Stratasys 3D industrial printer using FDM technology, which is capable of creating parts of complex shape, while being durable enough to work in extraterrestrial conditions.

For the 3D printed parts NASA used ABS, ABS + PC, and PC.

Source: cdn.cati.com

Stratasys F900 is designed specifically to be used in manufacturing, defense and heavy industry.

Stratasys F900

Specifications:

Turkey-based Efes Bronze is a leader in bronze sculpting artistry. Their pieces of art can be seen in many countries around the world. The large build volume of Modix Big60 allows them to create large models that can be utilized for casting with the lost-wax technique.

The Big60 is a large-format 3D printer with a build volume of 610x610x610mm. The machine supports dual extrusion and can be upgraded to the 120X version. 120X has the build volume of 1200x610x610mm, which is one of the biggest, even among large-format 3D printers.

Source: modix3d.com

The models are printed with PLA in parts to be later glued together. Wax is casted into a created negative silicon mold, then it’s smoothed out and made more detailed. Finally, everything is covered with plaster and bronze metal is cast inside.

Modix Big60 / 120X

Specifications:

gCreate was founded back in 2013, when its founders discovered the lack of large-format 3D printers. The company specializes on rather big machines that are great for consumer and professional use. gCreate had developed several large-format 3D printers that have many applications. In early 2019, the company announced its latest development: gCreate gMax 2, which has been redesigned and has much bigger build volume than its predecessors (457.2 x 457.2 x 609.6 mm).

The gMax 2 also features a filament runout sensor, and Mosaic Manufacturing Palette 2 compatibility for multi-color and multi-material printing.

Source: mosaicmfg.com

Although usually, such machines are used for industrial purposes, this one can also be utilized to create high-precision small or medium-sized prints.

Source: gcreate.com

gCreate gMax 2

Specifications:

Source: 3ders.org

Xuberance, a Shanghai-based design studio never ceases to amaze the audience with its stunning fashionable 3D-prints and accessories. Today, continuing to expand the boundaries of 3D-printed fashion design, the studio is working together with the Chinese company Farsoon to manufacture two collections of 3D-printed handbags: Dream Butterfly and Byzantine.

Although each product differs in its shape and style, both collections were created using the SLS technology and a Farsoon 403P industrial 3D printer.

Collaboration between Farsoon and Xuberance arose from a mutual interest in exploring the manufacturing capabilities of thermoplastic polyurethane (TPU), a hybrid material that combines hard and flexible polymers. The first 403P printer series was specifically designed for sintering such materials as TPU and PA6, with a melting point below 220 ℃.

Source: 3ders.org

TPU's properties are great for manufacturing women's handbags and purses, since the material is wear-resistant and has a high level of elasticity. TPU is also easy to process, and 3D printing allows for mass production of fashion accessories.

Source: 3ders.org

Farsoon 403P industrial printers are available in several configurations, but each model has improved protection against overheating. Besides that, powerful lasers and thermo controllers allow the 403P series to meet any business need - from prototyping to full production of polymer parts.

Farsoon FS403P

Specifications:

Source: uniontech3d.cn

Dongguan Yuyuan Mold Corporation, a subsidiary of the China-based PouChen Group, one of the world's largest manufacturers of sports and casual shoes, in early 2013 entered into a strategic partnership with UnionTech, a manufacturer of industrial 3D printers. The goal was to provide the supply of 3D printers and special software for designing 3D models of shoes.

Using UnionTech FM 450 3D printers, the shoe maker prints soles, shoe vamps and other parts.

UnionTech FM 450 produces highly elastic shoe models with a precise pattern and smooth surface that does not need to be polished. In other words, the cost of production is substantially reduced thanks to heat resistance, tensile strength and other physical properties of prints that significantly surpass traditional models. In addition, compared to the traditional injection molding process, 3D printing technology is more environmentally friendly and waste-free.

UnionTech FM 450

Large-format 3D printers are designed to complete such tasks as decreasing the cost of production, reducing waste, shortening of development and manufacturing cycles. Most importantly, large-format 3D printers have the ability to create unique, customized objects and parts for literally any application.

The Top 3D Shop team can help you choose a 3D printer of any kind: large and small, serious and not so much, amateur and professional. Contact us - we will help you get the machine that's best for you.

Update your browser to view this website correctly. Update my browser now

Write a comment