In 2022, modern businesses seem to face new challenges — and now the ceaseless development of technologies couldn’t be more appropriate for the production needs. As is known, 3D printing is not limited to SLA and FDM solutions, with some of the world-leading manufacturers offering industries more means to streamline their production without compromising quality.

This is Top 3D Shop, and today, we are going to review the Sinterit Lisa X 3D printer — a new iteration in the well-proven lineup of SLS equipment.

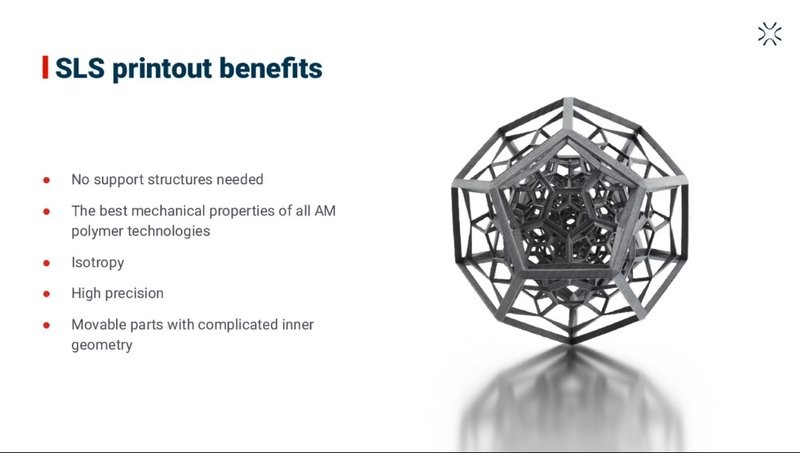

Selective Laser Sintering (SLS) is one of the additive manufacturing technologies that makes use of a high power laser to sinter polymer powders into solid objects. Coupled with the unique Auto Nesting solution built into the Sinterit Studio software, this method allows the entire volume of the build chamber to be occupied by products — with no waste of space and material on support structures. This certainly has a huge impact on productivity and gives SLS an advantage over FDM and SLA technologies. In addition, the absence of supports ensures a higher surface quality of products and greatly simplifies their final processing.

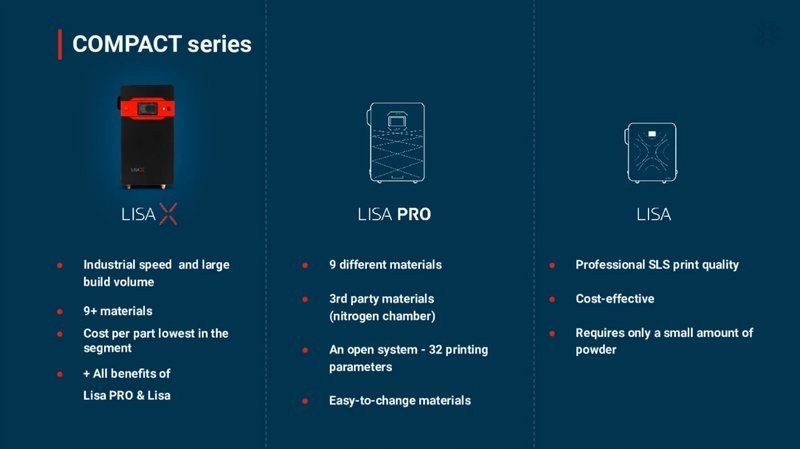

Being a successor to the two other models in the lineup, Lisa and Lisa Pro, the Sinterit Lisa X not only adopts the same printing technology but boasts a highly increased print speed, enlarged build volume, updated hardware, more connectivity options, and other smart features to enhance the capabilities of 3D printing. It is possible to greatly increase the amount and speed of production compared to the previous models. For example, the Lisa Pro can print 224 parts in 205 hours, while the Lisa X will do 540 same parts in only 26 hours. By the latter, the production rate increases more than twice.

Apart from that, the advanced slicing software offers a great many settings to adjust, making the process more convenient and the result more impressive. The device allows producing detailed, high-quality parts in a short time, which results in a great return on investment.

Look through the following table to compare the main differences between the original Lisa, Lisa Pro, and Lisa X 3D printers.

|

Parameter |

Lisa |

Lisa Pro |

Lisa X |

|

Build volume |

110 x 160 x 155 mm 4.3 x 6.3 x 6.1 in |

110 x 160 x 245 mm 4.3 x 6.3 x 9.6 in |

130 x 180 x 330 mm 5.1 x 7.1 x 13.0 in |

|

Max. print diagonal |

248 mm 9.8 in |

313 mm 12.3 in |

398 mm 15.7 in |

|

Print speed |

3 mm/h |

3 mm/h |

10-14 mm/h |

|

Laser type |

IR 5 W |

IR 5 W |

IR 30 W |

|

Wavelength |

808 nm |

808 nm |

976 nm |

|

Layer height |

0.075–0.175 mm 0.003–0.006 in |

0.075–0.175 mm 0.003–0.006 in |

0.075–0.175 mm 0.003–0.006 in |

|

Scanning type |

XY |

XY |

Galvo |

|

Laser spot size |

400 μm 0.0157 in |

400 μm 0.0157 in |

650 μm 0.0256 in |

|

Feed bed capacity |

3.4 L |

5.2 L |

14 L |

|

Inert gas control system |

- |

✔ |

✔ |

|

Display |

4" interactive touchscreen |

7" interactive touchscreen |

9" interactive touchscreen |

|

Connectivity |

Wi-Fi, USB |

Wi-Fi, USB |

Ethernet, W-iFi, USB |

Keep reading to learn the full list of Lisa X’s major tech specs and its highlights in detail.

The device comes with dedicated tools as well as other equipment to make printing and processing more comfortable and effective. Apart from the printer itself, the basic set contains:

For some items, package content may change. In case of any questions, please get in touch.

To further enhance operation and user experience, Sinterit offers additional equipment which can be purchased separately or as part of complete sets. We will dwell on it later.

The Sinterit Lisa X embodies the main benefits of the company against its competitors in the SLS market. Compared to the previous iterations in the compact series, the machine boasts industrial speed, increased build volume, smooth workflow, and the most effective production in the segment. Let’s have a look at some of the other prominent features that make the Lisa X a valuable solution with an innovative approach.

The Sinterit devices are associated with ultra-high precision of printing. The models always come with sharp edges and repeatable dimensions. This accuracy makes the Lisa X ideal for advanced technical 3D printing.

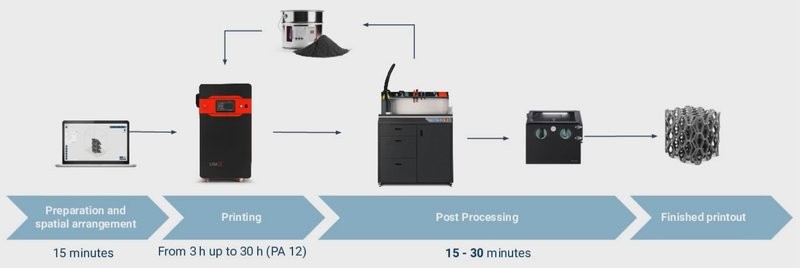

Thanks to the comprehensive set of high-end products provided by Sinterit, it usually takes less than 45 minutes for set up and post processing. The lightning speed of the Lisa X will ensure rapid printing, which is overall simple, fast, and effective.

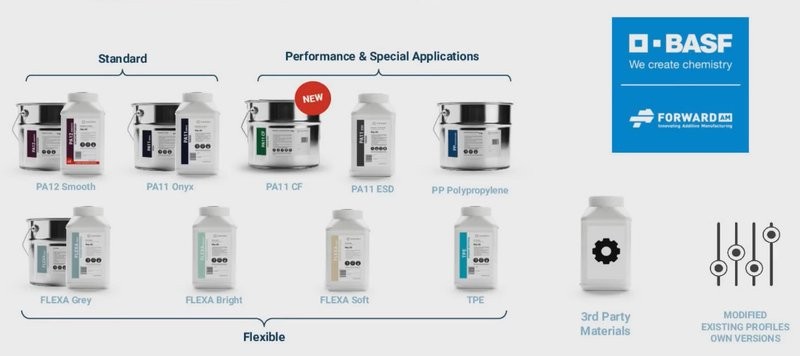

Sinterit offers 9 proprietary powders for various purposes: from the standard ones, like PA12 Smooth and PA11 Onyx, through the flexible and up to high performance materials, such as PA11 Carbon Fiber. Moreover, the Advanced version of the Sinterit Studio allows using 3rd party materials and modified profiles. Due to the partnership with BASF Forward AM, more options are going to be announced.

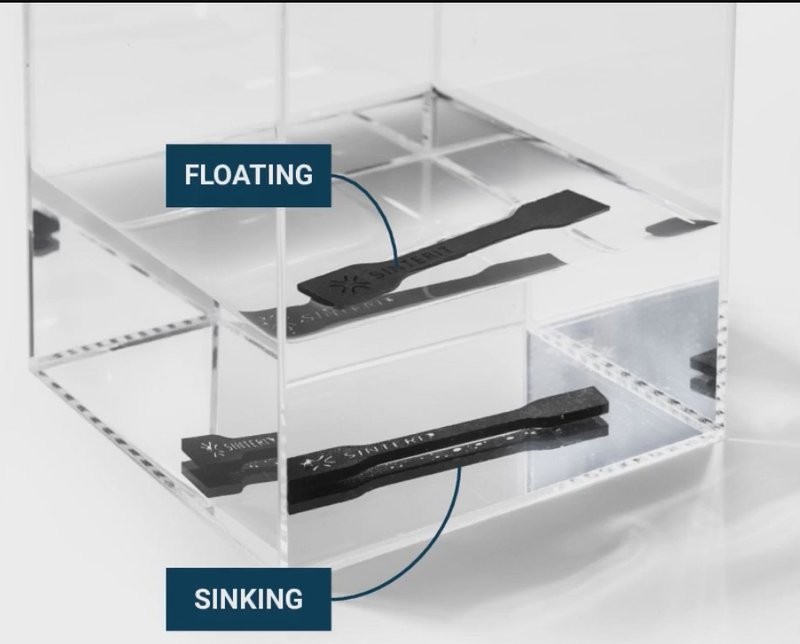

The Sinterit Studio Advanced gives access to 32 open printing parameters and use of 3rd party materials, which provides full control over the process and freedom to experiment with print settings, powders, and resulting models. The built-in nitrogen chamber adds even more to it. Make the same object act different in just a couple of clicks!

The Lisa X utilizes the company’s dedicated slicing software. The program is called Sinterit Studio, and it serves as a perfect tool for working with 3D models of all kinds. Apart from this, one can monitor the status of printing throughout the whole process and adjust up to 30+ flexible parameters. The Sinterit Studio allows creating new projects or working on the existing ones in the wide range of file formats: STL, OBJ, 3DS, FBX, DAE, 3MF. The software features:

There are two versions of the Sinterit Studio available — Basic and Advanced. They differ from each other in the scope of supported functions:

Sinterit Studio Basic: offers a standard feature set, such as printing with basic Sinterit powders (PA12 Smooth, Flexa Grey) without additional parameters or 3rd party materials.

Sinterit Studio Advanced: provides access to 32 open printing parameters, experimental settings, and 3rd party materials use.

The difference between two versions is detailed in the table below:

|

Sinterit Studio Basic |

Sinterit Studio Advanced |

|

|

Basic settings |

||

|

Changing Layer height |

✓ |

✓ |

|

Slicing |

✓ |

✓ |

|

Auto-nesting + collision detection |

✓ |

✓ |

|

Advanced settings (open printing parameters) |

||

|

Scale modification |

✓ |

✓ |

|

Printing temperatures modification |

basic |

✓ |

|

Warmup and cooldown modification |

— |

✓ |

|

Laser power modification |

basic |

✓ |

|

Laser movement and geometry modification |

— |

✓ |

|

Skeletons (enhancing fine details) |

— |

✓ |

|

Pre-defined profiles for Sinterit materials |

||

|

Materials available (check availability below) |

|

|

|

Open Profiles |

||

|

Open profiles for Sinterit materials |

— |

✓ |

|

Open profiles for 3rd-party materials |

— |

✓ |

The Lisa X can be purchased separately or as a part of the complete performance set that includes peripheral equipment for all stages of the 3D printing process.

The set comes with:

The Lisa X essentially keeps all the features of the two previous models from the so-called compact lineup yet boasts the increased industrial speed at the more spacious build volume. So, it is great for end-use parts, prototyping, advanced R&D, and education, granting even more benefits than the Lisa Pro version.

The Sinterit Lisa X is a new step in compact SLS printing that saves and multiplies the achievements of the previous models in the line. The machine impresses with the speed of production and creative possibilities provided by the open environment as well as its cost-effectiveness. In the combination with the dedicated peripheral tools, the device represents a powerful comprehensive solution for a wide scope of application.

Update your browser to view this website correctly. Update my browser now

Write a comment