Additive manufacturing technologies are on the rise today, conquering new industries and entering the consumer market where they were hard to imagine just a couple of decades ago. There are several types of additive manufacturing, more commonly known as 3D printing, but all of them utilize the same process of adding material, layer by layer, to create a 3D object.

This is Top 3D Shop, and in this article, we are going to tell you about selective laser sintering. Read on to learn about the materials used in SLS 3D printing, as well as about the applications of this technology, its advantages and disadvantages.

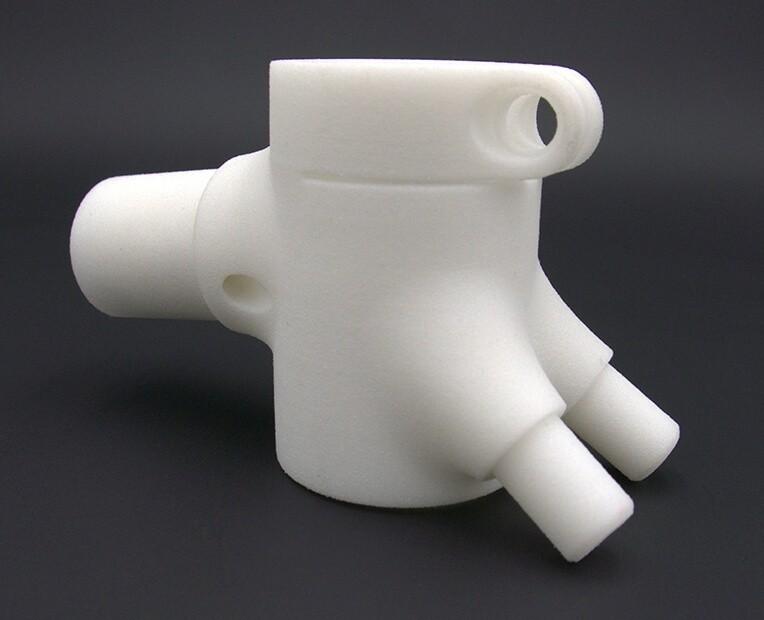

Selective laser sintering, or SLS, is a 3D printing technology that uses high-powered lasers to fuse small grains of polymer powder into a solid 3D model. The technology was initially used for functional rapid prototyping, but thanks to its ability to print finely-detailed durable models with very complex geometries incredibly fast, SLS printing turned out to be a perfect tool for small-batch manufacturing of end-use consumer products. Until recently, SLS 3D printers could only be used by large enterprises as they were enormous in size, extremely expensive, and required special skills in operation. But in 2014, when the last patent for SLS technology expired, it began to develop rapidly, and today there are a number of relatively affordable (under $10,000, compared to industrial machines starting with $100,000) benchtop SLS 3D printers struggling for the market.

Credit: protolabs.com

Dr. Carl Deckard and Dr. Joe Beaman from the University of Texas developed selective laser sintering technology in the mid 1980s. In 1984 Deckard, being a student, created the first concept of selective fusing of powdered material layers with a laser beam. Dr. Joe Beaman supported the talented student, and their cooperation gave the start to SLS 3D printing technology. Later on, in 1987, they founded the DTM Company producing SLS 3D printing machines. First commercial printers based on this technology hit the market in 1992.

Credit: sites.utexas.edu

SLS technology allows for the use of a wide range of different materials, from the most common nylons, valued for their durability and environmental stability, to metals and alloys, which need a high-powered laser to be sintered. Regardless of the type, all materials are always in powder form. It’s noteworthy that different printers feature different material compatibility: open-system devices can use various powders produced by third-party manufacturers, while a closed-system machine may be restricted to only 2–3 proprietary materials. Likewise, the number of supported material types varies a lot depending on a printer. Below are the most common SLS materials available.

The most popular material for SLS 3D printing used for general purposes. It is perfect for functional prototyping and small-batched manufacturing. Nylon 12 provides high durability, strength, and minimal water absorption. Some of the PA 12 materials are biocompatible.

Credit: sculpteo.com

Nylon 11 appears to be more flexible and shows better thermal, chemical, and impact resistance; it’s also more resistant to UV light and weather conditions, compared to Nylon 12. The material is suitable for making fixtures, snaps, clips, and hinges, as well as thin-walled ducts. It is also used in prosthetics.

Credit: sinterit.com

Filled Nylons are composite materials which are actually a mixture of nylon powder with different additives, like, for example, Carbon Fiber-Filled Nylon (PA 12 CF) which provides exceptional stiffness and low weight. Glass-Filled Nylon, or PA 12 GF, offers excellent stiffness and thermal stability. Alumide, or Aluminum-Filled Nylon, is known to have high thermal conductivity, but it’s not electrically conductive. Alumide is well-suited for objects with high metallic shine.

Credit: sculpteo.com

This group of materials feature both high elasticity and strength. Thermoplastic elastomers usually have a high-quality surface finish and are used to produce medical models, grips, gaskets, hoses, and toys.

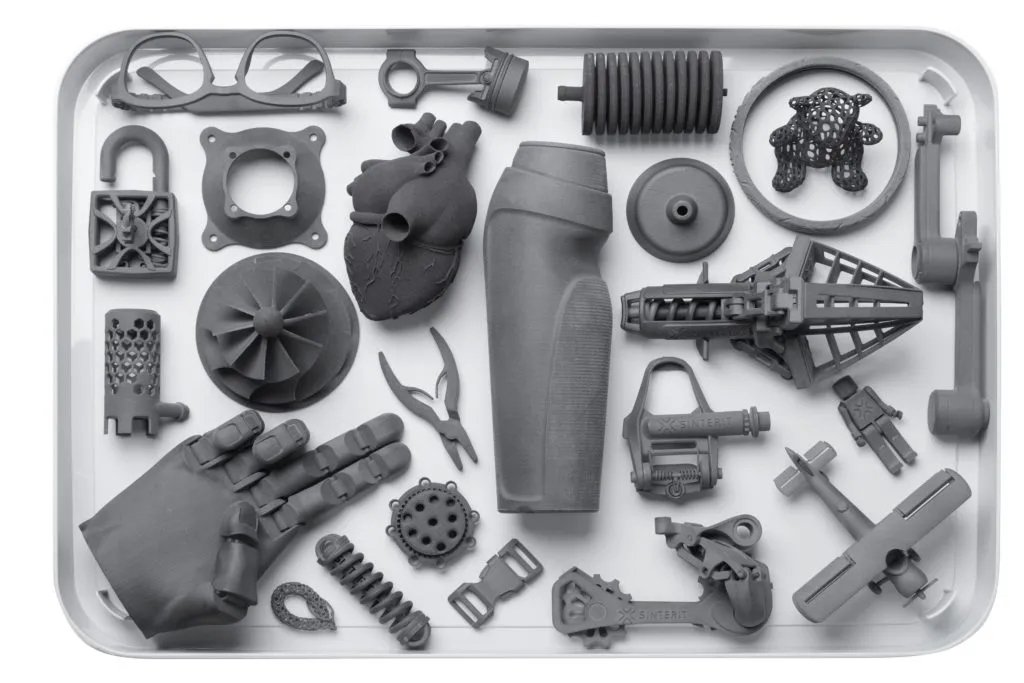

First invented for rapid prototyping, SLS 3D printing is nowadays widely used in a vast variety of industries, where accurate high-speed production of parts with complex designs is of great importance.

SLS technology is widely used in the field of medicine and healthcare to produce medical tools and surgical models. It also appears helpful in prosthetics, as some of the SLS materials, like Nylon 12, can be biocompatible and suitable for sterilization.

Credit: rapidmade.com

Selective laser sintering is utilized in electronics, as well as

in making durable tools and fixtures, and also in sports equipment production. Fashion and beauty take advantage of such equipment, too. For example, the famous Chanel Company made use of SLS printing technology to optimize their mascara brush. One more application where SLS appears to be pretty useful is spare parts production.

Credit: chanel.com

Organizations like NASA apply SLS 3D printing technology for prototyping, making special tools and end-use parts. The Boeing Company started to use this technology to make prototypes and functional parts for the secondary structure, such as ducts and fairings. According to Jerry Clark, manager of the Air Vehicle Configuration Design, Integration and Rapid Development Department of The Boeing Company in Mesa, this decision helped the company to significantly save time and reduce production costs.

Credit: boeing.com

Alongside making impressive prototypes, automotive companies use SLS for producing a variety of functional parts for their cars.

Credit: porsche.com

The process of SLS 3D printing is not complicated, but still there are certain things one should keep in mind to get a flawless result. Let’s look at it more specifically.

Credit: formlabs.com

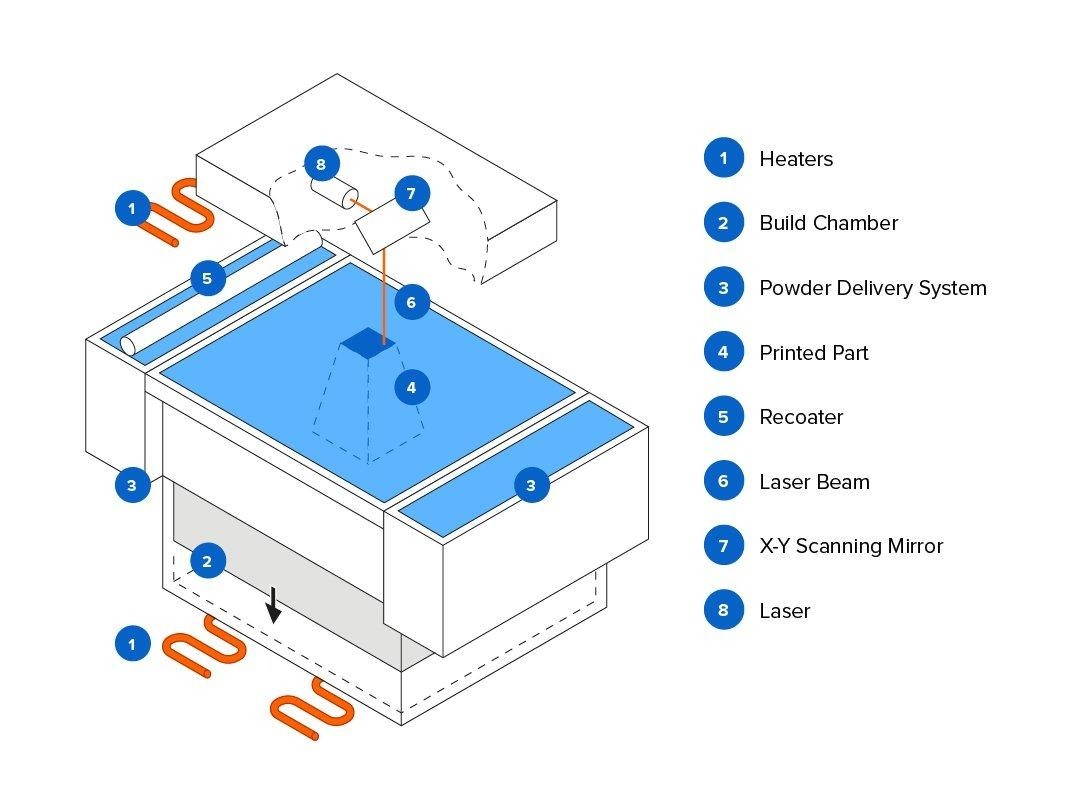

Like in any 3D printing technology, SLS being no exception, the process starts with preparing a printing file. First you need to design your model using any CAD software (or you can use a 3D scanned model instead), and export it in a 3D printable file format (for instance, OBJ or STL). Utilize your printer’s software to adjust printing settings and slice the model into layers for printing. As soon as the CAD file is ready, the software sends the instructions to the printer.

This step varies depending on the printer model. Some of them require special skills to operate, others, especially benchtop machines, are much more user-friendly and intuitive. In any case, you need to be sure that the build chamber is filled with printing material, as no matter how small a part you are about to print, the entire working area should be filled with powder.

The printing process starts with pre-heating the build chamber to the temperature a bit lower than the sintering point. After that, the roller disperses a thin layer of powder on the print bed. The laser(s) heats the areas that need to be sintered, according to the CAD file. The grains of powder are fused together mechanically, forming a solid structure — the first layer is ready. Then the platform descends a little, and the process of sintering repeats layer by layer, until the entire model is printed. The end result is a solid object covered in a mass of unsintered powder.

Credit: sculpteo.com

The printed model should gradually cool down inside the printer to obtain the necessary mechanical characteristics.

As soon as the object is cooled and removed from the build chamber, it needs to be cleaned of the excessive unfused powder. This is usually performed manually at a cleaning station with the help of compressed air. At this point the model is ready to use. You may want to add some additional steps of post-processing, like polishing, dying, or applying various purpose coatings depending on your requirements.

Credit: sculpteo.com

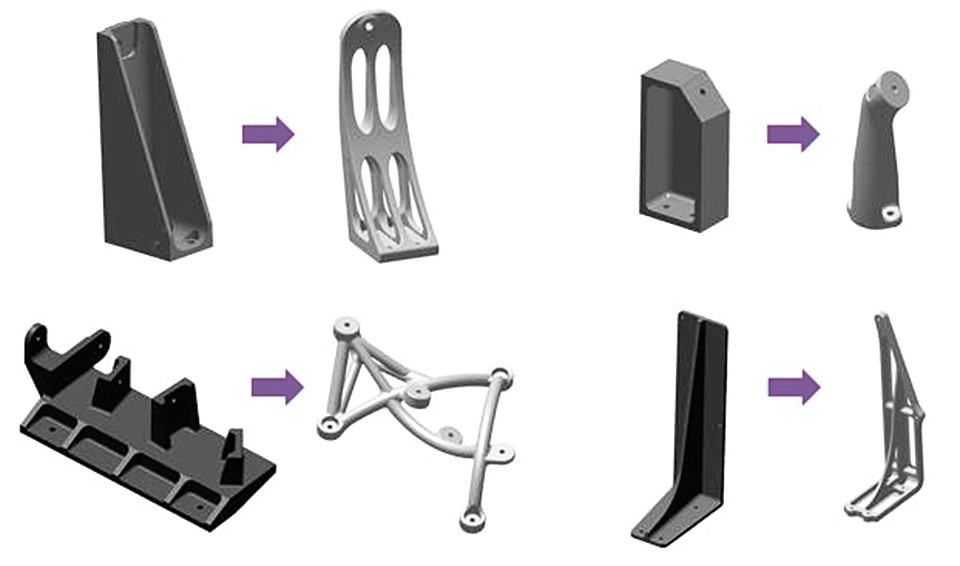

Unlike other 3D printing technologies, SLS doesn’t require any support structures for the object being printed, which is a huge benefit, as it creates endless opportunities for the designers to make very complex models. As the entire build chamber is filled with material, the unsintered powder is used to support the part during the printing process.

Due to the ability of nesting a number of parts for a single printing cycle, high-speed printing and simple post-processing, SLS technology, although quite expensive at the initial stage of investment, quickly pays off for enterprises with large production volumes. Adding the possibility to use recycled materials, we can see that SLS is one of the most cost-effective 3D printing technologies.

SLS is an incredibly fast technology due to its high-powered laser and the possibility to fully load the build chamber with numerous parts at a time.

Credit: sinterit.com

Earlier in this article we listed the most common materials used for SLS 3D printing, all of them featuring different properties that can meet almost any requirements. Besides that, many printers allow using various types of materials produced by third-party manufacturers, which makes the choice literally endless.

Credit: sculpteo.com

Once the object is printed, the excessive unsintered powder can be sifted and used again. It only needs to be mixed with fresh powder for every new print. This allows for practically wasteless production and increases cost effectiveness of the technology.

SLS 3D printers, although becoming more and more affordable, are still expensive and relatively seldom used by consumers.

Each 3D model should be cooled down after printing and cleaned up. Then you can either use it immediately or, considering the fact that SLS objects are monochrome and have a somewhat grainy finish, you may want to apply one or several post-processing operations to them.

Powders for SLS printing may shrink after being sintered. The printer software usually allows for adjusting shrinkage parameters to get the perfect model.

This drawback is compensated with the usage of recycled materials and the absence of support structures.

Normally 3D printers are rather quiet, producing the noise level of 40–50 dB. This can be compared to a quiet conversation or to a refrigerator. Still, there are different factors affecting the noise level. Printers with enclosures are usually less loud than those with open moving parts. Cheap models produce more noise as they are equipped with less quality components. Regular maintenance is very important, as it prolongs your printer’s lifetime and reduces the noise level which can be otherwise increased because of the friction of moving parts.

Not long ago, SLS printers were only meant for large enterprises and the price of such machines reached hundreds of thousands dollars. Today, with compact desktop devices having hit the market, SLS printing is becoming more affordable, still remaining rather costly. But considering its low cost per part and the wide range of consumables, it’s just a matter of time for it to become less expensive and much more popular with customers.

Both selective laser sintering and selective laser melting employ powder as printing material. SLS technology uses a lower temperature, which is not high enough to completely melt the material, but just to sinter it to make a solid structure. SLM uses a higher temperature, and the printing powder is completely melted. This results in more homogeneous parts with smooth surface finishes.

3D printing is not considered to be a power-intensive technology. The average power consumption of a 3D printer is 150–250 Wh. For comparison, the Xbox consumes 50 Wh, and a microwave about 1000 Wh. The most power-intensive 3D printers are those based on SLA and DLP technologies, while SLS printers consume less power.

Update your browser to view this website correctly. Update my browser now

Write a comment