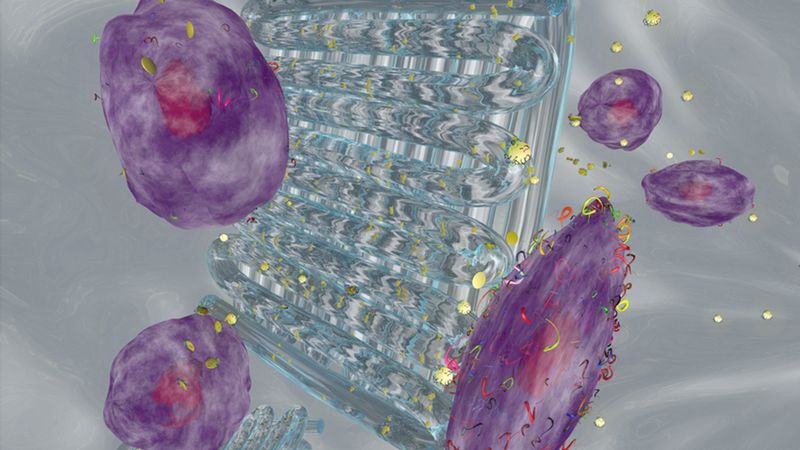

In 2019, 3D bioprinting technologies rapidly developed in speed and precision. The progress is so undeniably significant that there is no doubt that it will soon be possible to produce fully functional organs and tissues using bioprinting.

To learn about the most significant achievements of 2019 in the field of 3D bioprinting, read this article.

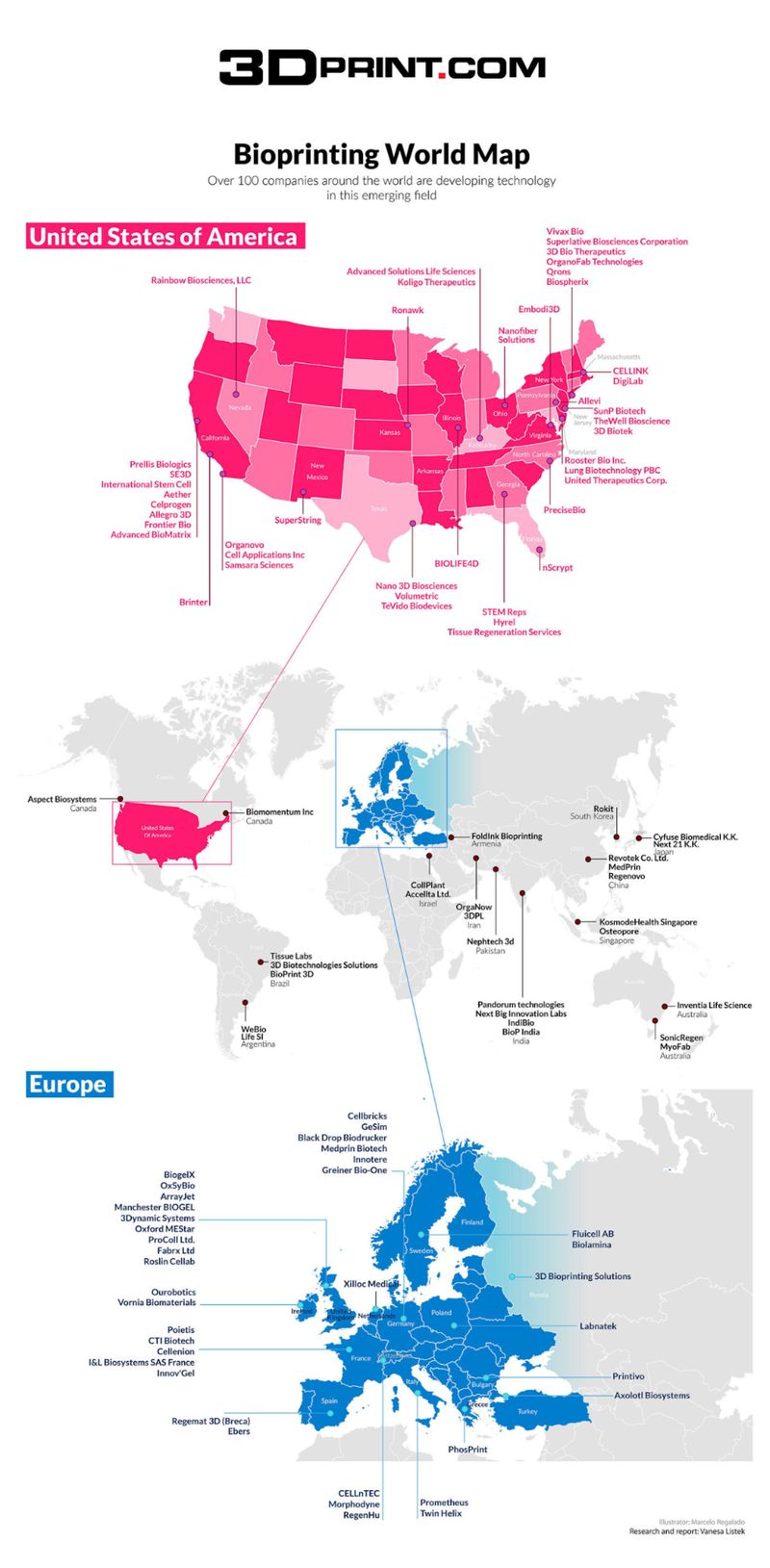

Source: 3DPrint.com

This map was developed by 3DPrint.com – an online magazine, which is a world-famous information resource specializing in 3D bioprinting. The map shows almost every company that is engaged in the development of bioprinters and bio interfaces - ranging from recognized centers for the bioprinting development to innovative startups that strive to revolutionize 3D bioprinters and materials.

Source: 3dprint.com

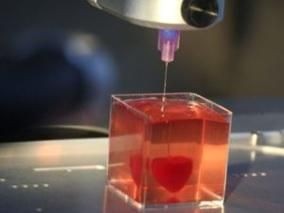

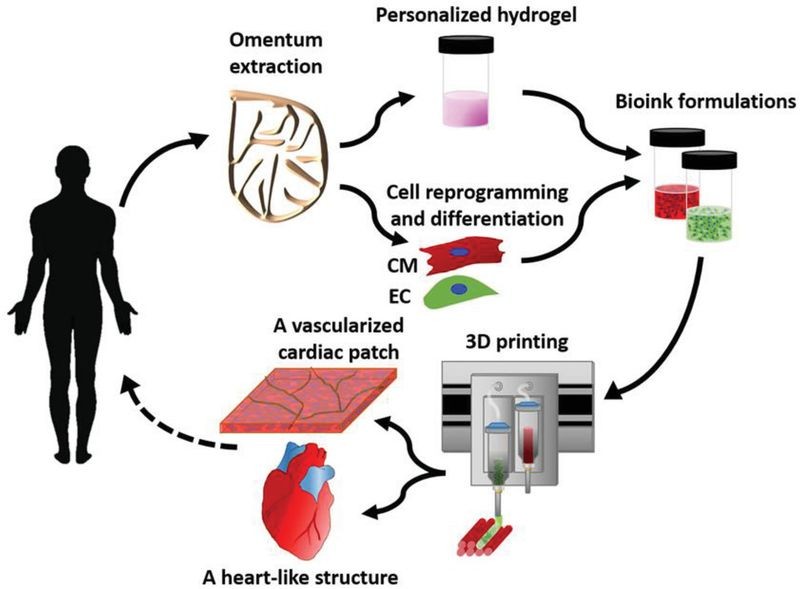

In April 2019, specialists from the Tel Aviv University published an article entitled "3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts". News agencies, without understanding the essence of the message, spread the news that the Israelis have learned to print hearts suitable for implantation. The reality was somewhat more modest.

So far, this technology developed by Israeli experts allows to:

Cardio patches are already a reality, the next step is to print a fully functional heart.

Source: onlinelibrary.wiley.com

This technology has enormous potential both for heart disease treatment and for transplantation purposes. The possibility of fully creating a new heart from the biological tissues of a patient eliminates the need for a donor, and in addition to that it provides a practical solution to all problems related to tissue biocompatibility and the size of the organ transplant.

Source: The Wyss Institute for Biologically Inspired Engineering

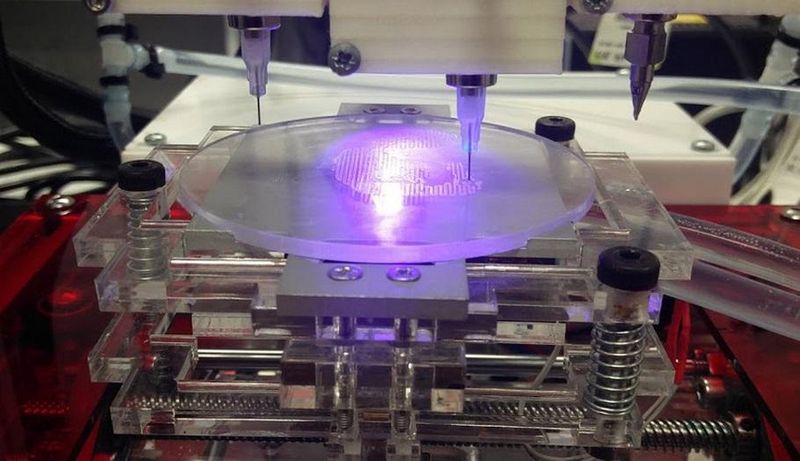

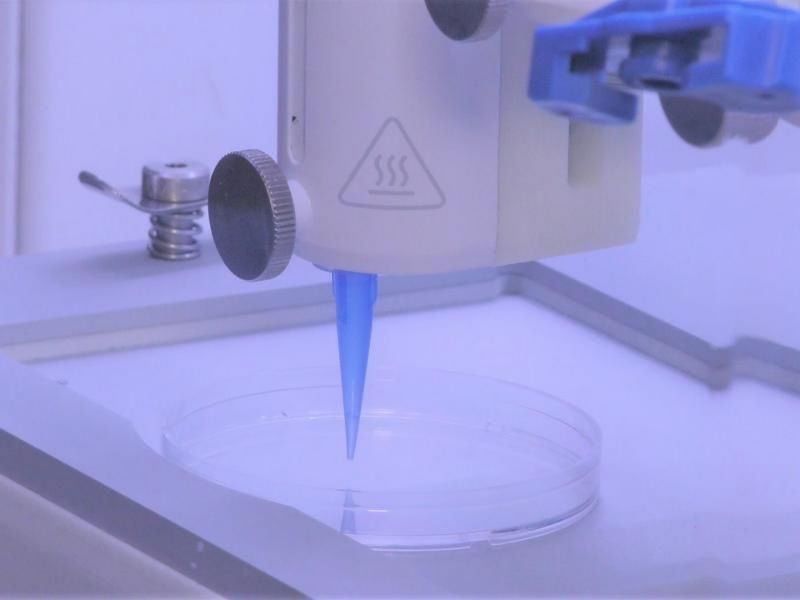

With most commercial printers, it is possible to create objects using one material at a time, while jet printers that are capable of multi-component printing are limited by the physics of droplet formation. Extrusion 3D printing allows you to print using a wide range of materials, but the printing process is very slow.

Now a new technology called Multimaterial Multinozzle 3D (MM3D) has been developed at Wyss Institute at Harvard in cooperation with John A. Paulson School Of Engineering And Applied Sciences. This technology is based on the use of high-speed pressure valves and multi-nozzle printheads, which themselves are also manufactured using 3D printing. Each nozzle enables the use of up to eight different materials, with the ability to switch them up to 50 times per second.

To demonstrate their technique, the researchers printed a Miura origami structure consisting of rigid “panel” sections connected by very flexible “hinge” sections. Previously, it was possible to create such a structure only with the help of manual assembly. In MM3D, the printhead was able to print the entire object in a single session, using eight nozzles to continuously extrude two types of epoxy ink, the stiffness of which differed by four orders of magnitude after curing.

Source: mimixbio.com

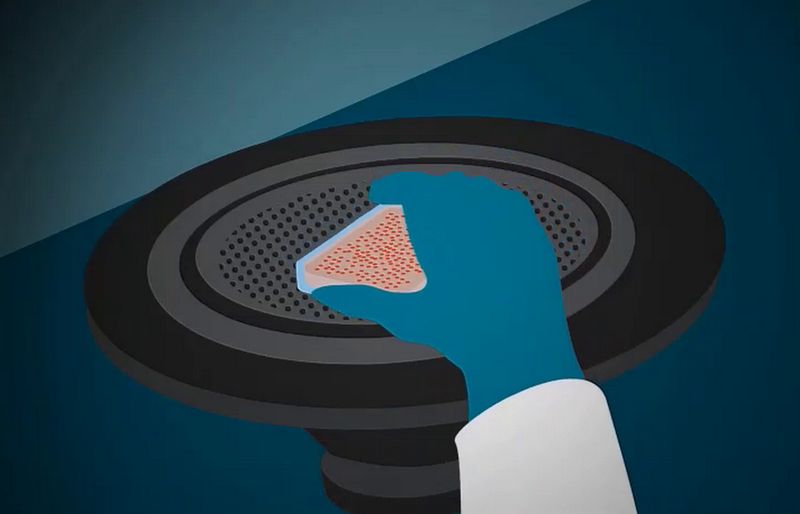

Mark Turner, the founder of the well-known company regenHU, has launched a new startup - mimiX biotherapeutics. The project was designed to commercialize a new bio-processing technology called Sound Induced Morphogenesis (SIM). This technology is based on the process of creation of well-defined biological patterns, which independently form into living functional tissues when exposed to sound waves. SIM offers a highly effective strategy for creating dense and organized cell structures.

MimiX biotherapeutic devices use sound waves. Cell culture medium is placed on a specific type of speaker and, depending on the emitted sound and the shape of the dish, structures of various shapes are formed – a grid, concentric circles, etc.

Source: mimixbio.com

Source: mimixbio.com

Source: mimixbio.com

According to Turner, bioprinting using conventional dosing systems is good for scientific research, but too complex for clinical use due to problems with scalability, speed, and high complexity of processes. SIM-based systems are designed to radically simplify and speed up the printing process. The portable device is suitable for any office, and its reasonable price ensures high availability.

Source: Biopixlar

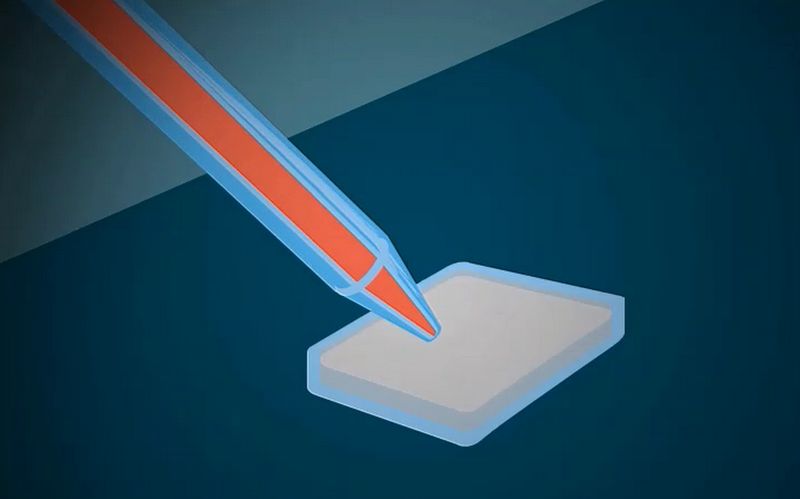

Fluicell, a Swedish biotech company, specializes in development of platforms for cell behavior research. It introduced Biopixlar - a bioprinting technology, which allows you to create complex tissue-like structures. To control the positioning of individual cells in these structures you can use a gamepad - just like in a video game.

Biopixlar uses microfluidics that allow you to control the material at the micro level, thanks to the precision of the pump or microfluidic tube when it comes to directing the flow of the biomaterial to the printing execution. With such a precise micro-level control, systems naturally scale up to the macro-level, which allows to create high-resolution prints. In addition to that, the technology allows you to create multi-component structures, and makes it possible to create the materials within the printer itself, so there is no need for laboratory fabrication of the material. The microfluidic chamber controls the mixing of various materials. The result is a complete three-dimensional printed structure - created without the use of gels or scaffolds.

The main advantages of Biopixlar technology are:

Thanks to these features, the technology is a perfect tool for processing rare materials such as stem cells, primary cells, and biopsy samples.

Source: CELLINK

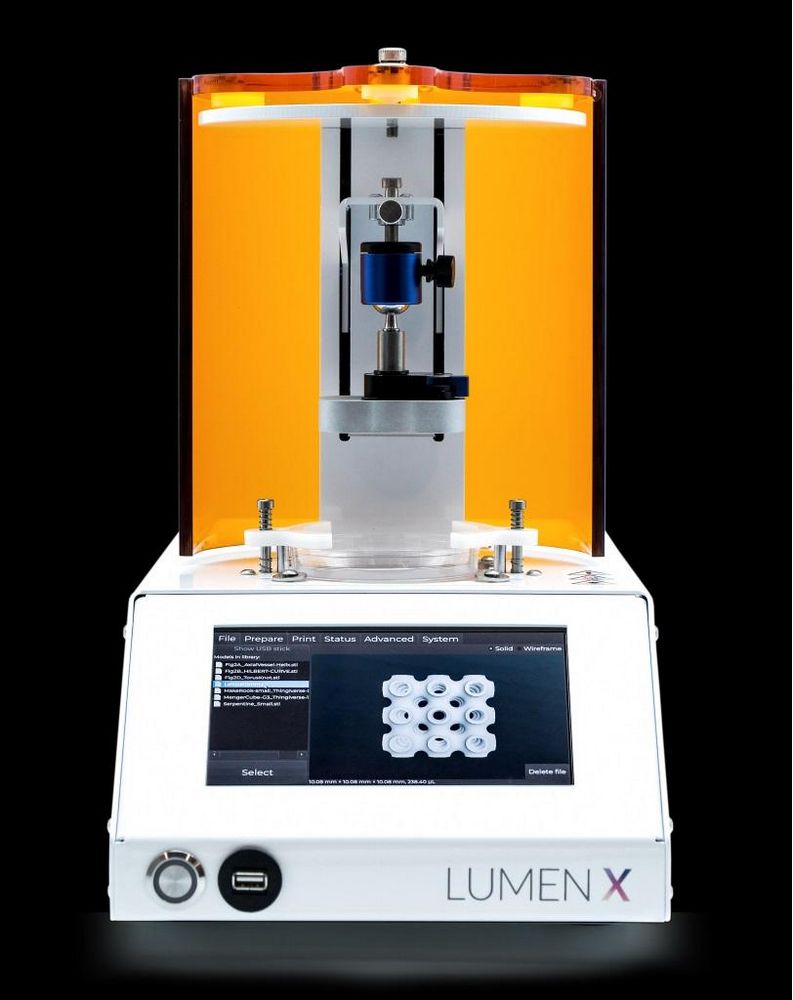

The Swedish company CELLINK specializes in developing bioprinting technologies for a wide variety of industries - from medicine to cosmetology. The company's products are used for printing liver, cartilage, skin tissue, and other types of tissues. In 2019, the company introduced two new bioprinters - Bio X6 and Lumen X.

Bio X6 is designed to make structures with any type of cell, which makes it possible to produce any tissue found in the body. The company claims that this new development allows you to combine more materials and tools and get results faster than ever before.

The printer combines six print heads with CELLINK’s patented clean chamber technology, two powerful fans that create excessive air pressure inside the chamber, and intelligent replacement head technology. It is possible to combine multiple materials in a single print with an architecture of increased complexity.

Source: CELLINK

The Lumen X bioprinter is the result of CELLINK's collaboration with the American startup Volumetric, a company that specializes in developing biopritners which use SLA technology. Despite the modest size and cost, the printer combines high performance and high precision, which is essential for the creation of vascular structures.

Lumen X works with biocompatible blue light, allowing you to form complex branching vessels and stitching layers into a single structure ten times faster than any other printing methods.

Source: 3dprint.com

A team from the University of Wollongong (UOW), Australia, has developed 3D Alek - a bioprinter that produces human ears for use in reconstructive surgery. The company uses stem cells to create the bioinks used in the printing process.

The new technology, according to researchers, can revolutionize the treatment of children with microtia. Microtia is a birth defect that causes outer ear to stop developing during the first trimester of pregnancy. Treatment of ear deformities is associated with significant difficulties caused by the specific complex shape of the organ.

Ear bioprinting technologies are extremely promising, because they allow to design and customise an ear graft according to the shape of the patient's face using their natural tissues. These factors would result in a reduced operating time and an improved cosmetic result, as well as help to avoid problems associated with finding a cartilage donor site.

Source: 3dprint.com

Specialists identify more than 500 vital functions of the liver from filtering blood to enzyme activation. Due to the complexity of production, only a handful of researchers and companies specialize in liver bioinks. One of them is Allevi - a Philadelphia-based biotechnology company. Now, you can already purchase Allevi Liver dECM in the company’s online store. The product makes it possible to create tissue-like structures that replicate the natural tissue characteristics.

Such structures are used in the study of the physiological activity of cells in vitro, which is crucial for better understanding of the course of diseases and the development of more effective drugs and treatments.

Source: 3dprint.com

Biogelx was founded in 2013 at the premises of the University of Strathclyde in Glasgow, Scotland. It was established in order to develop and produce synthetic materials for three-dimensional bioprinting. Biogelx hydrogel bioinks have a unique physical and chemical tunability that allows you to successfully replicate various tissue characteristics so that cells can interact with the environment, which is as close to natural as possible.

Biogelx’s bioinks provide high reproducibility, simple crosslinking method and viscosity control. In addition to that they allow to maintain high cell viability. They do not require the addition of reactive crosslinking agents, UV curing, pH adjustment, or extreme temperatures. These features ensure that the inks can be compatible with a wide variety of 3D bioprinters.

Source: 3dprint.com

A team of researchers from the Texas A&M University (TAMU) has developed a hydrogel bioink containing mineral nanoparticles that can deliver protein therapeutics to control cell behavior. These biologically active inks can be used for the creation of vascularized tissues for regenerative medicine.

TAMU researchers have developed a new class of hydrogels based on an inert polymer - polyethylene glycol (PEG). 3D printing with PEG-based inks is challenging because of the low viscosity of the ink. Trying to overcome this limitation, the team has found that adding silicate nanoparticles significantly increases the viscosity of bioinks, nearly avoiding any changes in the inks’ characteristics. This technology allows to cure the inks swiftly, which provides higher structural fidelity.

Source: Smithsonian Magazine

To create a durable natural-looking skin substitute for covering burns or other injuries has been the main challenge in the field of bioengineering for decades. Today, there are two approaches to treating large-scale skin lesions. The first method is autologous skin grafts, where doctors remove pieces of healthy skin to cover the damaged area. The second is skin substitutes made from various materials - from bovine collagen to polymer foam. Both approaches have serious drawbacks. Autologous skin grafts are painful and result in new wounds. Skin substitutes are usually a temporary solution, since they look very different from natural human skin and cannot cover deeper wounds.

A new skin transplantation technique promises revolutionary changes in the treatment of patients with burns and other injuries. A study conducted by specialists from Rensselaer Polytechnic Institute (RPI) and Yale University led to the creation of bioinks made from live human cells. This ink is used to print artificial skin, which then is able to grow its own vascular system.

Skin grafts are made from two types of bioinks, which contain different sets of human cells, suspended in collagen from rat tails. The first ink forms the inner layer of the skin (dermis), and the second type of ink forms the outer layer (epidermis). Then, in the petri dish, the layers are fused to create the finished graft. Experiments with mice showed that the blood vessels in the artificially grown skin grew connected with the mice's own blood vessels within four weeks. That means that the graft can become a fully functional part of the body within this period.

Source: 3D Bioprinting Solutions

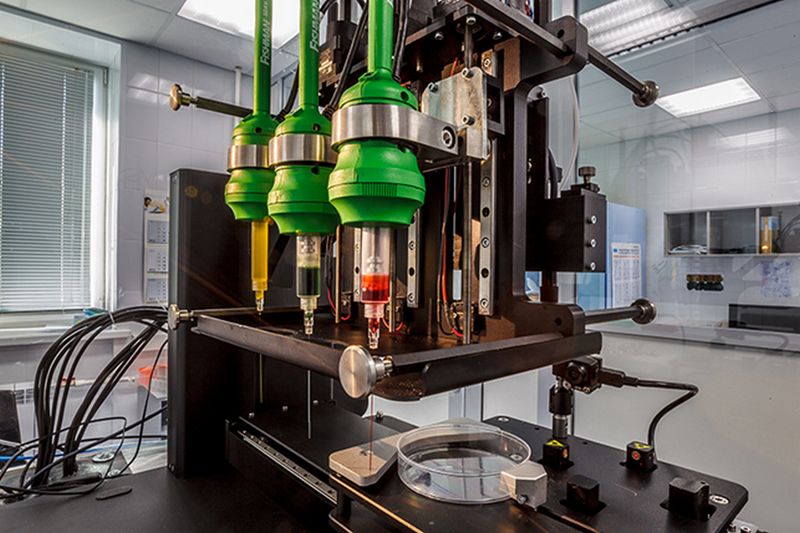

In Russia, the concept of "bioprinting" is closely connected to 3D Bioprinting Solutions – the only Russian company on the world map of bioprinting. Founded in 2013, it introduced FABION - the first Russian bioprinter - in 2014. This printer is still known as one of the most multi-functional in the world.

By the spring of 2015, the 3D Bioprinting Solutions laboratory successfully printed and transplanted an organ construct of a mouse thyroid gland. The report on this achievement was presented on 7 March 2015 at the Brazil National Centre of Metrology.

In 2016, a printhead was developed to automatically extrude tissue spheroids for three-dimensional bioprinting. It was used in an updated version of the bioprinter, called FABION-2, which also includes an HMI interface, new software, a printhead for two-component printing, and other features.

After the creation of the FABION-2, scientists and engineers started developing a fundamentally new bioprinter that uses magnetic levitation technology. The printer provides an opportunity for self-assembly of micro-tissues and micro-organs from tissue spheroids. The first prototype was released in the fall of 2016, and in March 2017, the assembly of the first fully functional magnetic bioprinter was completed. On April 12 of the same year, it was presented at the "Biofacturing in space" symposium in Skolkovo.

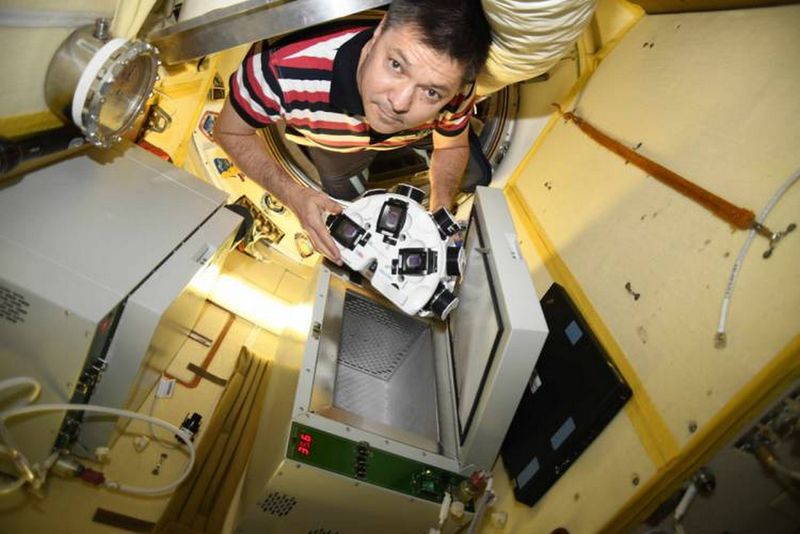

Source: 3D Bioprinting Solutions

In August 2017, an agreement was signed with RCS Energia to conduct a space biofabrication experiment on board the Russian segment of the ISS. During the following year, the printer named Organ.Aut was prepared to work in zero gravity. Members of the main and backup crews of the Soyuz MS-11 ship, Alexey Ovchinin and Oleg Kononenko, were successfully trained in the 3D Bioprinting Solutions laboratory. In December 2018, the “Magnetic Bioprinter” experiment was launched on the ISS. During this experiment the samples of the mouse thyroid gland, as well as human cartilage and bone tissue were printed.

Source: top3dshop.ru

In addition to this, the team conducted experiments on bovine muscle tissue 3D printing.

Yusef Khesuani, co-founder and managing partner of 3D Bioprinting Solutions

According to Yusef Khesuani, co-founder and managing partner of 3D Bioprinting Solutions, these experiments are "a stepping stone to sustainable production of cultured meat products during deep space expeditions and first colonies on the Moon and Mars." He also told about the use of 3D printing in medical research:

"In 2019, the so-called in situ bioprinting was carried out in Moscow - this is a method in which bioprinting is performed directly into a wound in the operating room. In this case, the process is controlled by a special robot manipulator that applies biological material to the injured surface according to a given digital model. This way, for example, it is possible to perform the replacement of skin defects in ulcerative lesions”.

In Russia, such an experiment was conducted on laboratory animals (more than 50 mice) for the first time and showed promising results.

In 2020, they plan to repeat this experiment on larger animals, for example, minipigs.

One of the most interesting applications of 3D printing in medicine is an opportunity to use bioprinting technology to replace the lost function of endocrine organs, such as the thyroid gland, pancreas, ovaries, etc. In 2015, we demonstrated the fundamental possibility of restoring the function of the lost thyroid gland after transplantation of a printed construct. In 2016, scientists from Chicago were able to restore ovarian function by transplanting a bioprinted ovarian construct containing mature follicles. However, it should be noted that these studies are still at the stage of preclinical testing and are being conducted exclusively on laboratory animals."

In 2019, 3D printing with biocompatible and live materials continued to develop. It can provide more and more prospects not only for medicine and related fields, but also, for example, for the food industry. For example, growing meat from individual cells eliminates the need to slaughter animals - a development of crucial importance, as it can help solve the food and ethical problems that humanity faces today.

The areas of application of bioprinters are not limited to transplantology, as well as medicine in general.

Research and development in the field of 3D bioprinting continues, and in 2020 we will definitely be presented with even more discoveries.

Here you can learn more about the Rokit Invivo 3D bioprinter and its applications.

Buy a 3D bioprinter in Top 3D Shop - buy original professional equipment with an official warranty and the best possible service.

Update your browser to view this website correctly. Update my browser now

Write a comment