3D printing is a vast and ever-expanding sphere, which is ready to welcome everyone with a touch of enthusiasm and a bit of spare money. While the industry becomes more and more diverse, new opportunities open up not only for large-scale producers, but also specialists in medicine, education, design, science, engineering. And with affordable technologies, even your hobby can now reach the next level. One of the perfect examples of 3D printing accessibility is personal and professional manufacture of desktop miniatures for popular table games, such as D&D, Warhammer 40K, etc.

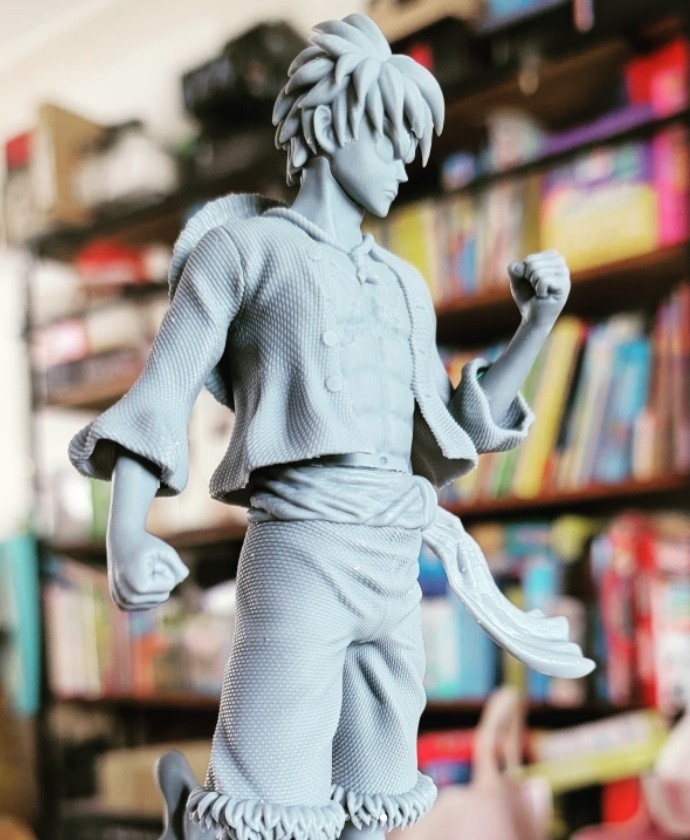

Credit: @inquisitornero / Instagram

This is Top 3D Shop, and today we are going to tell you about making miniatures for your favorite board games and more. Read on to find out about the best 3D printers for your future creations as well as their potential price tag and useful download sources.

Credit: @cyberforgeminiatures / Instagram

When searching for the best 3D printer for miniatures, one should consider between the two most common and cost-effective options, which are resin and FDM-based machines.

The choice greatly depends on your aims. First, note that materials for FDM printing are more affordable compared to photopolymer resins for devices based on stereolithography (SLA) technology. Apart from that, models printed with resins are more difficult to post-process. Still, the total accuracy, complex geometry, and surface finish quality is better in SLA. Other than that, FDM printers offer larger build volumes, which is important for making terrain and mass production of miniatures.

Overall, when choosing between these two types, it comes down to the following advice: FDM printers are best for beginners and large projects, while 3D printing experts prepared for complex operations and striving for highly detailed outputs might opt for a resin 3D printer.

SLA (Stereolithography), DLP (Digital Light Processing), and LCD (Liquid Crystal Display) are the main technologies used in resin 3D printers. Despite their similarity, there are some slight differences that should be considered when choosing a machine for certain purposes.

The SLA printing technology has come a long way and become a powerful means of production in various areas, including creative crafting. Classic 3D printers based on this technology utilize UV lasers focused on specific points to cure subsequent layers of resin. The light source is placed under the resin vat, while the print base goes up with the object being printed progressively.

Resin 3D printers in general can also be referred to as SLA 3D printers as they are all based on the principle of stereolithography.

Credit: @variedtechniques / Instagram

DLP is basically identical to SLA, the only difference being the use of a UV projector instead of lasers. This makes such printers faster than their predecessors: where the laser traces the surface of each layer, a DLP device prints a whole layer over the same time. DLP 3D printers usually provide highly precise and repeatable results since their light projection is more direct. Moreover, DLP machines serve longer compared to LCD ones.

In the case with the latter, the light projected by LEDs is masked with an LCD screen to get the desired shape for each layer (it is also called MSLA, or Masked Stereolithography). It’s the most common type of resin 3D printers with several minor subcategories. Generally, LCD printers benefit from softer edges, where with DLP peculiarities they are sometimes too sharp.

What matters most when we talk about printing desktop miniatures, is layer height. If it is too high, you will see separate ridges, which will definitely spoil the impression of the model. This is mostly the case with FDM printers: they require post-processing to smooth out the aforementioned ridges. As for resin 3D printers, individual layers are almost invisible.

With so many thoughtful devices available, it’s hard to choose the best for making high-quality tabletop miniatures. Let’s look through several top-notch devices for every aspirer to find a model according to their plans and needs.

The Phrozen Sonic XL 4K 2022 is a professional LCD/MSLA 3D printer. Due to a custom-made monochrome LCD screen with 4K resolution and a parallel UV LED matrix backlight system featuring uniform light exposure, it is able to produce highly detailed prints at top speed. Among other appealing qualities, the machine boasts a large build volume of 190 x 120 x 200 mm, reliable construction, outstanding accuracy of up to 10 microns, fast curing (0.2 seconds per layer), and open material system expanding your creative possibilities. Most importantly, the Sonic XL 4K 2022 is extremely easy to use, which makes it a perfect device for beginners.

Credit: @billonbass / Instagram

With a build area of 292 x 165 x 400 mm, the Flashforge Foto 13.3 LCD-based 3D printer is a tempting offer for mass producers and large format lovers. In addition to its decent print chamber, the device features high precision with a minimum layer height of 25 microns and 76 µm for XY resolution. It guarantees finely detailed models with satisfactory smooth surfaces. The reliable mechanism applying a dual-linear ball screw ensures stable printing and effective performance.

Credit: @Filaments.ca / Facebook

The Anycubic Photon S is an upgraded version of the Photon model introducing some hardware and software tweaks that enhance the precision and accessibility of the device. The Photon S is engineered with a Z-axis dual linear rail providing overall stability of the printing process, charcoal air filter for comfortable use, and improved UV LED system. In combination with a sufficient print area (115 x 65 x 165 mm) and user-friendly software, the machine is great for hobbyists and small-scale manufacturers of highly accurate miniatures.

Credit: @Popkusa สอน 3D / Facebook

Let’s now compare the listed models according to the important technical parameters:

|

Connectivity |

USB, microSD, Ethernet, Wi-Fi |

USB, Ethernet |

USB |

|

Display |

5" color touch screen |

4.5" color touchscreen |

2.8" touch screen |

|

Light source |

ParaLED 3.0 |

UV matrix LED |

UV-LCD (405nm) |

|

Manufacturer country |

Taiwan |

China |

China |

|

Outer dimensions |

290 x 330 x 470 mm |

380 x 380 x 685 mm |

230 x 200 x 400 mm |

|

Weight |

19.5 kg |

35.5 kg |

5.9 kg |

|

Print speed |

90 mm/h |

10–30 mm/h |

20 mm/h |

|

Slicing |

Phrozen 3D |

FlashDLPrint |

Photon Workshop |

|

Build volume |

190 x 120 x 200 mm |

292 x 165 x 400 mm |

115 x 65 x 165 mm |

|

Min. layer height |

10 microns |

25 microns |

10 microns |

|

Technology |

LCD |

LCD |

SLA |

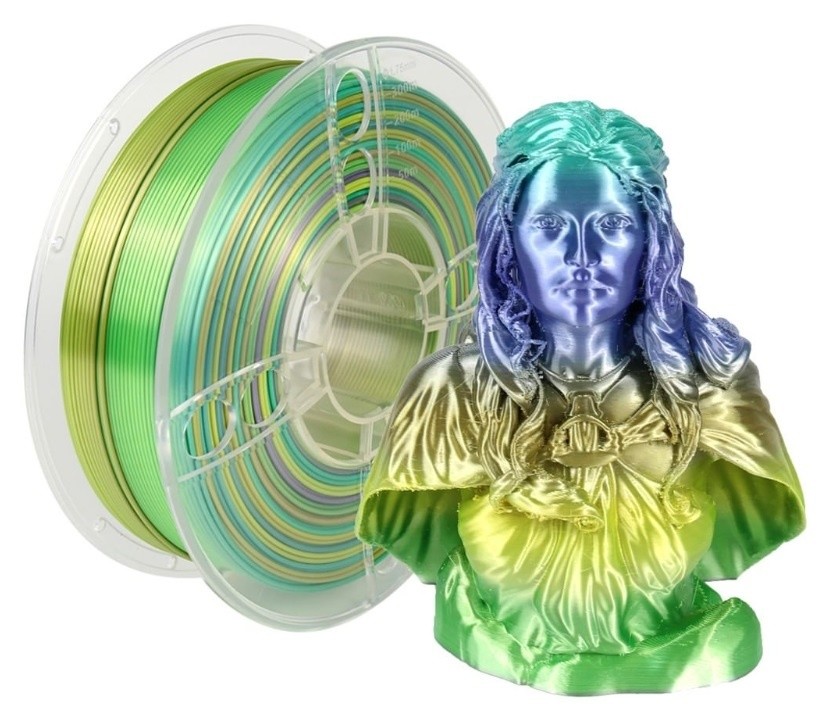

FFF/FDM printing has been available for quite a while, but in recent years it has become even more available. Due to its main advantages, such as scaling and material diversity (even inexpensive 3D printers now support a wide range of filaments), it is a perfect starting point for miniature makers.

Credit: @dicetaverngames / Instagram

With this technology, thermoplastic is heated to the melting temperature and then extruded through the nozzle. By moving the print head, the machine prints layer by layer of the given model.

The quality of FDM prints depends on multiple factors, including the filament type, nozzle size, minimum layer height, and the user’s skills. As a rule, the quality here is not as high as with resin printing, but where FDM loses in terms of detailing, it certainly leads in size and simplicity.

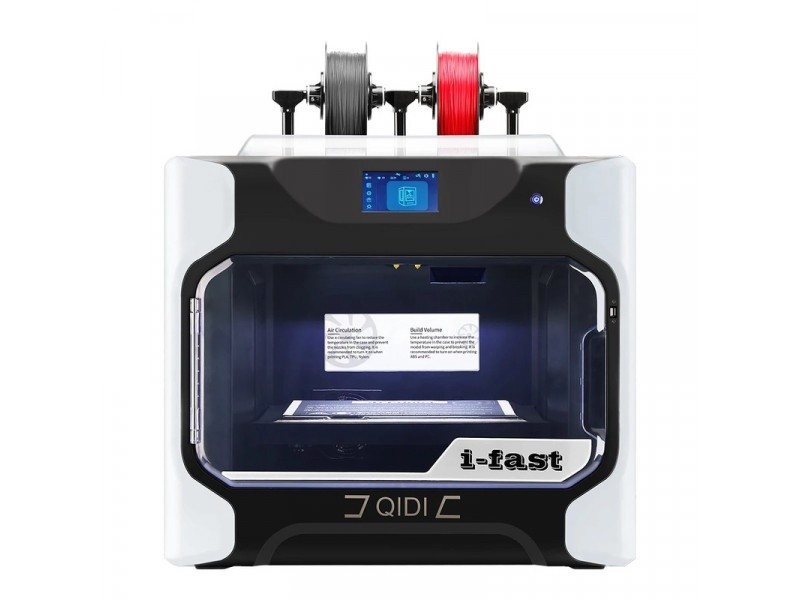

The QIDI Tech i-Fast lives up to its name by enabling rapid and hassle-free printing of remarkably accurate models. This industrial-grade FDM 3D printer is based on the dual extrusion technology, which lets you print soluble supports and multicolor models as well as two similar objects simultaneously. The build volume depends on the print mode: it’s 330 x 250 x 320 mm for two extruders and 360 x 250 x 320 mm for one. Thanks to the enclosed all-metal construction and heated chamber, the QIDI Tech i-Fast easily handles high-temperature materials. The advanced features like a direct drive extrusion system, detachable magnetic heat bed, wear-resistant ruby nozzle, and powerful thermal insulation provide smooth printing experience and reliable output.

Credit: @QIDI TECH / Facebook

For a personal 3D printer, the QIDI Tech X-MAX has quite a professional approach. This fully-enclosed device comes completely assembled and ready to work. The machine boasts two interchangeable extruders with multiple filament options: one set for high-stability PLA, ABS, TPU printing and one for high-performance PC, Nylon, and Carbon fiber. Add to that a robust structure, flexible removable print bed, silent operation, air purification, Wi-Fi connectivity, easy-to-use software, and regular upgrades — and you’ll get a reliable tool for any complex project.

Credit: @QIDI TECH / Facebook

The Raise3D E2 is an IDEX (Independent Dual Extrusion) 3D printer capable of printing in the mirror and duplication modes. Due to a heated flexible print bed, the machine is particularly great for multi-material projects. The large build volume of 330 x 240 x 240 mm (in the single extruder mode) allows printing objects of various sizes in whole. Being the first 3D printer with a dedicated video-assisted offset calibration system, the Raise3D E2 is a high-performance, user-friendly device for time- and cost-effective production at a professional level.

Credit: @robin3dverse / Instagram

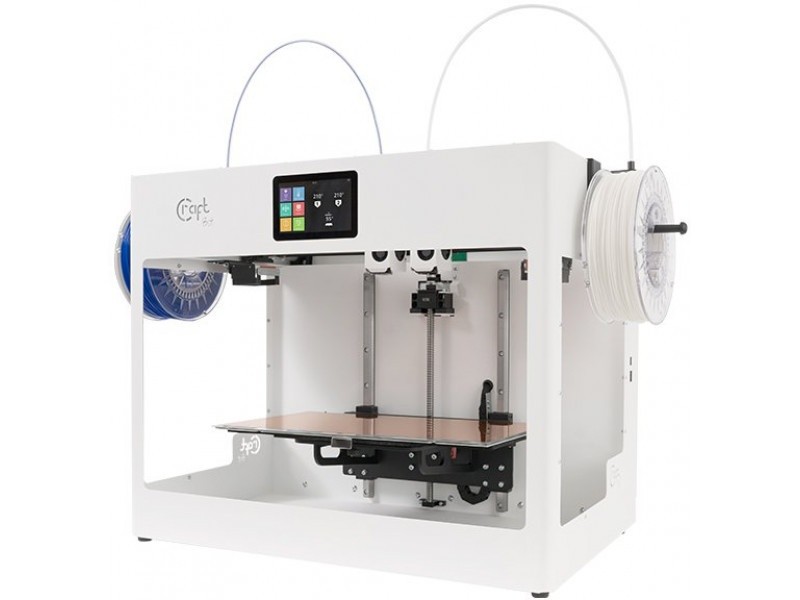

The CraftBot Flow from CraftUnique is an IDEX 3D printer of a new generation. Its reinforced steel construction provides extreme stability and reliability of the printing process. The all-metal hotends make extrusion really smooth, while a layered heated bed ensures optimum adhesion and easy print removal. Overall, the machine is quite beginner-friendly: with functions like pause and recovery throughout a session, filament runout sensor, and built-in camera as well as the function of print resuming after power outages, it is very convenient to handle regardless of the user’s experience and skills.

Credit: @fuse3d1 / Instagram

The table below shows the major differences between the mentioned devices in terms of their technical specifications:

|

Print chamber |

Enclosed, heated (up to 60 °C) |

Enclosed |

Enclosed |

Open (upgradable) |

|

Connectivity |

USB, Wi-Fi, SD card |

USB, Wi-Fi, LAN, SD card |

Wi-Fi, LAN, USB, Live camera |

USB, Wi-Fi |

|

Display |

3.5" touch screen |

5" color touch screen |

7" touch screen |

5" color LCD touch screen |

|

Extruder type |

Dual |

Single |

IDEX |

IDEX |

|

Manufacturer country |

China |

China |

USA |

Hungary |

|

Max. extruder temperature |

300 °C |

300 °C |

300 °C |

300 °C |

|

Max. heated bed temperature |

60 °C |

100 °C |

110 ºC |

110 °C |

|

Nozzle size |

0.4 mm |

0.4 mm |

0.4 mm (default), 0.2/ 0.6/ 0.8/ 1.0 mm (available) |

0.4 mm |

|

Outer dimensions |

710 x 510 x 670 mm |

737 x 660 x 610 mm |

607 x 596 x 465 mm |

635 x 450 x 540 mm |

|

Weight |

33 kg |

27.9 kg |

N/A |

35 kg |

|

Print speed |

150 mm/s |

60 mm/s |

30–150 mm/s |

200 mm/s |

|

Printable materials |

PLA, Nylon, TPU, PETG, ABS, PC, Wood, CF, and more |

ABS, PLA, TPU, Nylon, CF, PC |

PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Infused / Carbon Fiber / Infused / Metal Fill / Wood Fill |

PLA, ABS, PET, Nylon, Carbon-fiber reinforced composites, wood, brass, and more |

|

Software |

QidiPrint, Cura, Simplify3D |

QidiPrint, Cura, Simplify3D |

ideaMaker |

CraftWare |

|

Build volume |

360 x 320 x 250 mm |

300 x 250 x 300 mm |

Single extruder: 330 x 240 x 240 mm; dual extruder: 295 x 240 x 240 mm |

425 x 250 x 250 mm |

|

Min. layer height |

50 microns |

50 microns |

20 microns |

50 microns |

|

Technology |

FFF FDM |

FFF FDM |

FDM |

FFF FDM |

Not every machine will be great for making quality tabletop miniatures and detailed figurines, so mind that there are certain aspects defining a 3D printer as a perfect option or a no-go.

Precision and layer height: one of the natural requirements for desktop miniatures is their detail quality. To achieve this, look for a machine providing sufficient print accuracy and which is capable of delivering smooth surface finishes thanks to low layer heights.

Cooling: deformation is one of the most typical issues coming in the way of good models. Yet, it can be easily avoided with a decent cooling system. When the fan works evenly for each angle and layer of the print, you are sure to get a great result.

Print area: depends on your purpose. If you plan to mass produce miniatures in a quick and effective way, search for a corresponding build volume.

Stable construction: heavy metal frames are less susceptible to vibrations and other circumstances that might affect miniature quality.

So, you’ve found a fitting 3D printer, but technical parameters alone will not do the trick. Here are some recommendations on how to fine-tune the machine to get perfect miniatures of top quality.

Credit: @caphminipainting / Instagram

The printer’s precision depends directly on the size of the nozzle: the smaller it is, the more accurate models you get. Naturally, it also affects print speed, but miniatures don’t take much time all the same.

It’s totally advisable to slow down your printer when dealing with miniature models: that way, they will be more precise. Try 20–30 mm/s to see major differences.

This parameter essentially specifies the strength of your miniatures. In addition, it defines material costs. To save on the latter, set infill to 10%. Otherwise, try a higher option.

Optimal retraction settings help to avoid oozing and filament stringing, which is a general case with some printing materials, especially PLA.

Though it’s not a part of the printing process, focus on the final look of your miniature: paint it, sand, or polish its surface to get a nice result.

With a massive amount of 3D printers available on the market, those who want to make tabletop miniatures should first look at several crucial parameters to choose a right device depending upon their preferences.

Credit: @cobramode / Instagram

The most important aspect for miniature crafting is the printer’s ability to convey all the details. It is indicated by the following factors:

Nozzle diameter: ideally, it should not exceed the standard 0.4 mm to print fine details, and 0.2 mm is even better, so search for the models with interchangeable nozzles of two or more sizes.

XY precision: it is basically determined by the quality of the bearings, belts, motors, and frame. All-metal construction in combination with reliable kinematics provides a stable base for high accuracy.

Layer thickness: as we’ve already mentioned, the lower it is, the more detail your model will get. With FDM printers, the minimum layer thickness for miniatures should be well under 100 microns.

This part is very simple: with a large build chamber, you will be able to produce single massive models or a quantity of smaller miniatures. Thus, instead of 10 figurines, you can make 100 over the same time.

After all, 3D printing is generally quite slow, so the speed of the process can be compensated by a capacious device. Just keep in mind that a bigger build volume implies a larger weight and dimensions.

When you aim for precision, the quality of the 3D printer and its components is crucial. With a subpar framework and assembly, the device will likely give you some issues during the printing process, such as clogging, vibrations, skipping, etc. Naturally, this will result in poor print quality, especially in the case with desktop miniatures.

Here, only trusted and well-known brands with a lot of feedback should be given priority. Choosing the best 3D printer for minis is a long and demanding task of acquaintance with hundreds of tests and printouts. Luckily, we’ve already complied with it for you.

3D printing is all about potential: with the right machine, material, and settings, you can create almost anything within the capabilities of your device and imagination.

Credit: @talisman_miniatures / Instagram

Speaking of desktop miniatures, there are several categories of models you can print with some knowledge and preparation.

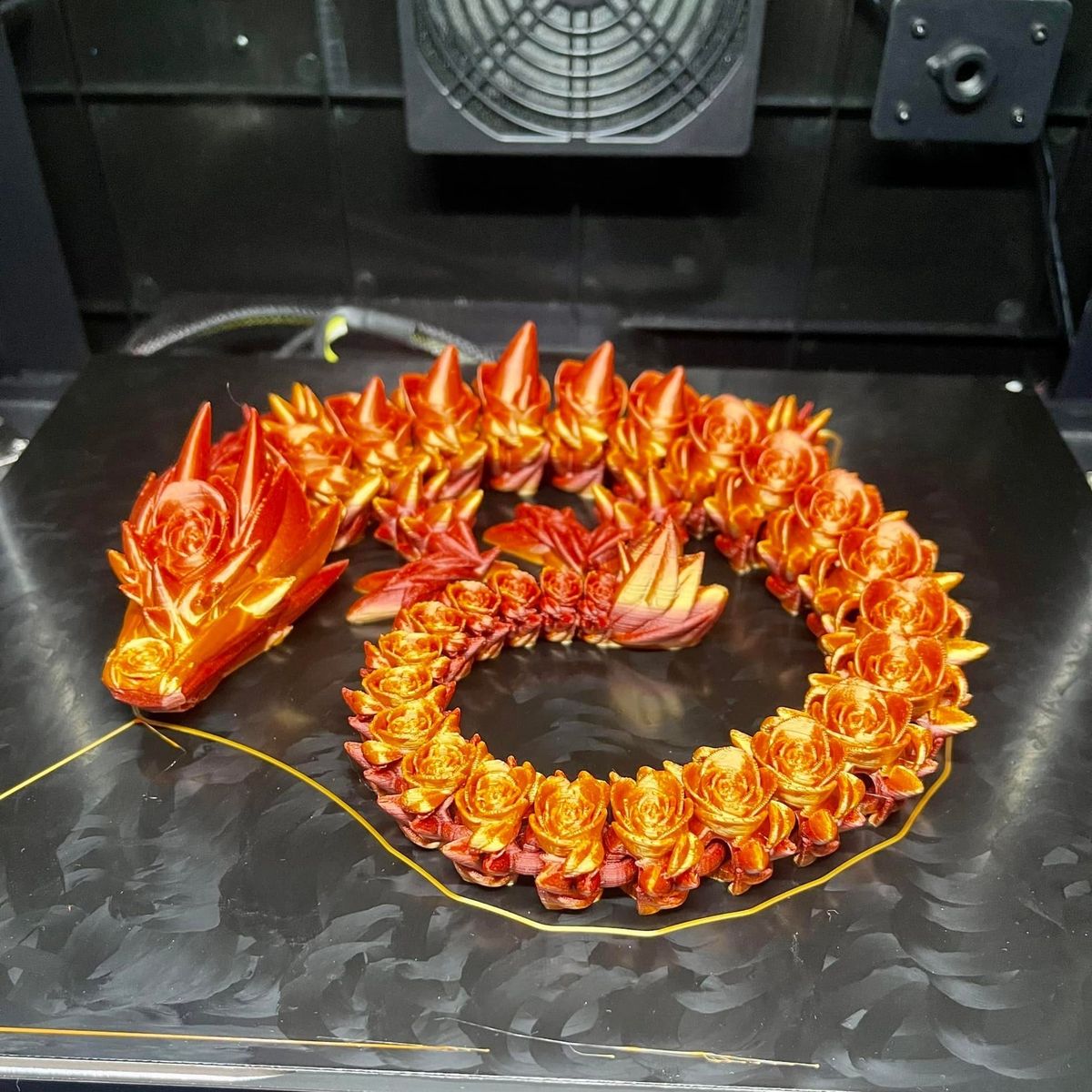

To make your game even better, you can print not only miniatures, but also terrain and small props for greater immersion and exciting pastime. A 3D printer is a perfect tool to diversify the story by adding more content to the game.

Credit: @radium.minis / Instagram

However, what’s best for minis is not necessarily good for terrains. While the level of detail might still be important, the size will definitely be the priority for this category. Thus, you will need an FDM 3D printer with a large build chamber. Not only will it provide a sufficient volume, but also simplify the printing process.

However, the size of the chamber is not the limit: you can always split a model into several parts, effectively arrange and bond them afterwards to get a highly detailed yet big enough terrain, building, prop, etc.

Credit: @blackforge_games / Instagram

For the majority of 3D printers, a 54 mm figurine is not a challenge. The size of a miniature is directly proportional to the number of details that can be added to make it more interesting and recognizable to players. Plus, turn to some post-processing to make your minis truly gorgeous. Some small features added by paint or sculpting might be a real highlight of your creation.

Investing in a resin 3D printer is also an option, since they boast higher precision and smooth surface finish. Nevertheless, larger models will require a lot of resin, which is more expensive compared to filament.

Credit: polygon.com

Making smaller miniatures between 28 and 54 mm is the hardest task for a 3D printer. First, make sure you have a machine with suitable capabilities stated above. If you don’t, small features will be all meld together in something indiscernible.

Small models won’t be a problem for a regular SLA printer with appropriate layer height and nozzle parameters. Although, it will take some patience and practice to achieve the best possible quality. The professional-grade FFF devices are also fit for such projects, but they come at a price and need additional treatment to clear some print lines for better appearance.

3D printers use model files of various formats that come from CAD software. With some skills in 3D modeling, you will be able to print your own designs through the export feature. It is also possible to scan a desired model with a 3D scanner and make a corresponding mesh for further printing. But what if you don’t have 3D CAD experience and additional devices or physical models at your disposal?

Fortunately, there are numerous online sources to get all types of files you might need to make minis with any convenient slicer at hand, from original editable CAD files to printable ones. Now, let’s see what the best of them are.

Credit: @dutchmogul / Thingiverse

Thingiverse — a community-fueled repository of 3D printable files, including optimized ones. There are plenty of D&D minis and a number of thematic fantasy sets.

MyMiniFactory — generally similar to the previous website with a free and premium versions. Moreover, it has a dedicated tabletop gaming section with a fine selection of figurines.

Cults3D — a great source of fantasy and anime designs. However, most files here are not free.

Pinshape — a free/premium source with a vast selection of minis related to popular franchises.

Youmagine — mostly similar to the sites described above.

Kickstarter — a crowdfunding platform, where you can support designers and get new models and whole sets instantly or after a while. Still, note that most of them are enthusiasts.

Patreon — a subscription-based source that mostly offers a welcome and monthly packs of models from the creators you decide to support.

You can also check out some popular tabletop mini designers to see what they have to offer. We recommend the following profiles:

Credit: @3dprintingminis / Instagram

Apart from the initial cost of purchasing a 3D printer, it is only necessary to pay for electricity and printable materials to keep making miniatures, props, and terrains to your heart’s content. Since the majority of modern devices are low-energy, all expenses are basically reduced to filament or resin price. Essentially, it comes to the volume of material used, and miniatures clearly are too small to take much. But let’s look at the numbers.

With an FDM 3D printer, it takes just a few grams of filament to print a single mini at a height of around 1 inch. A standard price for 1 kg of PLA or ABS is approximately $20, which amounts to 2.5 cents per gram or 20 cents per figurine.

Speaking of a regular SLA printer, a 1L bottle of resin is enough for at least a hundred of minis. On average, it costs around $50 per liter. If larger models might take 100+ ml of resin, smaller ones are far less expensive. Each miniature will cost you +-60 cents in most cases.

Credit: @gsun3d_official / Instagram

Since resins do not fall within the category, the best material for tabletop miniatures, props, and terrain is definitely PLA. Due to its lightness, low strength, versatile and common nature, this material is by far the most universal option both for beginners and professionals. Among other features, it is very easy to print with and supported by all ordinary FDM 3D printers.

Credit: @cyberforgeminiatures / Instagram

Regardless of one’s experience, everyone is sure to find an ideal 3D printer for making desktop miniatures according to their goals. The current market has plenty of options for users of all levels, while online sources are there to lend a hand in terms of ready-to-print models and valuable tips on technical matters.

After all, printing custom miniatures for D&D, Warhammer 40000, and other popular franchises is more economical than buying them. And of course, it is an incredible experience, which might become a good or even profitable hobby, not to mention more vivid impressions from your favorite board games.

Update your browser to view this website correctly. Update my browser now

Write a comment