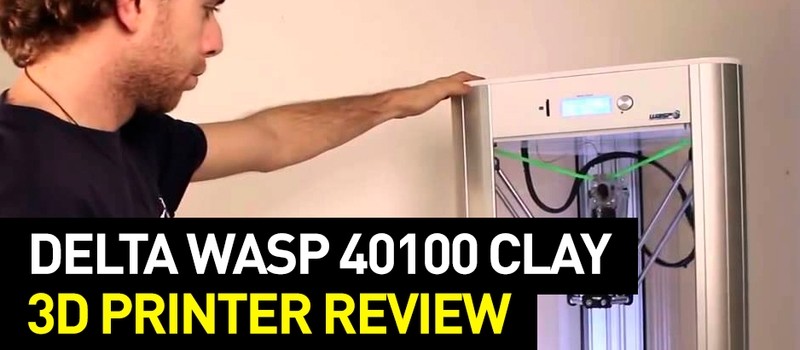

3D printers, with their ever-evolving functionality and opportunities they provide, are able to strike the most skeptical users. With the Delta WASP 40100 Clay, a top-notch 3D printer designed to work with ceramics, it’s just one of those times.

This is Top 3D Shop, and in this review we are going to tell you everything you want to know about the Delta WASP 40100 Clay, its main features and applications. In addition, we’ll discuss how to expand the possibilities of the printer with the optional LDM WASP Extruder XL 3.0. Read on to learn more.

WASP stands for World's Advanced Saving Project. The company was founded in 2012 by Massimo Moretti, an electronic technician with more than 20 years of experience in open-source product development. WASP is a bold experiment where science, economy, and politics are intertwined in order to add economic value to useful knowledge, reinforce social responsibility, and establish equal opportunities for everyone.

Credit: 3dwasp.com

The WASP team is going to invest the revenue obtained from the selling of 3D printing machines in projects that aim to spread advanced technologies all over the world and make them accessible to everyone.

"We're not so crazy to think we can save the world, but we're crazy enough to work for it”, — Massimo Moretti, the CEO of WASP.

Credit: 3dwasp.com

Credit: 3dwasp.com

In 2018, the company’s product line was replenished with a brand new model — Delta WASP 40100 Clay. The device creates objects using WASP’s proprietary technology called LDM (Liquid Deposition Modeling). One of its undeniable advantages is that the technology can be easily adapted for most 3D printers currently available on the market. WASP has always strived for developing optimal solutions for digital 3D printing systems that use ceramics (including polymeric and zirconium), clay, porcelain, and aluminum. After two years of research, WASP has finally created an outstanding extruder model with the ability to abort and restart the extrusion of such difficult materials in an extremely accurate way.

The material under pressure is delivered to the print head and then extruded with the help of a transport screw from a stepper motor. Since the printing bed doesn’t move, no vibrations occur during the printing process, and the piece is not subject to deformation.

Credit: 3dwasp.com

The Delta WASP 40100 Clay prints with various materials including porcelain, ceramics, refractory materials, clay, and many others. The print volume is impressive — Ø 400 mm × h 1000 mm. The accuracy of the finished parts is also great, while the layer height starts from 0.5 mm.

The WASP Clay is equipped with a 3 L (0.8 gal) tank which can be replaced with a 5 L (1 gal) one. The tank can be easily refilled or cleaned by opening two caps located on the top. Inside the container, the piston with two gaskets creates the pressure of 4 bar (58 psi) and pushes the material down the 12 mm (0.5 in.) teflon pipe. On the back of the tank, there is another cap with a safety valve set at 8 bar (116 psi).

Credit: 3dwasp.com

The device is made of aluminum and steel, ensuring stability and accuracy even when printing with exceptionally dense materials. The configuration provides the maximum printing speed of 150 mm/s. The standard nozzle diameters are 1.2 and 2 mm, which can be altered to 4, 6, and 8 mm with an optional LDM WASP Extruder XL 3.0.

The Delta WASP 40100 Clay boasts a handy feature — a recovery system called Resurrection. This function easily resumes the printing process if the device shuts down due to a sudden blackout, for example. The extrusion data is saved on the SD card in the "resurrection.g" file, which allows the user to resume printing once the printer is turned back on.

If the Resurrection system has failed, or you are not satisfied with the final result after resuming the printing process, there is the Free Zed function. It allows for the launch of printing from a certain height, specified in millimeters (along the Z-axis). After you’ve set the height, the printer is waiting, while the printing process is shown on the display, until the set height is reached — and the extruder resumes printing.

Credit: projects.fablabs.io

Unlike the previous model, the Delta WASP 2040 Clay, the Delta WASP 40100 Clay allows printing on a removable printing platform made from stainless steel, or even directly on the floor. Once the part is finished, you can continue printing without waiting for it to dry, simply by moving the printer from one platform to another, or by replacing the platform.

If the 5L (1.3 gal) material supply tank is topped up, the operation time of an hour and a half is guaranteed while printing with a 4 mm extruder.

Credit: 3dwasp.com

The printer is delivered fully assembled. The package includes:

Credit: 3dwasp.com

Since the printer is delivered fully assembled, you will not have to tinker with a preliminary setup. If you are planning to print on the original printing platform, you will need to run calibration before the first use. If you want to use a printing platform of another manufacturer, you will have to adjust the height along the Z-axis to match the thickness of the platform.

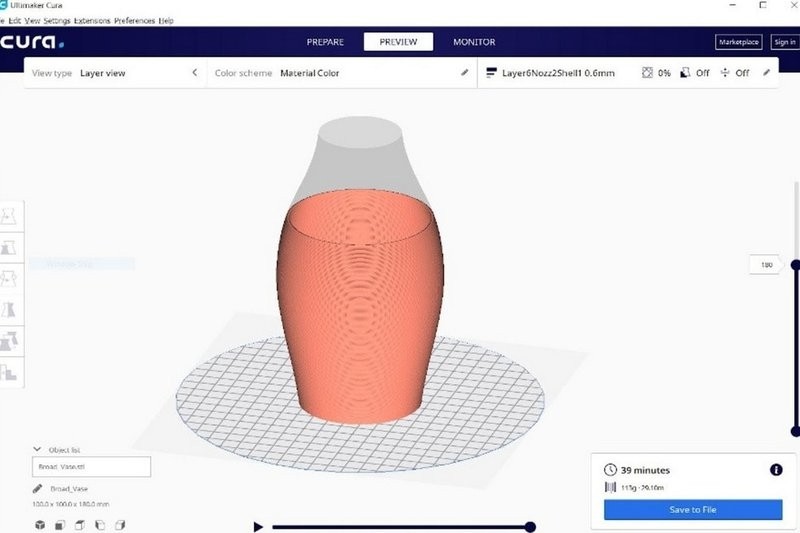

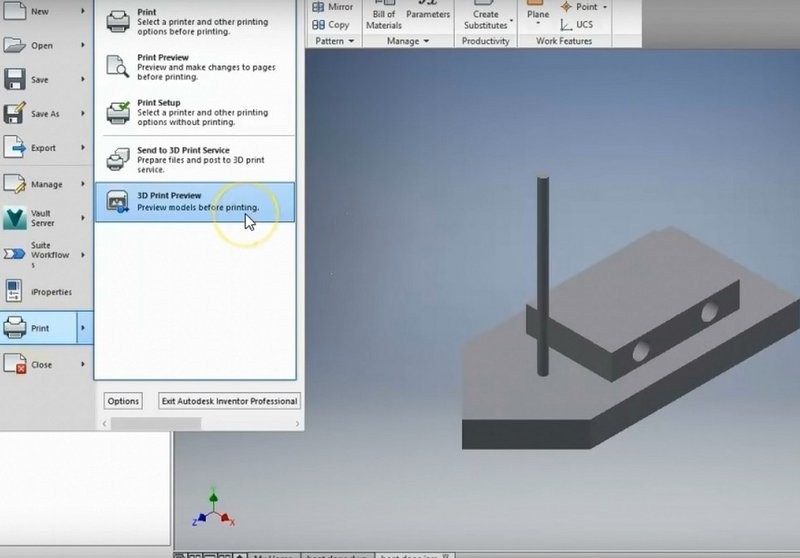

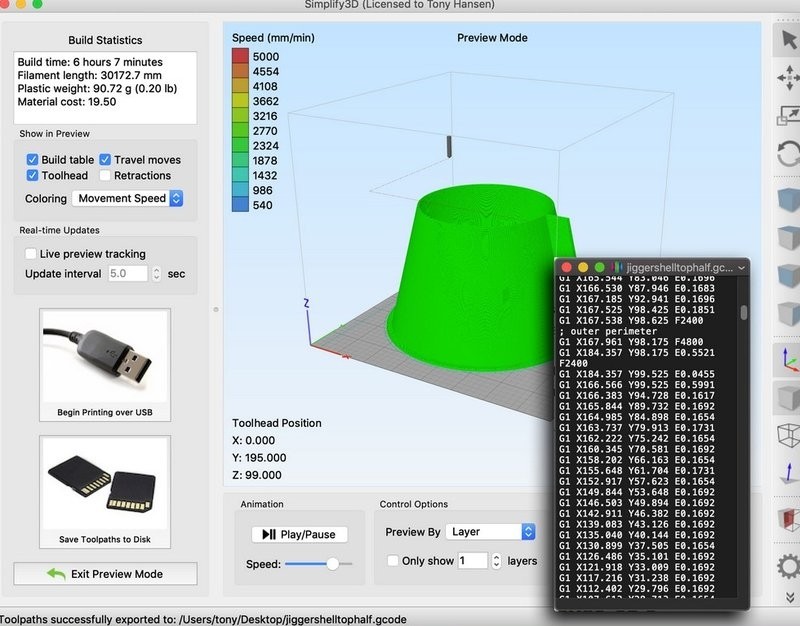

You can use any available slicers to work with the printer, including Cura, Slic3r, or Simplify3D. The printer supports .stl, .obj, .gcode file formats. You can use an SD card to import the finished g-code to the 3D printer's memory to reproduce a piece in standalone mode.

Credit: wikifactory.com

Cura is one of the most popular slicing software solutions for 3D printing. Even though it is currently owned by Ultimaker, the platform remains open-source and can be accessed with LGPLv3 license. This means that Cura is free to use, all the future updates included. The main advantage is that this software provides a lot of possibilities that help simulate and optimize the printing process. Cura is also known for its large community which creates and maintains a great number of useful plugins intended to improve and expand the program’s functionality.

Credit: youtu.be

Slic3r is another great software solution, also free to use. It features advanced configuration settings, an option for simultaneous printing on separate devices, infill optimization, and several options to preview the printing process. Slic3r is perfectly optimized, providing a fast and convenient workflow with almost any machine.

Credit: digitalfire.com

Simplify3D is popular 3D printing software that, among other advantages, transforms digital models into the instructions your printer understands best. The program features a two-week trial period, allowing for a full refund in case the product doesn’t meet your requirements. Simplify3D is compatible with almost any 3D printer, including rare models, features a user-friendly interface and manual optimization of support structures.

The optional LDM WASP Extruder XL 3.0 is the new extruder for fluid deposition modeling. It’s compatible with the Delta WASP 40100 Clay and allows for fast, precise, large prints. The construction of the extruder prevents air bubbles appearing in the mixture; the high torque motor allows working with hard doughs. Thanks to the new technopolymer extruder body, the cleaning procedure takes just a few seconds. The LDM WASP Extruder XL 3.0 comes with 3 stainless steel nozzles: 4, 6 and 8 mm in diameter.

Credit: 3dwasp.shop

Credit: thepoolnewyorkcity.com

Andrea Salvatori is a virtuoso of contemporary ceramic art. Representing Italian informalism and abstractionism, the master presented a number of various ikebana vases during his personal “Ikebana Rock'n'Roll” exhibition held in New York from April to May, 2019. Every piece of art was printed with the Delta WASP 40100 Clay.

Credit: 3dwasp.com

Andrea explains: “The search for balance between all the elements also passes through the container. There are numerous schools of Ikebana and each one opts for a particular arrangement. Some use tall vases and vertical lines, others use shallow containers. I decided to add digital technologies into the mix”.

Credit: 3dwasp.com

Salvatori created a number of asymmetrical masterpieces for the exhibition. The vases were encrusted with pink-colored spheres of various shades that represent musical notes, highlighting Eastern spirituality and the calmness of nature combined. In order to create compositions of astonishing beauty, the artist uses flowers, branches and other natural elements.

Credit: 3dwasp.com

Jonathan creates his masterpieces in his own workshop located in Suffolk, the UK. For some of the country colleges, he teaches the students to apply digital technologies in the field of art while giving profound lectures and consultations.

Credit: 3dwasp.com

Credit: empirica.aalto.fi

The School of Arts, Design and Architecture at Aalto University, Finland, held a two-day international workshop dedicated to collaborative learning of the ceramic 3D printing technique in February, 2019. The printing machine, Delta WASP 40100 Clay arrived only a couple of days before the beginning of the workshop, and was tested by the participants for the first time during the event.

Credit: empirica.aalto.fi

One can hardly find any crucial drawbacks to the Delta WASP 40100 Clay. There are, however, some general disadvantages of ceramic printing on the whole. These include:

The use of 3D printing in such a traditional craft as pottery opens up completely new opportunities for designers, allowing for the creation of very complex unique models and making the process faster. Clay 3D printers can be successfully applied in the field of pottery making, in art and statuary, and in architecture, helping create interior design elements and even construction parts, like walls or pillars.

The Delta WASP 40100 Clay was designed specifically for professional printing with ceramic materials, and the use of the optional LDM WASP Extruder XL 3.0 expands its opportunities even further. The machine is capable of making fairly large prints of extremely high quality, and it doesn’t take long. With this printer you can create objects that could never be made using traditional methods.

Update your browser to view this website correctly. Update my browser now

Write a comment