3D Printing with ceramic and fluid-dense materials such as clay has always been a challenge. Unlike polymers and plastics, it's harder to make well-detailed models with such materials, because of different temperature requirements and the fact that ceramic-based materials have to dry much quicker than their counterparts.But nowadays there are various possible ways to work with ceramics as a 3D printer hobbyist or organization. One of the solutions is offered by Italian manufacturer WASP and is a professional delta-type FDM 3D printer named Delta WASP 2040 Clay.

Source: 3dwasp.com

WASP is an Italian 3D printer manufacturer that was founded in 2012. The majority of the company's 3D printers are of the delta type and they are usually large in size. The company has gained its fame and respect by making large-sized 3D printers focused on building houses. But they have shown interest in ceramic 3D printing early on: in fact, the company’s first machine, the PowerWASP was able to work with the ceramic mixtures among other things. The WASP has also developed an LDM (Liquid Deposit Modeling) WASP Extruder.

The next step for the company was to develop extrusion-based 3D printers that are focused to work with clay right out of the box.

This is how the Delta WASP 2040 Clay 3D printer was born.

This professional FDM 3D printer is a high-quality machine that comes fully assembled. Minimalistic delta-styled design and relatively compact body combined with a decent-sized build volume make the device a good fit for those who don’t want their machines to have a big footprint. The machine is quite sturdily built, so the level of wobble is rather low. It can deliver unexpectedly smooth and high-precision outputs at a minimum layer height of 50 microns.

The feature set is pretty solid. It is a powerful workhorse that features sturdy build. Indeed, the device boasts its firm, almost unyielding structure made of all-metal sheets that ensures consistency during printing by eliminating any unwanted vibrations. Its reliable aluminum frame allows you to make parts with astonishingly smooth surface finish. The WASP 2040 CLAY offers a compact, stylish all-white design, making this clay 3D printer a perfect addition to any workshop or office.

The machine has a heated print bed made of wooden multi-layered material, a smart “Resurrection System'' that lets you effortlessly resume your printjob after a power outage. In addition, you can always stop the machine by pausing the printing process. The printing process can be resumed later at any time you want. Moreover, the printer is supplied in a fully assembled state and boasts an auto-leveling function that levels the build plate by itself, letting you proceed to the actual clay printing as soon as possible.

Since the WASP 2040 Clay is a Delta-style 3D printer, it offers quite a swift print speed of 150 mm/s. The machine comes with two interchangeable LDM WASP extruders of 2 mm and 1.2 mm — a proprietary and effective solution for working with ceramic-based materials, such as clay, porcelain, gres, earthenware and others. The extruder is equipped with a pressure chamber to provide increased quality of clay-based outputs. There is an air pipe connection system integrated into the machine which is a must for printing with dense materials. The air pressure eliminates air bubbles in the tank, ensuring smooth flow and preventing the nozzle from being clogged. Please be advised that in order to print with clay solutions you’ll have to use an air compressor.

The printer offers an open-frame design, providing easy access to the printed model and allowing the user to pause the printing and interact with an incompletely built object during the process. The user can then analyze and review the design and dwell on its flaws in case some problems appear. The WASP 2040 Clay offers the suspended Bowden system — a self-developed solution for Delta 3D printers that furtherly decreases the intertia onto hanging gantries, ensuring high-quality outputs and increasing the printing speed. The movement system has been reinforced by using nylon wheels on aluminum slides.

In addition, the WASP 2040 Clay offers “Free Zed System” — an integral solution that aims to take the print recovery function to the next level, allowing to continue the printjob even without resurrection data in case it’s been corrupted. The machine is highly accessible and can be controlled via a Wi-Fi module. For other advantages, the machine offers adjustable zero plays scroll, detachable heated bed, and a powerful 32-bit mainboard for optimal user experience.

The printer comes fully assembled in a large box with the contents including:

Source: youtube.com

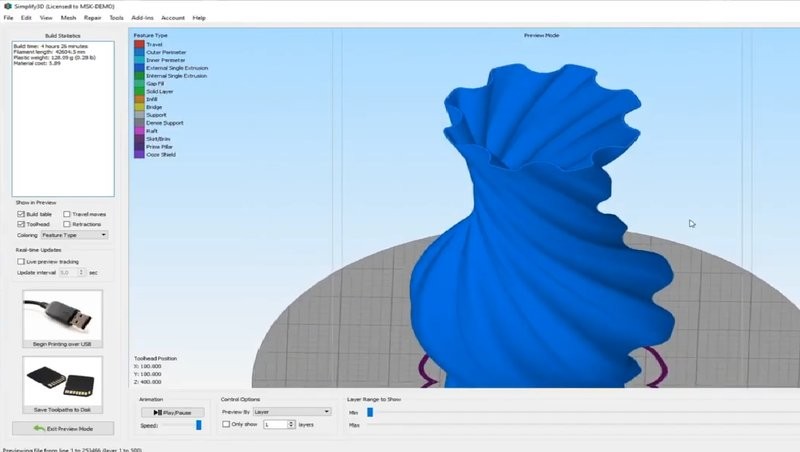

The printer doesn’t come with any pre-installed software, and the user is free to work with any slicing solution available on the market. Cura, Simplify3D, Repetier-Host, and Slic3r are recommended.

The WASP 2040 Clay is a highly accessible machine since it is equipped with a WiFi module for remote control. The machine is compatible with .STL, .OBJ, and .GCODE file formats. Aside from employing the WiFi connectivity, it can be controlled via a user-friendly built-in LCD screen with intuitive logic behind menu options, making the printer easy to control.

Below is the screenshot of Simplify3D used for slicing a model that will be printed on the WASP 2040 Clay.

Source: youtube.com

Below are some of the examples of the models printed using the WASP 2040 Clay.

Each model is unique and has a good surface finish.

As you can see the models can be decently-sized and large, thanks to the machine’s build volume.

Pros

Cons

Robust, affordable and able to work with a wide range of ceramics, the Delta WASP 2040 Clay is the great choice for anybody who wants to try their hand at printing ceramics without breaking the bank. The machine is made by a known manufacturer (although the brand’s reputation comes mostly from designing gigantic 3D printers for architectural purposes), and features and decent pack of technologies, including heatable bed, automatic calibration and print recovery. Such smart features make it easier to operate the machine.

Update your browser to view this website correctly. Update my browser now

Write a comment