In the following article, we would like to take a closer look at the WASP 4070 lineup of innovative delta printers for large-format tasks. Made by the Italian company WASP, the 4070 series includes several machines: the universal ZX model, the FX for working with flexible materials, and the HDP model for printing in plastic pellets. Below, you will find information on their main features and technical parameters of the series.

Starting with the name, the 4070 index in the considered WASP 3D printers lineup is a reference to the dimensions of the cylindrical build chamber with the base diameter of 40 cm and a height of 70 cm.

As for the WASP 4070 HDP delta printer, it is a completely unique machine designed for printing with plastic pellets in a convenient non-stop manner. It can handle a wide range of proprietary and third-party materials, including recycled ones, and boasts a vast number of handy automated features that will be covered further.

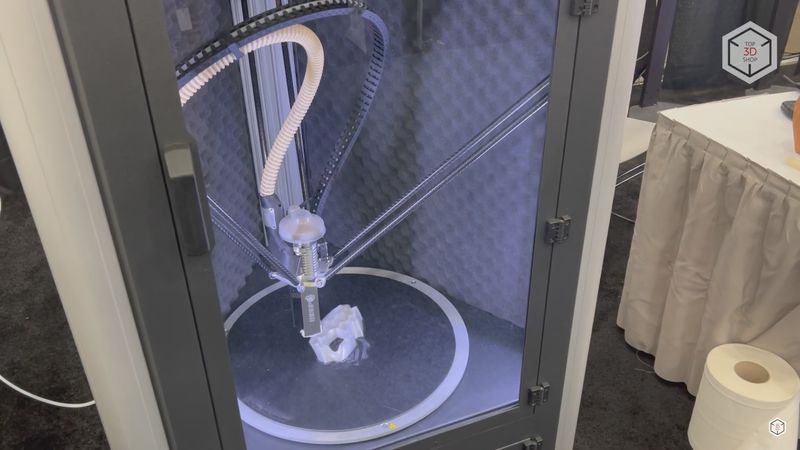

The WASP 4070 HDP 3D printer is equipped with a closed, thermally and acoustically insulated chamber with the maximum heating temperature of 50 °C. Due to these impressive dimensions, one can easily print large parts in one go without splitting the 3D model into several smaller parts, which significantly accelerates the production.

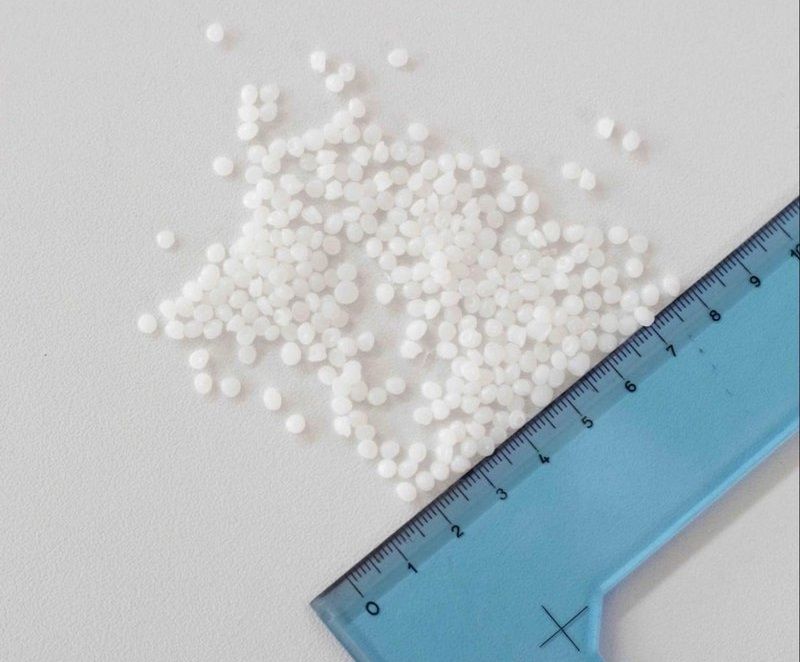

Interestingly, the WASP 4070 delta printer is based on a pneumatic system for continuous supply of the material and features a specially designed WASP HDP extruder. Plastic pellets are fed from a 5 L container, with the material consumption reaching up to 350 g per hour.

Due to the standard filament diameter support, the WASP 4070 HDP delta printer works with standard and technical thermoplastics, such as ABS, PLA, TPU, ASA, and more. In addition, the machine is ready to print with recycled plastic pellets. This solution allows for up to a tenfold consumables cost reduction, compared to conventional filaments.

Credit: 3dwasp.com

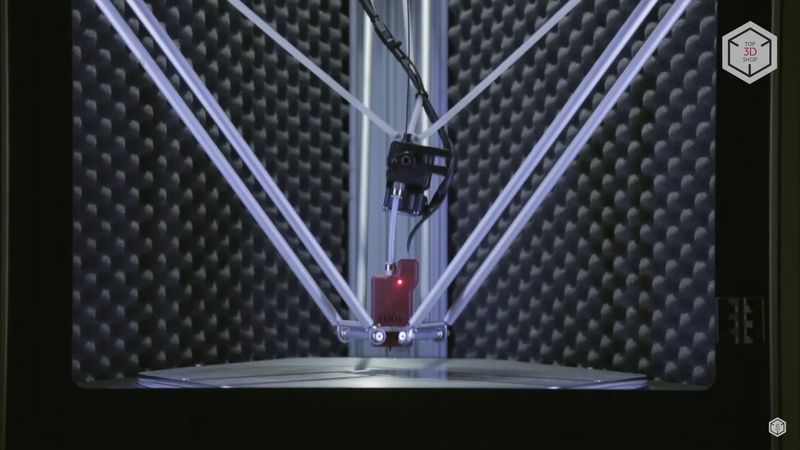

All 3D printers of the WASP 4070 lineup are designed with maximum stability and reliability in mind. Thus, the frame and the critical components of the construction are made of steel and metal alloys, ensuring high-quality and stable printing. Plus, the improved kinematics with powerful motor drivers and stepper motors guarantee precise and silent operation.

The machines are engineered with manifold advanced features that facilitate and greatly improve the whole printing process, among which are: automatic calibration system, material runout sensors, wireless modules, thermal and sound isolation, a power outage recovery system, HEPA filters, etc.

Moreover, the WASP delta printers come with a proprietary vacuum print bed changing system. This innovative solution allows the user to swap-out the printing platform in just a few seconds without additional calibration procedures, which makes for fast and seamless production.

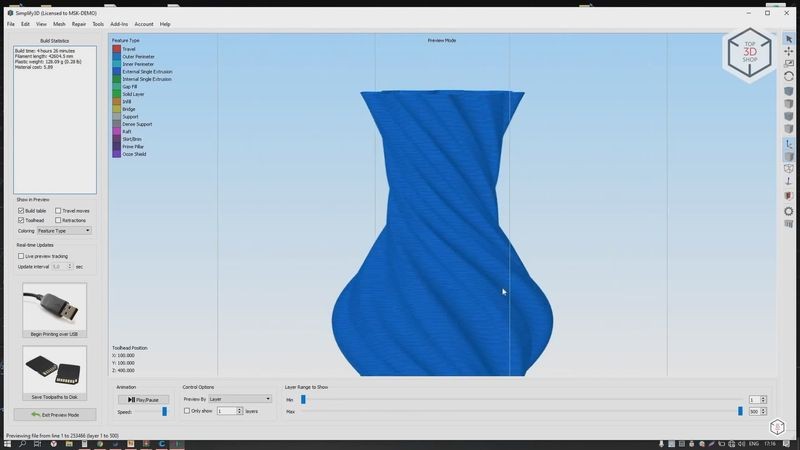

Another nice feature is that WASP does not limit the user in the choice of digital file processing software. Their machines are fully compatible with Cura, Slic3r, and Simplify3D, so you are free to use your favorite slicer with the desired set of functions.

The WASP delta printers are controlled through a convenient 7" LCD touch screen. Additionally, they are supplied with a built-in video camera for remote monitoring and timelapse of the printing process.

Sliced files can be safely transferred to the printer’s memory by means of a USB flash drive, Wi-Fi, or local area network.

The following items clearly demonstrate the 4070 printers’ enhanced capabilities in manifold applications:

All the mentioned properties, technical characteristics, and cutting-edge functions of the WASP 4070 delta printers allow us to conclude that the machines might serve as a perfect tool for industrial and creative use in workshops, design studios, educational centers, and other establishments aimed at reliable and cost-saving production.

Update your browser to view this website correctly. Update my browser now

Write a comment