Today, we will tell you everything there is to know about a Tel-Aviv-based, global manufacturer of professional large-format industrial 3D printers — Modix. As always, we will dwell upon the prominent features and application range of the equipment in question, as well as demonstrate some of the most noticeable use cases.

Modix was founded in 2014 by Shachar Gafni with the headquarters in Tel Aviv. Ever since its establishment, the company earned a reputation of an excellent manufacturer and continues to satisfy the customer needs in a top-notch manner. Even though being Israeli-based, the company’s main markets are North America and Europe.

The business started with the development of Agam — a small desktop 3D printer that is still being used by local educational institutions, service centers, and a number of individuals.

Modix Tango was the prototype of the company’s first large-scale printer and was presented in 2016, when the company rearranged the production to manufacture such sizable devices. The printer was equipped with independent dual extruders that could simultaneously operate on a printing bed as large as 400 x 400 x 400 mm. Unfortunately enough, the device has not been commercially launched. Nevertheless, it laid the foundation for BIG-60 and BIG-120 — the company’s current lineup that has now reached its fourth generation.

At present, Modix 3D printers are available in more than 40 countries all around the globe. The devices offered by the company are of great interest to start-ups and research centers due to their ability to accurately and reliably print large functional prototypes, end-use products, and top-quality spare parts in a cost-efficient manner.

Nowadays, Modix focuses solely on their ‘BIG’ series of affordable modular 3D printers that includes five models differing in terms of build volumes and various built-in functions. After several generations of innovation and improvement, the V4 machines introduce all sorts of advanced capabilities and neat modifications making the Modix devices even more precise, fast, reliable, and user-friendly than before.

Let’s take a look at the currently available models and their main features. In the comparative table below, you can see their basic technical characteristics:

| BIG-60 | BIG-120X | BIG-120Z | BIG-180X | BIG-Meter | |

| Accuracy | 4 x 10 x 0.5 micron | 10 x 10 x 0.5 micron | |||

| Build volume | 600 x 600 x 660 mm | 1200 x 600 x 640 mm | 600 x 600 x 1200 mm | 1800 x 600 x 600 mm | 1010 x 1010 x 1010 mm |

| Layer height | 40–800 microns | ||||

| Print speed | 250 mm/s | ||||

| Max. extruder temp | Up to 500 ℃ | ||||

| Connectivity | SD card, USB cable, Wi-Fi (optional) | ||||

| Display | 7" LCD touchscreen | ||||

| Enclosure | Optional | Included | |||

| Leveling | Fully automatic | ||||

| Material system | Open | ||||

| Outer dimensions | 906 x 1060 x 1356 mm | 1556 x 1060 x 1506 mm | 906 x 1060 x 1916 mm | 2630 x 1060 x 1573 mm | 1300 x 1470 x 1830 mm |

| Weight | 120 kg | 170 kg | 140 kg | 210 kg | 200 kg |

Modix BIG-60 V4 is an improved version of the previous model — Modix BIG-60 V3. Similar to its predecessor, the machine boasts a sturdy modular construction composed of T-slot aluminum profiles and a robust motion system. However, as the Generation 4 representative, the device is now easier and faster to assemble and features a number of handy upgrades in terms of hardware alongside fresh design tweaks.

The most distinctive features of the new version are its premium key components. Namely, the printer is equipped with a powerful electronic expansion board Duex 5 enabling fully automated calibration, stronger Nema-23 motors, optical end-stop switches for higher accuracy and repeatability, filament sensor, and optional Wi-Fi module for remote control. What has not changed is the printer’s large build area of 600 x 600 x 660 mm that lets the user print just about anything.

The machine is supplied unassembled, with a DIY kit and a thorough guide, including video materials and interactable 3D models. Like any Modix device, the BIG-60 V4 3D printer has been developed with future enhancements in mind, which means it is ready to support ongoing upgrades.

Modix BIG-120X V4 is essentially a supersized version of the BIG-60 model, featuring double the volume of its counterpart. In addition, it comes with all the enhanced components that make the latter a high-performance professional device, such as an upgraded Griffin printhead, Duex 5 expansion board, CNC machined brackets, and integrated emergency stop button ensuring immediate response.

Similar to other Modix devices, this modular 3D printer supports a wide range of add-ons for advanced operation, including a renovated enclosure for enhanced temperature control and stability, high-precision HIWIN linear rails, magnetic print bed, IDEX, etc.

Due to its size, the Modix BIG-120X V4 is expected to be used by experienced makers. With the right set of parts and skills, you can get similar results as with a pre-assembled, industrial-level machine but at a much better price.

In essence, the Modix BIG-120Z shares many similarities with the BIG-120X model. The main difference between these two machines is the orientation of their build chambers. Targeted to the professional market, the BIG-120Z stands out for its capability of printing super-tall objects in one piece.

Available as a DIY kit, boasting the massive build volume of 600 x 600 x 1200 mm, and offering features meant to accommodate for the printer’s size, the BIG-120Z is a durable device producing high-quality large-scale prints with impressive speed and detail.

The printer of the fourth generation is equipped with all the recent upgrades and premium parts, including HIWIN rails as default, built-in clog detector that can effectively indicate under-extrusion and filament run-outs, enclosure composed of aluminum composite panels for better heat and noise insulation, upgraded optical end-stop switches, and more.

As one of the tallest models, the BIG-120Z is also supplied with a handy tilt screen ensuring easier access to information and commands, frontal secondary power switch for convenient operation in tight spaces, and additional reset button.

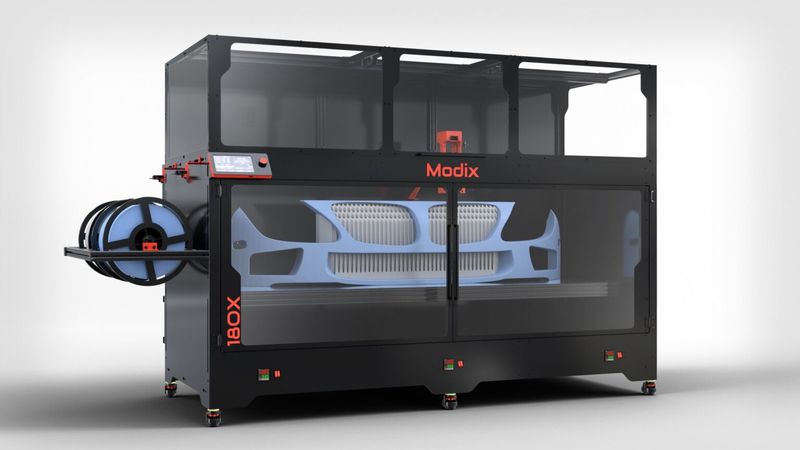

Being one of the latest additions to the company’s ‘BIG’ series, the BIG-180X expands the user’s printing capabilities even more. Aside from an outstanding build volume reaching 1800 x 600 x 600 mm, the machine offers a handful of useful features enhanced with the Generation 4 total upgrade.

In contrast to the lesser models from the series, the BIG-180X is equipped with HIWIN motion rails, enclosure, and casters by default.

The Modix BIG-180X comes stock with a 0.4 mm nozzle, giving you the best balance between speed and detail. It is compatible with nozzles of different sizes, allowing you to choose the best option for a particular application. The printer can also be equipped with the IDEX add-on for multi-material printing of complex internal geometries.

Among other practical expansions is a magnetic bed, Super Volcano heat-block, three-phase air filter, and improved control set consisting of a secondary tilt screen, emergency button, and frontal power switch.

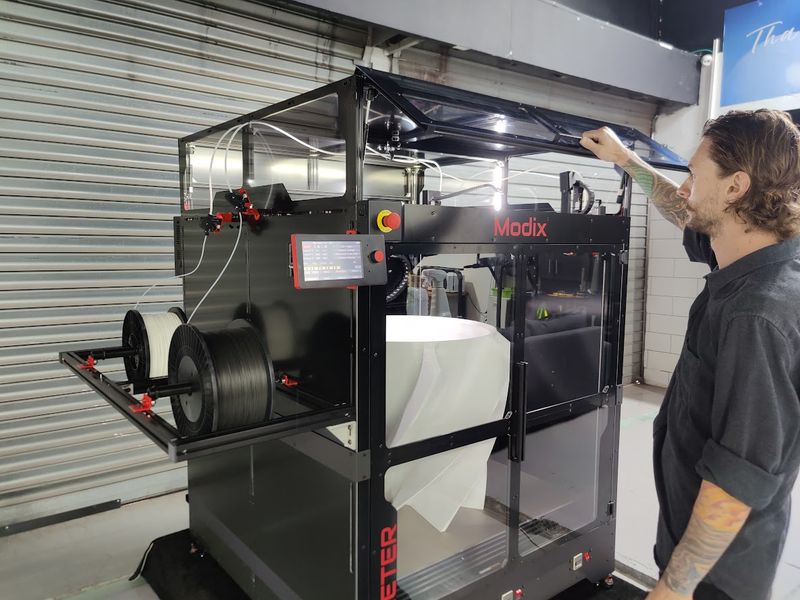

Modix BIG-Meter is undoubtedly one of the most ambitious devices in the world of large-format 3D printing. Thanks to an exceptional build volume of 1010 x 1010 x 1010 mm and handy modular construction, it is great for efficient batch production of small-to-medium items. Additionally, it can produce large models without dividing them into several parts, which makes for their strength and saves time on post-processing.

Naturally, with such a large build volume combined with outstanding print quality, the BIG-Meter model can be used for a broadened range of professional applications, including production of enclosures and casings for other 3D printers.

As with the afore-mentioned models, the BIG-Meter offers a handful of useful features and top-quality components enhanced with the recent V4 upgrade. Apart from the improved control set, default HIWIN rails, enclosure, and casters, the printer is equipped with all the latest Modix innovations that will be additionally covered further on.

Modix continues to innovate and redesign its 3D printers to revolutionize the world of large-scale 3D printing and provide a growing value to its customers.

During Formnext 2022, an annual exhibition of additive manufacturing technologies, the company presented the fourth generation of their flagship ‘BIG’ series of 3D printers. Here is a short list of changes introduced by Modix:

To find out more, check out the video below:

It can be expected that Modix will further expand 3D printing capabilities of their devices and even develop the proprietary line of filament to provide top-quality experience for the company’s customers using the new IDEX add-on.

Given all the introduced and improved parameters, Modix BIG 3D printers are ideal for a wide spectrum of professional applications, including prototyping, batch production of automotive and other technical parts, product development, research, restoration, sculpting, film-making, advertising, fashion, design, and more.

Here are just some examples of use published on the Modix official website by the company’s customers.

The part in the photo was printed with Modix BIG-180X by Illumaesthetic — a leading developer and service provider in the automotive after-market industry (California, USA). For their creative projects involving some of the most unique and innovative parts, the company uses multiple Modix machines, but an item this big can be printed in one piece only with the mentioned model.

Titan International is a US-based company that also owns Titan and Goodyear Farm Tire brands. The company specializes in the manufacturing of wheels, tires, and undercarriage products for a wide range of agricultural and off-the-road vehicles.

Zach Pope, the tire design engineer for Titan International Inc, commented upon the Modix BIG-60’s performance:

“The printer has been doing well. We have at least 72+ days of print time on our machine and it’s still doing great. We’ve printed with PLA 100% of the time and only yesterday successfully printed a grommet for the factory using some flexible TPU filament.”

When it comes to bronze sculpting proficiency, a Turkey-based company Efes Bronze stands out as one of the undeniable leaders, with their art pieces presented in a number of countries all around the globe. Efes employs the large build volume provided by Modix BIG-60 in order to create large-scale models. The models are then used to create the sculptures: they are covered with plaster, burned, and then the metal is cast inside.

Serdar Eraol, the head of Efes Bronze elaborated on the process specifics: “We print with PLA and use PrintinZ bed sticker instead of PEI. The bed temperature is 55c. The print layer is 0.3mm in the base, body parts 0.2mm, and face 0.1mm. We use 0.4mm nozzle and 7-8% infill. After 100-150 layers we change infill to 2-3% only. Some parts are 3 perimeters and some just 2.”

A + A Schoenmakers is a Dutch company that uses 3D printers offered by Modix in order to manufacture 10 mm-wide shoe lasts. In addition, they print variously sized prototypes and different jigs for their machines.

A Reddit user Pedro shared some of the outstanding results of his experience with Modix BIG-60 3D printer, and gave a quick review about the device:

“The printer is pretty much awesome all around. The automatic bed leveling works like a charm!… The instructions are pretty good.”

If you find yourself in need to manufacture a number of large-scale parts, we wholeheartedly advise taking a closer look at the devices offered by Modix. With such characteristics and a wide spectrum of applications, these modular 3D printers tend to be one of the most optimal solutions for the production of large objects. The machines apparently become more powerful with each generation and yet remain accessible to a wide range of users within various industries.

Update your browser to view this website correctly. Update my browser now

Write a comment