3D printers are complex machines, with all the parts having to work coherently to provide high-quality results. So, precise adjustment of the distance between the print nozzle and the build plate is extremely important, unless you want your prints to be ruined by poor first layer adhesion.

This is Top 3D Shop, and in this article, we will touch upon the feature of automatic bed leveling, as well as look at some of the best 3D printers offering this function.

Manual print bed leveling can be pretty tiresome and time-consuming, especially for those who are new to 3D printing. Besides, the process should be repeated after a few prints, as the bed’s position can slightly change. Fortunately, a lot of 3D printers today, including entry-level consumer models, come with an automated bed leveling function that makes the process easy and quick.

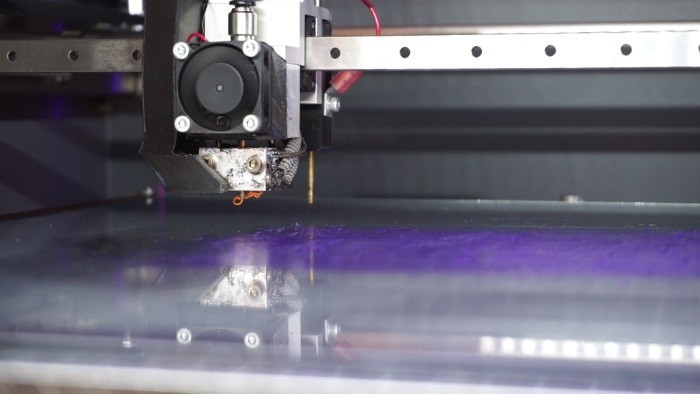

The auto bed leveling function implies using a built-in proximity sensor near the tip of the nozzle. When activated, the sensor measures the distance between the nozzle and the print bed at several points on the print bed. Based on these calculations, the firmware adjusts the position of the print head right on the go, to keep the even distance between the nozzle and the bed over the entire build area during printing.

If you want to learn more about this function, read our Auto Bed Leveling Guide.

In short — yes, auto bed leveling is worth its money, as it saves a lot of time, and allows the user to avoid print failures caused by a poorly leveled print bed.

Credit: instructables.com

On the other hand, if you are an experienced user, and you don’t mind spending time on manual bed leveling (and know pretty well how to do it properly), you can, probably, do without this useful feature.

If you are new to 3D printing, the auto bed leveling function will help you avoid such troubles, as poor first layer adhesion, nozzle clogging caused by too close position of the nozzle to the print bed, or scratching the print bed.

If your 3D printer is not equipped with this function, you can upgrade it with an optional auto bed leveling (ABL) sensor available in the market.

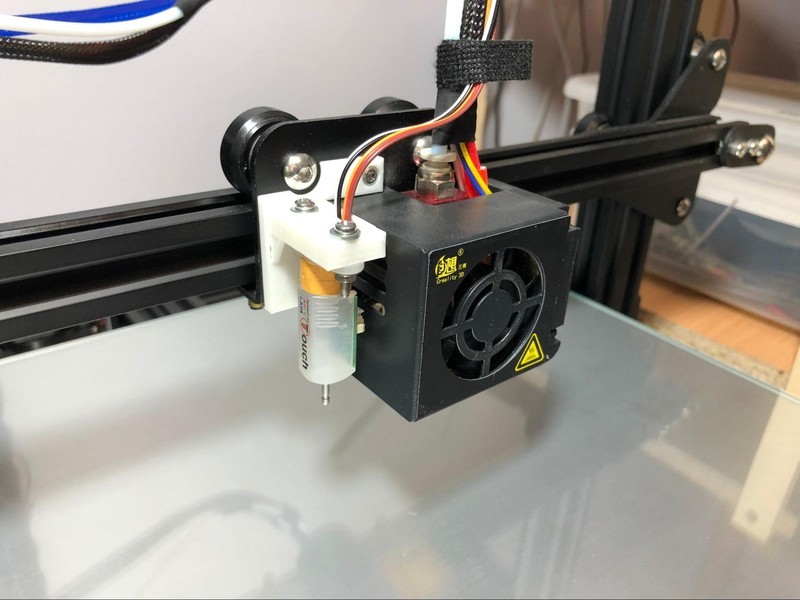

There are various types of ABL sensors, the BLTouch being the most popular. It’s a mechanical sensor, consisting of a microcontroller, a Hall sensor, a magnetic switch, and a pin probe used for measuring the distance between the nozzle and the print bed. Since the sensor uses physical contact for calculating the distance, there are no restrictions for the print bed material. You are free to use the BLTouch sensor with glass, metal, or any other print bed type. The sensor is mounted near the nozzle tip and connected to the motherboard. When the pin touches the print surface, it immediately retracts, causing changes in the electromagnetic field and triggering the magnetic switch. In such a way the sensor checks several points on the print bed, and its position is calculated from the values obtained. It’s important that your print bed is absolutely clean when using BLTouch, as any material residues, for example, may lead to inaccurate calculations.

The BLTouch sensor can be used with most of the 3D printers in the market, but it is recommended to check your printer compatibility just to make sure.

The Artillery Genius Pro is a compact FDM 3D printer featuring the build volume of 220 x 220 x 250 mm and the Titan direct drive extruder with a 0.4 mm Volcano nozzle, that enables uniform filament extrusion and provides decent print quality with the minimum layer height of 100 microns. The extruder of the Genius Pro, unlike the original Genius model, is equipped with a touch sensor enabling the auto bed leveling function. The maximum nozzle temperature is 240 °C. The print bed, made of tempered glass, can heat up to 120 °C in 3 minutes. The printer is compatible with PLA, ABS, wood composites, PVA, HIPS, and flexible materials. The filament runout sensor and the resume printing function prevent possible print failures. The Genius Pro is compatible with Cura, Simplify3D, and Slic3r software and is operated via a 2.8" color touchscreen. The device comes as a kit, requiring self-assembly.

Credit: reddit.com

The Ender-3 S1 Pro is a compact FDM 3D printer capable of working with high-temp materials, like Nylon and Polycarbonate, alongside other popular filaments, such as PLA, ABS, wood composites, TPU, and PETG. The full-metal dual-gear direct extruder is equipped with a brass nozzle that can reach the temperature of 300 °C. The PEI-coated flexible magnetic build plate, made of spring steel, ensures proper first layer adhesion and easy removal of the printed part. The printer has a build volume of 220 x 220 x 270 mm and provides the minimum layer height of 50 microns, which is good for an entry-level FDM machine. The auto bed leveling function uses CR Touch probe to measure 16 points on the print bed and adjust the print head. The machine also features the filament runout sensor and resume printing function.

Credit: thetechnologyman.com

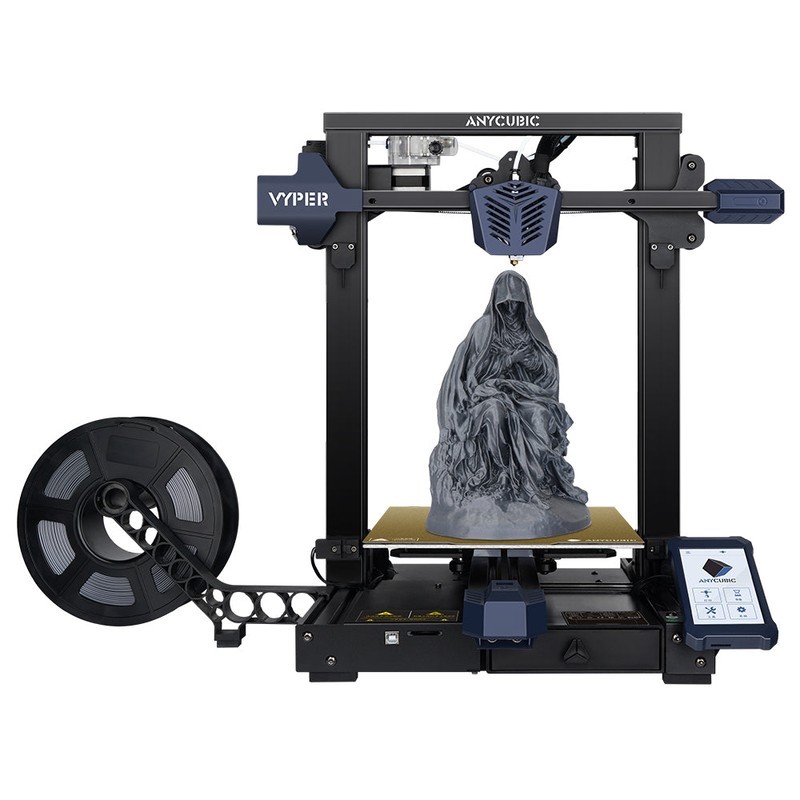

The Anycubic Vyper is another entry-level FDM printer that comes semi-assembled and features a modular design, allowing for easy upgrades. Like all the models in our list, the Vyper sports the auto bed leveling system, which uses a pressure sensor, activated when the nozzle hits the print bed, providing 16-points precise bed leveling. The build volume of 245 x 245 x 260 mm is quite decent for a compact desktop device. The printer is equipped with a dual-gear extrusion system with two cooling fans that allow printing with PLA-like materials. The maximum nozzle temperature is 260 °C. The heated spring steel magnetic build plate with a scratch-resistant coating ensures good adhesion and easy removal of the prints. The Anycubic Vyper is operated via a 4.3" touchscreen; the recommended software is Cura slicer.

Credit: 3dprintingmedia.network

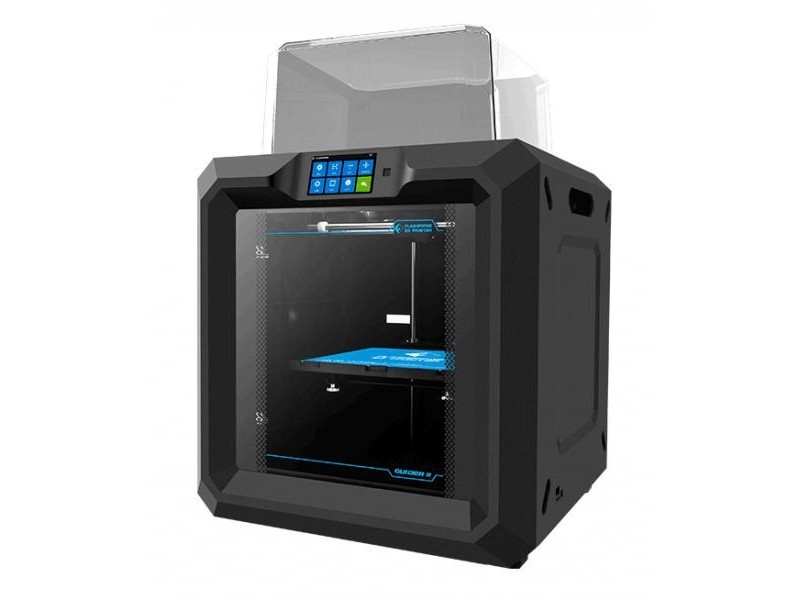

The FlashForge Guider 2 is an FDM 3D printer featuring professional-grade quality, yet affordable price. The Guider 2 has the auto bed leveling function but, unlike the other printers in this article, it’s an assisted automatic process. That means the printer gives the user instructions during the calibration process, rather than automatically adjusts the position of the print head while printing. A removable heated print bed and an enclosed build chamber allow printing with ABS-like filaments. The device features a spacious build volume of 280 x 250 x 300 mm. The filament runout sensor and resume printing function stand for the reliability of the printing process. The printer comes with the FlashPrint proprietary slicer.

Credit: @matisboerodisign / instagram

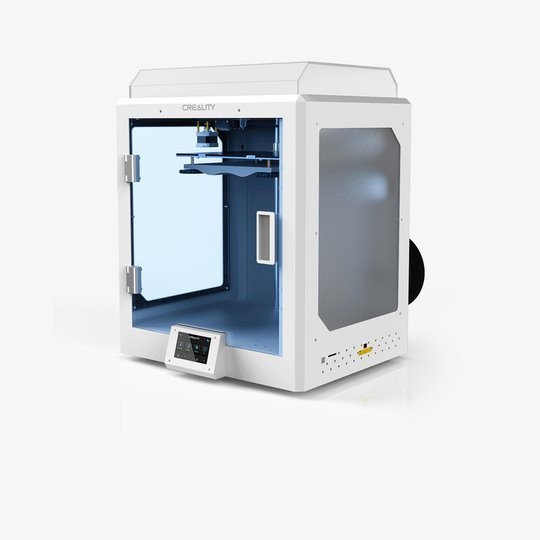

Due to the maximum nozzle temperature of 300 °C and the fully-enclosed build chamber, the Creality CR-5 Pro High-Temp version can print with high-temperature materials, like PLA, TPU, ABS, and others. The carbon glass-coated print bed can heat up to 110 °C and features a BLTouch auto leveling function. The build chamber dimensions of 300 x 225 x 380 mm allow printing large models or multiple smaller parts at a time. Consistent failure-proof printing is provided by the filament runout sensor, resume printing function, and cloud printing support. The CR-5 Pro HT can be operated via a 4.3" touchscreen, or remotely with the Creality Cloud application.

Credit: @Just Vlad / youtube

The Raise3D E2 is a professional FDM 3D printer, boasting a great number of advanced functions that stand for industrial-grade quality and consistency of the printing process. The device is equipped with the IDEX dual extrusion system with two independent extruders, that allow printing the same model in mirror or duplication mode, or printing dual color or dual material parts. The maximum nozzle temperature of 300 °C gives the possibility to print with a great number of filaments, like PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG, ASA, PP, PVA, carbon and glass-filled, and others.The standard 0.4 mm nozzle can be replaced with optional 0.2–1.0 mm nozzles, if needed. The printer sports an automatic multi-zone bed leveling system with a BLTouch sensor. Other smart features include a built-in camera and a filament runout sensor.

Credit: @3deltaworkshop / Instagram

The Raise3D Pro 3 professional FDM 3D printer features a sizable build volume of 300 x 300 x 300 mm. The bed auto leveling function ensures a perfectly even print area which improves the first layer adhesion, and the flexible steel build plate makes for the convenient removal of the printed parts. The Pro 3 is a dual extrusion system with two independent extruders and interchangeable nozzles with available diameters of 0.2–1.0 mm. The printer is an open-material system, allowing for the use of third-party materials alongside the proprietary filaments. A set of smart features, like built-in camera and door opening detection, provide a smooth printing experience.

Credit: @okada_ss / Instagram

The Fusion3 EDGE is a fast professional FDM 3D printer with a large build volume of 368 x 368 x 343 mm and the minimum layer height of 20 microns. Due to the proprietary ANVIL print head with the maximum temperature of 320 °C, and wear-resistant surgical steel print tubes, the EDGE can print with high-temp and abrasive materials. The printer is equipped with a 1/4" aluminum print bed with standard glass surface and can be upgraded with an optional magnetic build plate. The flat surface combined with the mesh probe bed leveling system ensure perfect first layer adhesion. The multi-zone print bed can heat up to 145 °C, and the temperature in the passively heated build chamber reaches 70 °C.

The Modix Big 60 V3 is an affordable large-format FDM 3D printer. Like all the Modix printers, the Big 60 V3 comes as an assembly kit and features modular design allowing for easy upgrades. The V3 version is based on the previous Big 60 V2 model; the improvements include a 10% larger build volume of 600 x 600 x 660 mm and the new Duet 2 powerful controller unit, which offers a lot of enhancements, like Wi-Fi connectivity, remote control option, or dual extrusion support on the main board (and up to five more extruders on the optional expansion board). The automatic bed leveling function, using BLTouch probe with 100 points probing mesh, is activated before each print. The machine is capable of working with high-temp materials, and can print at 40-micron minimum layer height, providing industrial-grade print quality and consistency.

Credit: @hwangjoonha_ / Instagram

The Modix Big 120X V3 is another large FDM printer from the BIG family, featuring an impressive build volume of 1,200 x 600 x 640 mm, which allows you to print parts of almost any size. The machine is a self-assembly kit with the same open modular structure, as the other Modix Big printers. The enclosure comes as an option and should be bought separately. The Big 120X V3 is equipped with the new Griffin print head with the maximum hotend temperature of 285 °C, which can be further converted to 500 °C. The aluminum heated build plate features auto leveling function with the 200-point probing mesh. Modix offers a variety of components you can buy in addition to the basic package, like DUEX expansion board, E3D V6 and Super Volcano hotends, a magnetic print bed, and more.

Credit: @rebeca_gi_sa / Instagram

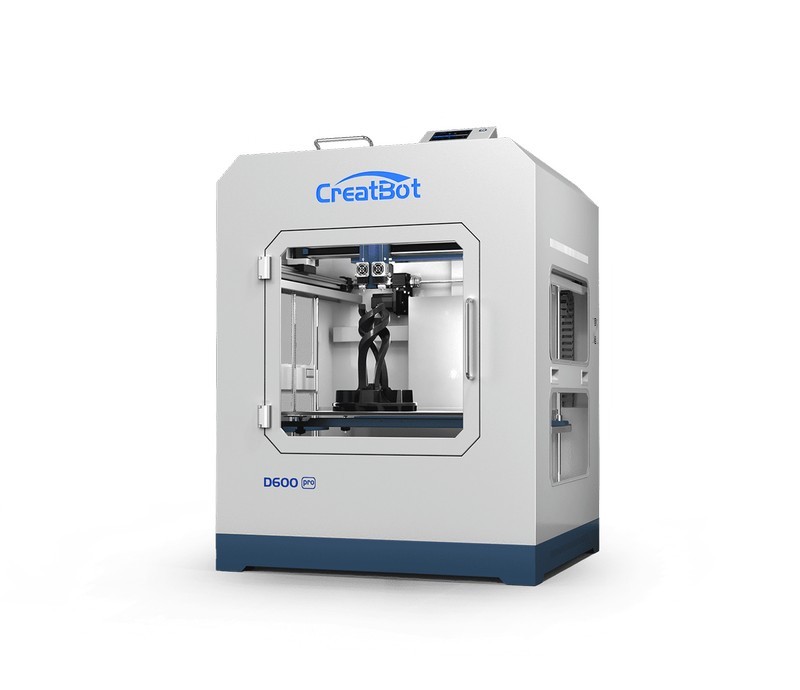

The Creatbot D600 Pro is a large-scale FDM 3D printer featuring a build volume of 600 x 600 x 600 mm and a dual extrusion system with the maximum nozzle temperature of 420 °C. Combined with the heated ceramic-glass print bed and the hot air chamber, maintaining the constant temperature of up to 70 °C, this allows the D600 Pro to print with high-performance materials, like high-temp nylons, carbon fiber-filled thermoplastics and PC. The precise auto bed leveling system using BLTouch sensor greatly adds to print quality, ensuring proper first layer adhesion. The printer comes with free CreatWare software based on the popular Cura slicer.

Credit: @3dprimade / Instagram

Update your browser to view this website correctly. Update my browser now

Write a comment