Over the past few years, the Chinese-based manufacturer Raise3D has become global — although the company's headquarters are still located in Shanghai, the main markets for Raise3D equipment are the United States and European countries.

The concept of the E2 3D printer was being developed for more than two years and even continued after the premiere — having identified a number of problems, the company delayed the start of sales in order to be completely confident in the quality of the model.

This is Top 3D Shop with a detailed review of the Raise3D E2 3D printer which takes advantage of the IDEX technology as well as a plethora of other advanced features. Look through the specs of the device and read on to get a full insight into what benefits are offered by the machine.

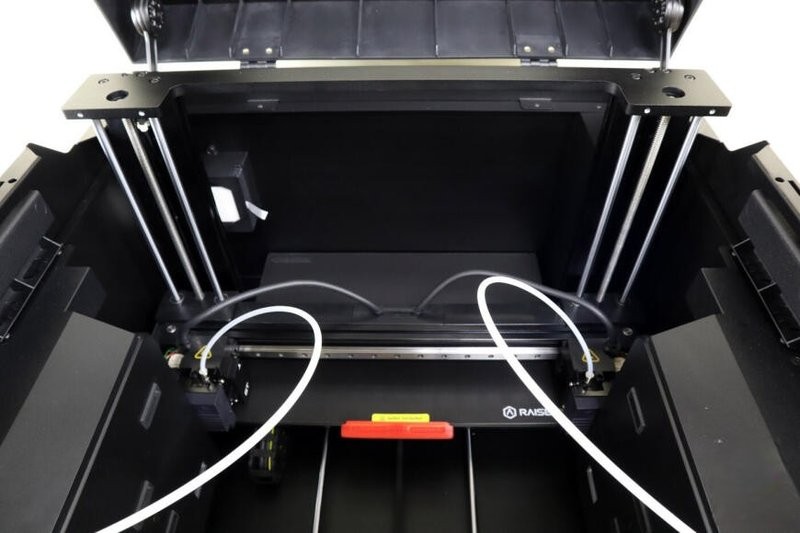

The main difference between the E2 and its predecessors from the Pro2 series is the IDEX system, which stands for Independent Dual Extrusion. Although Raise3D is not the inventor of this technology, it should be noted that the E2 is distinguished from all competitors by its high quality of performance and a number of engineering improvements.

The IDEX system has several advantages over the conventional arrangement of two extruders in one print head. First, it is a significantly lower weight, which helps avoid unnecessary inertia when moving. Secondly, the advantage of the extruder independence, albeit partial, makes it possible to increase the performance of a 3D printer without reducing its functionality.

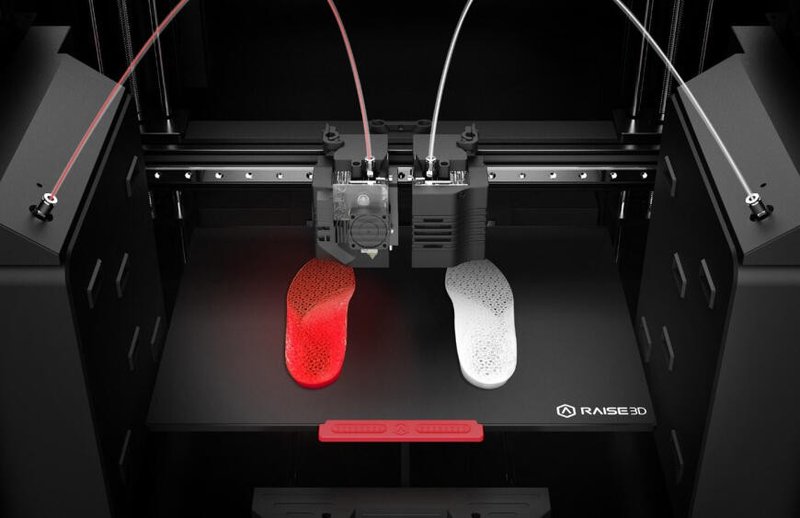

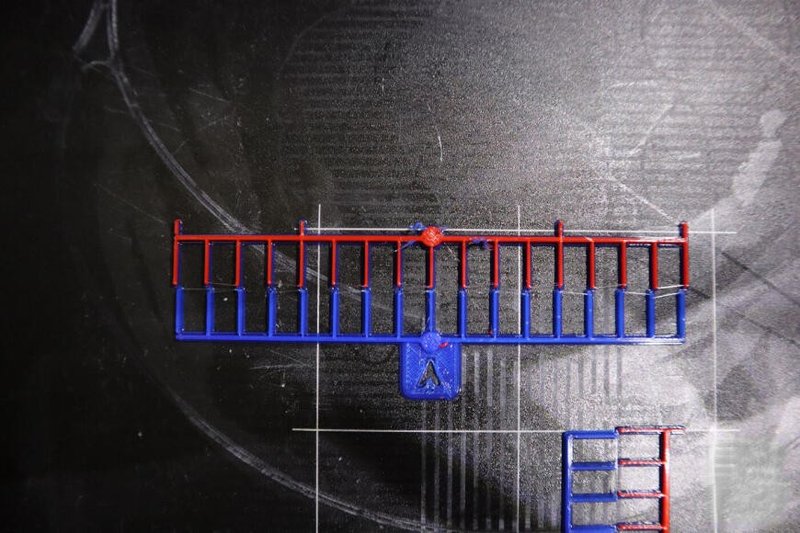

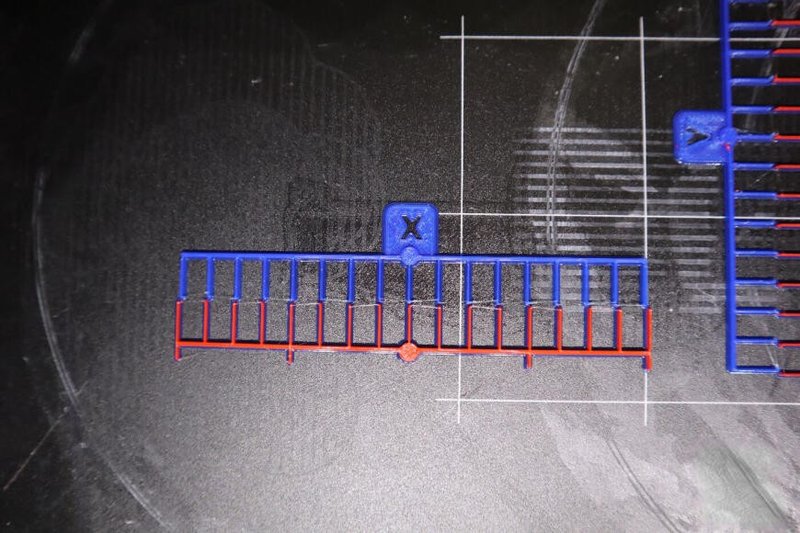

First sales of E2 printers had shown that customers often compared them to the Pro2 model. Indeed, these devices are quite close to each other in terms of specifications, but the IDEX system does make a fundamental difference, expanding the variability of the printer's operating possibilities. The photo below shows the process of printing a face shield in Duplication mode.

So, the E2 model can print in several modes: single extrusion, dual extrusion, and Duplicate or Mirror mode. Also, it is possible to print the same model with different materials and different temperature settings.

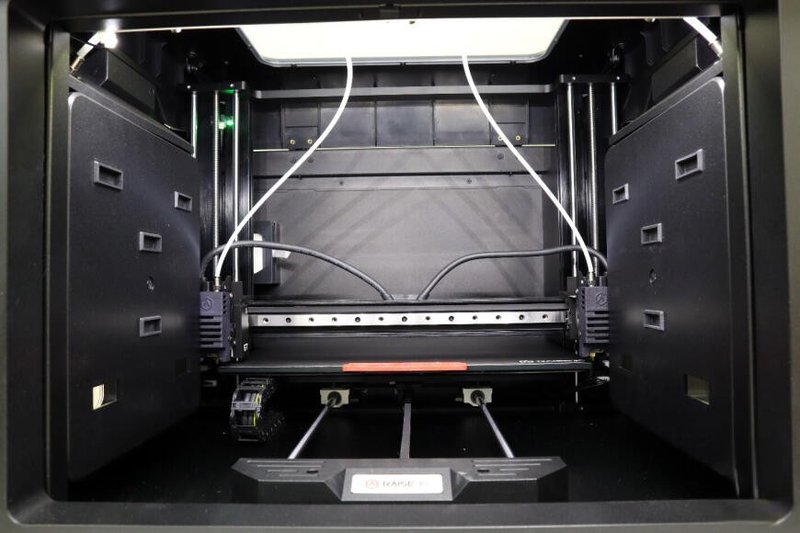

The Raise3D E2 3D printer sports a sturdy, durable, and rather heavy construction made of aluminum and high-quality molded heat-resistant plastic.

The size of the printer — 607 x 596 x 465 mm — is quite bulky for an office desk, and of course it is larger than many desktop printers, but the build volume is also significantly more sizable than those of direct competitors such as the Ultimaker 3 and the Zortrax M200 Plus. In addition, note that in order to load the filament into the compartments on the sides of the device, you need to open their doors, and this requires another 30–40 cm of free space. Besides, there must be space for opening the top cover, which in turn requires about half a meter.

It is also noteworthy that it is possible to set the pause of printing in case of opening the front or top doors and then continue the job after they are closed. This is necessary for safe use of the printer in schools, where children can get burned.

The print area with a single extruder is 330 x 240 x 240 mm, and with two of them — 295 x 240 x 240 mm. These sizes are quite enough for most tasks, but for larger projects, you should go with the Raise3D Pro2 Plus.

The print bed heats up to standard 110 °C, while the maximum temperature of the extruders is 300 °C, which allows you to comfortably work with materials characterized by high shrinkage and solves the problem of the first layers getting torn off when printing with high-temperature plastics. The bed heats up not quickly but steadily, while the power consumption of 350 watts seems quite economical. These temperature parameters enable the user to employ a wide range of 3D printing materials, including nylon (polyamide), polycarbonate, ASA, carbon, glass-filled nylon, carbon-filled ABS, and others. Only high-temperature engineering plastics such as PEEK and Ultem 9085 remain beyond the capabilities of the E2, like in the Pro2 series.

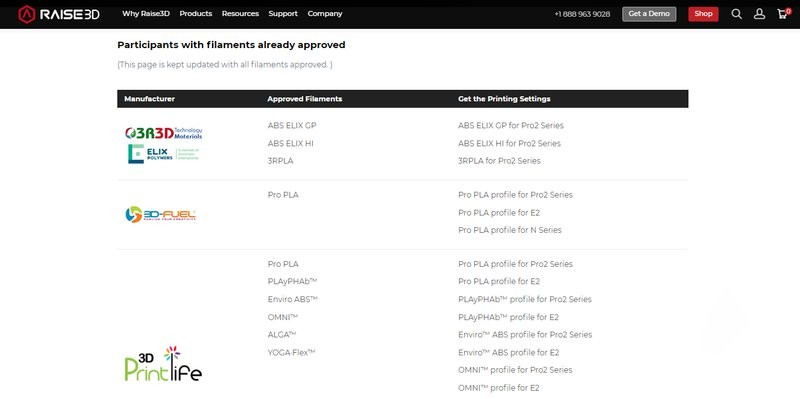

Just as before, you can use both original Raise3D consumables and any third-party materials, many of which are in the OFP (Open Filament Program), allowing third-party manufacturers to test their filaments on Raise3D printers and create profiles for each material to provide maximum user convenience.

An important role is played by the enclosed chamber of the printer, making it possible to maintain a stable temperature of 30–40 °C, which is necessary for printing high-temperature materials that feature a high degree of shrinkage.

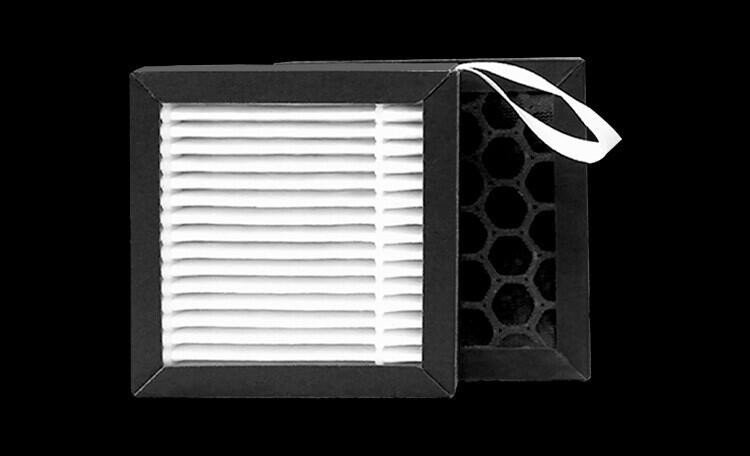

The special HEPA filter ensures odor-free operation even when using ABS filament. Not only does it capture the smallest polymer particles, preventing them from entering the working environment, but it also blocks unpleasant and harmful fumes emitted when printing with some technical polymers.

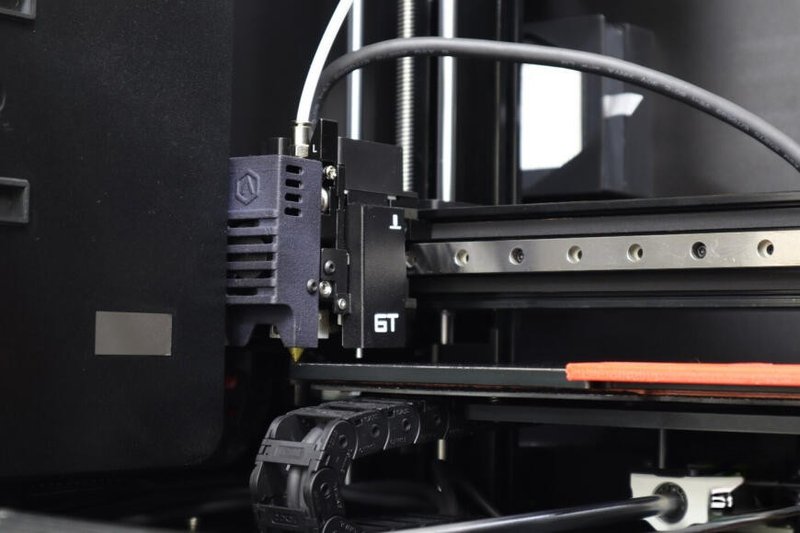

The kinematic scheme of the Raise3D E2 printer is a gantry structure with a movable platform. The X and Z axes are combined in a rigid module, where two extruders independently move on rail guides. It is the first time that Raise3D used rails in their product, departing from the Ultimaker kinematics on which the N and Pro2 series were based.

The advantages of such mechanics are high accuracy, reliability of printheads, and wide operational variability coupled with the high stability of results.

Among the shortcomings is a relatively low print speed due to excessive movements when switching the activity of the print head as well as high inertial moments of the build plate with the part printed on it. Although engineers did everything possible to reduce the weight of the print bed, sometimes, during sudden movements, “ringing” vibrations can be observed, which in the worst case can lead to delamination of the part from the surface.

Like in the Pro2 line, the E2 features an aluminum plate with a BuildTak surface, which offers high wear resistance along with good adhesion. But, the build plate in this model is removable and flexible, with magnetic fixation. Therefore, it requires frequent calibration of the print surface.

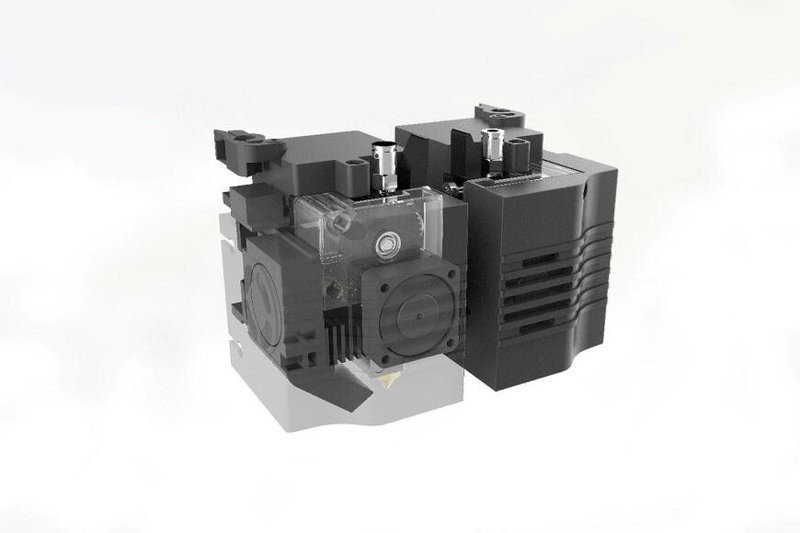

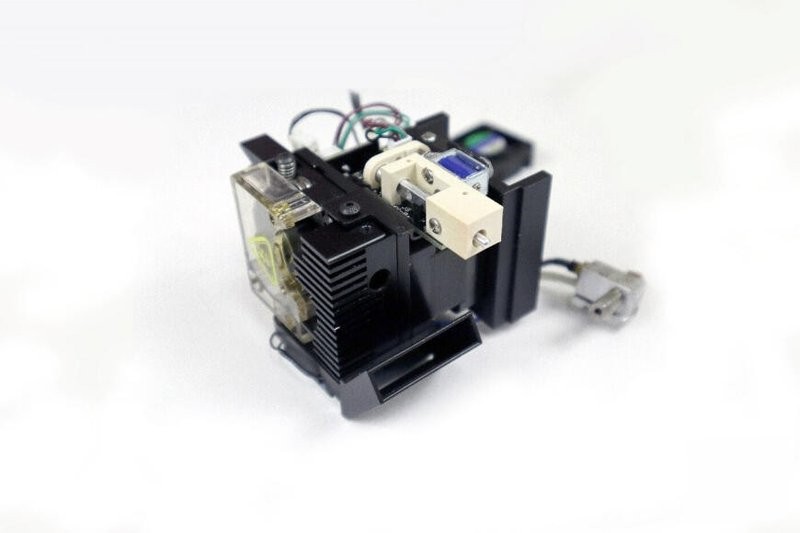

The E2’s direct extruder is compact, lightweight, and thoroughly designed. It has a reduction gear and, as we assume, a double-sided toothed clamping for the filament, similar to the BMG gearbox. This solution allows you to confidently work with soft and "slippery" plastics.

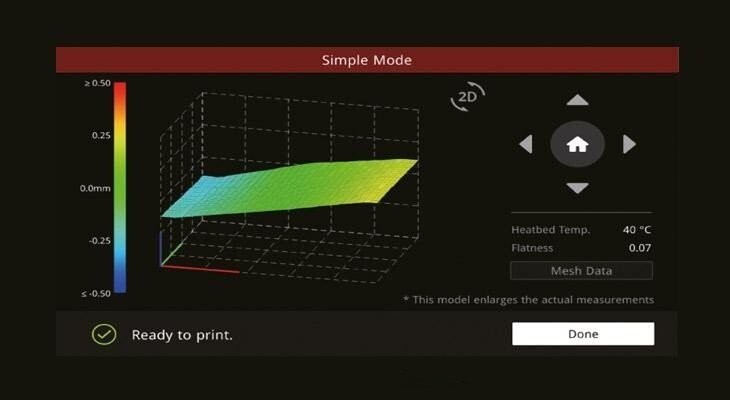

Near the extruder, on the left print head, there is a BLTouch-type sensor, a two-position electromagnetic probe with an optical fixation sensor.

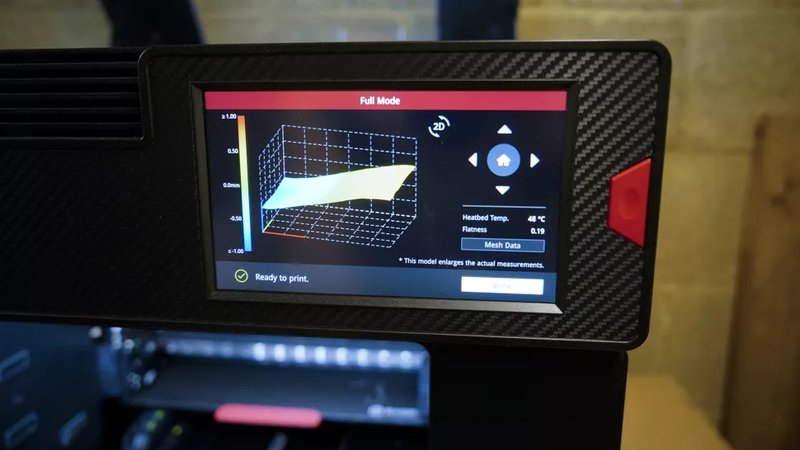

The Raise3D E2 uses a multi-zone bed leveling system.

It is carefully packed in a metal casing that protects it from mechanical damage and high temperatures.

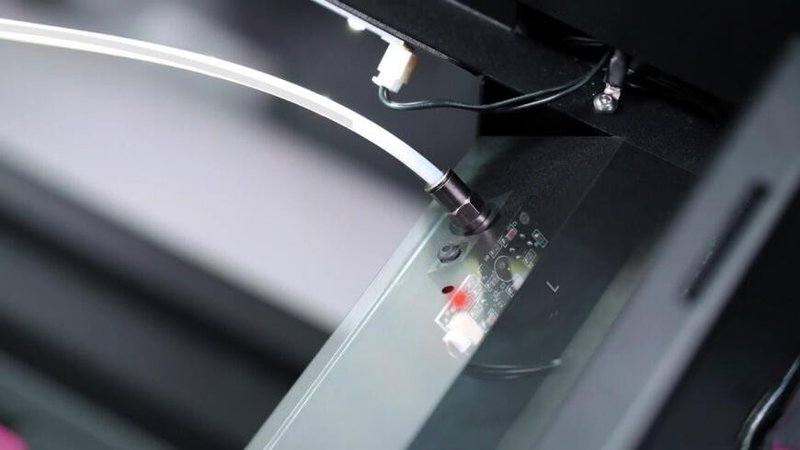

The printer is equipped with filament detection sensors, so you don’t have to worry about sudden material runouts during prolonged printing — the device will pause and continue printing after a new spool is installed.

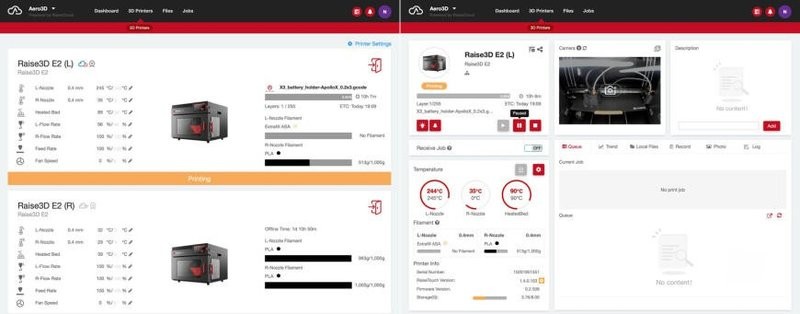

The machine also boasts a video camera that allows you to record and remotely control the printing process using integrated Raise3D cloud services.

In addition, it is worth noting the large red button located next to the printer display. This button activates the mode, in which the lighting of the build chamber and display indication are turned off when the operator deems it necessary — for example, during multi-hour or even multi-day printing. If held down for more than 10 seconds, the button reboots the device.

The powerful NXP ARM Cortex-A9 Quad 1 GHz processor ensures comfortable operation and smooth printing process. The major electronic components are located in the front upper unit with a decorative carbon look. All necessary wiring is housed in cable channels or fireproof silicone harnesses.

The large 7-inch touchscreen has been the hallmark of Raise3D printers since the first N series. The display functionality and visualization still provide an incredibly comfortable user experience. The control system has a built-in non-volatile memory that will resume the print job in the event of a power outage. As before, the system is controlled by a Linux-based OS.

Good calibration is essential for a successful use of the device, and Raise3D did its best to make this process as clear as possible, especially for first-time 3D printing users.

For accurate conjugation of nozzles, there is a special calibration system with a simple video instruction on the printer display. This unique function for 3D equipment was first implemented by Raise3D, and, like many other innovations of the company, it will probably become a standard for professional 3D printers.

The disadvantage of this feature is the long time required for the calibration procedure — it takes about 20 minutes, but at the same time it must be understood that the key to successful printing is the correct calibration of both the print bed and nozzle conjugation.

Files for printing can be downloaded via Wi-Fi through a standard RJ45 connector located on the back of the frame, which also allows connecting the printer to a local area network.

Another option is offline connectivity using USB ports: simply insert a flash drive with a file prepared for printing into the connector and press the Print button on the display, select the file, and follow the system prompts. Files downloaded to the printer are stored in the internal memory, as well as video reports on the results of the previous print.

The filament loading procedure is semi-automatic: you need to select the corresponding option in the control menu and place a filament spool in the insulated compartment with a translucent lid through which you can visually check the amount of remaining plastic. Then put the thread through the fitting into the filament path until it stops in the gear wheel and follow video prompts on the display.

The intelligent multi-zone bed leveling system coupled with an informative video interface will help quickly make a profile of irregularities with an accuracy of hundredths of a millimeter. This allows the printer to reliably build the first layer, which is essential for a successful outcome. From a visualization point of view, this solution is absolutely unique in the field of 3D printing.

As a slicer, all Raise3D printers use the proprietary ideaMaker software that features a very wide functionality. It is an extremely advanced tool for implementing the most complex tasks, and in conjunction with the RaiseCloud service, it gives the user truly unique opportunities for preparing models and controlling the entire printing process, with the possibility of subsequent analysis of the results obtained.

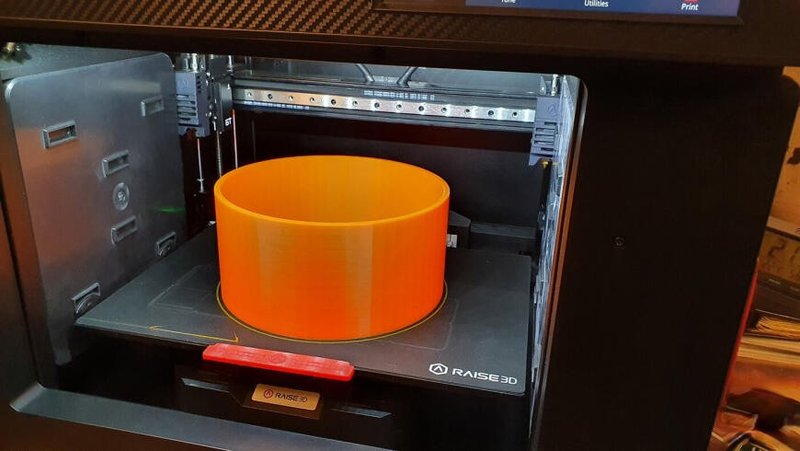

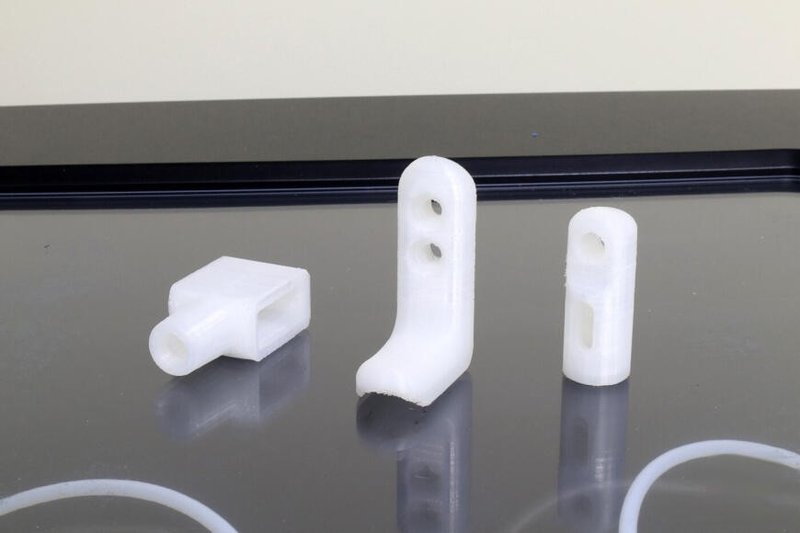

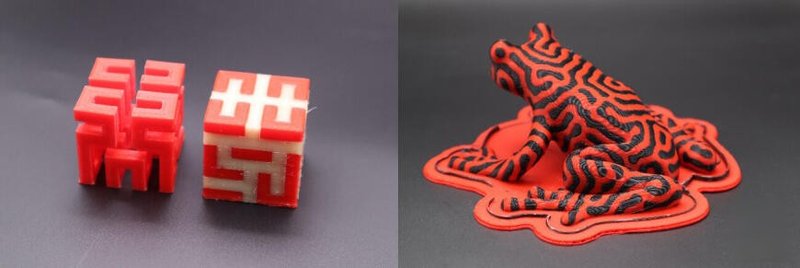

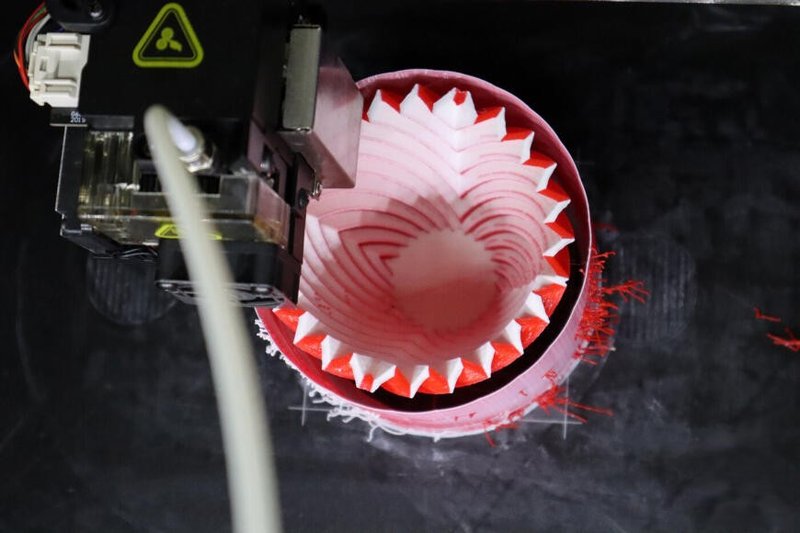

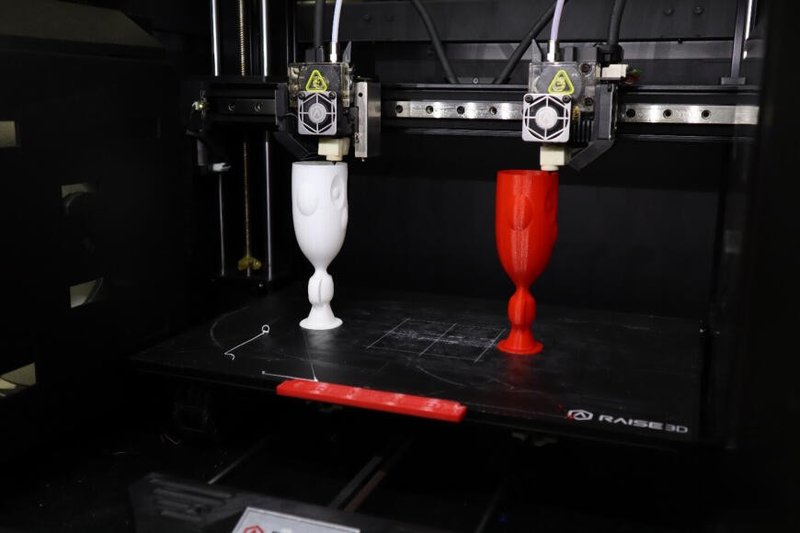

Now, let’s have a look at a few models made with the Raise3D E2 printer.

These are fairly lightweight models printed in ePA (nylon) filament from ESUN. Although the lack of flat surfaces made them a little difficult to print, the device coped with the task.

Next is a quite complex model of a fog lamp for Citroen in a 1:1 scale, printed with ABS+ and HIPS by ESUN. The example shows the capabilities of the E2 in the mode of printing with two extruders using a support material.

The following prints are the well-known PLA plastic cube with a water-soluble PVA support and a poisonous tree frog printed in two colors with PLA.

And this is a two-color print of a vase:

It was printed with two Raise3D PLA 1.75 mm filaments (red and white). Layer: 0.18 mm. Nozzle temperatures: 225/225 °C. Bed temperature: 60 °C. Speed: 60 mm/s.

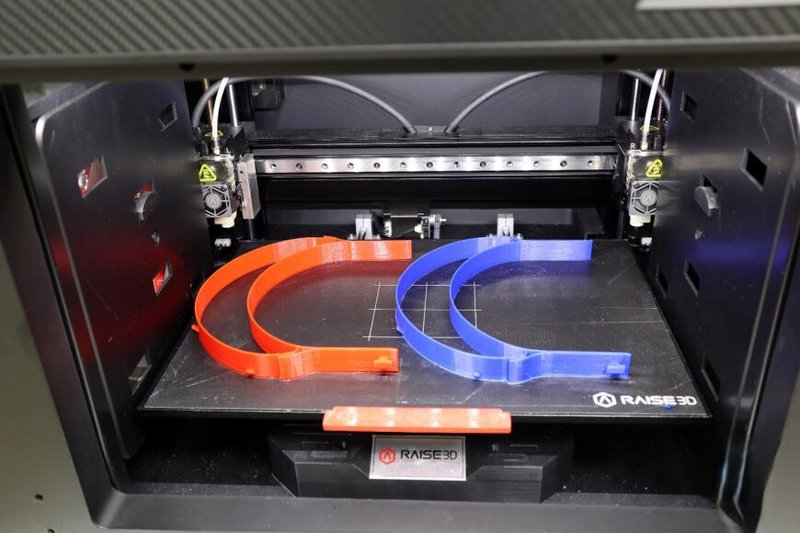

The last photos show two glasses printed in Duplicate mode. Layer: 0.08 mm. Nozzle temperatures: 225/225 °C. Bed temperature: 60 °C. Speed: 50 mm/s. Filament: Raise3D PLA (red and white).

The Raise3D E2 features high and stable print quality, simplicity and ease of use, versatility and high performance — virtues that are difficult to find in one 3D printer model. The device will serve as a great tool for designers and engineers who wish to bring their ambitious ideas to life. Its variability can provide competitive advantages and increase the economic effect of 3D printing. The IDEX technology will save time and effort by increasing performance and expanding functionality. The informative and user-friendly interface will allow even a beginner to get started without any difficulties. In addition, Raise3D has its own industrial ecosystem comprising a slicer, cloud service, technical support, and its own line of consumables including profiles for them.

Update your browser to view this website correctly. Update my browser now

Write a comment