Polycarbonate (PC) is a type of plastic known for its extraordinary strength, durability, and transparency. Actually, it is the same material used in bulletproof glass, CDs, and even astronaut helmets.

Due to their outstanding properties, polycarbonate filaments are a popular choice for 3D printing enthusiasts who need extra strength and durability from their prints. However, working with polycarbonate requires specific conditions and a lot of patience to learn how to do it properly.

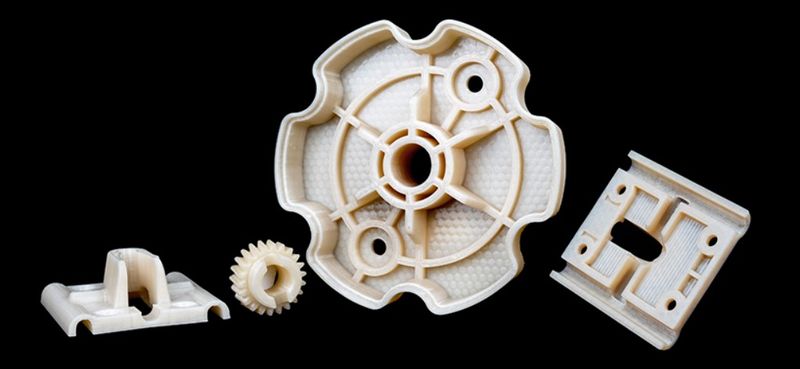

Credit: 3dsourced.com

This is Top 3D Shop, and today we are going to delve into 3D printing polycarbonate — one of the most tricky materials for the majority of users, especially beginners. Let’s find out what its properties are, how to deal with its challenges, and which 3D printers are considered the best to produce top-quality PC parts.

Credit: airwolf3d.com

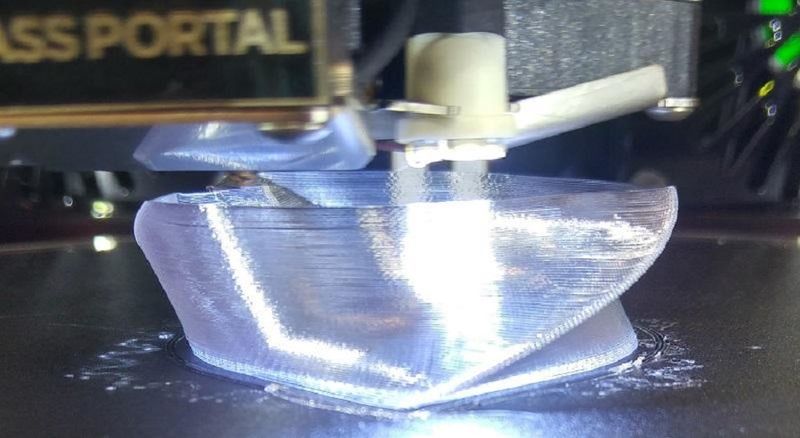

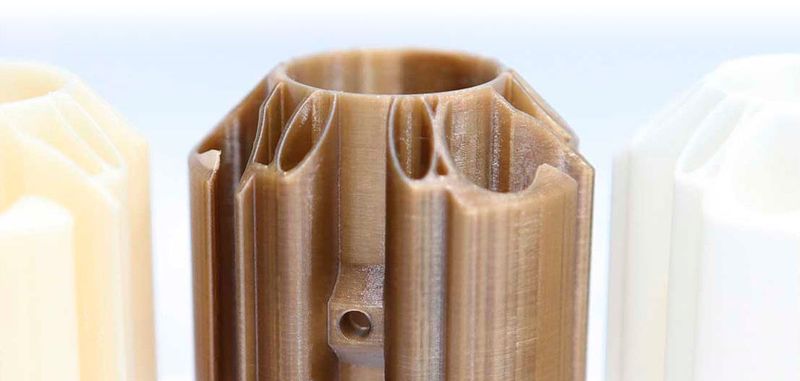

Polycarbonate or PC is a special high-performance material that is extremely durable, lightweight, transparent, and dimensionally stable. It boasts a high impact strength that greatly surpasses that of glass and acrylic materials like PMMA. At the same time, it has less than half the density of glass, with a comparably high level of transparency, which makes for a good light transmission. In addition, polycarbonate is bendable, with this flexibility allowing it to withstand high tensile forces that break or shatter filaments like ABS. The latter makes 3D printed PC parts increasingly wear-resistant.

Polycarbonate has a high glass transition temperature of 150 °С and is also heat-resistant up to temperatures of 115 °С. Although this opens up many new applications for PC parts, it also results in a relatively high printing temperature and some other peculiarities of the printing process.

Being a hygroscopic material, polycarbonate can absorb water from the atmosphere. Since the moisture can ruin the filaments’ performance and mechanical strength, it should be kept in airtight, moisture-free environment before and during printing.

Finally, PC is rather peculiar about printing conditions and devices to work with it. For compatibility with desktop 3D printers, these filaments contain some additives that do not affect their impressive characteristics.

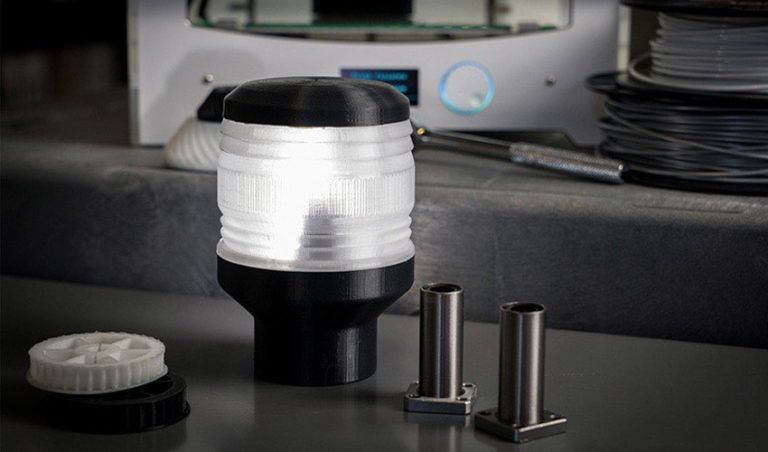

Given the properties described above, there are numerous reasons why one might choose to use polycarbonate when 3D printing. From its light weight and transparency to incredible strength and flexibility, this demanding yet relatively cheap material is an obvious choice for a wide variety of commercial applications.

Credit: simplify3d.com

Polycarbonate boasts fantastic mechanical properties. Its strength and durability make it an excellent choice for items that will undergo significant wear and tear. With such a high impact resistance and natural bendability, PC parts do not deform or break, so they can stand up to a variety of demanding applications. By comparison, other transparent thermoplastics, like PMMA, will crack and break if bent. This makes polycarbonate an excellent choice for making functional prototypes, especially where transparency and non-conductivity are desired.

Polycarbonate stands out for its excellent heat resistance. It is able to withstand high temperatures without deforming, making it perfect for parts that will be exposed to heat.

Polycarbonate’s transparent nature and light transmittance allow for a number of unique applications in the creation of high-quality clear or translucent objects with beautiful looks. In contrast to PETG that is also transparent, PC provides far better impact and temperature resistance.

So, what is the workflow when 3D printing with polycarbonate?

Credit: 3dsourced.com

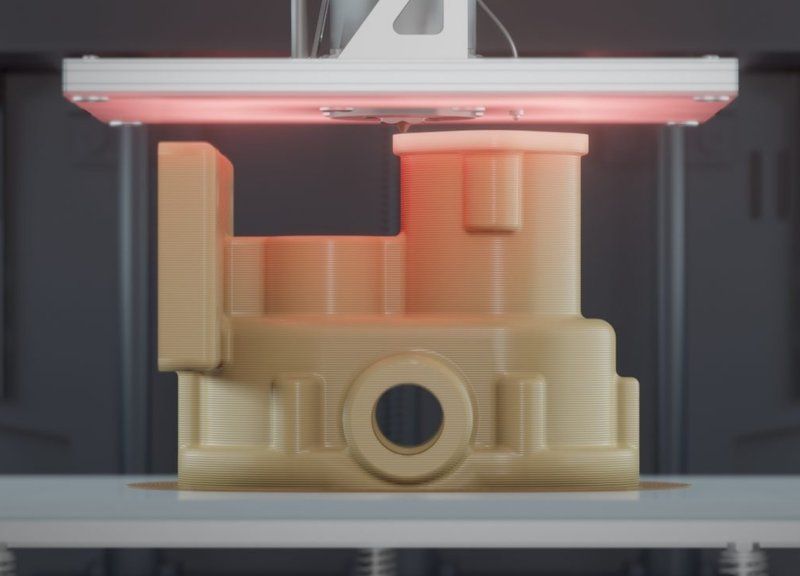

Setting up your printer. To print with polycarbonate, you will need a 3D printer capable of reaching high temperatures. You may also need a heated bed and an enclosed print area to maintain a constant ambient temperature.

Temperature settings. Polycarbonate generally prints at a higher temperature than other plastics, often between 260–300 °С, so make sure the extruder is capable of reaching these values.

Post-processing. As with other 3D printing materials, this stage involves steps like cleaning up the print, removing supports, and sanding the object to make it smooth and ready for use.

Credit: 3dnatives.com

Polycarbonate has found its way into various industries, from automotive to aerospace, thanks to its unique properties.

Outside of 3D printing, it is commonly used to make various household products, such as CDs and DVDs, water dispensers, electronic display screens, phone and computer cases, food containers, and much more. Due to its high strength, impact resistance, and transparency, PC is also found in manufacturing sunglass lenses, scuba masks, bike and motorbike helmets, car body parts, riot gear, and even bulletproof glass.

As for proper 3D printing uses, polycarbonate is a perfect option for engineering applications requiring its high strength and flexibility. PC based filaments are frequently used for projects that need to handle higher temperatures and strong impacts, like 3D printed car parts.

While polycarbonate 3D printing offers many benefits, it is not without challenges. Depending on your setup, PC can be tricky to print with due to its high-temperature requirement, sensitivity to cooling, hygroscopic properties, and adhesion issues.

High printing temperature. Standard 3D printers are not always capable of achieving the processing temperatures required that should be above 300 °C. Most will also struggle to maintain the heated bed temperatures at the right level. Plus, an all-metal hotend is needed to effectively 3D print with polycarbonate. Thus, if you have a standard 3D printer, certain modifications may be required.

Warping issues. Since PC is extremely prone to warping even in comparison with ABS, it requires precise printing settings to avoid this.

Hygroscopicity. When left out in the open, polycarbonate absorbs a lot of moisture from the air, which worsens its 3D printing characteristics. PC based filaments must be kept in airtight, dry conditions at all times.

Sensitivity to UV rays and hydrolysis. Polycarbonate is degraded by sunlight and reacts poorly to water, which makes it unsuitable for any outdoor applications.

As you can see, polycarbonate 3D printing does come with a unique set of challenges, but with the right settings and practices, these can be easily overcome. When taking into account several important factors, such as a stable temperature, slow print speed, and low cooling rate, you will be able to produce successful PC prints.

Credit: geeetech.com

When dealing with polycarbonate, ambient temperature plays a crucial role. It is essential to maintain a controlled, warm environment to prevent warping or cracking of the printed parts. For this, your printer needs an enclosure that is consistently heated up to 60–70 °C. In addition, the temperature of the print bed should be kept at 90–120 °C to avoid warping and eliminate potential delamination issues.

Polycarbonate requires a higher nozzle temperature compared to other thermoplastics, typically around 260–310 °C. This particular material takes a long time to melt, so high printing temperatures ensure a uniform filament flow. Another important part is fine-tuning. When the printing temperature is too low, this will lead to quality issues, like layer separation, cracking, warping, etc. Still, if the nozzle temperature is too high, there is a risk of stringing and oozing.

Due to its high glass transition temperature, PC can be printed at a lower than optimal temperature, but more slowly, in direct proportion to the temperature selected. Thus, at 265 °C, polycarbonate will provide decent results at a speed of 30 mm/s. It also works the other way around: with a higher extruder temperature, you can experiment with a faster print speed up to 60 mm/s.

Using a heated bed with an adhesion solution, such as Kapton tape, ABS slurry, borosilicate glass, or special build surface sheets like PEI, can ensure your model properly sticks to the bed throughout the printing process. Plus, when printing the first layer, it is recommended to lower the print speed and turn off cooling completely. Also, try increasing the layer height and width by 50% to further improve bed adhesion.

Polycarbonate is highly hygroscopic, so it is crucial to properly store your filament and consider drying it before printing. Otherwise, it will cause problems with extrusion due to bubbles and inconsistent flow, which can result in a ruined design of your models.

Not all polycarbonate filaments are equal in quality. Choosing decent consumables can significantly improve your 3D printing experience and final outcomes.

Now, let’s take a closer look at the currently best 3D printers capable of high quality and reliable printing with polycarbonate.

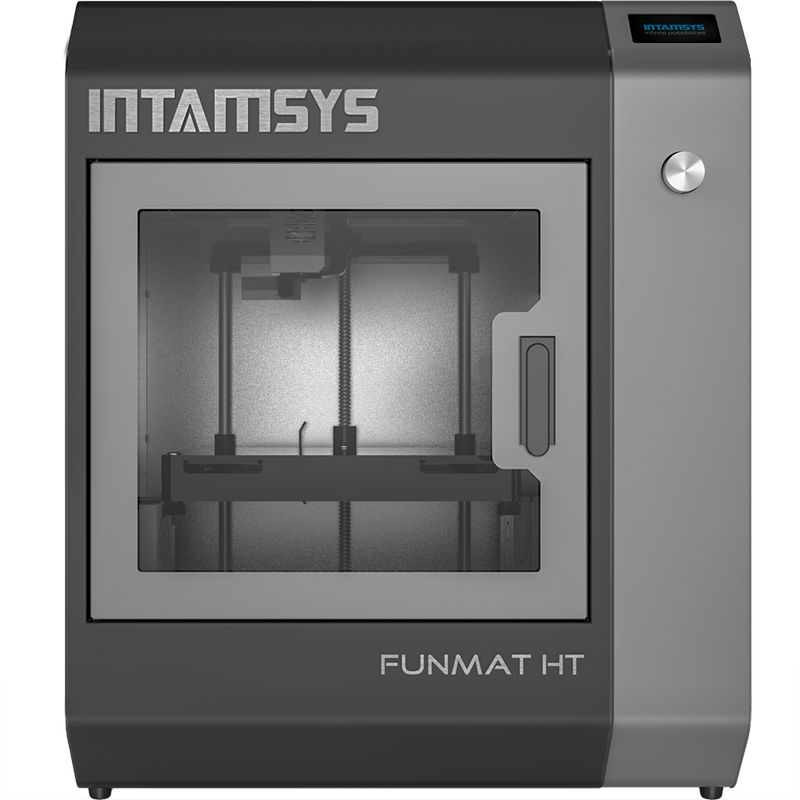

The Intamsys Funmat HT is a high-performance industrial FDM 3D printer with advanced high-temperature capabilities. It is tailored for smooth, fast (up to 300 mm/s), and reliable printing with professional-grade materials like PC, PEEK, ULTEM, PEI, and PPSU. Available now in the Enhanced version, the machine features a convenient auto-leveling function with improved nozzle, 4 independent drivers for extra precision, and a redesigned removable glass-ceramic build plate with PI film. The improved hot bed alongside the constant-temperature heated build chamber up to 90 °C grants excellent thermal and noise insulation. Thanks to these enhancements, the Funmat HT lets you produce complex yet extremely resistant parts with difficult-to-print consumables right out of the box. Thanks to the open material system, one can use filaments from any brand on the market.

Despite its rich functionality, the Funmat HT sells at a reasonable price, being ideal for most small businesses and 3D printing services looking to enter the professional 3D printing world with the ability to work with demanding engineering materials, PC being one of them.

Credit: @cadsolutions / Instagram

The Flashforge Creator 4 is a professional FFF 3D printer that perfectly combines functionality, flexibility, and productivity in creating top-quality models with smooth exterior surfaces, complex geometry, and detailed composition. Equipped with two interchangeable independent extruders and a fully enclosed chamber that can maintain a constant temperature up to 65 °C, the Creator 4 supports stable printing with high-temp and engineering-grade filaments as well as carbon or glass fiber composites. Moreover, thanks to the efficient IIDEX system, the device features duplication and mirror modes, doubling the production volume and enabling dual-color or dual-material printing, including soluble support structures.

The printer’s generous build volume of 400 x 350 x 500 mm meets most manufacturing needs and allows printing a single large part or simultaneously producing several smaller ones in batches. Additionally, the Creator 4 offers multiple advanced functions, such as the intelligent filament management system, material runout detection, auto bed leveling, resume printing, effective heat dissipation, and more.

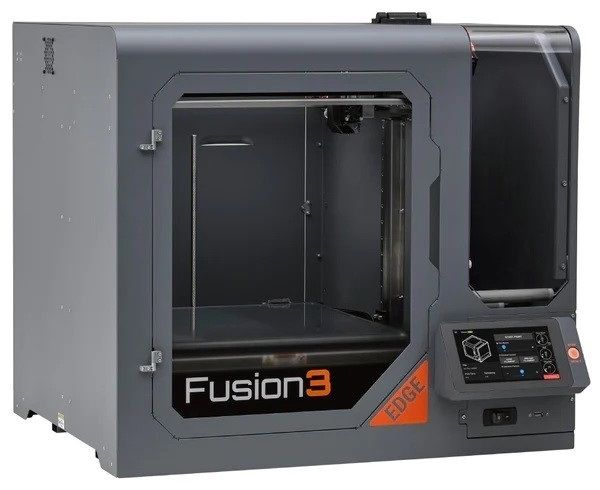

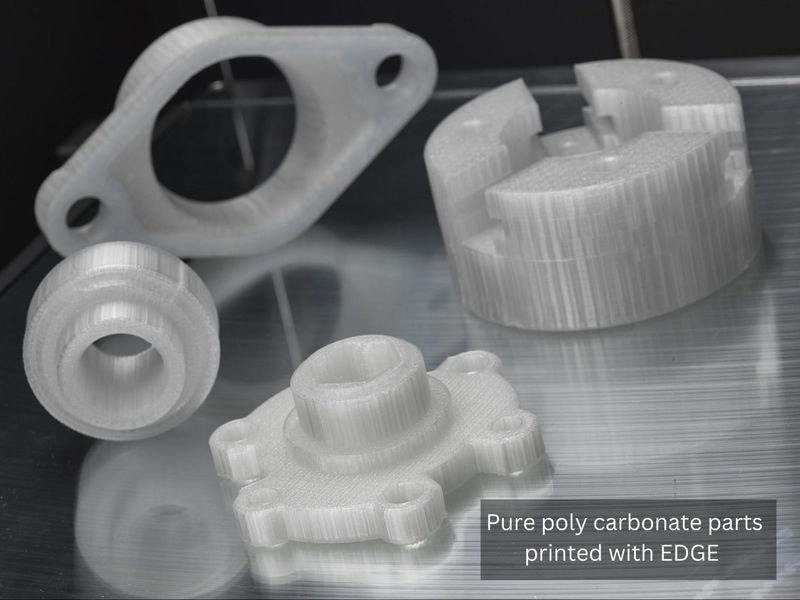

The Fusion3 EDGE is one of the fastest commercial FDM 3D printers. Utilizing the proprietary “F-Series” motion control system, the EDGE can reach the print speed of 250 mm/s still providing highly precise and accurate parts with smooth exterior surfaces, complex geometry, and detailed composition. The patented ANVIL print head heats up to 320 °C, which in combination with the printer’s enclosed design, multi-zone heated bed, and passively heated chamber allows for a wide range of materials with temperature-sensitive and engineering properties, including PC. Due to a wear-resistant interchangeable print tube that comes in 0.4, 0.6, and 0.8 mm diameters and is made of surgical steel, the EDGE can also work with abrasive materials, such as carbon fiber or fiberglass. In addition, the device comes with a new mesh bed leveling system, remote management tools, intuitive software with optimized material profiles, door interlock function, and more.

Being an affordable high-performance 3D printer of industrial scale, the Fusion3 EDGE is a perfect tool for professional use in multiple spheres, including small businesses, rapid manufacturing, end-user production, and education.

The HTX from 3D Labs is a professional high-temperature desktop FDM 3D printer that is aimed at cost-efficient additive manufacturing with the most demanding materials, such as PC, PEEK, PEI, ULTEM, etc. With the layer height of 40 microns, it can create dimensionally accurate and incredibly durable functional parts for multiple applications. To boost productivity and achieve greater quality consistency, the machine is equipped with a large build volume of 350 x 300 x 300 mm as well as advanced components, including a high-temperature bed probe ensuring proper mesh and bed leveling, actively heated chamber, redesigned dual extruder enabling multi-material printing, improved cooling fans providing optimal performance without warping, stringing, etc., and carbon fiber removable build plates for time- and cost-saving production.

One of the key peculiarities of the model is its neatly-looking UI and streamlined system behind menu options. Powered by the proprietary 3D Labs Ion software offering remote control functionality, curated profiles for quick-start printing, and handy automated functions, the 3D Labs HTX comes as a completely user-friendly solution.

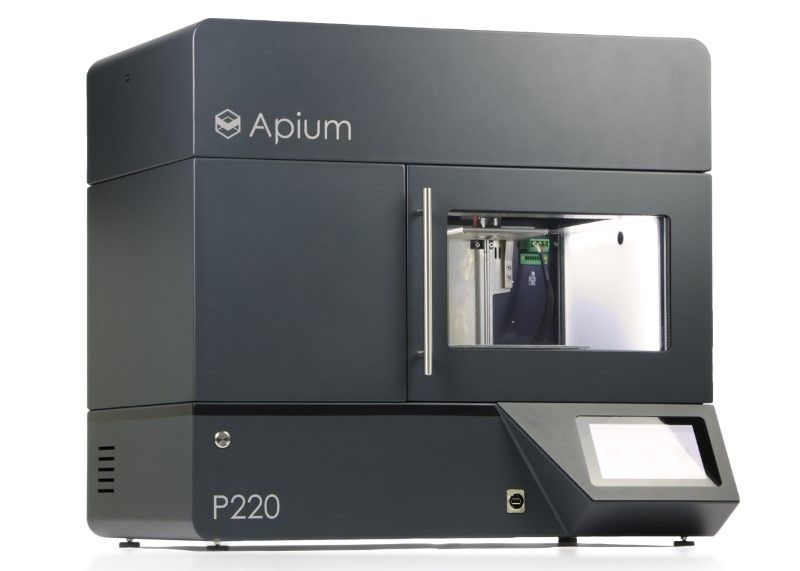

The Apium P220 is a fairly compact industrial FDM 3D printer capable of working with high-temperature engineering filaments. Equipped with an innovative adaptive zone heating system and high-performance 540 °C extruder with 4X higher feeding force, the machine ensures time and energy saving and provides optimal printing conditions for demanding materials, including metal-filled ones. With the heater integrated into the print head, the system precisely adjusts the heating power to achieve a complete part crystallinity, strong layer adhesion, and excellent surface quality with a minimum layer height of 50 microns, which is ideal for a variety of applications in different industries, including automotive, aerospace, engineering, and others.

To ensure top-notch quality and extended service life, the Apium P220 features a sturdy construction with an industrial-grade threaded rod and two linear guides preventing vibrations and making for print precision. The integrated software guides the user through semi-automatic bed calibration or reminds about the necessary maintenance. With the built-in camera, it is possible to monitor the printing process and automatically record all important printing parameters in a PDF protocol.

The Raise3D E2 is a powerful dual-extrusion FDM 3D printer equipped with the IDEX system and targeted at the professional market. Its autonomous print heads can print objects at 20 microns layer height in both mirror and duplication mode, producing two high-resolution parts or the identical part symmetrically at the same time, with almost no need for post-processing. Apart from this, the E2 is packed with a set of advanced features for a smooth and streamlined operation experience. It is the first 3D printer that includes a video-assisted offset calibration system. Plus, to prevent common printing failures and user injuries, the Raise3D E2 is equipped with a print recovery function, filament run-out detection, door opening detection, energy-saving mode, on-screen assistance, and efficient air filtration.

Thanks to its closed design and high-quality hardware, the Raise3D E2 is compatible with a number of filaments, from standard to professional ones. Perfect for engineers, industrial designers, and other pro users, the E2 is a smart workhorse that perfectly fits on any benchtop.

Credit: @robrimell_3d / Instagram

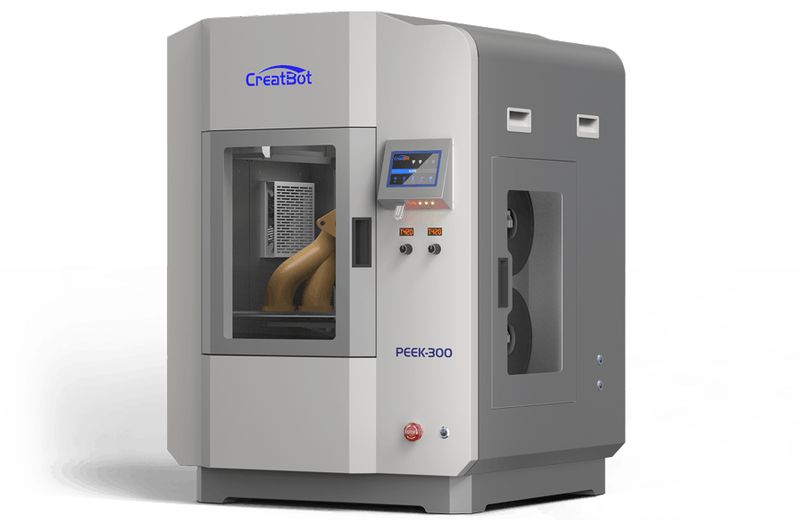

The Creatbot PEEK-300 is an industrial FDM 3D printer specially designed for working with demanding materials. Equipped with an all-steel body and engineering-grade components, such as ultra-high-temperature nozzles (500 °C), a heated build chamber, and heat-resistant motors, rails and belts, the machine ensures long-lasting, reliable performance over time. The PEEK-300 also boasts a state-of-the-art thermosetting technology, which relies on both circulating liquid and air pump cooling. With a triple heat isolation system as well as the self-developed patented Direct Annealing System (DAS), the machine minimizes warping and cracking issues, in particular when printing large-size functional parts with smooth surfaces and fine details. To provide streamlined and convenient operation, the printer comes with a power-recovery system, filament run-out detection sensor, and emergency stop switch.

Generally affordable for almost any company and organization, the Creatbot PEEK-300 may prove expensive for some users. Nevertheless, its advanced functionality and high performance can be considered a worthy investment when dealing with professional-grade materials.

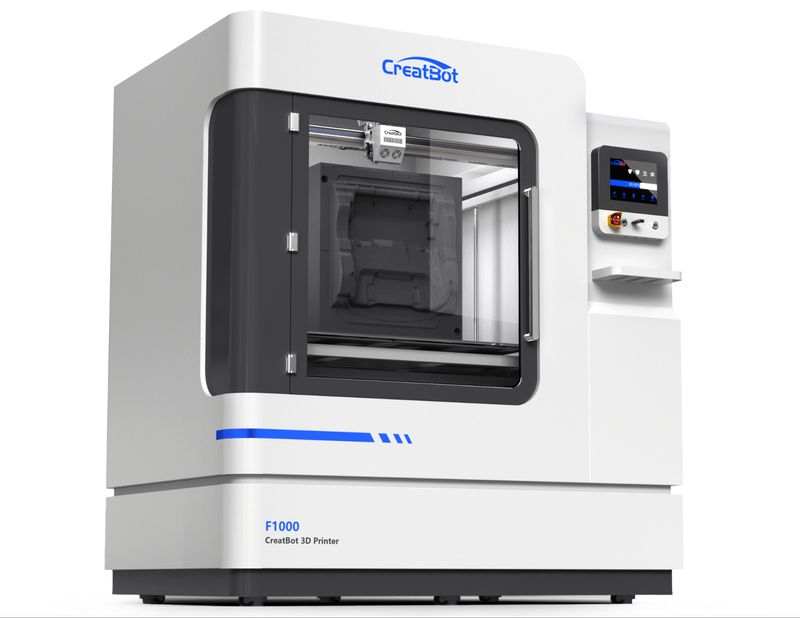

The Creatbot F1000 is a cost-effective large-format FDM 3D printer that comes with a massive build volume of 1000 x 1000 x 1000 mm, making it one of the largest on the market. As a high-performance industrial machine, it is engineered with a dual extrusion system that lets the user produce multi-material and multi-color items with a reasonable resolution and impressive printing speed of up to 300 mm/s. Despite being a professional large-scale solution, the F1000 is easy to operate thanks to intuitive UI, multiple connectivity options, and on-board camera enabling remote control for standalone operation 24/7. Due to a hot build chamber, heatable bed, and high-temp extruders, the machine is capable of effectively printing with PC, ABS, Carbon Fiber, PETG, Nylon, flexible filaments, and other advanced materials.

With the intelligent power-off recovery and filament detection systems, automatic bed leveling, quality construction, and effective thermal design, the Creatbot F1000 offers great value for money. One can safely use it for making the largest industrial parts as a whole.

Credit: @creatbot_japan / Instagram

Polycarbonate offers immense potential for 3D printing, with its superior strength, heat resistance, and optical clarity. With a glass transition temperature of around 150 °C, nothing in the FDM range can compete with it. Recommended for durable, lightweight, flexible, and transparent parts that must withstand tough conditions, it is great for a variety of high-temperature engineering applications. However, careful considerations and settings adjustments are needed to successfully print with this material.

Update your browser to view this website correctly. Update my browser now

Write a comment