To track all the changes happening in the constantly developing world of additive manufacturing can become a real challenge. New technologies and materials make possible a lot of things that looked fantastic not long ago. It is not surprising that 3D printing has made its way into our lives and today more and more people start thinking of purchasing a 3D printer. But with plenty of various options offered by the market, the choice is not at all easy.

This is Top 3D Shop, and in this article we are going to review the existing 3D printing technologies, their strengths, weaknesses, and what they are best suited for. Read on to learn more.

In 2015, the International Organization for Standardization (ISO) developed the ISO/ASTM 52900 standard describing the additive manufacturing process and defining its main terms and concepts. In 2021 this standard was revised. It describes seven additive manufacturing processes that are the basis for numerous 3D printing technologies used by different types of 3D printers. In the table below you will find a short summary of all the seven processes with the most common corresponding technologies. Then we will discuss each of the technologies in more detail.

|

AM process |

Technologies |

Materials |

Pros |

Cons |

Applications |

|

Material Extrusion |

Fused Deposition Modeling (FDM) |

Plastic and fiber-filled polymers |

Cost-efficient Fast Wide range of materials |

Support structures required Rough surface finish No speed gain for batch-production Anisotropic |

Prototyping End-use parts (jigs, fixtures, etc.) Hobbyist printing |

|

Vat Photopolymerization |

Stereolithography (SLA) Digital Light Processing (DLP) Masked SLA (MSLA) |

Photopolymer resins |

Fast (DLP and LCD) High resolution Smooth surface finish |

Support structures required Post-processing is necessary UV sensitive |

Visual prototyping Dental and medical appliances Mold patterns Model making |

|

Powder Bed Fusion |

Selective Laser Sintering (SLS) Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM) Electron Beam Melting (EBM) Multi Jet Fusion (MJF) |

Polymer, metal, and ceramic powders |

Complex geometries Functional moving parts No need for support structures (SLS and MJF) Great mechanical properties |

High cost Post-processing required |

Functional prototyping Low-volume end-use part manufacturing Parts with complex geometries |

|

Material Jetting |

Material Jetting (MJ) Drop on Demand (DOD) |

Liquid photopolymers, wax, metals, ceramics, flexible plastics |

Incredible surface finish High dimensional accuracy Multi-color and multi-material printing |

Brittle parts High cost |

Full-color visual prototyping Medical devices Investment casting in jewelry |

|

Binder Jetting |

Sand Binder Jetting Metal Binder Jetting Plastic Binder Jetting |

Ceramics Metals Sand Plastics |

Large build volumes No need for supports Wide material range Fast and cost-efficient |

Metal parts require post-processing Risk of distortion during post-processing |

Visual and functional prototyping High-volume production Sand casting cores and molds |

|

Direct Energy Deposition |

Electron Beam Additive Manufacturing (EBAM) Laser Engineered Net Shaping (LENS) Cold Spray |

Metals in the form of wire or powder |

Good mechanical properties Large build volumes Wide material range |

Low resolution Rough surface finish |

Part repair in automotive, aerospace, and other industries |

|

Sheet Lamination |

Laminated Object Manufacturing (LOM) Ultrasonic Consolidation (UC) |

Sheets of metal, paper, or plastic |

High speed Low cost Multi-material printing |

Requires post-processing Low accuracy |

Non-functional prototyping |

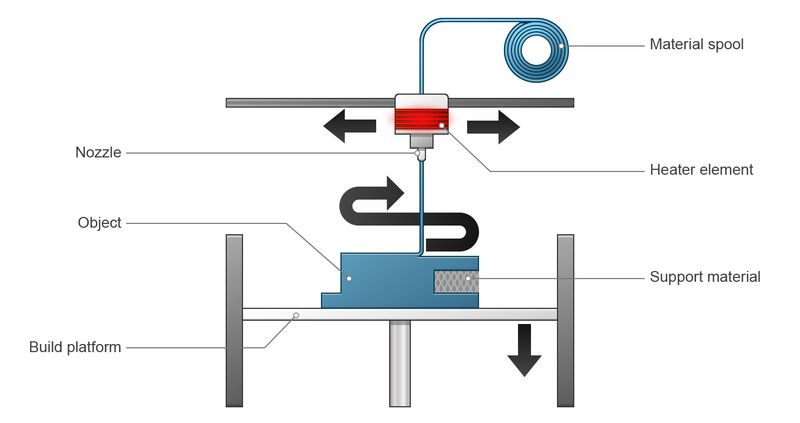

Material Extrusion is the process in which molten material is deposited through a nozzle, following a predefined path, to form a solid 3D object in a layer-by-layer manner. Material extrusion underlies one of today’s most popular 3D printing technologies, which is Fused Deposition Modeling, or FDM.

Credit: make.3dexperience.3ds.com

The FDM technology, also referred to as Fused Filament Fabrication (FFF), uses various types of thermoplastic polymers in the form of filaments that are fed through the printer’s nozzle onto the build plate. As the nozzle is hot, it melts the plastic, and the molten filament forms layers of the future model that solidify in the process of printing, while gradually cooling down. Some FDM printers, for example Creatbot PEEK-300, can reach the extrusion temperature of 500 °C, which allows printing with high-temp engineering plastics, like PEEK or Ultem. Being one of the most affordable and easy-to-use technologies, FDM printing is highly popular among hobbyists.

Credit: kimya.fr

One of the main advantages of FDM printing is the vast choice of materials with various properties. In most cases FDM printers work with different thermoplastic filaments, such as ABS, PLA, PETG, PET, TPU, Nylon, ASA, PC, HIPS, PEEK, PEI, and more. As various plastics require different printing conditions, the printer's range of compatible filaments is determined by several factors, the most important being its nozzle temperature, the presence of an enclosed build chamber and a heated print bed, and some others. Besides pure plastics, FDM machines can print with composite filaments reinforced with fibers, such as carbon, glass, or kevlar, to achieve even better physical properties of printed parts. Finally, FDM is capable of metal printing with such filaments as, for example BASF Ultrafuse 316L, which is made of stainless steel particles in a polymer base. Models built with such materials require further debinding and sintering to remove the plastic binder and get a full-metal part with excellent mechanical properties.

FDM printing often requires building support structures for parts with overhanging elements, hollows, or bridges. This means it is not the best option for printing models with complex geometries. The typical layer height of 100–400 microns implies you will need some post-processing if you want a really smooth surface finish. Industrial FDM machines can have huge build volumes that allow printing fairly large parts.

FDM printed parts have different mechanical properties depending on the material used. The common feature is their anisotropy which means their mechanical properties are directionally-dependent.

FDM printing is one of the most cost-efficient technologies both in terms of equipment and material cost. As for production speed, it is considered to be pretty fast for printing single parts, but does not give a gain in speed for batch production, like SLS or DLP printing.

Due to its low cost and short lead times, FDM is a perfect technology for prototyping, especially for form and fit testing, although industrial-grade machines are capable of making functional prototypes as well. The technology is widely used for fabrication of end-use parts, such as jigs and fixtures, electrical housing, and others.

Credit: @flyingpurplebovine / Instagram

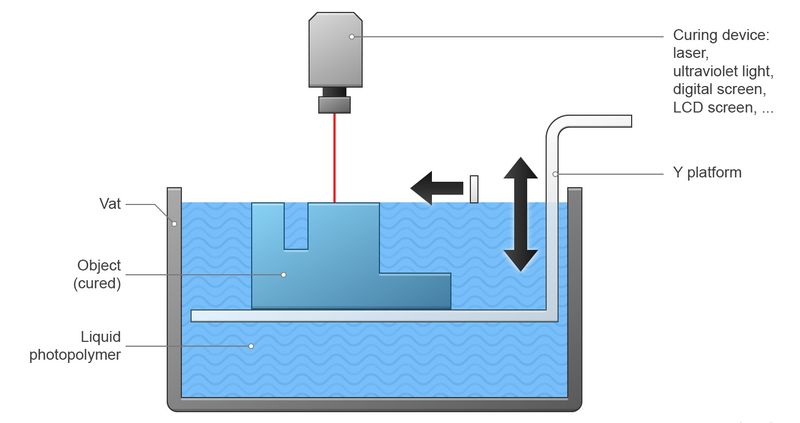

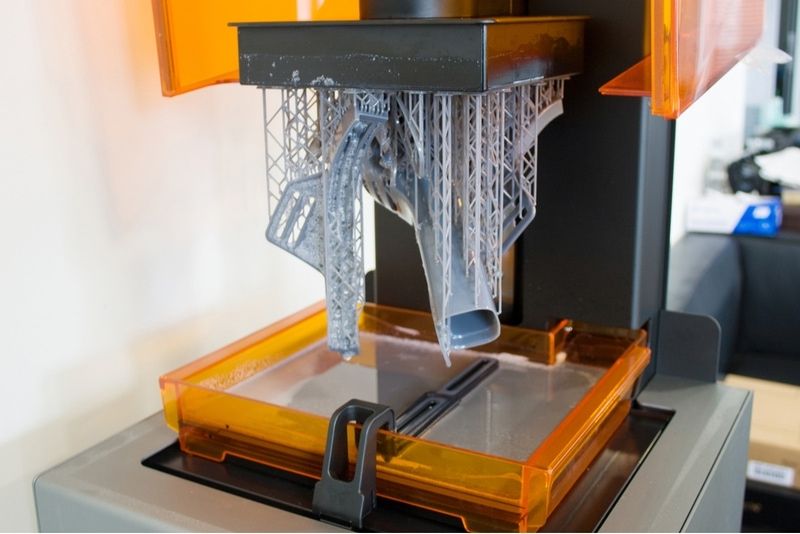

Vat Photopolymerization is the process of curing liquid photosensitive polymers by a light source of certain wavelength, most common being 405 nm. Before printing, a vat is filled with resin, and a thin layer of it on the build plate is selectively exposed to light to form a solid layer. As various light sources can be used for curing layers of resin, there are different corresponding technologies based on the Vat Photopolymerization process.

Credit: make.3dexperience.3ds.com

The first 3D printing technology ever, SLA, or Stereolithography Apparatus, employs a laser beam directed by a system of mirrors to selectively cure the resin in a point-to-point manner. Such a method ensures high precision but can take quite a long time to print a single layer.

DLP resin printers use a digital light projector and an array of micromirrors, directing the light, to flash an image of an entire layer, making it solidify all at once. It is significantly faster than SLA printing with its single laser beam, but the downside is the digital nature of the light source which results in the square shape of layer pixels (called voxels) and inability to create a perfectly round shape of the model surface. Yet, this drawback is hardly visible and the resolution of DLP printers is still higher than those based on many other 3D printing technologies.

Masked SLA is also called LCD which explains the printing mechanism used by these machines. The light source here is an array of LEDs emitting UV light through an LCD screen which serves as a mask, transmitting the light only in required areas. Like with DLP printers, the technology provides faster print speed than SLA and the same “voxel” issue (which is not really a problem in most cases). Thanks to its low cost, the LCD technology is widely used in consumer resin 3D printers.

Apart from the three technologies mentioned above, there are different modifications offered by manufacturers, like Low Force Stereolithography (LFS) developed by Formlabs.

Vat Photopolymerization 3D printers use photosensitive polymers, or resins, as printing materials. Besides general-purpose resins, there are materials with different physical, chemical, or visual properties, like transparent resins, tough, flexible, or biocompatible resins for medical applications. Wax-like castable resins are widely used in jewelry to produce high-quality mold patterns that burn out completely, leaving no residue. There are also ceramic-filled resins featuring high rigidity.

Credit: karkhana.io

Resin 3D printers usually have smaller build volumes than FDM machines. Most models require support structures, yet it is possible to build rather complex models, compared to FDM printing. An undoubted advantage of Vat Photopolymerization is its high print resolution with an incredible level of detail and perfectly smooth surface finish.

Vat Photopolymerization allows producing dimensionally accurate parts with high repeatability as well as air and watertight models. Printed parts always need post-processing, including at least support removal, washing and post-curing steps. Once fully cured, the printed models acquire optimal physical properties and isotropy.

DLP and LCD technologies are considered ones of the fastest and besides, they allow for considerable time saving when it comes to small and medium-batch production. As for the cost of resin printing, in general it can not be called cheap, and while the printers gradually become more affordable, the material cost remains fairly high.

The process of Vat Polymerization is ideal for visual prototyping and end-use part fabrication, when smooth surface finish and overall appearance of the model are a priority. It is suitable for applications requiring high resolution, like manufacturing of patient-specific dental appliances or mold patterns in jewelry. Resin printing is a go-to option for makers due to the flawless model’s look and feel.

Credit: amfg.ai

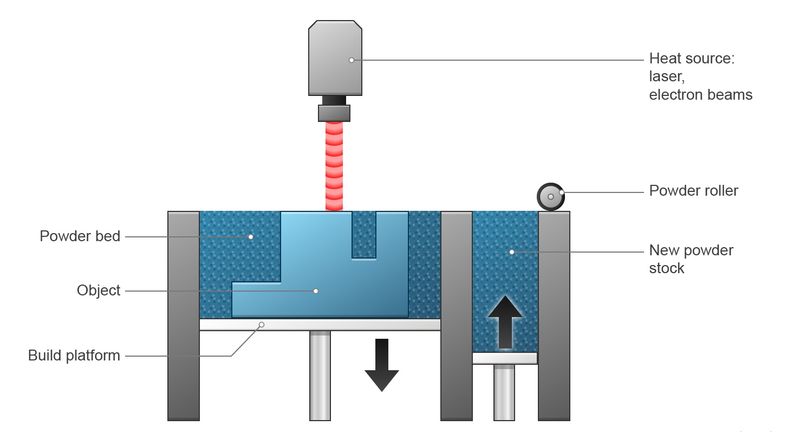

Powder Bed Fusion is an additive manufacturing process in which selected areas of a plastic, metal, or ceramic powder layer are fused by a thermal energy source. Before printing, the build chamber is filled with material and pre-heated. Then a thin layer of powder is deposited over the print bed and selectively heated to fuse powder particles together and form a solid layer. The print bed lowers to a single layer height, and the process repeats until all the layers are built. The unfused powder serves as a support for the model being printed, so there is no need for additional support structures (with the exception for metal printing, more of that below). There are various 3D printing technologies based on the Powder Bed Fusion process, differing in the energy source, powder type, and the degree of fusion between powder particles, which can be melted to form a homogeneous part or only sintered at the temperature just below the melting point.

Credit: make.3dexperience.3ds.com

SLS is the most common Powder Bed Fusion technology for processing polymer powders. The powder particles are heated by a CO₂ or fiber laser (or lasers) and sintered together to form a solid object layer by layer. The unsintered powder can be collected and reused for the next prints.

DMLS and SLM technologies work in the same way as SLS printing, but they use metal and metal alloy powders instead of plastics. Metal printing requires higher processing temperatures, so it often needs building support structures to avoid any distortion of the model. Metal parts usually undergo heat treatment to eliminate the residual stress and achieve the best mechanical properties.

Electron Beam Melting is used to process metal powders with the help of a focused electron beam. Only conductive metals can be printed this way and the whole process should be performed in a vacuum. The print speed is usually faster compared to SLM / DMLS printing as the EBM technology uses a higher density energy source.

Credit: eurekalert.org

MJF is HP’s proprietary technology for printing with thermoplastic powders. After a layer of powder is spread over the print bed, an array of inkjet nozzles runs across the print area to deposit both fusing and detailing chemical agents onto the powder in selected areas. Once it's done, an infrared heating unit melts the areas with the fusing agent while leaving unfused the areas where the detailing agent was applied. The technology does not need building supports, and features fast print speed and perfect layer adhesion, as each layer is fused together with the previous one to achieve absolute homogeneity.

Depending on the technology, the Powder Bed Fusion process uses different materials in a powder form.

SLS and MJF printers use thermoplastics, such as Nylon, which is by far the most common, PP, or flexible materials.

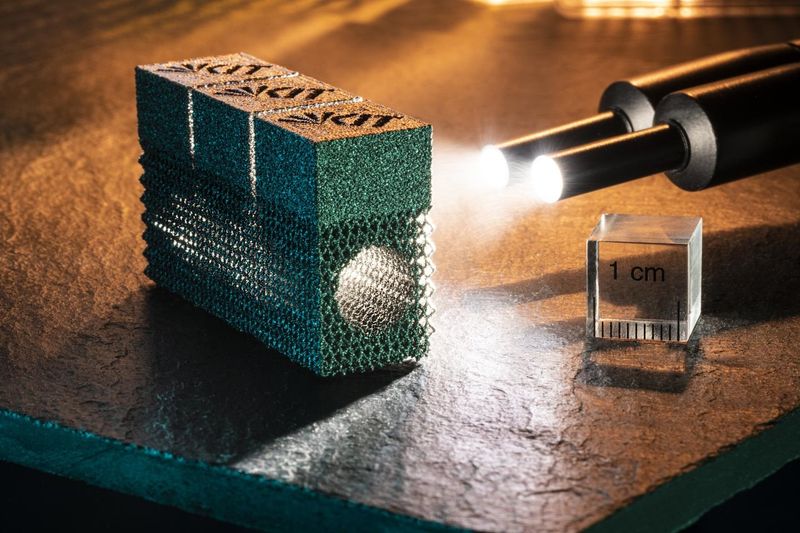

Metal 3D printers utilize metal or metal alloy powders, such as steel, aluminum, titanium, cobalt, inconel, or copper to name a few.

Ceramic powders, such as alumina, silica, or dental porcelain, can also be printed this way.

Credit: inspire.ethz.ch

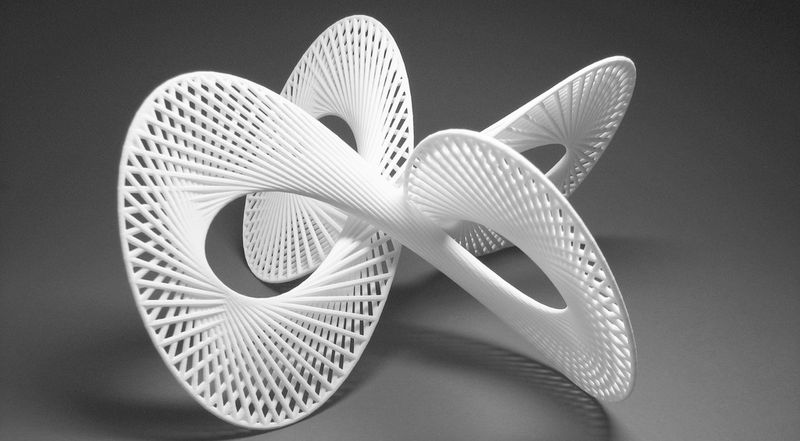

Powder Bed Fusion can produce parts with very complex geometries and a lot of inner hollows as well as functional moving parts and assemblies. Unlike FDM, it allows making use of the entire build chamber volume as the unsintered powder serves as a support for parts being built. The PBF-based technologies provide dimensionally accurate parts with high resolution.

Both plastic and metal PBF parts have excellent mechanical properties comparable with traditional manufacturing methods. It is possible to produce fully functional durable models featuring high strength.

In terms of speed, PBF 3D printing technologies are not so fast while printing a single model, but they are extremely time-efficient for batch manufacturing.

The technology is used only for industrial printing and the PBF machines are fairly expensive so far.

Due to its ability to produce moving parts with complex geometries, PBF printing is ideal for functional prototyping and low-volume manufacturing of end-use parts in various industries, such as automotive, machinery, aerospace, and others. Metal printing is also widely used in medicine to produce dental appliances, prosthetics, and surgical tools.

Credit: tmrblog.com

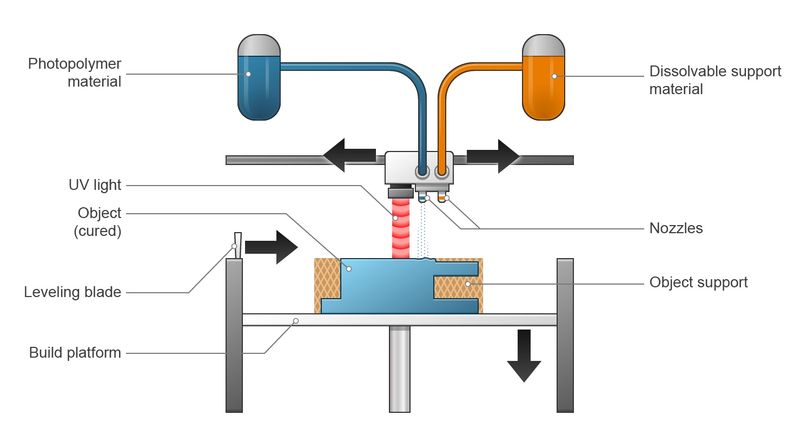

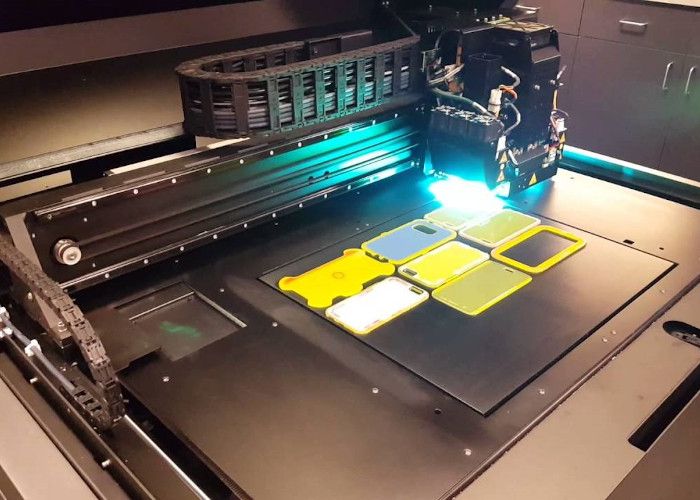

Material Jetting is a process in which tiny droplets of liquid material are selectively deposited onto a build plate and cured by heat or UV light. The material is fed through a print head with hundreds of jets, which allows for multi-material and multi-color printing as well as for building soluble support structures.

Credit: make.3dexperience.3ds.com

Material Jetting printers are equipped with a print head that jets lines of photopolymer resin droplets which are cured by UV light. Once the first layer solidifies, the build platform descends and the process repeats layer after layer. MJ printing requires support structures that are built simultaneously with dissolvable support material and then removed.

Credit: additive-manufacturing-report.com

DOD is a material jetting technology developed specifically for wax printing. The printer is equipped with two inkjets — one for the main material, and the other for soluble support printing. The technology allows for high dimensional accuracy and is used for investment casting in jewelry manufacturing.

Material Jetting uses various liquid materials depending on the technology. The most common are photopolymer resins and wax, but flexible plastics, ceramics, and metals can also work for this process.

Material Jetting printers can make pretty large parts with rather complex geometries. The printed models have very tight tolerances and incredibly smooth surface finish.

Despite the impressive appearance and dimensional accuracy, the models lack strength and are pretty brittle.

Material Jetting is rather expensive and is not as popular as FDM or SLA printing. The print speed is decent enough and can be compared to PBF printers.

As Material Jetting technologies are too expensive for everyday printing, they are mostly used for applications where visual appearance and extreme precision are of great importance. MJ printers are used for full-color visual prototyping, medical devices, or jewelry manufacturing.

Credit: 3dnatives.com

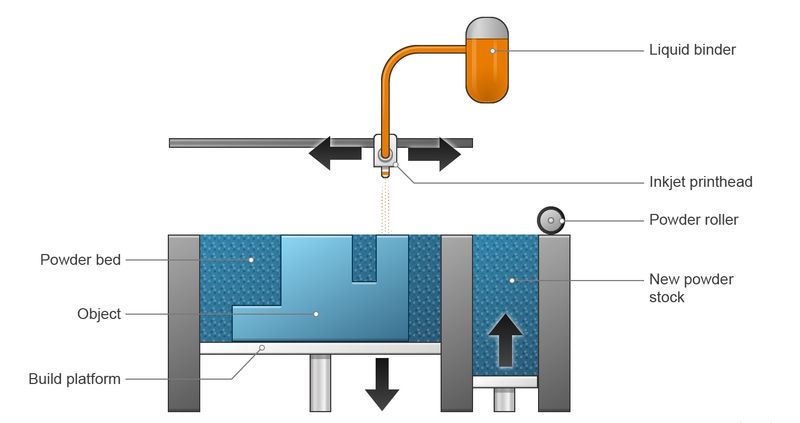

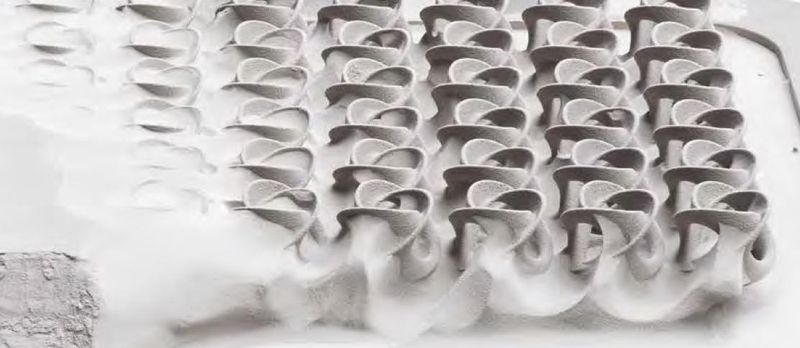

Binder Jetting is similar to PBF technologies, where a build chamber is filled with powdered material which is deposited over the print bed in a fine layer. Unlike the PBF process, when a source of thermal energy is used to harden the material, in Binder Jetting droplets of liquid bonding agent are deposited onto the build platform in selected areas to bind the powder particles together and form a solid layer. Once the model is complete, it is left in the powder to cure and acquire optimal strength.

Credit: make.3dexperience.3ds.com

Sand Binder Jetting is a fast and low-cost method of cores and molds fabrication in the foundry industry. The molds are usually ready for casting as soon as they have been printed and are broken apart after casting to remove the metal model. The technology allows for complex designs without building support structures and very fast print speeds.

Credit: pick3dprinter.com

Metal Binder Jetting is a low-cost method of 3D printing complex metal parts that do not require support structures. The printed models consist of metal powder and polymer binding agent. Immediately after printing the models are in a so called “green state” and need post-processing. The post-processing involves heat treatment in a furnace to eliminate the polymer and the following infiltration of the voids, left after removing the polymer, with bronze, which results in strong parts with low porosity.

Plastic Binder Jetting technology is very similar to Metal Binder Jetting with the use of polymer powder and liquid binding agent instead of metal powder. Plastic parts are generally ready to use once printed, but they can also be infilled with other material if needed.

The most common materials for Binder Jetting are metals, sand, plastics, or ceramics in a powder form. Potentially, Binder Jetting can be used with any materials that can be powdered. There are cases of using this technology to print with sugar and wood powder.

Credit: exone.com

Binder Jetting printers have huge build volumes and allow printing models with complex geometries without the need for support structures. The models boast high resolution, but dimensional accuracy can become a problem when printing with metals because of high shrinkage during post-processing.

Metal parts are weak and brittle in their “green state” but they acquire strength and density after post-processing.

Binder Jetting is definitely cost-efficient compared to other 3D printing technologies and traditional manufacturing methods. It is also fast and due to large build volumes, is capable of high-volume manufacturing.

Binder Jetting is good for prototyping and manufacturing parts with complex geometries. It is incredibly cost-efficient for high-volume printing. Sand Binder Jetting is ideal for casting mold fabrication.

Credit: amfg.ai

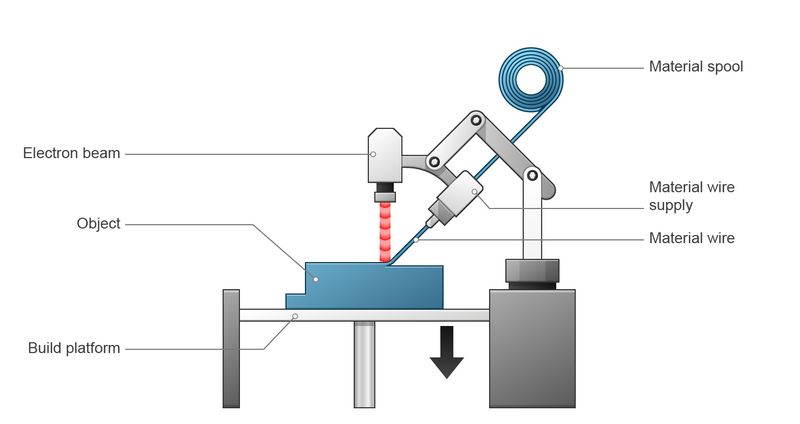

Direct Energy Deposition is a process in which focused thermal energy is used to fuse materials at the point they are being deposited. The material, which is usually metal in the form of wire or powder, is extruded through a nozzle and fused by an energy source. The energy source can be a laser, an electron beam, or a plasma arc. There are 3 or 5-axis DED machines. In 5-axis printers the nozzle is not restricted to building parts layer by layer but can deposit material from any angle. That is why DED technology is often used to repair the existing parts rather than to build up new models.

There are a number of technologies associated with the DED process developed by different manufacturers.

Credit: make.3dexperience.3ds.com

The EBAM technology is very similar to FDM printing as it uses metal wire and an electron beam to melt it. The most common material for this technology is titanium, widely used for medical implants, such as artificial joints. Alloys of copper, titanium, cobalt, and nickel are also popular.

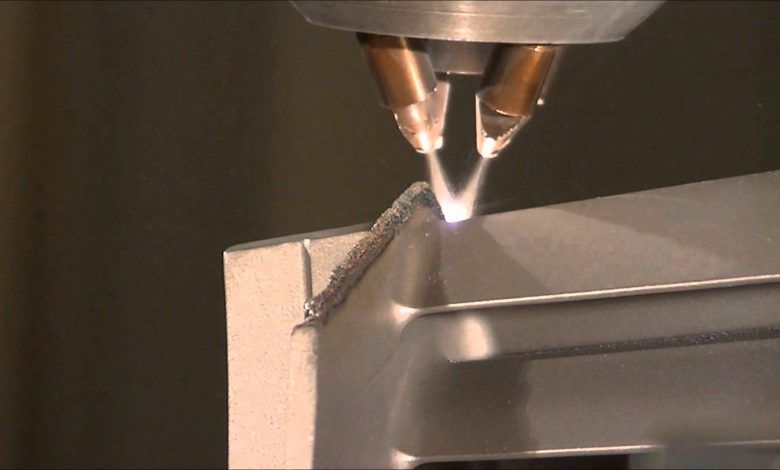

The LENS technology uses metal powder which is sprayed through a nozzle and melted with a powerful laser. The printing process requires an enclosed build chamber as it uses an inert gas (usually argon) to eliminate oxygen and moisture to avoid surface oxidation and achieve better layer adhesion. Among metals, most often used with this technology, there are titanium, stainless steel, aluminum, and copper. Repairing aerospace and automotive components is the common application of the LENS technology.

Credit: 3dprintingmedia.network

Cold Spray is not a typical DED technology as it does not use any thermal energy source to melt the material. In Cold Spray printing, the metal powder is deposited at supersonic speeds to bond the particles using its own molecule velocity. This results in the absence of thermal stress in the printed parts.

Materials used for the DED process are generally powder or wire forms of metals, including stainless steel, titanium, aluminum, nickel, and others.

DED printers can feature very large build volumes. Support structures are difficult to build, so the DED process does not normally imply building complex geometry models. The resolution is not the strong point of this technology as well as the surface finish which is pretty rough and needs post-processing.

DED 3D printers are capable of producing metal parts with good mechanical properties, comparable with forged models, but featuring residual stress that can be eliminated by post-processing steps.

All DED technologies are rather fast and the material cost is quite reasonable.

The DED process is most often used for part repair in the aerospace, automotive, heavy machinery, and other industries. It can also be employed for functional prototyping and end-use part manufacturing, but due to the relatively low resolution, models often require serious post-processing.

Credit: sciaky.com

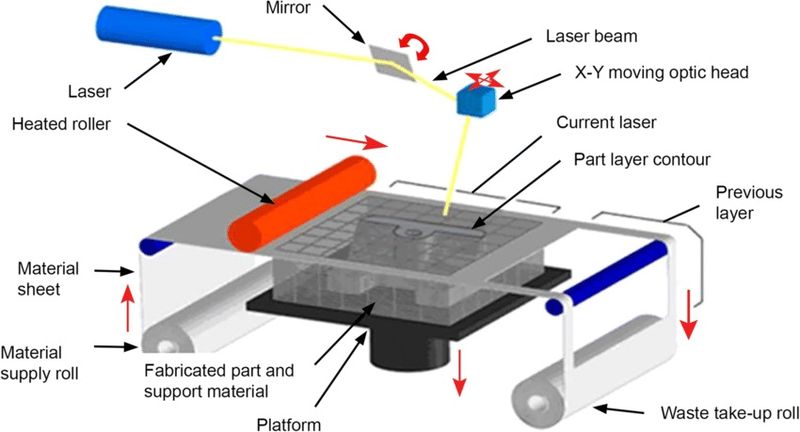

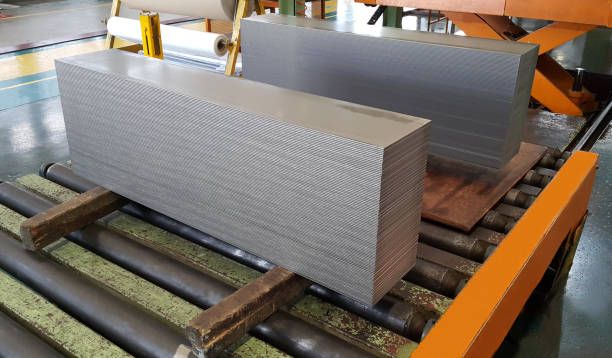

Sheet Lamination is a process of bonding thin sheets of material to form a 3D object. Different sheet lamination technologies use various materials and lamination methods, such as bonding agents, heat, or even sound. In most cases sheets of material are laminated and then cut to size. The method is one of the fastest and low-cost of all 3D printing technologies, but it lacks accuracy and requires post-processing.

Credit: researchgate.net

LOM is the most common technology based on Sheet Lamination. Sheets of material are bonded with an adhesive and then cut using a laser cutter, a CNC router, or a water-jet cutter.

Credit: omnexus.specialchem.com

Ultrasonic Consolidation works with metal sheets and bonds them by means of ultrasonic vibrations. After that a CNC router is usually used to cut the model to size.

The technology uses paper, polymer, or metal sheets and various bonding methods.

The Sheet Lamination technologies do not usually allow for complex structures, and accuracy is not their strong point.

Printed parts are not strong enough to be used as functional prototypes. The technology is capable of building composite models combining different materials and colors in a single part.

High print speed and relatively low cost are the reasons to use Sheet Lamination in the production cycle.

The Sheet Lamination process is mostly used for non-functional prototyping.

Credit: pick3dprinter.com

Micro 3D printing is a relatively new technology that produces parts with micron-sized features. The technology requires the use of special 3D printers capable of very high resolution and small layer height. Some technologies make it possible to print parts which are measured in nanometers. Most micro 3D printing technologies are based on polymerization of photosensitive resins but some other materials are also used for printing extremely small parts. We will talk about the most popular micro 3D printing technologies.

Credit: @bmf3d / Instagram

Microstereolithography works pretty much the same as common SLA 3D printers which cure layers of photosensitive resin with a laser beam. The difference is in the use of special resins and the laser capable of generating extremely small light points. The technology finds its application, for example in medicine or microoptics.

As with µSLA, the Projection Microstereolithography is similar to DLP 3D printing technology where a digital light projector is used to cure a layer of photosensitive resin all at once.

The Two-Photon Polymerization is regarded as the most accurate micro 3D printing technology capable of a resolution of less than a micron. The technology prints with acrylic and epoxy resins and uses a femtosecond laser to cure the resin. Application range for the technology includes medical printing, microoptics, micromechanics, and other fields.

In Lithography-based Metal Manufacturing, metal powder is evenly dispersed in a vat of photosensitive resin and exposed to blue laser light. The “green” parts are debound to remove the polymer and then sintered in a furnace. The list of compatible materials includes steel, titanium, tungsten, brass, copper, silver, and gold. Such industries as aerospace, semiconductor manufacturing, or watch-making will definitely benefit with the development of micro metal 3D printing.

Credit: metshape.de

Update your browser to view this website correctly. Update my browser now

Write a comment