Rapid development of additive manufacturing leads to considerable changes in a lot of industries. Some of them use 3D technologies at all the stages of production, starting with 3D scanning and then employing 3D printing for prototyping or end-use parts production. Jewelry is one of the fields where digital technologies have only started their expansion, often being a bridge to traditional methods.

Credit: n-e-r-v-o-u-s.com

The craft of jewelry is as old as time, and it has always involved a lot of skill and time spent on every single item creation. Besides, there are always limitations to human possibilities — however skillful a craftsman was, some most intricate design concepts could only exist in their imagination.

Credit: Pinterest

With 3D printing development, more and more people in the jewelry industry are discovering the opportunities it provides both from the artistic and business perspective.

The traditional method of jewelry manufacturing implies lost-wax casting. Casting patterns creation is an expensive and time-consuming part of the process, and this is where 3D printing can be of great help, becoming a bridge to conventional manufacturing. What’s so good about using digital technologies in such a traditional field? Let’s see.

Credit: fastcastings.com

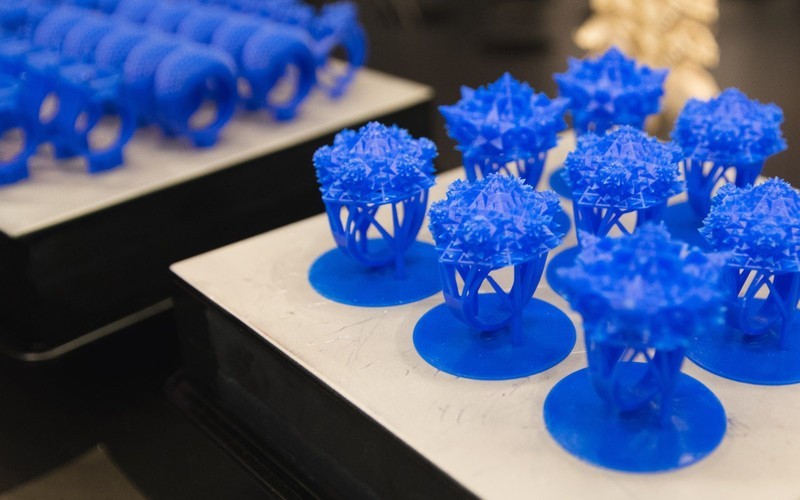

As mentioned, there are certain design limitations in traditional production of casting patterns that are made either by hand or using CNC machines. With digital design opportunities and 3D printers capable of reproducing the digital models with extreme precision and accuracy, it’s now possible to create wax casting patterns of any complexity. The use of 3D printing has brought up new standards in the art of jewelry, allowing for the designs that could have never been realized before.

Credit: indiamart.com

Customization is of considerable importance in jewelry as customers often want to get one of a kind adornment. 3D printing provides vast opportunities for custom products, either created from scratch, or by adjusting the already existing design according to the customer’s wish. The customization process doesn’t require additional costs and takes considerably less time and effort than in traditional production, where any changes made upon the product jacked up the price.

Credit: sculpteo.com

With 3D printing, customers have a try-on option to make sure the model fits perfectly and completely meets all their needs, before the final part is made. Printed resin prototypes are affordable and quick to make, they feature high quality and precision and can give the true-to-life impression of the future model.

Credit: additive-plus.com

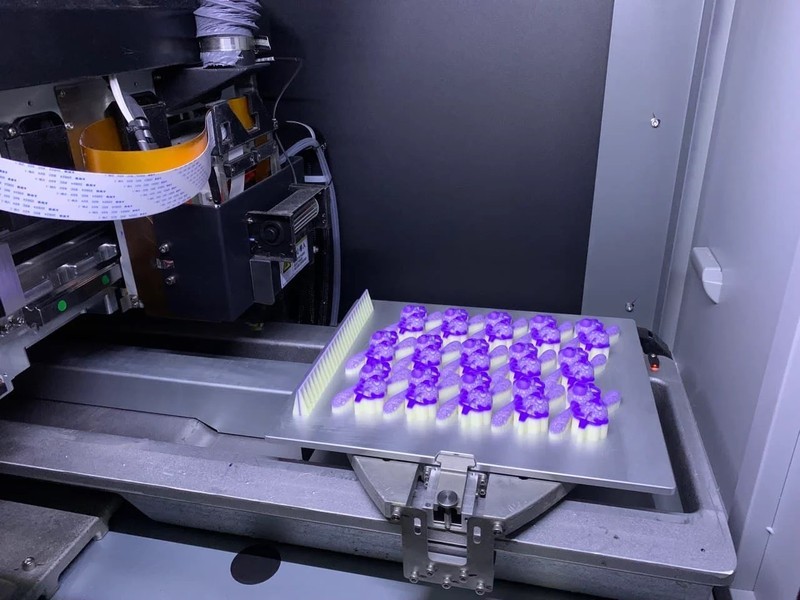

Batch-manufacturing in jewelry 3D printing allows reducing the production costs, as a whole run of wax patterns can be printed in one go, thus saving material and shortening the production time; you can also print different designs at a time. All this makes jewelry manufacturing more cost-effective than ever before.

Credit: hubs.com

Basically, there are two ways of implementing additive manufacture into the jewelry business, namely direct and indirect 3D printing, the former being less common, at least for now.

Direct 3D printing of jewelry implies using metal (SLM or DMLS-based) printers to build the final parts right from the digital models, created in CAD software. The parts can be printed with gold, silver, or platinum alloys or other metal powders. Such an approach completely excludes traditional techniques from the production cycle and turns it entirely digital.

Credit: Pinterest

Despite all the general advantages of 3D printing, discussed above, this particular method is not very popular as it is more expensive than investment casting, and the printed parts require significant post-processing. Besides, precious metals are very difficult to print as they are highly reflective and thermally conductive. So, there are few printers in the market that can work with them. Still, rapid progress in digital technologies can change the situation for the better.

In this method, 3D printing is used to optimize the traditional lost-wax casting process to speed up the production and make it more flexible and cost-effective.

Credit: reddit.com

For direct metal printing, SLM or DMLS printers are used. However, very few of them can work with precious metals alloys, so other metals, like steel or bronze, can also be used.

Some jewelers create their collections using SLS technology, printing unique modern jewelry pieces with nylon or polyamide.

Credit: dianalaw.com

3D printing of wax casting patterns requires exceptional precision and accuracy, as well as the use of appropriate wax-like materials that can be completely melted or burnt out afterwards. So, the best options possible here are resin or material jetting technologies.

Now let’s see which printer models are the most suitable for jewelry manufacturing.

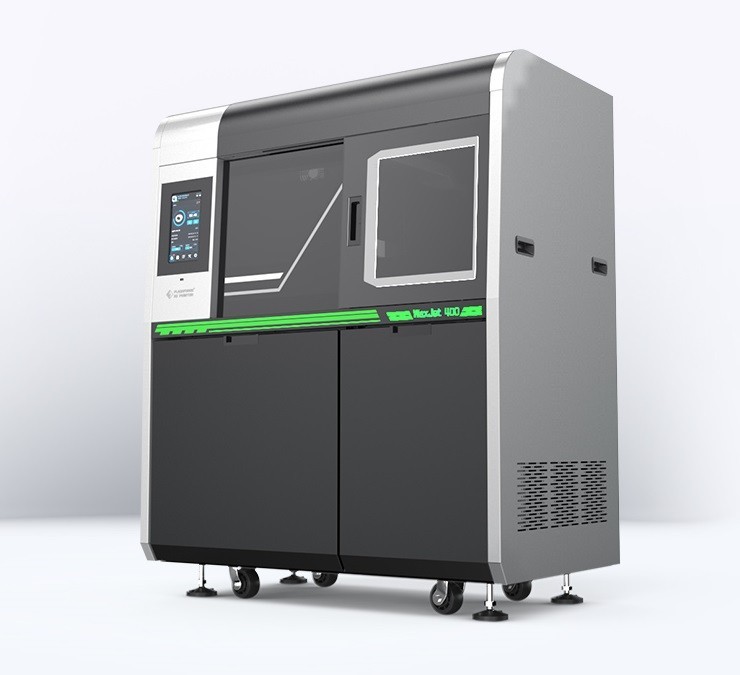

The Flashforge WaxJet 400 is a professional 3D printer based on MJP (MultiJet Printing) technology. It prints wax casting patterns for investment casting and works with proprietary materials for parts and support structures printing. The device can print layers at the height of 16 microns with the printing resolution of 1200 x 1200 x 1600 dpi and the accuracy of ±0.04 mm / 20 mm, which provides accurate highly detailed models with smooth surface finish. The large build volume of 289 x 218 x 150 mm allows printing multiple models in one go and together with fast print speed makes for high productivity of the WaxJet 400.

The Phrozen Sonic 4K 2022 is a large resin 3D printer designed for the dental industry, and it absolutely meets the requirements of jewelry production. It sports a monochrome LCD matrix with a resolution of 3840 x 2160 and a build volume of 135 x 75 x 200 mm. The optical system of the device has been improved compared to the previous models. The Phrozen Sonic 4K is equipped with a powerful ParaLED® 3.0 module which provides uniform light exposure and, consequently, uniform layer thickness over the entire area of the print. The minimum layer height of 10 microns ensures exceptional print quality. Phrozen offers a choice of castable resins that can be used with the Sonic 4K 2022 to print mold patterns for investment casting.

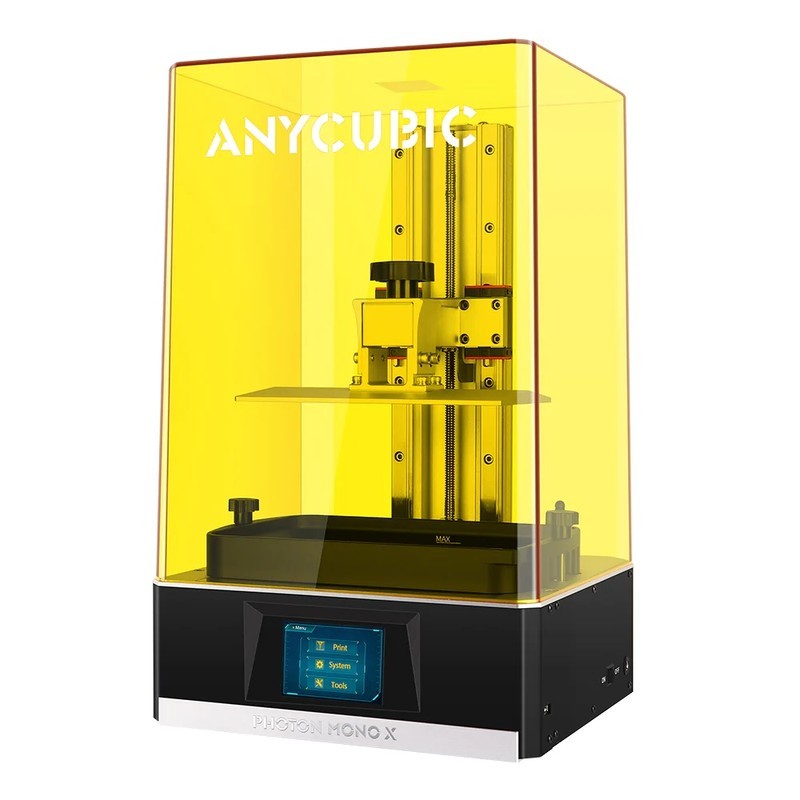

Credit: @georgebulte / Instagram

The Anycubic Photon MonoX is a large-format resin 3D printer based on LCD technology. Uniform light exposure over the entire print area is provided by the 8.9" 4K LCD screen and a new parallel light source. The build volume of 192 x 120 x 245 mm and fast print speed stand for high productivity, while the 10-micron minimum layer height allows printing high quality casting patterns for jewelry manufacturing. For better performance and more convenient post-processing the Photon Mono X can be supplemented with the Anycubic Wash and Cure Machine 2.0.

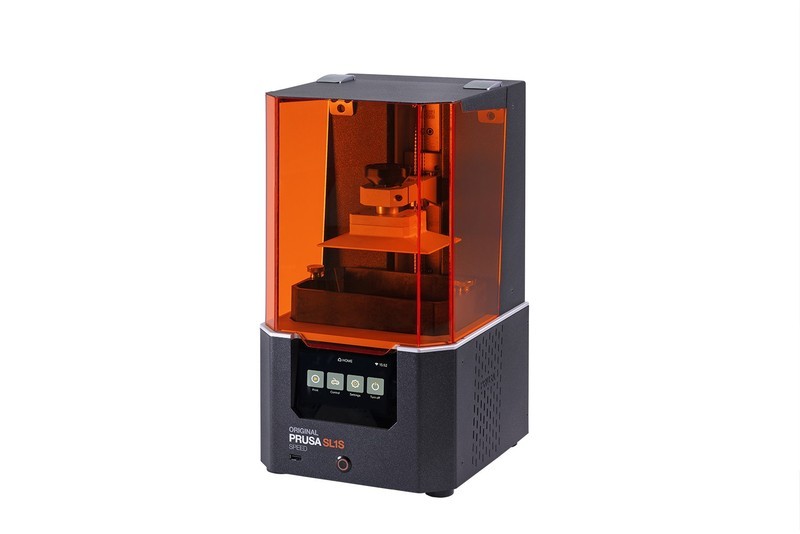

The Original Prusa SL1S Speed is an LCD-based resin 3D printer featuring a 5.96'' monochrome LCD screen with 2560 x 1620 resolution and a new optical system with a four times more powerful UV LED panel than the previous SL1 model. The print speed of the SL1S Speed is remarkably fast — the curing time for a single layer is just 1.4 seconds. Fast accurate printing and compatibility with different types of 405 nm UV resin make the Prusa SL1S a great option to use in jewelry for casting patterns production. The printer can be bought stand-alone or as part of a special bundle of the Original Prusa SL1S 3D printer and the Curing and Washing Machine.

The Farsoon FS273M is an MLS (metal laser sintering) industrial 3D printer featuring rather compact size for a professional machine, still high throughput and impressive build volume which is a cylinder of 275 x 275 x 355 mm. The FS273M can be equipped with a single or dual 500W fiber laser and a high-precision digital galvo system, and can print layers at the height of 20 microns providing detailed precise models that are a must while printing jewelry. The printer is an open material system and is compatible with a great variety of proprietary and third-party metal powders, some of them being suitable for printing end-use jewelry pieces.

The BLT-S210 is an SLM 3D printer capable of printing with a large number of metal alloys, including Titanium, Aluminum, Cobalt Chromium, Stainless Steel, Copper, and a lot more. The 500W laser and F-Theta optical system ensure high-quality metal parts with excellent mechanical properties and repeatability. The compact build area of 105 x 105 x 200 mm is perfect for batch-manufacturing of small jewelry items or for printing larger parts. Operation and maintenance of the device are easy and convenient due to the modular design of the S210. The printer is an open-parameter system, so the user is able to edit 294 parameters to precisely adjust the printing process and get the best result possible.

The use of additive manufacture technologies in jewelry has given a boost to the industry development and set up new standards in jewelry design. The possibility to print objects of extremely complex geometries and ultimate customization options open unlimited opportunities for the designers and provide the customers with absolutely new fascinating jewelry pieces.

Update your browser to view this website correctly. Update my browser now

Write a comment