3D printers, wondrous smart machines capable of reproducing various details and products directly from computer files, are rapidly replacing conventional fabrication techniques such as die-casting, milling and grinding, allowing you to quickly create literally anything from prototypes of engine parts to individual smartphone cases. In this article, we will speak about the most popular high-precision 3D printers.

There are several ways of how a business can benefit from 3D printing. For example, such a machine can produce details and products of superior precision. In fact, if you see some model on the screen, a powerful 3D printer can meticulously reproduce it turning a 3D picture into a real-world object.

3D printing often allows you to forget about the tried-and-true methods of casting, molding, milling and finishing products using subtractive-fabrication processes that let a significant part of the material be wasted. A 3D printer, to the contrary, builds an object directly from a CAD file through additive manufacturing technologies where a whole part is produced at a time.

In other cases, 3D printing can effectively complement these processes, for example, when creating prototypes and master models of future products.

3D printing technology is used not only for the fabrication of plastic objects, but it is quickly harnessing new materials including metals and composites based on carbon and glass fibers. Think of 3D printing as the equivalent of a laser printer with an ability to reproduce real objects, not just paper documents.

The speed, efficiency and quick ROI of 3D printing can revolutionize the entire industrial landscape. You no longer need to concoct or purchase special forms or tools – with a proper 3D printer at your fingertips you can simply print the necessary detail or instrument.

Along with specific fields of application and a certain printing technology, each 3D printer also has such an important parameter as resolution. This feature indicates the minimum feature size or the level of the object’s details that can be produced by this machine using a specific material. For example, an FDM printer can have a resolution of 100 microns along the Z-axis, that is, a layer thickness, but its level of detail is not that high along the X and Y axes.

Need greater accuracy? The resolution can be increased up to 75 or even 50 microns that is equal to the thickness of a human hair. Some advanced stereolithography printers provide resolution of up to 16 microns, which is far thinner than pollen.

Finally, there is a new generation of 3D printers that can fabricate objects up to a micron by size, which is equal to 1/2000 of human hair thickness. Today there are special devices that are used in the creation of high-precision turbine blades or micro-optics, but soon these machines will also be used for the production of prostheses and minuscule machines.

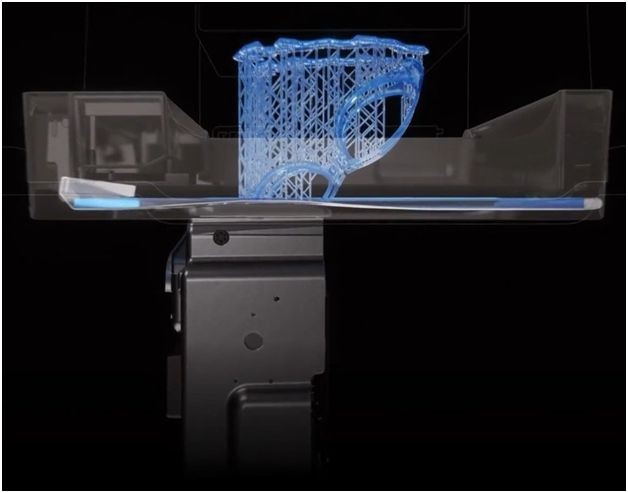

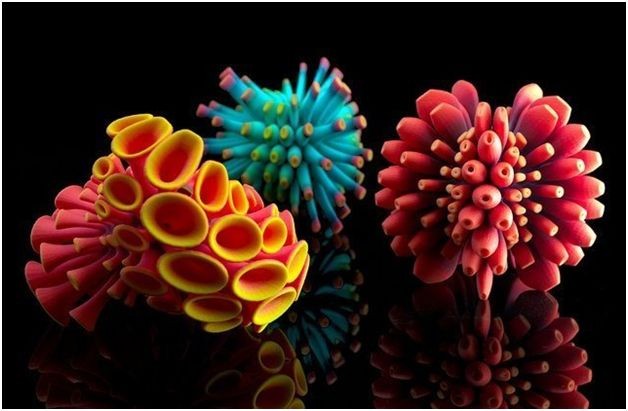

In the photo: An example of high-precision 3D printing.

FDM or Fused Deposition Modeling is the easiest method adopted by extrusion machines. They work by melting the thread of material and creating a layer of the element on the working platform through the precise movements of the extruder. After completing one layer, the platform makes one step down or the print head rises one step up (a step is equal to the layer thickness), and printing is repeated. Generally, FDM technology involves the use of several extruders – some for working materials, the others – for support materials, which will then be removed.

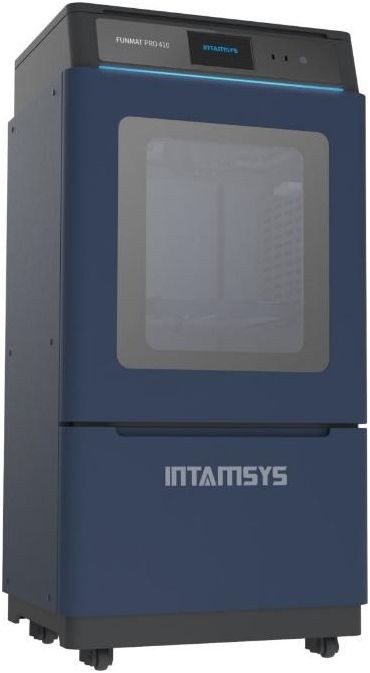

SPECIFICATIONS

FUNMAT PRO 410 gives you the possibility to print using a wide range of engineering and structural materials such as PEEK, polycarbonates, ABS, composites and many others. This printer allows you to print end-use functional parts of fairly large dimensions of 305 × 305 × 406 mm.

Other remarkable features of this apparatus include dual-extrusion 3D printing, layer resolution up to 50 microns, the support of more than 20 high-quality materials, maximum nozzle temperature up to 450° C, mounting plate temperature up to 160° C and a stable work chamber temperature of 90° C.

Along with pro-grade capabilities, FUNMAT PRO 410 is notable for its ease-of-use, which is ensured by the automation of many functions, such as the table auto-leveling, alerts on a stuck or improper thread, automatic nozzle cleaning and printing resume after power failure.

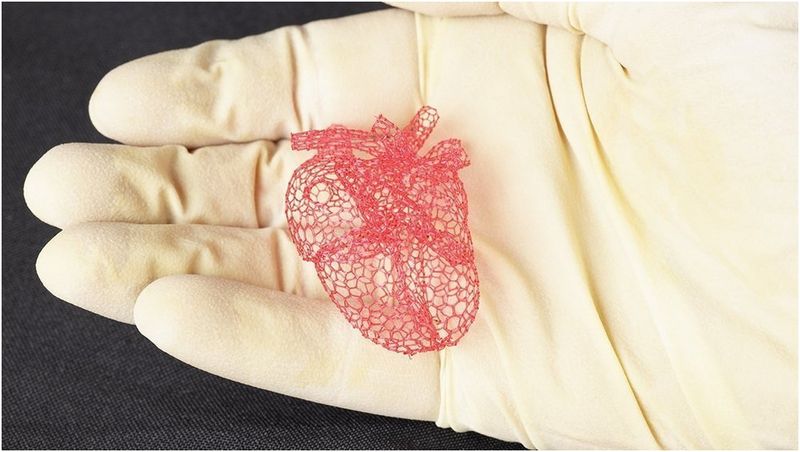

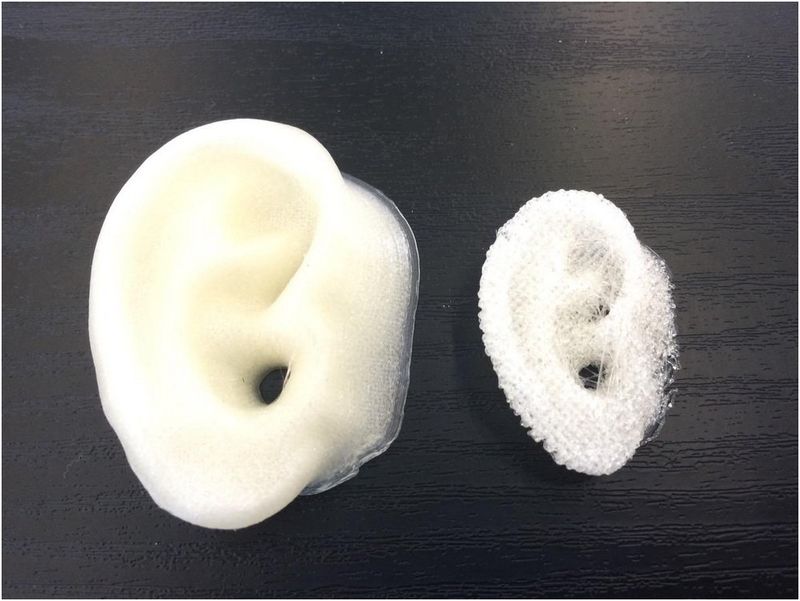

3D bioprinting for the production of biological structures involves a gentle application of living cells layer-by-layer as well as preparations to ensure their growth on bioinert or biocompatible carcasses. The 3D-printed tissue is then placed in an incubator where it will completely mature. Like traditional ink printers, bio-printers have three main components: high-precision technical means of applying materials, bio-ink (a preparation made from living cells) and biomaterial for printing the objects.

3D bioprinting uses inkjet printing and high-precision extrusion. Inkjet bio-printers are typically used to quickly print relatively large objects. Similar to conventional 3D printers, extrusion bio-printers print cells in layers. Moreover, extrusion bio-printers can use hydrogels together with living cells.

SPECIFICATIONS

Rokit Invivo is a groundbreaking 3D printer for bio-printing designed to promote and accelerate the research efficiency in the field of tissue engineering and regenerative medicine.

The mode of action of Rokit Invivo 3D bioprinter involves the creation of three-dimensional cell structures through printing solid tissues on carcasses using bio-ink for the creation of soft tissues.

Rokit Invivo is the world’s first hybrid and modular 3D bio-printer that enables the researchers to easily use different materials and elements to facilitate the rapid creation of living tissues.

SPECIFICATIONS

Electron Beam Additive Manufacturing (EBAM) by Sciaky is a unique 3D printing technology for metal products, most suitable for the manufacture of heavy high-precision metal details. EBAM allows for the production of top-quality large-sized metal structures made of alloys based on wolfram, titanium, tantalum, and nickel in a matter of days and with very low material consumption.

An electron beam gun with a power of up to 42 kW applies the molten metal layer by layer until the detail takes the necessary shape. The positioning of the beam with the help of an electromagnetic field instead of the mirrors system allows for achieving exceptional accuracy due to the lack of mechanical focusing.

The EBAM dual wire feed system makes it possible to combine two different metal alloys in one molten pool and change the proportion of the material components depending on the characteristics the finished detail should have. Moreover, to speed up the printing process, it is possible to change the diameter of the applied wire – to use the thin wire for high-precision details and the thick for details not requiring exact accuracy.

EBAM printing is carried out in a vacuum environment, meaning it does not require the use of argon or inert gas to protect objects.

The printing speed varies from 3.18 to 11.34 kg of metal per hour, depending on the chosen material and the objects’ complexity.

Today EBAM allows for printing details and structures up to 5.79 m × 1.22 m × 1.22 m in size or round details up to 2.44 m in diameter. The dimensions of printed objects are restricted only by the capacity of the vacuum chamber.

By default, the printer applies strips of 10 × 3 mm, but the resolution can be improved to a width of 1 mm and a thickness of 0.3 mm.

There is also a video camera for quality control in the print area.

CBAM technology is often called the fastest way to get 3D objects from 2D layers.

CBAM 3D printers use long-fiber sheets (rolls) of carbon or fiberglass alloyed with thermoplastic powders to create high-endurance composite details.

The layer images received by the printer from the AutoCAD development system are printed on the sheets of material, and the process is similar to how the inkjet printer prints images. Once completed, the layer is coated with a binding polymer, and the next layer of material is applied on top of the previous.

When the printing process is finished, the resulted layers go through compressing and high-temperature processing, which sinters the newly-minted layers into a single whole object. Surplus materials are removed by chemical treatment.

SPECIFICATIONS

The obtained polymeric fiber composite detail is significantly stronger compared to most other parts derived through 3D printing. CBAM-2 can produce carbon and fiberglass composite objects using PEEK, Nylon and many other industrial-grade polymers. At the same time, this printer can create objects tenfold quicker than other 3D printing technologies at a speed of 45 cubic inches per hour.

Unbeaten advantages of Impossible Objects CBAM-2 3D printer include:

SLA (SL) is a layer-by-layer 3D printing technology based on the solidification effect of a special polymer resin on exposure to light. In the process of a detail fabrication, an ultraviolet (UV) laser focuses on the necessary points in the basin with photopolymer resin, which leads to its solidification and the formation of a layer of the object to-be. Surplus resin is removed from the finished object using a special solvent.

SPECIFICATIONS

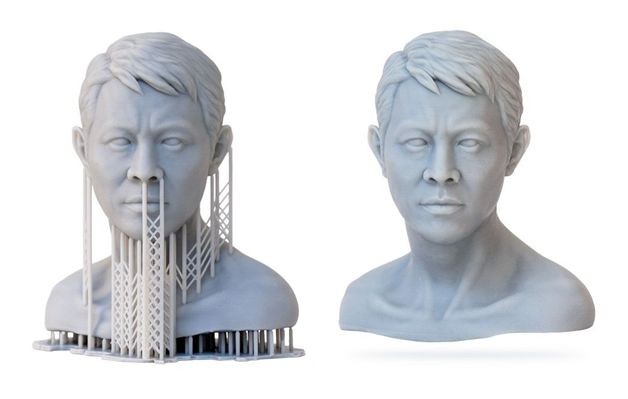

LFS proprietary technology is provided by a flexible assembly basin. Instead of standard tough basins, the LFS basin ensures the stability of the detail during and facilitates the removing after 3D printing.

LFS technology is also noted for an incredible level of detail, surface smoothness, and easiness of the support structure removal thanks to its unified light processing unit (LPU) containing a high-density laser. It also enables 3D printing of composite materials (such as high viscosity resins). Unlike it is in conventional fixed lasers or projectors, the print module in Formlabs Form 3 moves under the basin with resin, ensuring the motionlessness of the printed object.

Various optical sensors also ensure continuous automatic calibration and can even detect unwanted dust in the machine.

Users no longer need to manually pour the resin into the basin – materials can be changed simply by replacing the resin cartridge.

The manufacturer emphasizes that all main components of Formlabs Form 3 can be manually replaced by the user. It means users can quickly replace parts on-site instead of sending the 3D printer to the manufacturer for repair.

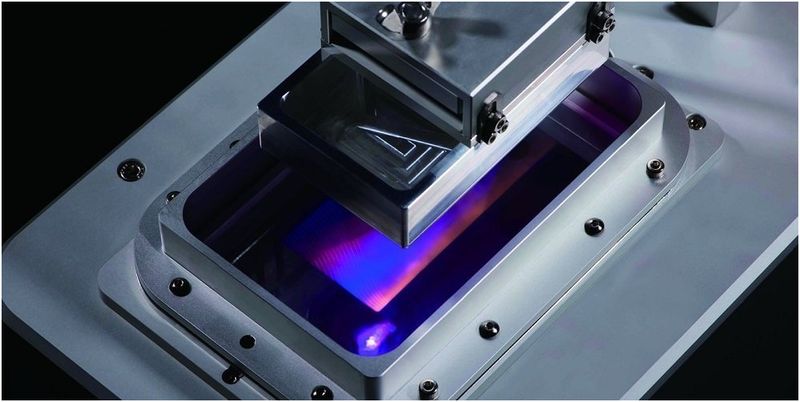

DLP printers use liquid photopolymer resins to construct 3D objects. To create each layer of the future object, TI DLP® DMD (the Projector Matrix Digital Micro-mirror System) projects a light matrix of the required wavelength for the polymerization of the material. The entire layer of material is exposed at the same time, which guarantees a high printing speed regardless of the object’s complexity. This technology also allows you to alternate the resolution on the image plane as surely as the layer thickness, which ensures surface smoothness and exceptional accuracy of the finished detail.

The absence of moving printing heads saves users from problems associated with mechanical accuracy and calibration.

The printer’s resolution is determined by the size of the micro-mirrors (7, 10, 13 microns) as well as their number.

Optical efficiency in the wavelength range from 363 to 700 nm allows the use of a wide range of photopolymers and resins.

SPECIFICATIONS

MoonRay S is a wireless desktop DLP 3D printer that excellently prints large objects while ensuring an extremely high level of detail. All this makes MoonRay S an ideal 3D printer for businesses and educational institutions as well as for home use.

MoonRay S is based on the specially designed, calibrated and durable RayOne DLP UV projector. RayOne uses the ideal wavelength throughout the whole platform for providing enhanced control over resin solidification and ensuring dimensional stability. This method of solidification also allows MoonRay S to achieve a print speed of 2.54 cm per hour with the Z-axis resolution of 100 microns. Objects fabricated by this printer are exceptionally detailed and boast accuracy up to +/- 50 microns.

SPECIFICATIONS

The printer is powered by the LCD DLP technology, which, instead of a projector located under the vat with resin, uses a screen that exposes the polymer layer between the basin’s bottom and the construction platform that descends from above.

Photo source: phrozen3dp.com

Affected by UV-radiation, the liquid photopolymer polymerizes and hardens, then the printer platform rises to the thickness of the next layer, and the operation starts again. This process is repeated layer by layer until the model is completely built. Then the finished detail is removed, cleaned from the remains of the photopolymer resin and exposed to a special UV chamber to complete the polymerization process.

Like most LCD 3D printers, Phrozen Shuffle and Phrozen Shuffle XL machines (boasting the building volume of 120 × 190 × 200 mm and resolution of 75 microns) are compatible with photosensitive resins with a working wavelength of 405 nm.

The biggest advantage of Phrozen Shuffle printer over the nearest competitors such as Anycubic Photon S is a unique matrix structure, the lenses on which provide a perpendicular direct stream of light without diffusion, which ensures higher print quality at the same nominal resolution.

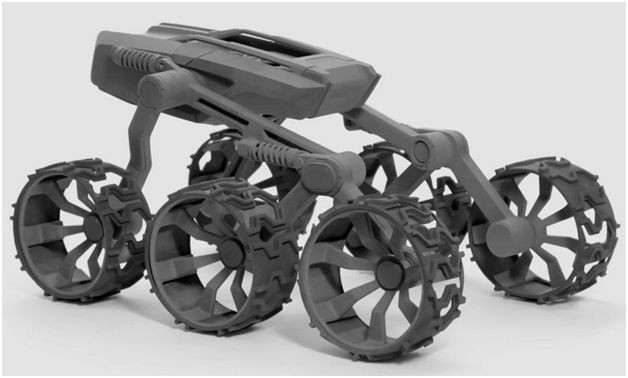

Selective laser melting or SLM, also known as laser powder bed fusion (LPBF), presents a rapid prototyping and 3D printing technology that uses a high power density laser to melt the working material in the form of metal powders.

SLM can work with various alloys, which makes printed objects as functional as those made of the same material by conventional production methods. Since the detail is constructed layer by layer, it is possible to design internal elements and holes of very intricate geometry that cannot often cannot be achieved by any other way.

Under selective laser melting, a thin layer of finely dispersed metal powder is evenly distributed over a base that is attached to a work platform moving along the vertical axis (Z). Printing is carried out in a chamber filled with an inert gas – argon or nitrogen. Using a powerful laser beam (usually it is a ytterbium fiber laser with a power of hundreds of watts), each two-dimensional layer of future detail is fused together with the previous one by selective powder melting. The process is repeated layer by layer until the whole detail is fully built.

Metal details obtained through the SLM technology are notable for their strength and durability and equally suitable for both test prototypes and end-use production parts.

SPECIFICATIONS

A cost-effective and robust machine for metal laser sintering, Farsoon is the only manufacturer of laser sintering systems providing total freedom of operation for its machines. This means that the user is no longer restricted in terms of choosing the machine parameters or powder, which provides previously unachievable levels of freedom and flexibility when it comes to MLS production.

The FS271M printer with its 500 W Yb-fiber laser, high-precision user-defined scanning algorithms and 275 × 275 × 340 mm building chamber is the ultimate choice for demanding customers to be used in aerospace, automotive and medical industries.

Selective laser sintering or SLS is an additive manufacturing (AM) method in which a laser is used to fuse powdered material. A 3D printer, aiming the laser at points in space defined by a three-dimensional model, sinters the working material, thus, creating a tight structure. The process is similar to selective laser melting (SLM), but in SLM, the material melts completely and does not sinter, which ensures multiple properties of the resulting product – a different crystalline structure, porosity, and others.

SPECIFICATIONS

The Sinterit Lisa Pro, a state-of-the-art 3D powder printer, is a well-designed and genuinely assembled machine. Thanks to the inert gas chamber, the apparatus allows for using a wide range of materials. The printer has a sturdy and robust construction that ensures low vibration, precise movements, and dimensional accuracy.

Lisa Pro can build functional movable parts without the need for assembly or post-processing. The printer is also capable of creating multiple objects at the same time to boost productivity.

Powder remained from one 3D printing process can be used in another printing session. New 3D prints can contain up to 100% of recycled powder.

Lisa Pro is built to the latest industry standards and comes with a number of outstanding design features including a front panel and a built-in 7-inch touch screen.

Material Jetting or MJ is an additive manufacturing process whose mode of work is similar to 2D printers. When manufacturing a detail, a print head (identical to the print heads used for standard inkjet printing) distributes drops of a photosensitive material that lately hardens under the influence of ultraviolet (UV) light, creating the desired object layer by layer. The materials used in MJ are liquid thermosetting photopolymers (acrylics).

MJ 3D Printing builds high-precision details with a blamelessly smooth surface. Multi-component printing and a broad range of supported materials (ABS-like, rubber-like and fully-transparent materials) make MJ a comprehensive solution for both visual prototypes and tool making.

SPECIFICATIONS

Multi Jet Fusion uses a fine-grained material that allows for getting ultra-thin layers with a thickness of 80 microns. This feature makes it possible to print details with a higher density and lower porosity compared to parts derived through laser sintering. The resulting surface is perfectly smooth, which minimizes the need for post-processing.

The most effective way to exploit 3D printers with Multi Jet Fusion technology is small volume manufacturing of geometrically complex details, prototypes of die-cast parts of different applications, small components that were previously manufactured by a pressure-die casting method.

Unlike most other 3D printing technologies, in MJ 3D printers, several inkjet print heads are attached to one structural element and apply working materials throughout the entire print surface in one pass. This allows different heads to dispense different materials. This makes multi-component printing, full-color printing and the creation of soluble support structures easy-to-use and be applicable in various spheres of business.

Photo source: top3dshop

3D construction printing or C3DP refers to technologies in which three-dimensional printing is used as the main method of erecting buildings or large building components.

Potential benefits of these technologies include faster construction, lower labor costs, higher complexity and accuracy of finished constructions, greater function integration, and less industrial waste.

Today, there are various approaches to the manufacture of buildings and their structures directly at the building site or outside it, for instance, through the use of industrial robots or portal systems.

C3DP technology has been gaining huge popularity over recent years resulting in the rapid evolution of the construction industry. The first 3D-printed building, the first 3D-printed bridge, the first 3D-printed part in a public building, the first residential 3D-printed building in Europe and the CIS, the first 3D-printed building in Europe, approved by the authorities are just a few examples of C3DP real-world applications.

SPECIFICATIONS

AMT S-300 is a large-format portal construction printer from Russia. This model boasts capacity of up to 2.5 cubic meters of concrete per hour and operational life of 60,000 hours. Intuitive controls enable the users to quickly master the work with this printer, while the ease of maintenance minimizes downtime.

The large operational field enables the S-300 3D printer to build structures up to 120 square meters and up to 6 meters high. A straight-flow print head allows for working with a large list of building concrete brands. The station productivity depends on the type of print head and extrusion speed.

All components of AMT S-300 construction printer are industrially manufactured and of exceptional quality, which provides for having continuous operation throughout the day at the facility.

Fused Granulate Manufacturing or FGF is an additive 3D printing technology in which a 3D model is printed layer by layer by fusing plastic granules and feeding the resulting mass through a nozzle to a building platform at a constant speed. Once a layer is completed, the platform lowers slightly, so that a new layer can be added. Changing the diameter of the nozzle allows for using more or less plastic per unit of time, which makes it possible to change the printing speed and accuracy depending on the size of the object.

Plastic granules are fed to a vertical extrusion screw that rotates, heats, and gets the material in a state of molten homogeneous plastic mixture. The resulting working fluid is then pressed through interchangeable nozzles of different diameters and shapes. Higher throughput capacity delivers a faster rate of construction but slightly worsens the quality of an object’s surface and vice versa.

SPECIFICATIONS

The 3D printer scene is a dynamic market that is expected to grow from $9.9 billion in 2018 to $42.9 billion by 2025. According to experts, 3D printer sales in 2019–2025 will grow by an average of 20.8%.

Despite the continual improvement and cheapening of printers in the “household-use” segment, analysts do not expect significant sales growth due to the high cost of expendable materials and electricity. But in the segment of industrial-grade machines (where the prices on professional 3D printers start at 100 thousand dollars and above), the market expects real explosive growth of tens of percent per year.

High-tech productions such as space, aviation, medicine and robotics industries are challenged with needs for high-precision 3D printers whose productivity can be compared with a black hole that can handle any manufacturing volume. Literally, any business can benefit from adopting 3D printing technologies.

Looking for professional 3D-printing equipment to boost your production? Contact our specialists, find out about all available options and choose the best 3D printing equipment for your specific business needs.

Update your browser to view this website correctly. Update my browser now

Write a comment