When speaking about 3D printing, the first material to come to mind is plastic. The most common additive manufacturing technologies use polymers in different forms depending on the printing process. FDM machines work with filaments, resin printers utilize liquid photosensitive resins, and SLS 3D printing makes use of a powdered form of different types of plastic which are selectively cured by a laser beam. SLS technology was exactly the one giving rise to SLM, or the selective laser melting process that is becoming more and more popular nowadays, as it is capable of printing with one of the most demanded materials in the market, namely metal or, more often, various metal alloys.

Credit: jellypipe.com

This is Top 3D Shop, and in this review, we are going to tell you about SLM 3D printing technology, its background, working principle, and applications. We will discuss the benefits of SLM and compare it to its predecessor — selective laser sintering. And, certainly, we will provide you with the list of the best SLM 3D printers in today’s market. Read on to learn more.

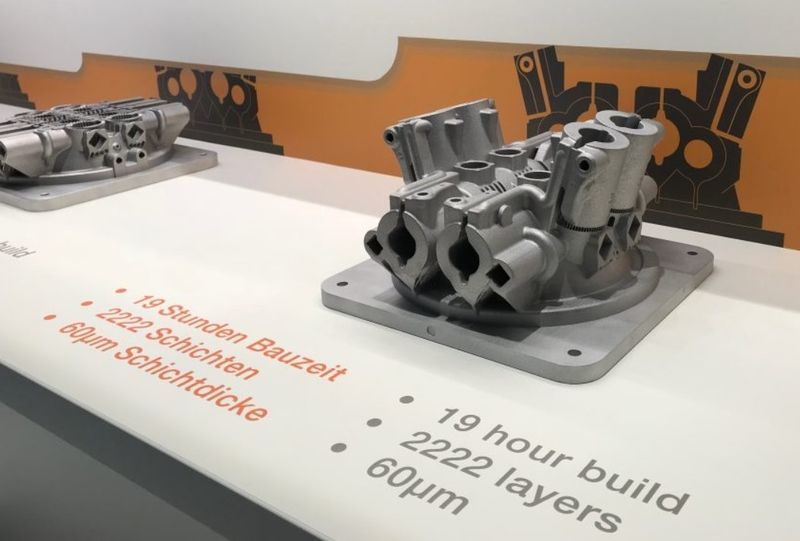

The development of SLM started in the mid 1980s when Carl Deckard, a student at the University of Texas, and his professor, Dr. Joe Beaman, invented and patented the technology of selective laser sintering (SLS). To commercialize the invention, the DTM company was founded and the first laser sintering system, called Sinterstation 2000, entered the market in 1992. In 1994, the second commercial SLS system, EOSINT (P) 350, was shipped by the German EOS GmbH company.

Both systems became commercially successful which prompted the manufacturers to go further in their research and introduce metal printing solutions, but they did it differently. The DTM company developed an indirect method, which they called ‘RapidTool’, that used polymer-coated metal powder to 3D print parts that were then annealed in the furnace. EOS cooperated with the Finnish Electrolux Rapid Development (ERD) company and in 1995 the EOSINT M 250 system appeared. It printed with bronze-nickel based powder, and the technology got the name DMLS (direct metal laser sintering).

Credit: caeonline.com

Printing with metal powders seemed to be very promising compared to traditional manufacturing methods, and in 1995 several German companies, including EOS, the Fraunhofer institutes ILT and IPT, Fockele & Schwarze, and others started a cooperative project aiming at further development of the DMLS process.

Since then the technology has been developed rapidly and today a number of manufacturers offer PBF (powder bed fusion) 3D printers based on the process of melting metal powders by a laser beam. The technology can have different names depending on the particular manufacturer, like direct metal laser melting (DMLM) by Concept Laser, laser metal fusion (LMF) by Trumpf and Sisma, direct metal printing (DMP) by 3D Systems, or selective laser melting (SLM) used by different manufacturers.

Before we dive into the list of the best models, let’s dwell upon the key points and fundamental principles of SLM technology.

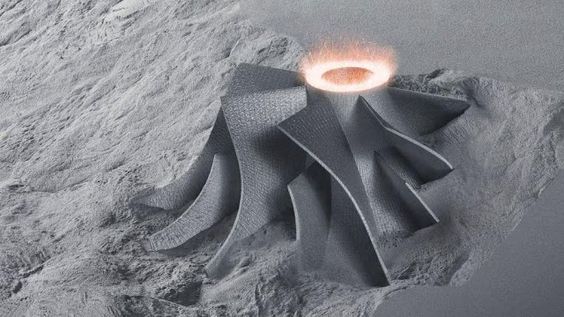

Selective laser melting is a powder bed fusion additive manufacturing method which uses a high power density laser to melt metal powders. The material is fused selectively according to a 3D CAD-model, and a three-dimensional homogeneous part is built layer by layer.

Credit: Pinterest

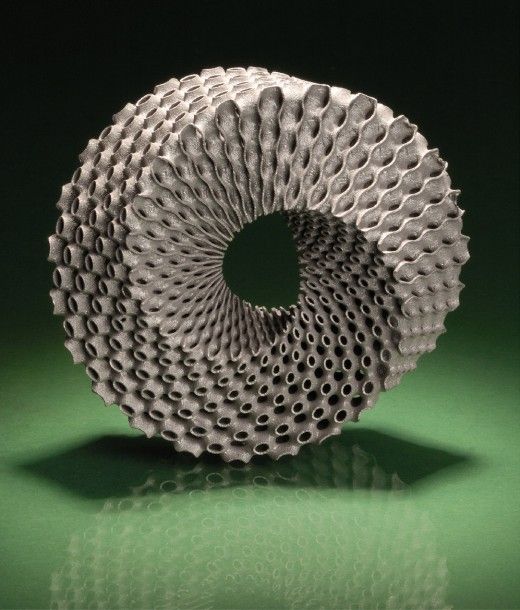

SLM printing is unique in its ability to create durable yet lightweight parts with complex geometries and internal structures, something not achievable with traditional manufacturing methods.

Laser type

SLM 3D printers are equipped with a laser (or lasers) to melt the metal powder. The power and beam quality of the laser are extremely important as they define the accuracy of the part, the print speed, and the overall efficiency of the process. First SLM systems used the same CO₂ laser type as laser cutting or laser welding machines. Some of the modern SLM 3D printers utilize more advanced fiber or disc lasers with higher beam quality and shorter wavelength, which allows for better absorption, higher power effectiveness, and faster printing.

Inert gas chamber

During the printing process the build chamber is filled with argon or nitrogen inert gas depending on the type of powder used. The most inert gas consumption occurs at the beginning of printing, when the air is completely removed from the build chamber. The absence of oxygen allows avoiding metal oxidation, which makes it possible to print with materials such as titanium.

Support structures

Unlike SLS printers with their advantage of support-free printing, SLM technology, though based on the same powder bed fusion process, needs building support structures to dissipate heat from the melted parts thus preventing models with hollows and overhanging elements from warping and deformation.

Credit: 3dprintingindustry.com

In most cases SLM 3D printing successfully replaces traditional manufacturing methods, as mechanical properties of the SLM built parts are often superior to those of products fabricated with conventional technologies.

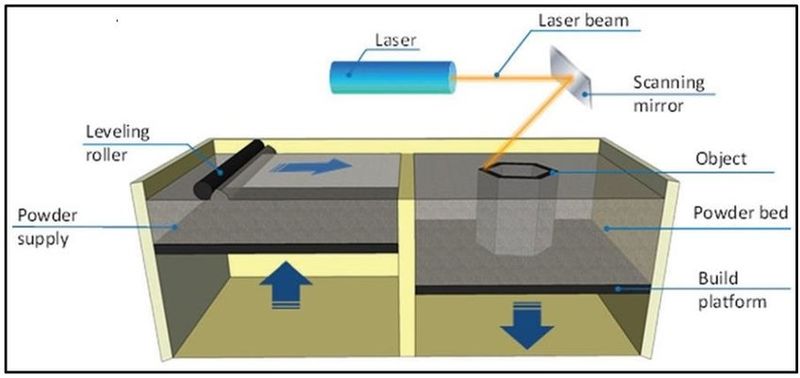

The printing process starts with preparing a 3D model and creating an STL file which is sent to the printer.

The build chamber is filled with metal powder and often pre-heated. When the machine is ready, a thin layer of powder is applied to a build plate with a special roller.

The laser beam selectively melts the powder, forming the first layer of the future part.

Then the build platform goes down slightly, and a new layer of metal powder is spread over the first layer. This new layer is also melted and fused with the previous one. These steps are repeated until the last layer is built and the part is complete.

Credit: researchgate.net

The model should be cooled down inside the build chamber and after that it can be removed and mechanically separated from the build surface. Support structures are also removed, and the model is ready to use, although you will probably want to use post-processing as the surface finish of SLM printed parts can be somewhat rough.

Credit: r-riparabile.com

SLM 3D printers differ greatly in their build volumes, accuracy, and other specs. Below you will find some important characteristics typical of most SLM machines.

Credit: Pinterest

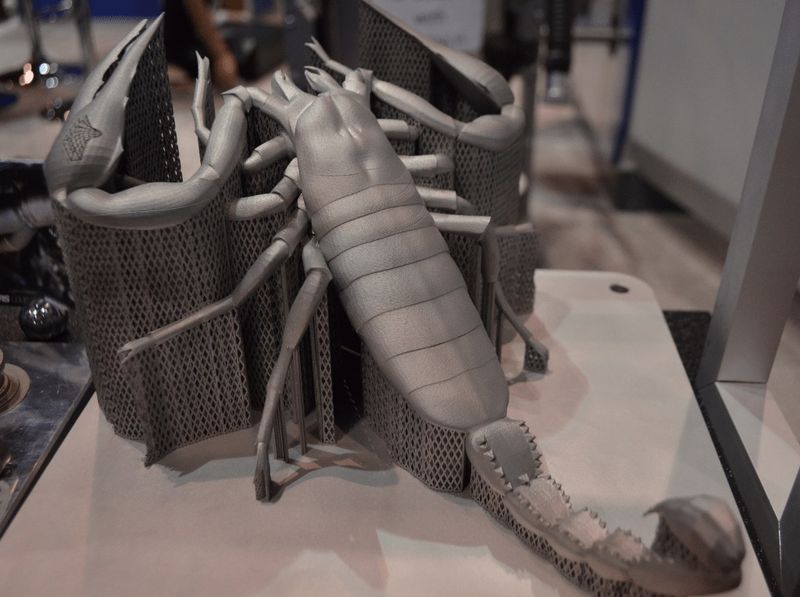

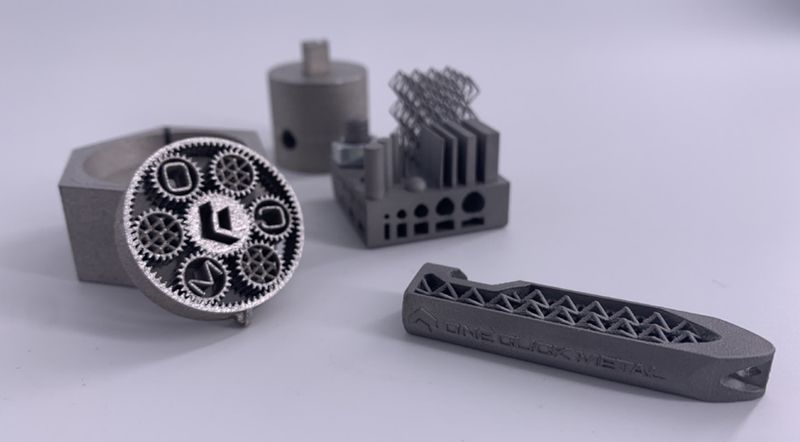

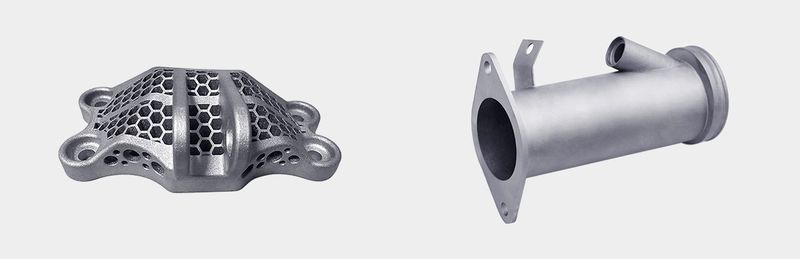

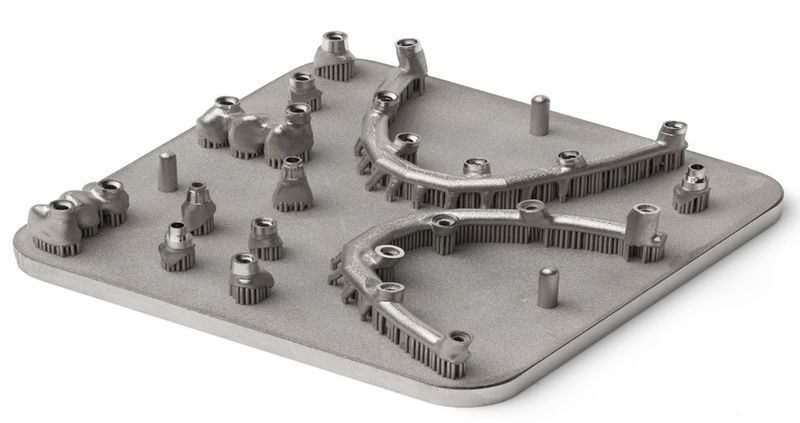

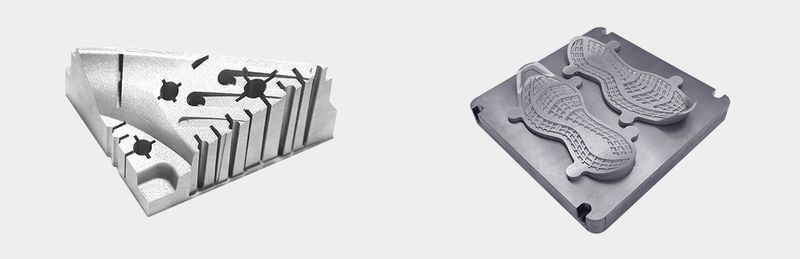

The technology is considered the best for manufacturing thin-walled, pressure- and heat-resistant parts with complex geometry, so it finds a use in a lot of fields including machining, aerospace, automotive, energy, medical, and other industries. First used mostly for rapid tooling, today SLM 3D printing helps produce:

SLM allows producing fully functional complex models with internal cavities and cooling channels.

Credit: materflow.com

Due to rational load distribution and use of internal ribs, cavities and lattice structures, the models can be considerably more lightweight still retaining their mechanical properties.

Use of SLM 3D printing allows for significant reduction of the manufacturing cycle compared to traditional production methods.

After the part is printed, the unfused material can be sieved and recycled, which also reduces the amount of waste. Besides, 3D printing does not require expensive tooling used in traditional manufacturing.

With SLM technology you have a wide choice of metals and metal alloys depending on your particular needs. Besides metals, you can print with ceramics and composite materials.

Credit: hoganas.com

Minimum post-processing includes washing and removing support structures. Metal parts often require heat treatment to achieve the final relative density and eliminate residual stress. They may also need sandblasting or other operations to improve surface finish.

Credit: madeinbritain.org

The pores, or tiny holes that form in a model while printing reduce the part’s durability and may lead to cracking. To minimize the risk of it, it is recommended using high quality powders with a uniform particle size and shape.

Temperature fluctuations may lead to residual stress, as the printing part is expanding and contracting during printing. Preheating the material and the build chamber helps minimize the risk of residual stress. It can also be eliminated while heating the finished part during the post-processing stage.

Now, let’s have a look at the best SLM 3D printers in the market in 2023.

As a tribute to the brand’s name, the MPRINT+ 3D printing system strives for streamlined, easy, and fully guided operation. Being a part of the manufacturer’s BOLDSERIES, the MPRINT+ offers optimal workflow in combination with the MPUREpro unpacking and sieving station (sold as a bundle). With a flexible build volume of 150 x 150 x 150 mm, potent 200W fiber laser, supportive MPrep software, remote control functionality, and unique cartridge system eliminating standard powder management difficulties, this LPBF device is a perfect entry point into small-scale metal 3D printing for efficient production of prototypes and industrial parts of almost any shape.

The Xact Metal XM200G is a high-performance LPBF 3D printer that boasts flexible settings and enhanced configurability. This open material platform comes with a single or dual fiber laser option of 100, 200, or 400W with simultaneous operation and overlapping work areas of 125 x 125 x 125 or 150 x 150 x 150 mm. Equipped with an integrated powder-handling system and an optional glovebox, the printer facilitates the work with powder alloys. Thanks to intuitive and user-friendly controls, the machine does not require special training, which in combination with its compact dimensions and simple set up makes the XM200G a great tool for various industries. It can be easily integrated into manufacturing, R&D, and other applications where print speed, part quality, and affordable price are essential.

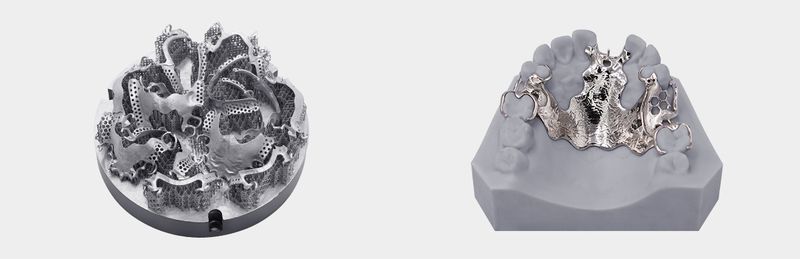

The HBD-150 is another affordable SLM machine with enhanced customization and a number of auxiliaries for cost-effective and conveniently automated metal 3D printing. It is particularly great for digital dentistry due to a fairly compact circular build volume of 159 x 159 x 100 mm, impressive scanning speed of 10000 mm/s, user-friendly multi-purpose software, and easy access to the printing area. A set of thoughtful safety functions, such as a door opening detection system, atmosphere purification, and automated monitoring of oxygen content, contributes to a safe and pleasant working environment. The machine is also available in the 150D version featuring increased laser power.

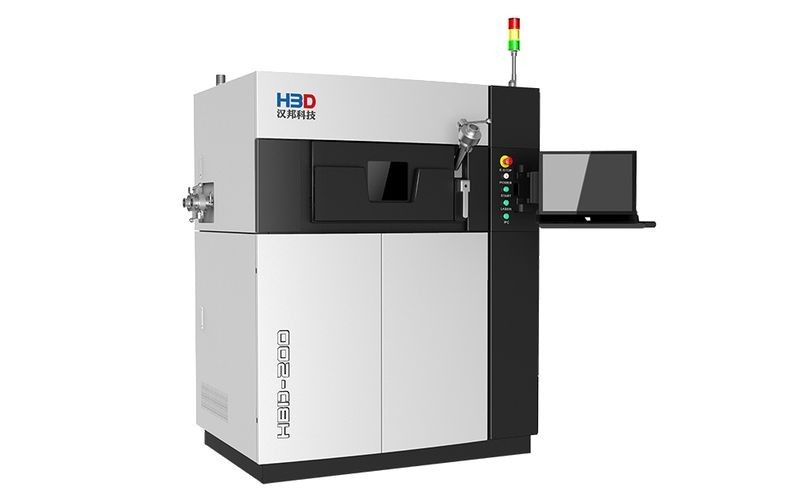

If the previous model seems insufficient for your needs, the enhanced HBD-200 will cover more tasks with increased build volume of 270 x 170 x 120 mm and two 200W lasers. The powerful SCANLAB galvo system with a minimum scanning track width of 40 microns ensures high accuracy up to 0.05 mm, which is perfect for products of various industries, including engineering, medical, jewelry, scientific research, etc. To provide a safe and stable titanium printing environment, the machine is equipped with an independent atmosphere purification system, sealed glove structure, and handy interface for powder management without opening the chamber. In addition, the aforementioned safety functions are enabled for all HBD devices.

The EP-M300 from E-Plus 3D is a powerful machine aimed at efficient mass production. Due to its build volume of 305 x 305 x 450 mm, the EP-M300 is capable of producing large models as a whole or batches of smaller items in one printing session. This opens up wide opportunities for the industries requiring series manufacturing of high-quality metal parts, such as aerospace, automotive, engineering, etc. To ensure highly accurate, stable, and fast printing, the machine is equipped with one or two lasers of 500 or 1000W each. The list of consumables includes metal powders based on titanium, aluminum, nickel, cobalt-chrome, copper, and various types of steel. With the help of integrated software, it is possible to divide a model into sections with different process parameters to build complex parts with required properties.

The ProX DMP 320 is a high-performance SLM printer from 3D Systems that is optimized for critical applications requiring complex, chemically-pure titanium, stainless steel, or nickel super alloy parts, including those in aerospace, automotive and healthcare. The device is based on technology called Direct Metal Printing that uses a laser as a power source to sinter powdered material, which makes it similar to SLM. The ProX DMP 320 features a large build volume of 275 x 275 x 420 mm and provides a minimum layer thickness of 30 microns. Due to its modular design, the system allows for really fast material changeover and effectively accelerates production cycle times. Overall, the unit is fully automated and ready to work 24/7.

The TruPrint 1000 is a compact and efficient metal 3D printer that is 80% more productive compared to similar machines. As a new generation of TRUMPF solutions, it boasts a number of technological improvements making for smart design, reduced costs, and premium quality. Among the printer’s most impressive features is a multilaser capability, powder bed monitoring system for efficient material application and distribution, interchangeable build cylinders for autonomous continuous production, adjustable laser spot diameter (55/80 µm), and more. Thanks to the machine’s inert powder cycle and low gas consumption, the TruPrint 1000 is one of the best choices on the market for processing titanium and amorphous metals. Primarily aimed at the dental sphere, the printer is also well suited for R&D area or small series production.

The Mlab R is a modular DMLM (Direct Metal Laser Melting) machine that offers a high degree of safety and user-friendliness when working with reactive and non-reactive materials, including titanium and titanium alloys. Able to create high-quality metal components with elaborate and dense structures as well as smoother surface finish compared to similar equipment, the device is ideal for research, prototyping, and manufacturing precious metal parts. Due to its modular structure, the printer comes with two build envelopes of 50 x 50 x 80 and 90 x 90 x 80 mm, which allows for quick and easy change of material without the risk of contamination. Furthermore, the compact size of the system makes it great for a production or lab environment with a limited footprint.

The RenAM 500 series by Renishaw consists of several high-performance metal 3D printers with varying configurations: the 500S with one and 500Q with four potent 500W lasers, and automatic or flexible (Flex) powder and waste handling. Despite their differences, all the machines share the core features, namely a typical build volume of 245 x 245 x 335 mm, advanced optics with dynamic focusing, configurable powder management, enhanced monitoring, and intelligent gas-flow system ensuring reduced argon consumption and emissions as well as uniform processing conditions. While scaling up the volume of production, the RenAM 500 printers support the Reduced Build Volume accessory for efficient material tests with only 0.25 liters of powder, which is great for laboratory tasks.

Credit: 3dprintingindustry.com

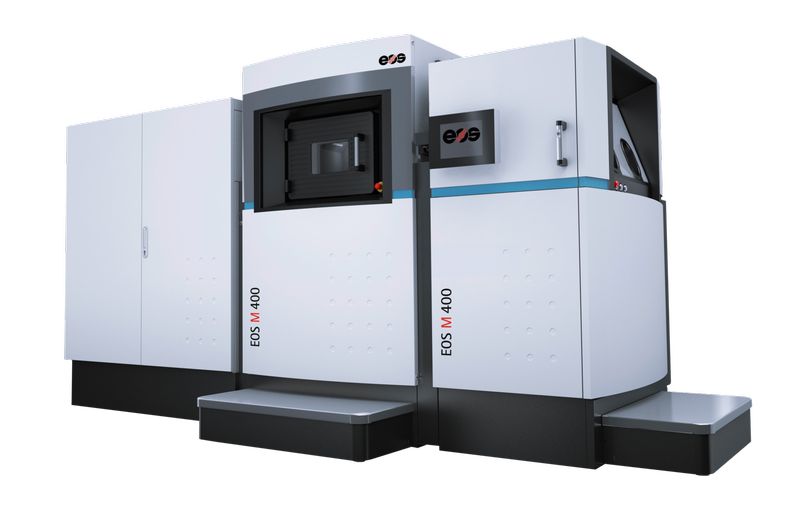

Among high-grade industrial SLM machines, the EOS M 400 stands out for its extensive capabilities, robustness, and capacious build volume. Designed for professional applications, such as serial manufacturing, it excels in producing large, high-quality parts with maximum dimensions of 400 x 400 x 400 mm. The unit is equipped with a 1 kW ytterbium laser and is ready to effectively print in metal powders based on aluminum, nickel, titanium, and steel. Like some of the previous models, it features a modular construction, which simplifies the operation and upgrades of the entire system. In terms of safety and ease of use, the EOS M 400 offers a circulating air filtering system with automatic cleaning, which implies fewer filter changes and longer service life.

The SLM 280 2.0 is an industrial 3D printer from the German company SLM Solutions. With a build volume of 280 x 280 x 365 mm, the device can print objects with the minimum layer height of 20 microns. The SLM 280 2.0 model can be equipped with one or two fiber lasers, 700W each. Due to patented multi-beam technology, the machine is able to achieve build rates 80% faster than a single laser system. In addition, manufacturing time is reduced thanks to bi-directional powder recoating. Used for medium- and high-volume production of metal parts and prototypes, the machine is compatible with a wide range of consumables, including pure metal powders and various alloys, including aluminum, titanium, and steel.

Positioned as the next-gen SLM printers, the Velo3D Sapphire solutions provide a new level of design freedom for producing metal parts with innovative properties. The series relies on the Intelligent Fusion manufacturing process and consists of the high-tech LPBF printers, Flow print preparation software, and Assure real-time quality validation and control software. Due to this comprehensive scheme, the Sapphire family ensures continuous monitoring and control over the build process layer by layer for reliable and efficient production. Offering unique support-free printing, powerful 1kW lasers, and thorough quality assurance in different build volumes, from 400 x 315 mm to 600 x 1000 mm, the Sapphire lineup covers a wide array of applications.

Due to the combination of key parameters, the Farsoon FS421M 3D printer is one of the leaders in its segment, especially when it comes to intensive manufacturing cycles with minimum downtime between sessions. The modular unit is equipped with a 500W fiber laser and allows installing a second one. The dimensions of the build chamber are 425 x 425 x 420 mm, with the minimum layer thickness of 20 microns. These characteristics are sufficient for the majority of AM tasks requiring high production rates and proper quality in automotive, aerospace and aviation, medicine, jewelry, mold production, etc. This automated system with easy-to-navigate interface is ready for long-term continuous operation with a variety of metal powders.

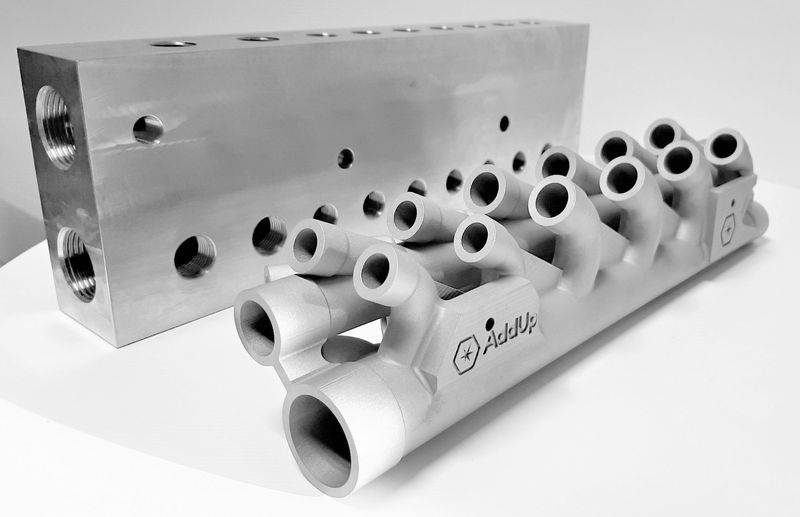

The AddUp FormUp 350 is a modular and scalable LPBF solution designed for increased productivity and safe manufacture of high-quality metal parts. Available in two basic configurations, it provides more than 25 options to be integrated at any time. To meet the most demanding application needs, the printer is equipped with up to four 500W lasers and a capacious build volume of 350 x 350 x 350 mm. The FormUp 350 is the only machine on the market with an interchangeable coating device: one can choose the powder spreading mechanism best suited to their production — a scraper system for maximum productivity or a roller system for improved surface finishing. The exclusively developed Autonomous Powder Module makes for continuous mass production with downtime reduced by 40%.

Credit: 3dprintingindustry.com

The HBD-350 is another comprehensive, customizable solution for most demanding metal 3D printing needs in a number of intense industries, such as mold, aerospace, aviation, automotive, medical equipment and functional parts production, jewelry, prototyping, and more. Being a standard model from the HBD lineup, the machine offers a large build volume of 325 x 325 x 400 mm, which makes for sufficient production speed and effective material usage. The unit is equipped with a single 500W fiber laser and powerful SCANLAB galvo system ensuring high accuracy and detail of the printed items. There is also a dual-laser version of the printer with increased productivity — HBD-350T.

The Lasertec 12 SLM from DMG Mori is a professional LPBF 3D printer with characteristics that make it perfectly suited for creating complex-shaped metal parts. It comes with a 125 x 125 x 200 mm build volume, layer thickness of 20 microns, and 200W or optional 400W fiber laser with a focus diameter of only 35 µm. Due to the optimized gas flow, the machine provides the highest component quality with minimum Argon consumption. Being an open platform, the Lasertec 12 SLM allows you to customize multiple printing parameters and print with a wide range of metal powders regardless of the manufacturer. As for material handling, the printer’s automated rePLUG powder module ensures fast change and effective recycling for maximum efficiency and highest work safety.

As a flagship and most versatile BLT model, the S310 is an additive metal printing system that meets the needs of diverse industries, including aerospace, aviation, automotive, medical, engineering, molding, R&D, and other. The machine can work with a wide array of metal powders, featuring a build volume of 250 x 250 x 400 mm, layer thickness from 20 to 100 microns, and build speed of 25 cm³/h. Depending on the modification, the printer is equipped with one or two lasers 500W each. Apart from reliable construction and advanced production automation system, the S310 provides manifold quality-of-life features, such as self-diagnosis, efficient powder management, real-time advanced monitoring, oxygen content control, and multiple interlocking safety mechanisms.

Due to outstanding performance and advanced production capabilities, the HBD-E500 model is recommended for aerospace, automotive, and medical applications. With a build area of 430 x 520 x 520 mm and minimum layer height of 30 microns, this industrial machine can be used to continuously produce top-quality end-use parts and large-scale prototypes in small batch production runs. The system is compatible with various metals and alloys, such as stainless and tool steel, cobalt-chrome alloy, titanium alloy, aluminum alloy, and some refractory metals like Tungsten and Tantalum. Depending on the modification, the HBD-E500 can be equipped with two or three 500W lasers.

Similar to the aforementioned HBD systems, the HBD-1000 meets most demanding metal 3D printing needs while still being an affordable entry point for SLM technology. Considering an impressively large build volume of 600 x 600 x 1000 mm, the machine can print the majority of items as a whole, without splitting them into several parts. In terms of power, the solution is available in two versions — with four 500W or 1000W lasers that provide outstanding sintering capacity. Thanks to the brand scanning speed of 10000 mm/s and flexible multi-purpose software with rich functionality, the machine offers smooth operation and elevated productivity alongside numerous safety features.

Speaking of the largest SLM devices in the market, it is hard not to mention the HBD-1200 boasting an impressive build volume of 460 x 460 x 1200 mm. The machine comes in two versions — with dual 500W or 1000W laser configuration. Like the rest of the company’s systems, the HBD-1200 is noted for its precision, high scanning speed, automated functionality, and thoughtful safety features. To simplify the production process, the independently developed HBD Build Expert software program provides a variety of smart tools for data slicing, path planning, intelligent measurement, material development, printing parameter editing, multi-laser coordinating, and more.

It is clear that selective laser melting is an innovative and promising technology shaping the future of manufacturing. Its ability to efficiently work with demanding materials and produce complex parts with impeccable precision and strength makes SLM 3D printing an invaluable tool in various industries, from automotive and aerospace to research, medical, and more.

Update your browser to view this website correctly. Update my browser now

Write a comment