In this article, we will tell you about how Farsoon metal 3D printers are used by the Falcontech additive manufacturing company. Read on to learn more about the influence of 3D printing on industrial-scale production.

China-based company Falcontech provides advanced and comprehensive metal 3D printing services for industrial customers.

Falcontech headquarters

The company's extensive capabilities include the development and production of metal powders, design and manufacturing of parts, post-processing, quality control and standardization.

One of Falcontech’s production shops

In 2018, after years of material development and technical research, Falcontech launched the efforts to source an SLM 3D printer with a build chamber of 600 mm for industrial-scale production.

The company wanted to find a local partner focused on industrial additive manufacturing, design and production of related equipment.

After a series of technical assessments, Falcontech entered into a long-term strategic partnership with Farsoon in 2019.

By the end of 2021, Falcontech ordered more than 40 Farsoon medium- and large-format SLM printers.

Falcontech employees at one of the Farsoon 3D printers

The collaboration with Farsoon allows the company to ramp up production capacity and implement plans to create the largest additive manufacturing factory. The next stage is the expansion of the equipment fleet to 50 Farsoon SLM printers, and to 100 industrial 3D printers subsequently.

The cooperation between Farsoon and Falcontech resulted in the expansion of the industrial equipment lineup. Today, Falcontech manufactures a wide range of industrial products, including large-scale aerospace components.

In 2019, Farsoon and Falcontech jointly developed the FS621M, which was the largest SLM 3D printer at the time. This industrial unit allowed the company to expand into the manufacturing of parts for the aerospace industry.

FS621M printing station

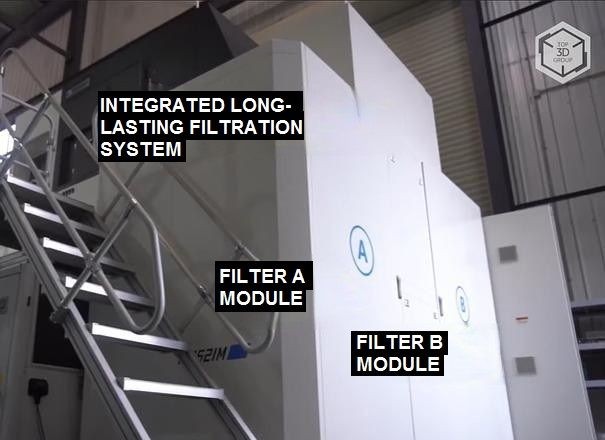

FS621M requires a separate filtration system

Farsoon's open platform strategy has enabled Falcontech engineers to achieve significant results.

For example, the company's specialists were able to reduce the surface roughness to 6.3 microns.

Finished parts have a low surface roughness even without post-processing

The open platform also gives a higher degree of flexibility in the selection of operation settings and machine control. A set of operating modes has been developed for different types and grades of metal alloys. The company's specialists managed to balance the resulting mechanical properties, residual stress, and accuracy.

Falcontech works closely with Farsoon technicians to introduce innovative equipment maintenance schemes, speed up the troubleshooting process, and improve overall operational management.

To learn more about the capabilities of Farsoon 3D printers, read the articles about their SLM equipment, Flight series using SLS technology, and case studies in medicine.

Update your browser to view this website correctly. Update my browser now

Write a comment