In this article, we will tell you about SLM 3D printers and related materials from the China-based HBD company, also known as H3D HBD. Discover what models are available in the lineup, their specs and features, as well as in which industries they are utilized.

To learn more about the manufacturer and examine application cases, read the following article.

HBD-150 and 150D metal 3D printers are widely used in medicine, particularly for dental and orthopedic applications, including 3D printing of implants and surgical instruments, rapid prototyping, education and research. Designed primarily for printing of dentures, crowns, and jaw implants, the HBD-150D modification is equipped with two 200W lasers. Both models feature a compact build volume which allows printing small to medium items as a whole or smaller objects in batches.

Dentistry: 50%

Education: 30%

Implantation: 20%

The HBD-200 is equipped with two fiber lasers and a dual galvanometer increasing its productivity and accuracy. The printer features a long build platform of 270 mm with a rather low height of the build chamber, which significantly reduces its cost, providing the possibility to build fairly large parts of small height.

Dentistry: 40%

Orthopedics: 30%

Prototypes: 20%

Education: 10%

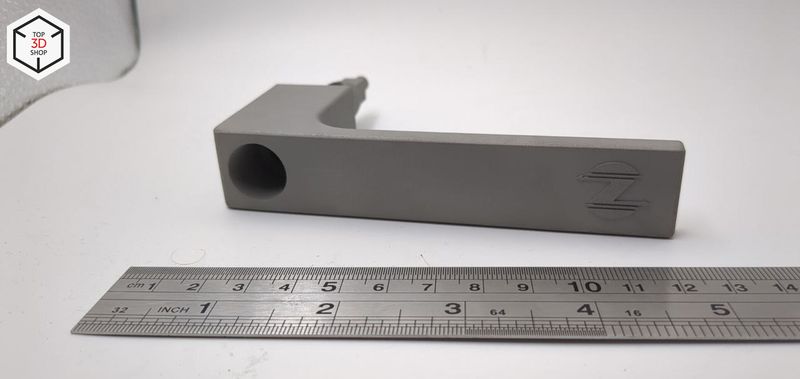

The HBD-350 is available in single and dual-laser configurations and features an efficient and reliable powder feeding system. Engineered with a closed automatic powder circulation system, it ensures a high safety level and control of the printing process. The unique multi-stage purification system of the HBD-350 meets the continuous production requirements and is suitable for 3D printing of press and injection molds, aerospace parts, automotive components, etc.

Spare parts: 30%

Aviation: 30%

Molds: 10%

Aerospace: 10%

Machine building: 20%

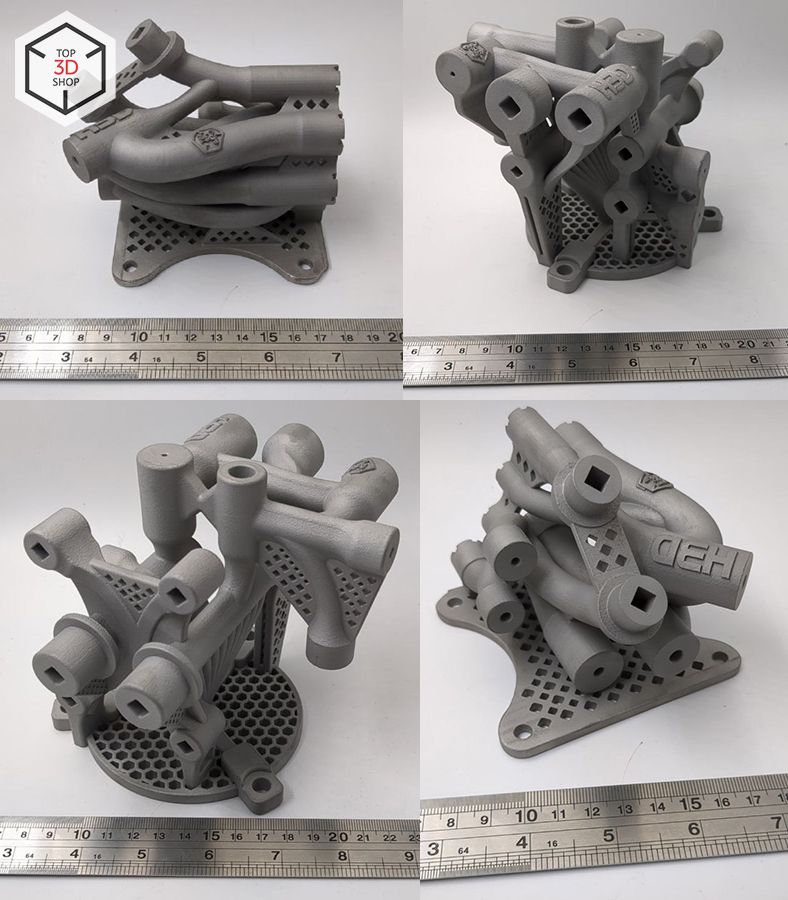

Depending on the version, the HBD-E500 can be equipped with up to three lasers, featuring an intelligent powder recoating monitoring system. The printer can print large, high-quality and precise parts for the most demanding industrial and aerospace applications. The HBD-E500 is used to print unique products based on generative design and topological optimization, which allows producing lightweight parts maintaining their strength properties while reducing material consumption.

Spare parts: 25%

Aviation: 20%

Aerospace: 25%

Machine building: 20%

Automotive: 10%

One of the most productive H3D HBD 3D printers, the HBD-1000 can be equipped with four 1000W or 500W lasers and features a closed automatic powder circulation system, an independent long-term multi-stage purification system, and integrated post-processing unit. The machine boasts a large build chamber making it suitable for almost any manufacturing industry, from aircraft to automotive.

Aerospace: 60%

Aviation: 30%

Other: 10%

The HBD-1200 is designed to print models of up to 460 x 460 x 1500 mm, which allows building large structural metal parts for aerospace, aviation, and heavy engineering. With one of the largest build chambers among metal 3D printers, the HBD-1200 meets all the basic needs of the aerospace and aviation industries. The device is available in two versions — with two 500W or 1000W lasers.

Aerospace: 80%

Aviation: 20%

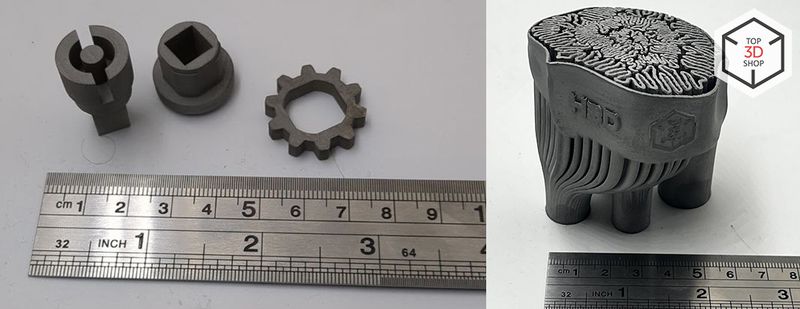

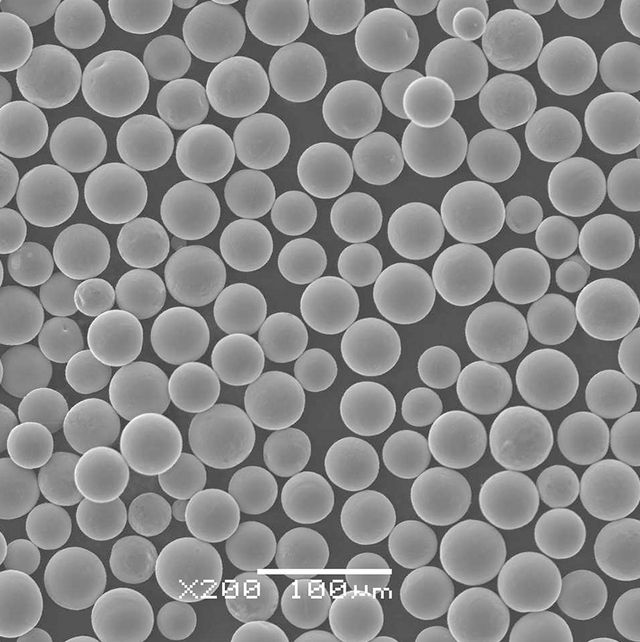

Aluminum powder pre-alloyed with silicon and magnesium has good casting properties and high strength and is used for printing thin walls and complex structures.

316L austenitic stainless steel has high strength and corrosion resistance, withstands wide-range low temperatures, and its overall performance is better than that of 310 and 304 steel. It also features good erosion resistance against chlorine compounds.

Ni718 is a nickel-based superalloy in a powder form with good aging resistance and high tensile and breaking strength, even at temperatures up to 700 °C. It has excellent corrosion resistance in a variety of aggressive environments.

Titanium-aluminum-vanadium alloy is characterized by high mechanical properties and good biocompatibility. Among other applications, it is used in medicine for 3D printing of endoprostheses.

An original mixture of pre-alloyed powders, designed for printing parts with cobalt-chromium-molybdenum superalloy. The alloy is characterized by excellent mechanical properties as well as corrosion and heat resistance. It is used for various purposes, for example, 3D printing of dental crowns.

Maraging steel is a powdered martensitic hardened steel of high strength, toughness and ductility which is easily processed. The hardness of printed parts after heat hardening does not exceed 55 HRC. It is used where other high-strength steels and alloys are too brittle due to their higher hardness.

H3D HBD provides complete metal 3D printing solutions, offering not only high-end SLM 3D printers with various build volumes and smart features, but also metal powders with different compositions and final part properties, meeting all the requirements of industrial metal 3D printing.

The cost-efficiency and high quality of HBD products are proved by numerous industrial companies which have purchased more than 500 company’s SLM 3D printers. Learn more about the application cases from this article.

Update your browser to view this website correctly. Update my browser now

Write a comment