Large-scale HBD SLM systems are used in industrial production by manifold companies, such as Matsui, WeNext, CISIRI. With more than 500 units sold, HBD continues to expand its research and development efforts to provide even more reliable 3D printing solutions. Currently, the company offers a lineup of AM equipment applicable in many industries characterized by high requirements.

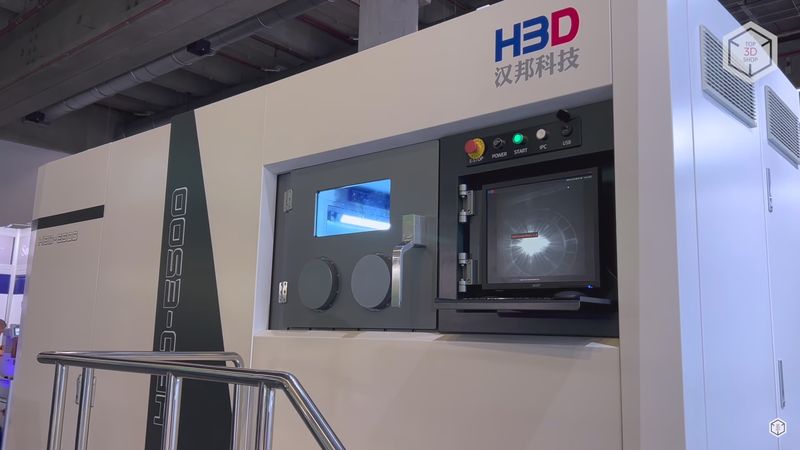

This is Top 3D Shop, and in this article we will take a look at one of the most in-demand SLM machines in the company’s lineup — HBD-E500.

Chinese company HBD was founded in Zhongshan, Guangdong Province, and entered the metal 3D printing industry in 2007 with certification by SGS-CE, ISO9001, AS9100D, and more than 200 patented technologies. In 2013, it launched the first product, the HBD-150.

Since then, the manufacturer has expanded its range of equipment and released more than a dozen new models of industrial printers that create top-quality parts with metal powder. The HBD devices employ SLM technology and differ in terms of volumes of the build chamber and the number of lasers. They can serve as a reliable and efficient tool in a wide range of modern industries, such as aerospace, automotive dentistry, orthopedics, molding, oil and gas, education, research, etc.

The HBD-E500 represents a complete, fully customizable solution with a range of auxiliary devices that meets the highest requirements for metal 3D printing while being quite affordable for an SLM system.

Depending on the modification, the HBD-E500 is equipped with two or three 500W lasers each.

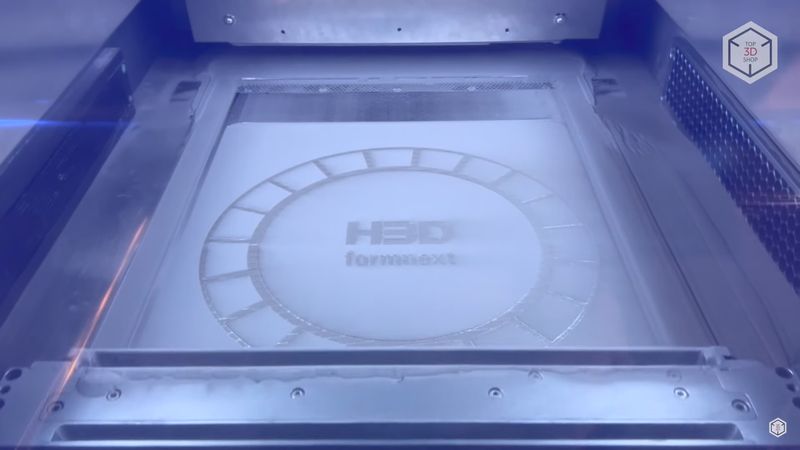

Intelligent systems for controlling powder deposition and blowing the print area with inert gas, nitrogen or argon are integrated into the unit.

The HBD-E500 has a build volume of 430 x 520 x 520 mm and the printing accuracy from 0.05 to 0.2 mm.

Other specs include the width of the scanned area from 70 to 100 microns and layer thickness from 30 to 100 microns.

The machine is compatible with fine metal powders of titanium, aluminum, chrome-cobalt, nickel alloys, as well as stainless and tool steel.

The HBD-E500 can be operated via a built-in control unit with a clear and user-friendly interface.

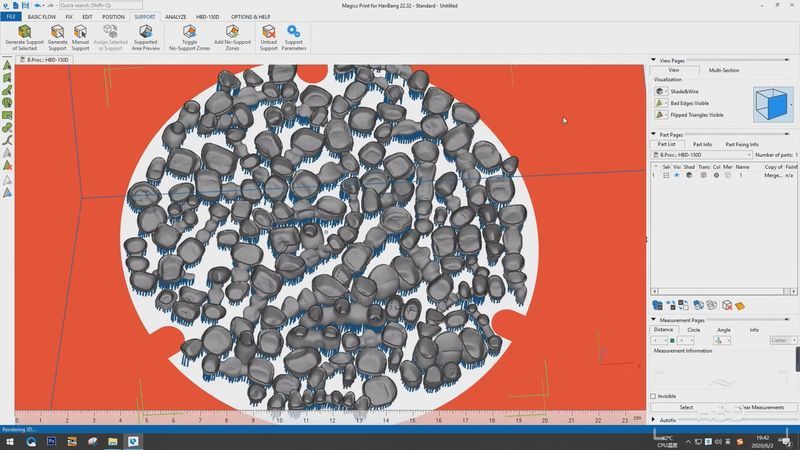

It is supplied with the in-house multifunctional HBD Build Expert slicing software, which provides a variety of smart tools for data slicing, path planning, intelligent measurement, material development, printing parameter editing, multi-laser coordinating, and more.

The device can print large parts of high quality and precision for use in the most demanding components of industrial equipment and aerospace technology.

Likewise, HBD-E500 is employed to print unique products using generative design and topological optimization, which allows obtaining lightweight parts with preserved strength characteristics while reducing the consumption of raw materials for printing.

The machine is ready for 24/7 operation and can be used for small to medium batch production of fully functional parts.

Depending on the version, the HBD-E500 can be equipped with up to three lasers, featuring an intelligent powder recoating monitoring system. This affordable SLM system can print large, high-quality and precise items for the most demanding industrial applications. With the HBD-E500, one can print unique products based on generative design and topological optimization, which allows producing lightweight parts with exceptional properties in an increasingly cost-effective way.

Update your browser to view this website correctly. Update my browser now

Write a comment