Protected by two hundred Chinese and three international patents and complying with fourteen different standards, HBD 3D printers are used in industrial production by manifold companies, such as Matsui, WeNext, CISIRI. With more than 500 units sold, HBD continues to expand its research and development efforts, aiming, for example, to build a facility on 6.5-acre property acquired last year. Currently, the company offers a lineup of additive manufacturing equipment and materials applicable in a number of industries characterized by high requirements.

This is Top 3D Shop, and in this article, we will discuss the fast-growing China-based SLM 3D printer manufacturer HBD, also known as H3D HBD. Learn more about the company and applications of its equipment.

HBD, or Hanbang United 3D Technology, manufactures SLM 3D printers that create industrial-quality parts with metal powder.

HBD was founded in Zhongshan, Guangdong Province, entered the metal 3D printing industry in 2007, and launched its first product, the HBD-150, in 2013.

Since then, the company has expanded its range by releasing several more models of industrial 3D printers, which also employ SLM technology, with different volumes of the build chamber and the number of lasers. From HBD-80 with a cylindrical 120 x 80 mm chamber to HBD-1500 with a build volume of 460 x 460 x 1500 mm and HBD-1000 with a chamber of 600 x 600 x 1000 mm, the company's 3D printers are used in many industries.

Mock-up of the planned HBD center in Shanghai. Credit: HBD

After raising $60 million, the company plans to build a research, development, and production center in Shanghai, in order to expand its market share in the industry.

“Metal 3D printing is rapidly maturing, and will become a new technology comparable to traditional machine tool processing and production methods in the future. The current mainstream aerospace, industrial, medical, mold and other fields, and other industries will also be more applied to metal 3D printing technology, giving birth to trillion-level market opportunities,” said Jianye Liu, CEO of HBD.

HBD’s manufacturing and research facility will be located in the new Lingang area, adjacent to other large enterprises such as Tesla. HBD plans to invest in high-tech research and development, technical team building, and high-tech manufacturing.

“We have seen the rapid rise of metal 3D printing [technologies]. Among them, we believe that the development mode, leading products and services presented by HBD have high-value content and long-term competitiveness. Grand Flight Investment will make full use of the strong financial and industrial background of the Far East Horizon Group to help HBD accelerate its breakthrough to the next stage of development,” commented Yun Pei, Executive Director of Grand Flight Investment.

According to HBD, many of the company's customers use its 3D printers for aerospace, automotive and utility applications, and effectively solve their production problems by introducing HBD equipment. For example, one client applied the company's technology to optimize the geometry of a reactor heat exchanger by reducing the height of the part from 10 meters to 40 centimeters.

Technologies applied in HBD systems include:

See below for application examples.

Reducing the weight of a spacecraft by one kilogram lowers the launch cost by $20,000, so every gram counts. In civil aviation, weight is just as important, and reducing it saves a lot of money, given the number of flights per year.

In a traditional design, executed without the use of additive technologies and generative design, such issues as uneven load and stress distribution and excess mass can occur. These issues can be solved by optimizing the structure in topological design. Metal 3D printing helps not only to maintain functionality while reducing the weight of the parts, but also to ensure their enhanced rigidity and strength, as well as to secure uniform and rational distribution of material.

With metal 3D printing, industrial players can create structures of any complexity, and the cost of production does not depend on how complex they are, which provides greater freedom in design.

Cooling circuit segment

Part

Turbine impeller

Water-cooled combustion chamber

Hollow titanium handle

Housing

Base

Topologically optimized structural part

Turbine

Metal 3D printed crowns can be made without wax contouring, casting, or other traditional processes, while significantly reducing the amount of post-processing. Labor costs and associated risk factors are reduced by introducing SLM technology, since the process is automated, leading to a lower rejects percentage.

3D printing, combined with 3D scanning, fully meets the needs for customization in the manufacturing process, which has always been the cornerstone of dental production, and allows converting dental enterprises from the labor-intensive to the high-tech category.

Dental crowns

Partial denture frame

Prostheses’ bases

Dental bridge

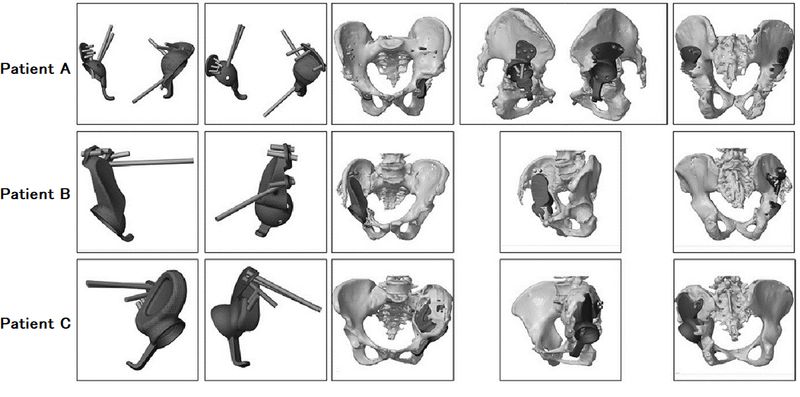

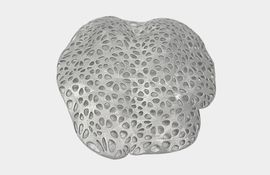

The use of metal 3D printing allows for manufacturing personalized joints and bones endoprostheses tailored to each individual patient, reduces the risk of complications, increases the likelihood of successful surgery, and shortens the rehabilitation period. 3D-printed porous and lattice bone implants have a faster period of integration into the human body.

Metal 3D printing is also used to produce surgical instruments, guides, and fasteners, such as titanium bolts fixing the endoprosthesis to the bone.

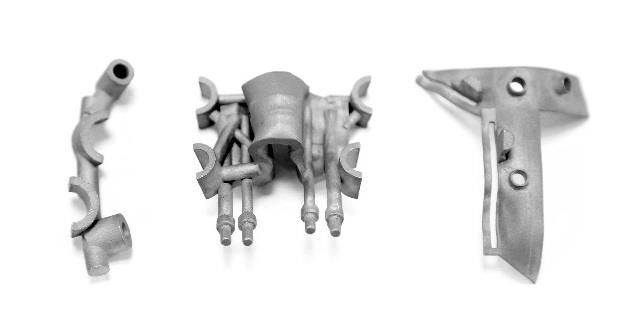

3D printing of a surgical instrument, pic. 1

3D printing of a surgical instrument, pic. 2

3D printing of a surgical instrument, pic. 3

Bone implants

Sacral bone implant

Spinal implants

Three hip implants integration examples

Hip prosthesis

Acetabular cup

Spine implant

Сranial implant

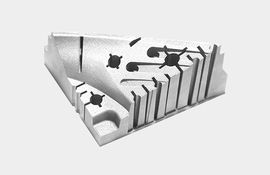

3D printing is effective not only for creating unique and low production volume products but also helps to improve traditional processes for mass production of identical parts, such as casting. In traditional casting, the molds’ cooling channels are usually straight, leading to slow and uneven cooling. 3D printing allows the creation of complex molds with conformal cooling channels. Compared to traditional molds, the conformal channels provide for faster and more uniform cooling, faster demolding, and overall higher quality.

Washing machine drum mold

The next two examples are part sprues, with the cooling channels marked in red:

Sprue 1

Sprue 2

Home appliance mold insert

Shoe sole mold fragment

A combination of computer-aided design methods and 3D printing in the automotive industry speeds up automotive parts development and reduces test periods. The production of molds using traditional technologies is labor- and cost-intensive, while 3D printing allows the production of parts of complex geometry and structures that do not require assembly, which greatly simplifies and speeds up the development of car prototypes, providing for quick design alterations at all stages. This reduces the costs of developing and launching individual parts and vehicles into production.

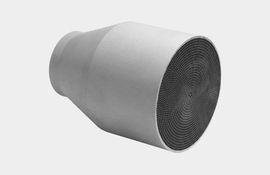

Exhaust filter

Intake manifold

Motorcycle intake pipe

Valve seat

Car part

In addition to SLM 3D printers, HBD offers its patented HBD-280F hybrid system, metal 3D printing powders, and devices based on a so-called LACM technology. The latter is a combination of metal 3D printing and laser cutting, which increases the dimensional accuracy of the resulting parts and ensures higher-quality surfaces, including internal ones.

HBD LACM 400 3D printer

The HBD lineup includes metal 3D printing systems with different chamber sizes designed for different tasks. The company is actively developing, which is evident not only in the increasing number of new equipment models, but also in the plans to expand the technical and research base. The quality, performance, and cost-efficiency of HBD systems are proved by over 500 units sold up to date. In the coming years, we can expect new breakthrough technologies from the company immediately after it finalizes the engineering and manufacturing center in Shanghai.

Learn more about HBD 3D printers from this overview.

Update your browser to view this website correctly. Update my browser now

Write a comment