From this article, you will learn about a new professional MIM (Metal Injection Molding) 3D printing system — MetalFuse by Chinese company Raise3D. Let’s shed some light on its main peculiarities and technical specifications.

MetalFuse is a complete solution based on indirect metal printing technology. It consists of the Forge1 metal filament 3D printer, the D200-E catalytic debinding machine using oxalic acid, and the S200-C vacuum sintering furnace. This impressive combination enables cost-effective manufacturing of high-quality metal parts comparable to wrought iron in its mechanical properties.

The complete solution is ideal for economical production of single metal parts as well as small-to-medium item batches. On top of that, the MetalFuse is energy-saving and more environmentally friendly compared to traditional CNC and SLM processes.

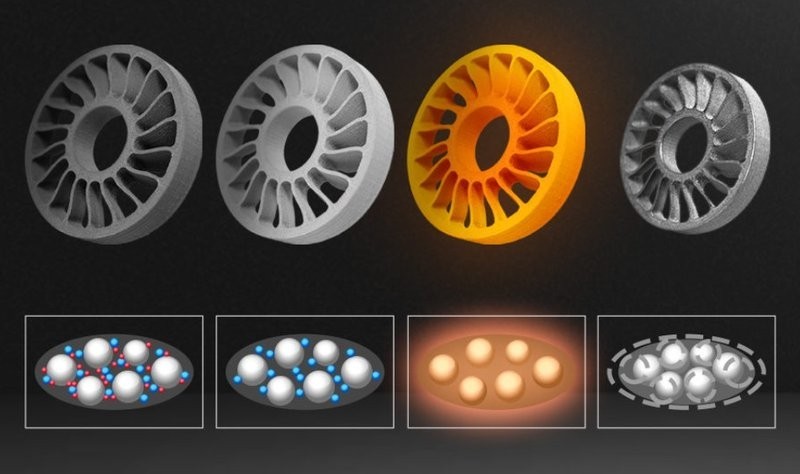

On top of the 3D printer, the MetalFuse system includes the D200-E cleaning station and the S200-C sintering furnace, which are used for post-processing of the so-called “Green parts”. The process is based on BASF’s know-how in metal injection molding.

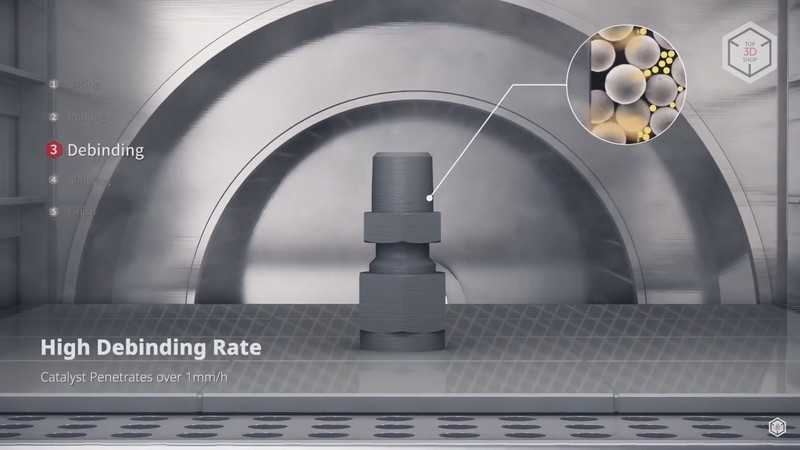

The catalytic debinding process used by MetalFuse is based on oxalic acid. It reduces binder removal time and allows increasing the final part density up to 97%, which is 52% more compared to products obtained by traditional debinding methods. Besides, this technology works even with titanium and copper.

Overall, the procedure is completely safe, easier than nitric acid treatment, and faster than solvent and thermal debinding.

The Raise3D Forge1 is equipped with two extruders with the maximum hotend temperature of 300 ℃. Another benefit of the printer is its decent build volume — a cube with an edge length of 300 mm — as well as the layer thickness of 0.1–0.25 mm.

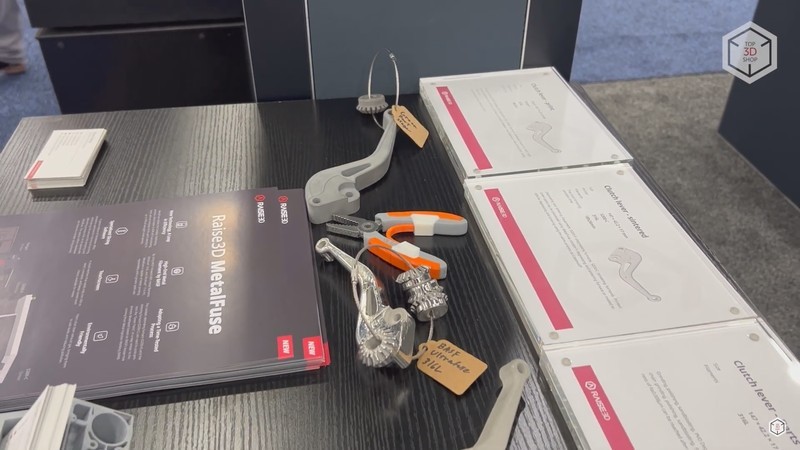

The Raise3D MetalFuse utilizes BASF metal filaments — UltraFuse 316L and UltraFuse 17-4 PH — as consumables. These composite filaments consist of 80–90% stainless steel of the corresponding grade and 10–20% resin binder. BASF plastics ensure excellent printing repeatability and high productivity.

All the MetalFuse system devices are equipped with large sensitive touchscreens featuring a carefully designed interface. Selecting the required profile and working with necessary files takes just a few clicks.

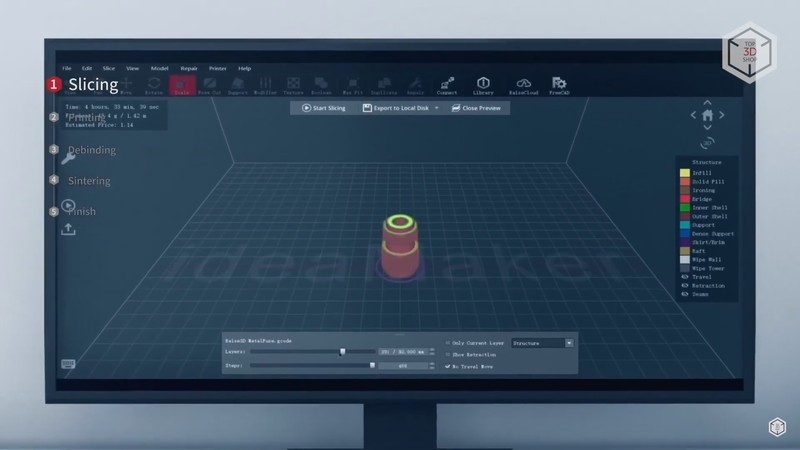

To prepare digital models for printing, Raise3D offers a special version of the ideaMaker software, namely the Metal Edition. The program offers special templates optimized for metal printing as well as smooth sintering and debinding processes. In addition, it provides simplified slicing algorithms for a user-friendly experience.

As of the moment, the MetalFuse system is expected to provide accurate calibration, precise printing, and decent quality surface for ready parts. Combined with several nozzle size options (0.4, 0.6, and 0.8 mm), the solution empowers huge possibilities in end-use parts production.

With the above mentioned features considered, the MetalFuse 3D printing solution is highly recommended for applications such as small-scale manufacture, as it is clearly aimed at reliable performance, smooth operation, low overhead costs, and efficient batch production of high-quality items with outstanding characteristics.

Update your browser to view this website correctly. Update my browser now

Write a comment