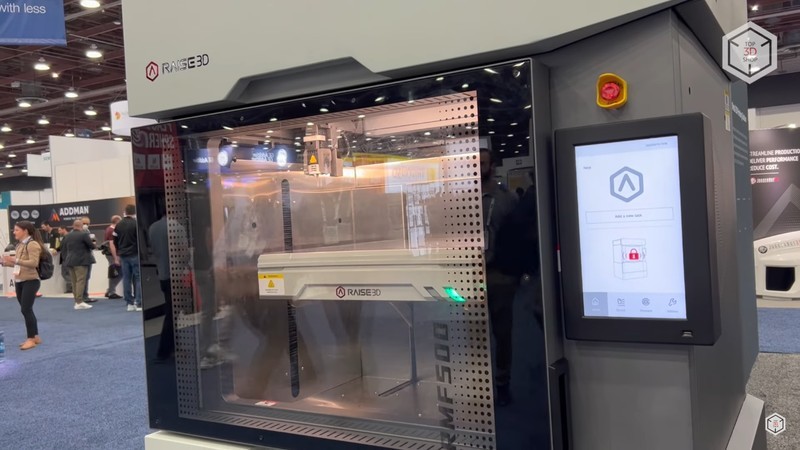

In November 2021, Raise3D introduced a new large-format 3D printer called RMF500, capable of handling carbon fiber-reinforced filaments with industrial precision and repeatability at high speeds. Let’s go through its specs and features and see what the machine is capable of.

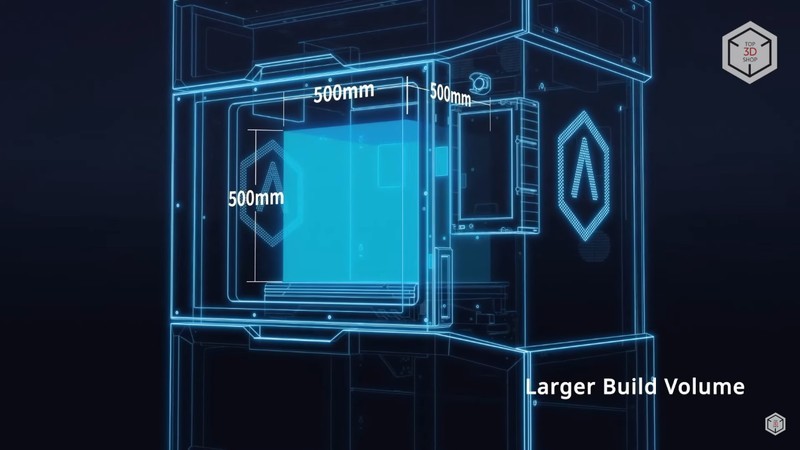

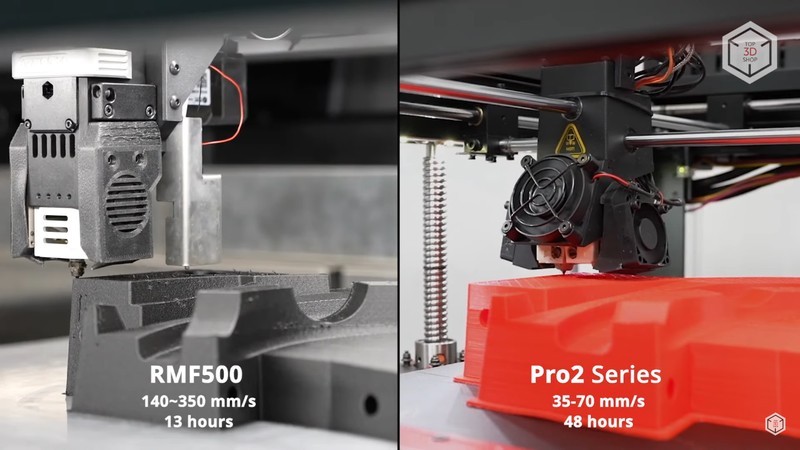

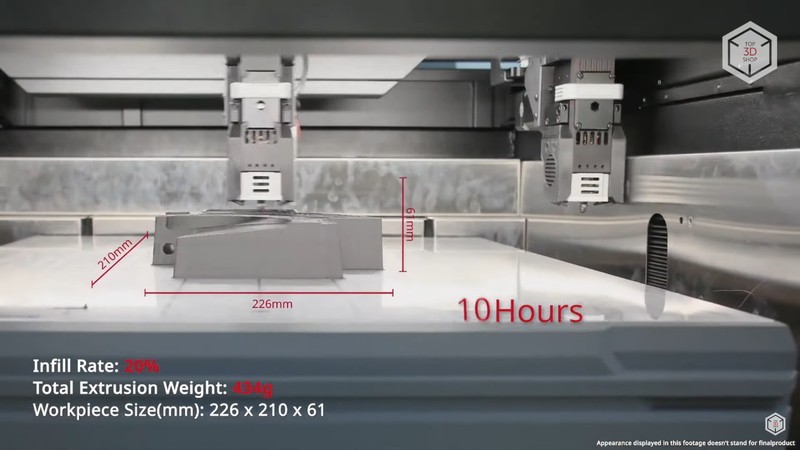

The RMF500 has a print volume of 500 x 500 x 500 mm and can reach print speeds of up to 300 mm/s, with 1000 mm/s travel speed and 2G acceleration at the print head.

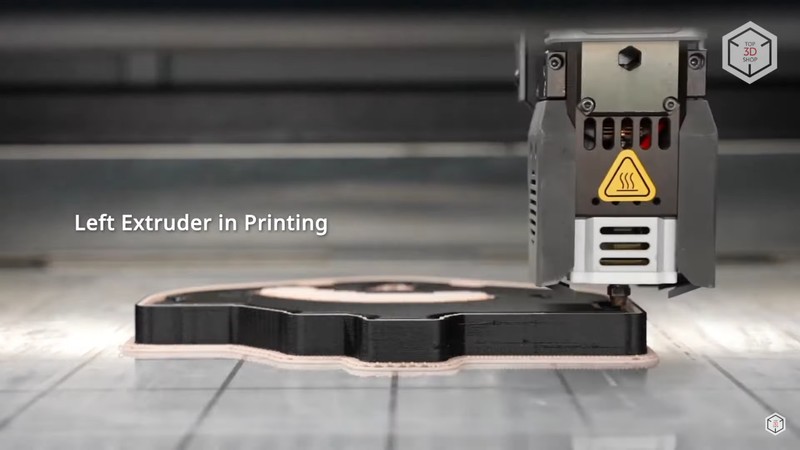

In addition, the IDEX (independent dual extruder) system can run two print jobs at the same time, making the RMF500 even faster and more productive.

The RMF500 brings high accuracy and reproducibility into the workflow, expanding production capacity in several ways. With the upgraded motors and rails, the RMF500 can print with an accuracy of 0.001 mm in the X and Y axes. Meanwhile, it reaches 0.0009765 mm accuracy on the Z axis. Its feedback-based synchronized control with 1 μm positioning decreases speed fluctuations when loads change, further improving accuracy.

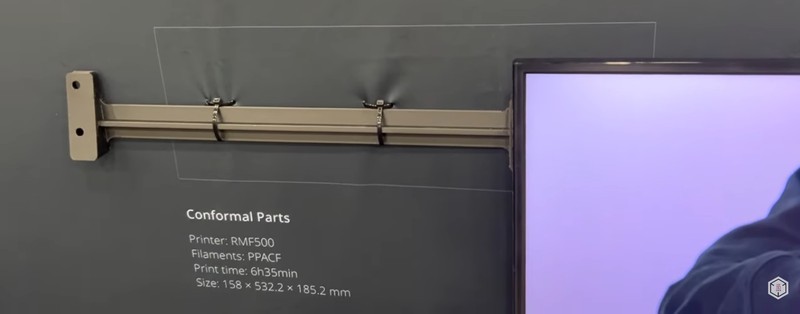

The RMF500 was designed keeping in mind the demand for more sustainable prints with fiber-enhanced filaments, needed to produce more durable, heat-resistant and lightweight parts.

Raise3D's R&D team devoted a lot of effort to identifying the best materials to print stress-resistant end-use parts reliably and continuously. The result of these studies focuses on carbon-fiber reinforced filament with increased stiffness and reduced shrinkage rates, which does not require an active heated print chamber. The final parts made with these types of filament are lightweight yet extremely strong, making them a potentially ideal alternative to metal structures.

To ensure trouble-free printing, the RMF500 holds four large, multipurpose filament cartridges, with each cartridge having a maximum load of 2.5 kg, connected for automatic switching between spools and pressure and humidity control. The 3D printer can automatically switch between primary and secondary cartridges, reducing the amount of time spent during the print process.

A humidity control system keeps the threshold below 5%, preventing high exposure to external moisture.

All hardware and load-bearing elements of the RMF500 are made of high quality hardened steel. The Z-axis can withstand a maximum load of 100 kg. The linear motor driven system has minimal play and does not require frequent maintenance. The Z-axis sag under high load, over the entire travel range, is estimated to be 50% lower than in other FDM 3D printers.

The maximum nozzle temperature of the RMF500 is 330 °C while the hotend is upgraded for printing composite fiber-infilled thermoplastics.

The printer is controlled by a 13.3-inch touchscreen and equipped with a webcam for remote monitoring of the printing progress. Wi-Fi, LAN, and USB connectivity options are supported.

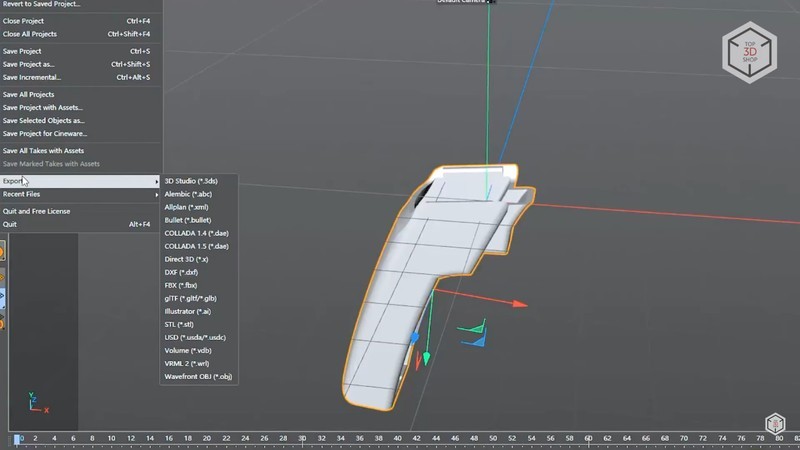

To prepare models for printing, Raise3D offers the proprietary ideaMaker slicer, which features high efficiency and a comfortable interface, streamlining the workflow.

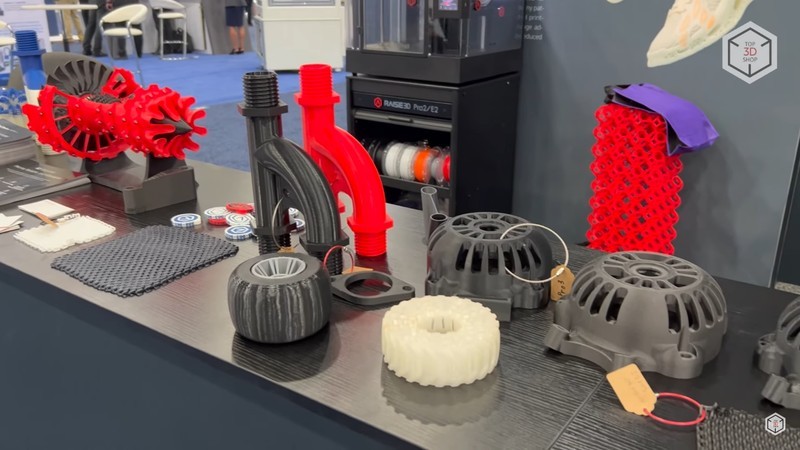

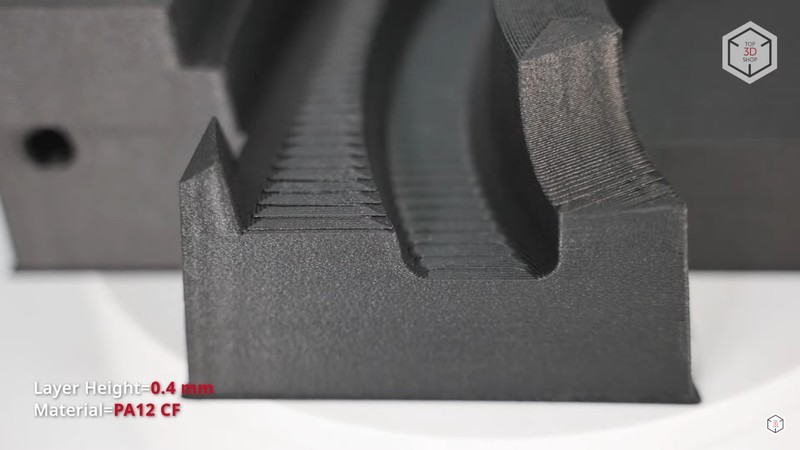

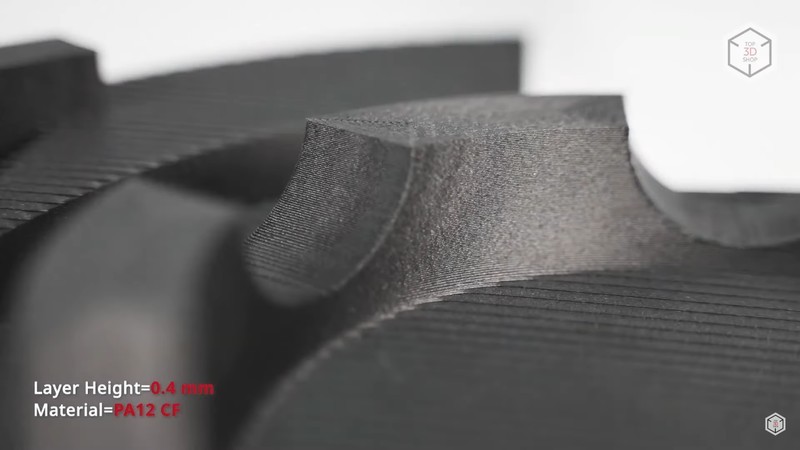

Check the following prints produced by the RMF500 with the proprietary high-performance materials.

And now take a closer look at the level of print quality the device is capable of.

The Raise3D RMF500 is a powerful tool for users who aim to expand their plastic production capacity with standalone carbon-fiber projects. Specifically geared for CF-enhanced thermoplastics and nylon, this latest addition to Raise 3D’s lineup is a great step towards making tougher and more demanding industrial-grade materials accessible to amateurs and professionals alike.

Update your browser to view this website correctly. Update my browser now

Write a comment