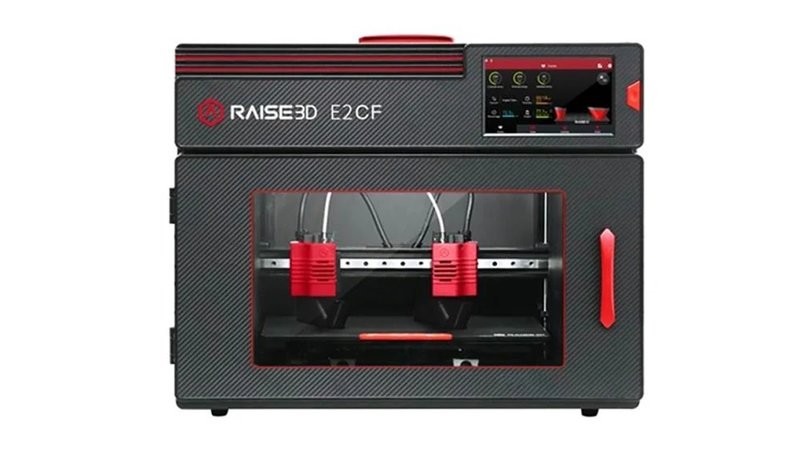

Hi everyone! This is Top 3D Shop, and in the following article, we will tell you about the Raise3D E2CF 3D printer. The new product is a successor to the award-winning E2 — it has the same IDEX technology and flexible build plate, but can print with carbon fiber-reinforced filament, which makes it capable of producing strong and lightweight parts.

The original E2 model turned out successful enough for Raise3D to utilize its design and features and launch a new lineup, with IDEX technology providing a number of advantages over the classic dual extrusion system. Initially, it was assumed that next products would be designed for specific tasks, for example, orthopedics or dentistry. However, the concept eventually changed, and it was decided to release a device not for a specific industry but for printing with a specific type of filament.

At first glance, the Raise3D E2CF is not much different from the E2. The device, too, uses IDEX technology and has a build volume of 295 x 240 x 240 mm and a minimum layer height of 10 microns. The extruder nozzle can heat up to 300 ºC, and the maximum temperature of the build plate is 110 ºC. The majority of characteristics being the same, the E2CF boasts some features making it stand out as a brand new product in the line. Read on to learn about all the specs and highlights of the machine.

As its name implies, the E2CF is designed to print in Carbon Fiber composites. Now, let’s have a look at the solutions used to make it possible. (For other features, read the detailed Raise3D E2 printer review)

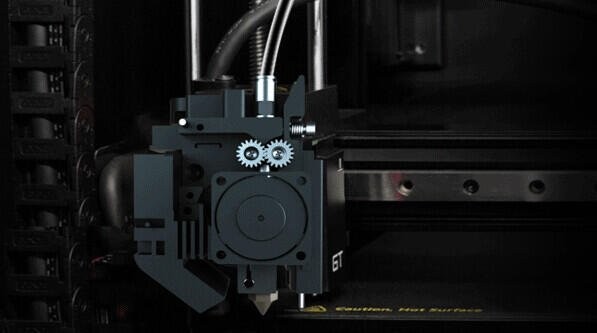

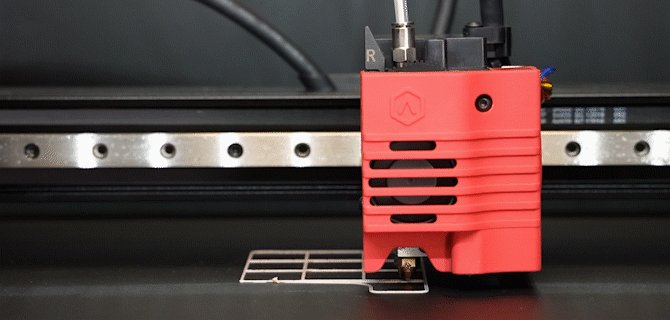

Aimed at creating reliable parts that remain robust under heavy use, the Raise3D E2CF is equipped with a dual direct drive extrusion system with a double gear optimized for the increased wear resulting from fiber-reinforced filaments.

The Raise3D E2CF is equipped with high-strength nozzles and reliable feeding system, thanks to which it is able to print with PA12 CF branded filament for more than 1,000 hours in a row.

Another useful innovation of the model is removable sealed dry boxes for filament, which protect plastic from ambient air moisture. Conveniently shaped as carrying cases with a handle, these boxes attach to the sides of the device and increase the quality of printing.

The E2CF adopts a high-precision optical sensor for auto bed leveling, which provides fast and accurate calibration — a very important feature for print quality.

Along with the E2CF 3D printer, Raise3D launched a new line of filament called Industrial PA12 CF, as well as a support material optimized for this machine.

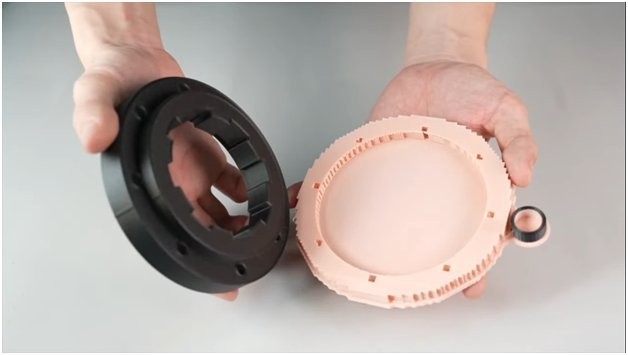

PA12 CF is a carbon fiber-reinforced nylon with a density of 1.04 g/cm3, a tensile strength of 72 MPa, and an impact strength of 12.5 kJ/m2. Its closest analogue is OMNI3D CF PA-12. Carbon fiber in the composition allows printing lighter parts while maintaining strength characteristics — or those conventional in shape and weight but with a significant increase in strength.

The support material is easily separated from the part and hardly leaves any marks, so printed objects require little to no post-processing.

The Raise3D E2CF is designed to meet the needs of engineers and designers in areas such as automotive, aerospace, healthcare, mechanical engineering, that is, everyone who cares not only about accuracy but also the strength and durability of printed parts. The device is also suitable for use in education, business, design, and new product development.

Raise3D’s Global CEO Edward Feng stated, “With the release of the E2CF, Raise3D fills the market gap for a desktop-level 3D printer optimized for fiber-reinforced filaments and will make carbon-fiber 3D printing affordable and simple at last. We are confident this is a relevant step in our mission to lead the promotion and implementation of Flexible Manufacturing Solutions used for low-volume or agile production, by removing another obstacle to the adoption of additive manufacturing as an alternative to traditional production.”

By way of summing up, it can be said that this approach is something intermediate between consumer 3D printers, such as the base model E2, and industrial solutions used for printing with carbon materials. The latter commonly have a build chamber with a maximum temperature of 90 °C, heated filament storage compartments, and high-temperature extruder that can heat up to 450 °C, featuring the reinforcement of polyamide-printed models with carbon filament. All these solutions significantly affect the cost of equipment, so Raise3D went the other way, offering a budget-friendly product which, nevertheless, is able to solve carbon-related tasks.

Update your browser to view this website correctly. Update my browser now

Comments