The prices of FDM 3D printers have been steadily going down for years. Less than a decade ago, buying a large-format 3D printer with a decent level of quality would be almost impossible for small businesses. But nowadays, it is totally affordable. The Modix BIG-60 V4 is one such device, combining capacious build volume, modular design, remarkable precision, and convenient maintenance.

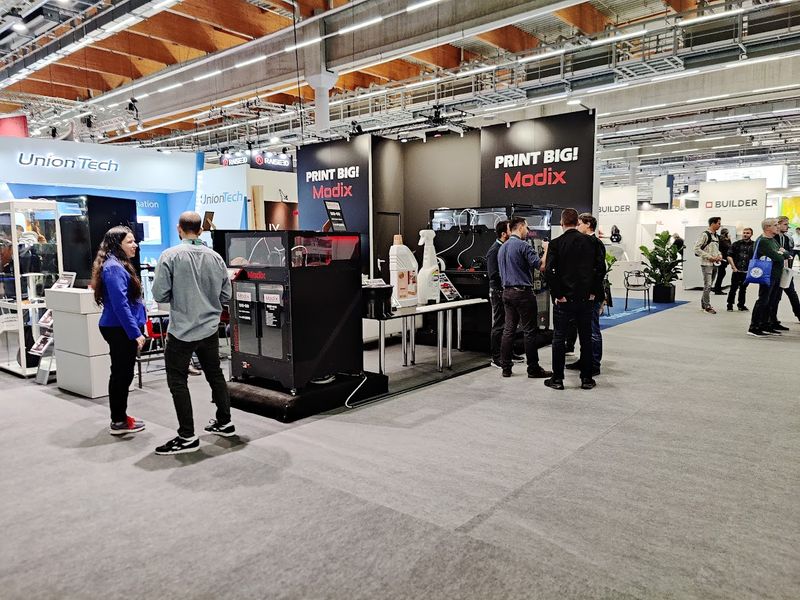

Modix is an Israeli startup based in Tel Aviv. Founded in 2014, the company went on to release their first 3D printer just a year later. The model was named Agam and turned out to be a successful educational model that is still used by various institutions.

Source: modix3d.com

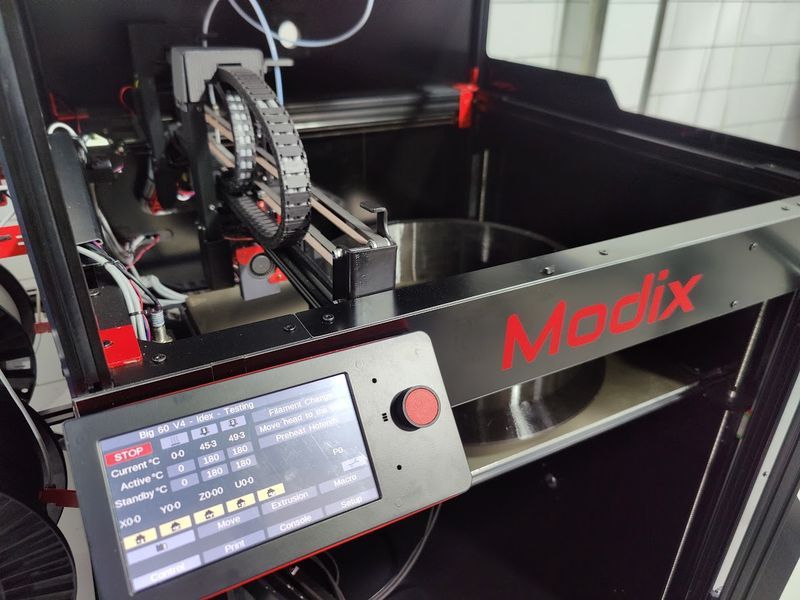

Nowadays, the company focuses solely on their ‘BIG’ series of affordable modular 3D printers featuring large build volumes in combination with high print speed and precision. The latest V4 iteration introduces a number of neat modifications aimed to make Modix devices even more precise, fast, reliable, and user-friendly. In particular, the company now offers major technical improvements in terms of default components, simplified assembly process, and thoughtful supply kits. To find out more, check out the video below.

The Modix Big-60 V4 is an upgraded version of the Modix FDM professional, self-assembly 3D printer kit — BIG-60 V3. Like all the machines from the fourth generation of the company’s major series, the BIG-60 features easier and faster assembly as well as enhanced stability, accuracy, and convenience of use. Moreover, the device can be easily personalized and enhanced in functionalities due to its brand modular design.

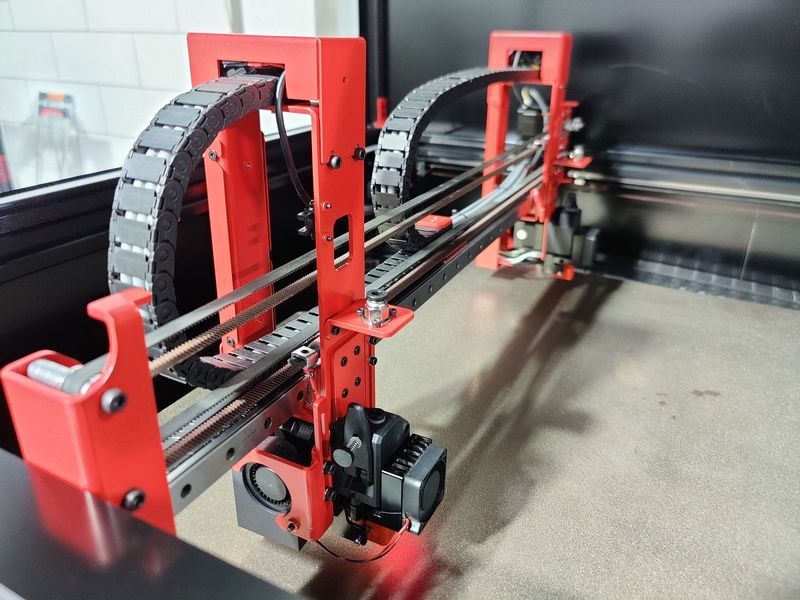

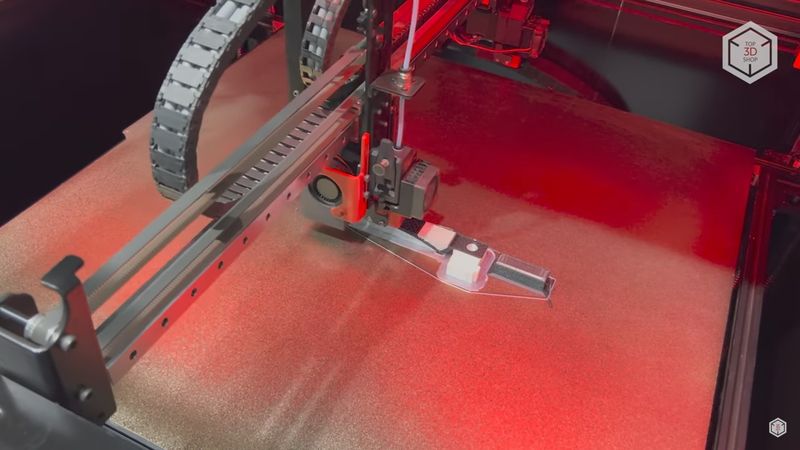

Apart from the new self-developed IDEX module for printing with independent dual extruder and water-soluble filaments, the Modix BIG-60 V4 supports a variety of optional add-ons, such as a redesigned enclosure, high-precision HIWIN linear rails, magnetic print bed, etc. With the right upgrades, you will get an industrial workhorse at a good price.

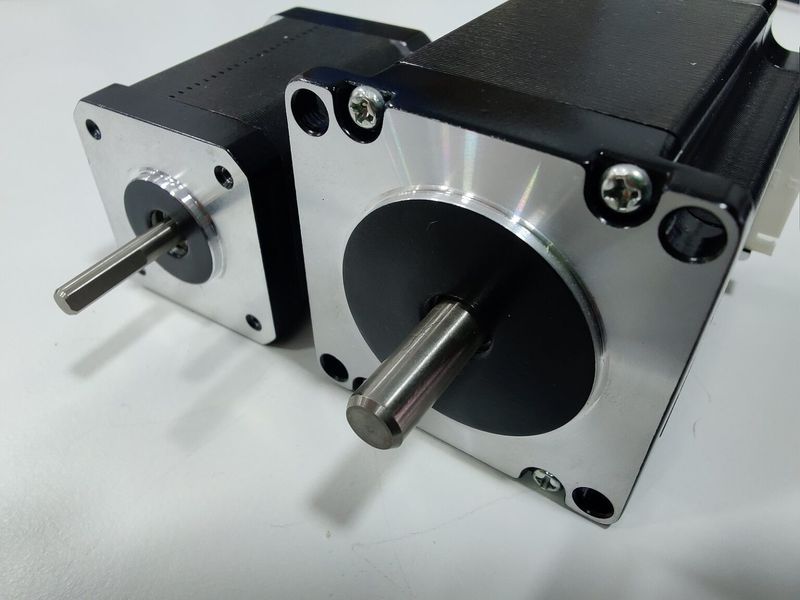

One of the most important changes is the upgraded Z-axis featuring strong Nema-23 motors and reliable CNC machined brackets that hold the bed firmly and add to the overall level of print accuracy. With the better motors on the X-axis, the printer also provides much faster printing than before, with the maximum speed of up to 250 mm/s.

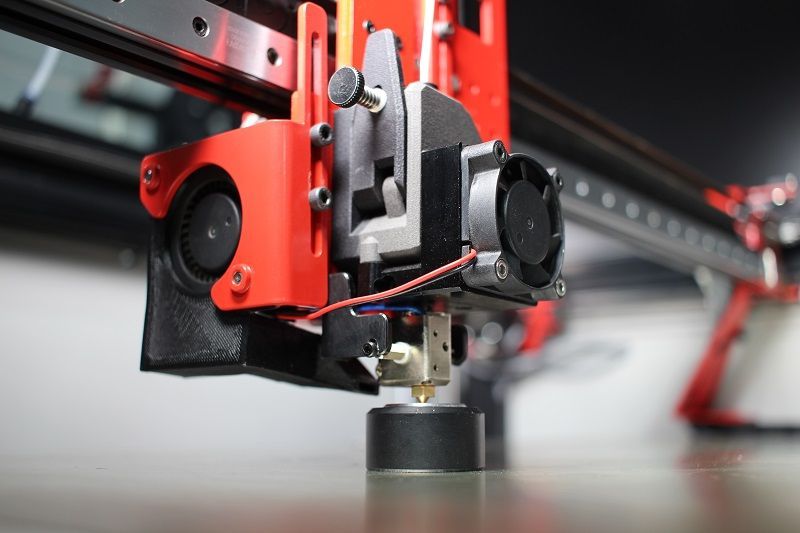

Another notable update includes some previous add-ons that are now available by default. Namely, the electronic expansion board Duex 5 enabling completely automated calibration, enhanced Griffin printhead made in collaboration with Bondtech, optical end-stop switches for higher accuracy and repeatability, built-in crash detector for additional safety, clog detector, and emergency stop button ensuring immediate response.

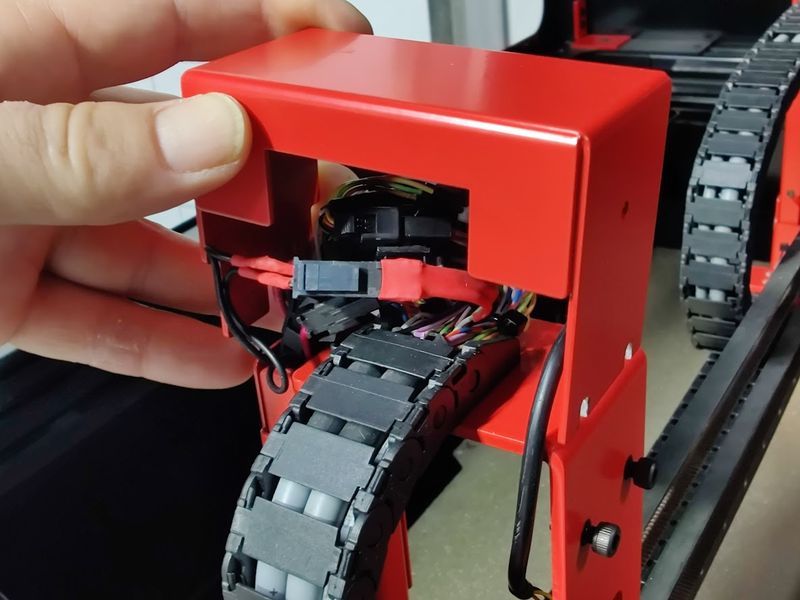

In addition, Modix has significantly upgraded the design of the machine for easier access and more convenient use. Alongside a new pneumatic top lid, rear maintenance opening hatch, sturdy door hinges, reliable door and lid sealing strips, and refined internal LED lighting, the BIG-60 V4 provides well-thought PTFE and wires management.

The wires connectors have been relocated on top of the print head, where both top and back covers can be easily removed for maintenance, with no mounting screws involved.

For more specific information, check out the product page in our shop.

The machine comes as a DIY kit and needs to be assembled. It comes in several boxes, the contents of which include:

Modix does not provide any proprietary slicing software for its printers, so the user is free to choose any free solution available on the market. For example, Cura, Slic3r, Simplify3D, Printerface, etc.

The Modix BIG-60 V4 is compatible with the majority of common file formats and can be connected to the PC by means of Wi-Fi or USB. There is a web interface for operating the machine remotely, as well as a dedicated mobile app.

Due to its reliability, precision, high build speed, and sturdy modular construction allowing for easily personalized system and future enhancements, the Modix BIG-60 V4 3D printer can be successfully used in prototyping and small-scale manufacturing for making functional prototypes, end-use products, and top-quality spare parts.

The BIG-60 V4 is the latest iteration of the Modix flagship 3D printer from the company’s ‘BIG’ series. Featuring a sizable build-volume, improved modular design allowing for extensive upgrades, and high quality of printing that can be compared to industrial-grade results, the BIG-60 is a great choice for experienced enthusiasts and commercial users. This massive yet fast and precise device in a rigid frame will provide top-quality prints at an affordable price.

Update your browser to view this website correctly. Update my browser now

Write a comment