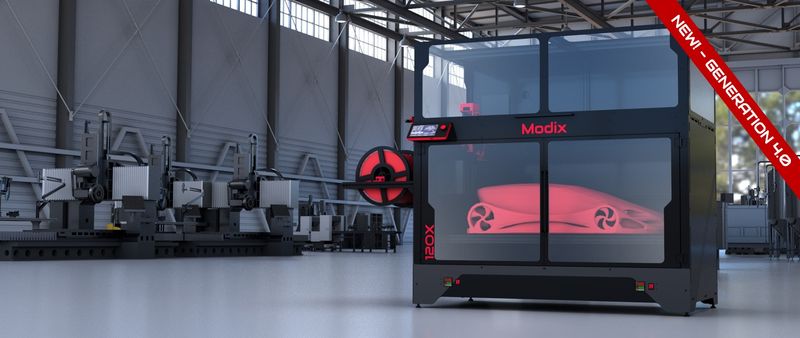

This autumn has graced 3D printing experts and enthusiasts with a number of delightful fruits, one of the major ones certainly being Modix’s introduction of the fourth generation of their modular FFF 3D printers. The upgrade pack comes with all sorts of advanced capabilities and neat modifications making the devices even more precise, fast, reliable, and user-friendly.

This is Top 3D Shop, and today we are going to cover all the main changes in the Modix Generation 4 3D printers.

Due to major technical improvements, the company has partially changed their supply kits. For example, some previous add-ons are now available by default, while others are included only with several models. To learn more, read the following sections.

|

BIG-60 |

BIG-120X |

BIG-120Z |

BIG-180X |

BIG-Meter |

|

|

Print volume |

600 x 600 x 660 mm |

1200 x 600 x 640 mm |

600 x 600 x 1200 mm |

1800 x 600 x 600 mm |

1010 x 1010 x 1010 mm |

|

Outer dimensions |

906 x 1060 x 1356 mm |

1556 x 1060 x 1430 mm |

906 x 1060 x 2000 mm |

2170 x 1060 x 1430 mm |

1300 x 1470 x 1830 mm |

|

Shipping weight |

120 kg |

170 kg |

140 kg |

210 kg |

200 kg |

|

Enclosure |

Optional |

Optional |

Optional |

Included |

Included |

|

IDEX |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Z axis guides |

HIWIN rails — optional |

HIWIN rails — optional |

HIWIN rails as default |

HIWIN rails as default |

HIWIN rails as default |

|

DUEX expansion board |

Included |

Included |

Included |

Included |

Included |

|

Tilt screen |

Optional |

Optional |

Included |

Optional |

Included |

|

Casters |

Optional |

Optional |

Optional |

Included |

Included |

|

Price |

$4,900.00 | $7,500.00 | $7,500.00 | $15,500.00 | $13,500.00 |

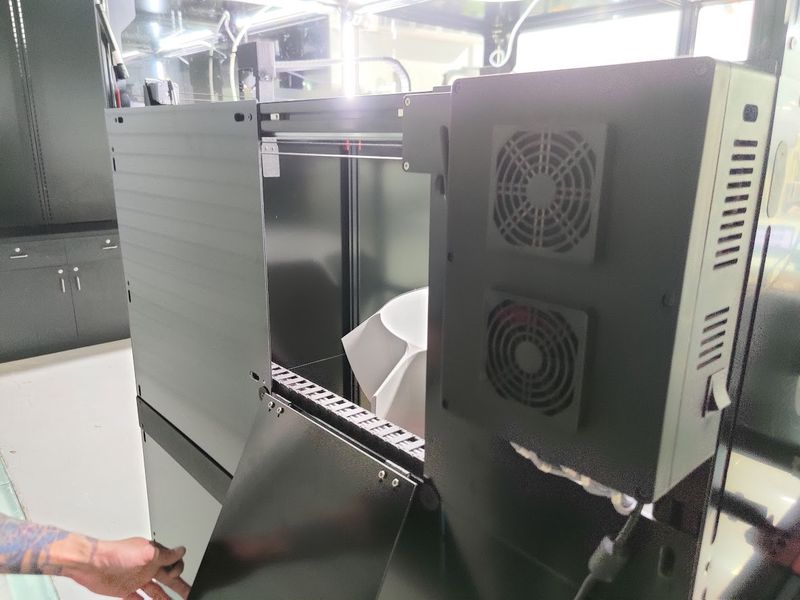

The renewed Modix V4 machines come with updated design features making for easy access and convenient usage.

The list of the added improvements includes a brand new pneumatic top lid, rear maintenance opening hatch, sturdy door hinges, reliable door and lid sealing strips, and refined internal LED lighting.

Another nice touch is a refreshed logo font.

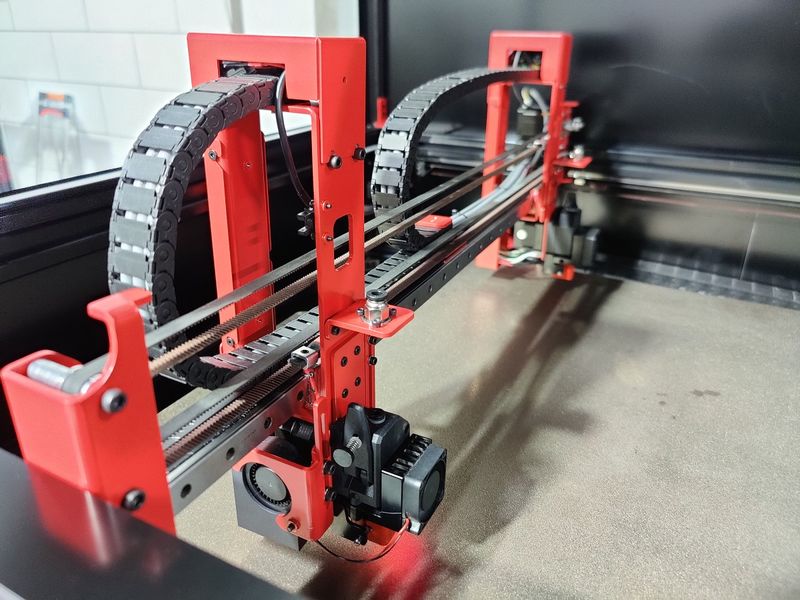

The IDEX optional add-on represents an independent dual extruder — an advanced system, where each extruder is controlled separately and is capable of moving independently from the other. This mechanism ensures high-quality dual material printing with accurate, smooth, and clean outcomes.

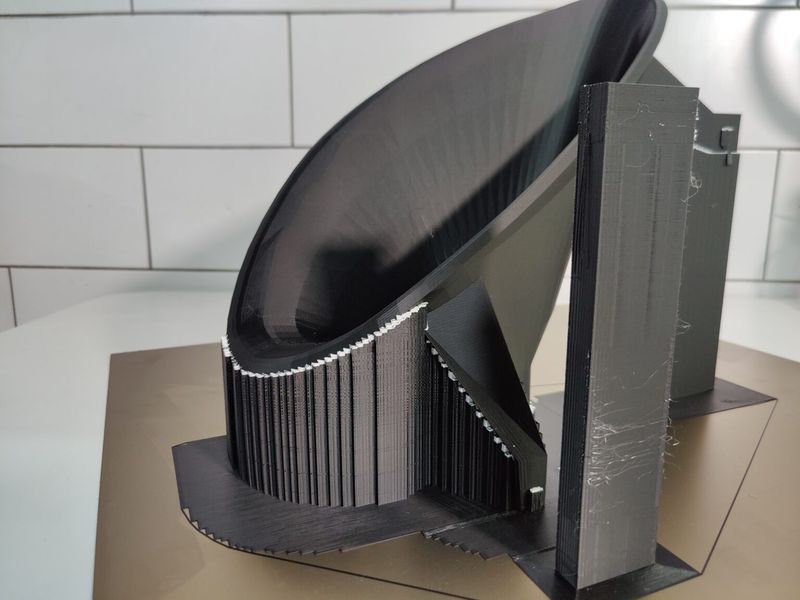

Due to this handy upgrade, the user will be able to print complex models with internal geometries with water-soluble filament or build dense support layers with breakaway support filament. Both variants provide prints with top-quality surfaces, which greatly reduces manual labor at the post-processing stage.

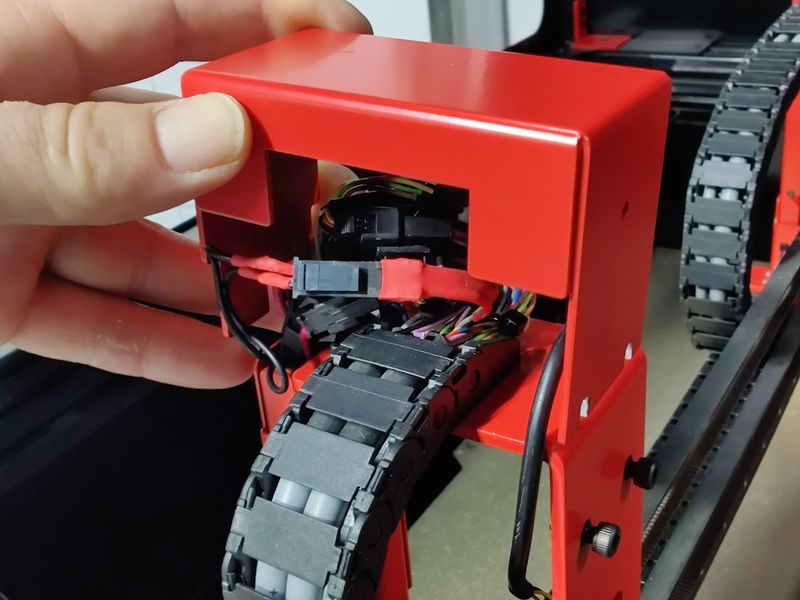

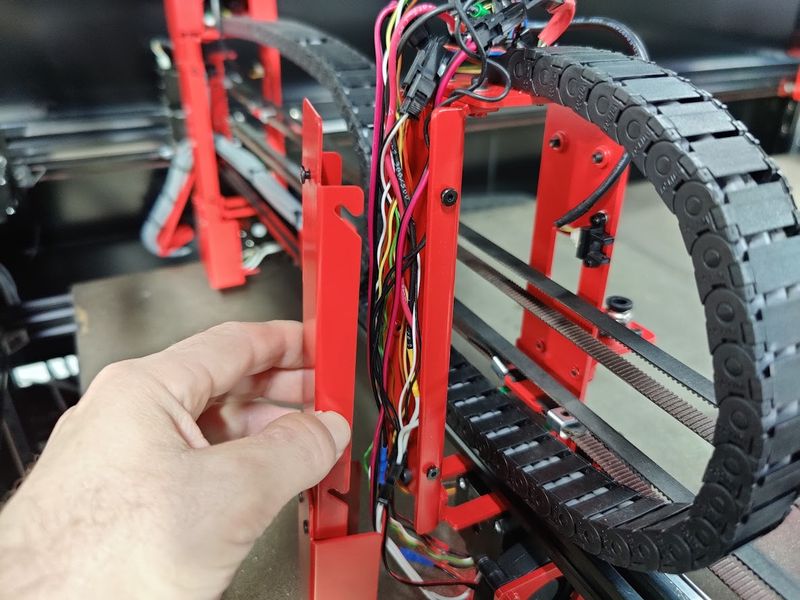

The add-on is purchased separately and supplied with a secondary printing subsystem (consisting of a Griffin print head, clog detector, PTFE, and spool mount), motion system (secondary Y axis motor), metal brackets, necessary wires, drag chains, and optical end-stops.

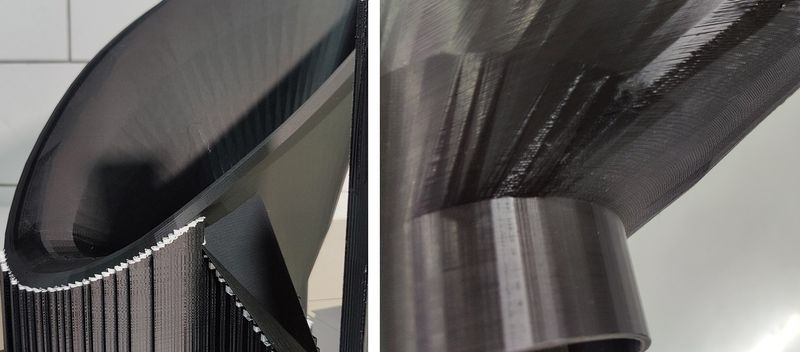

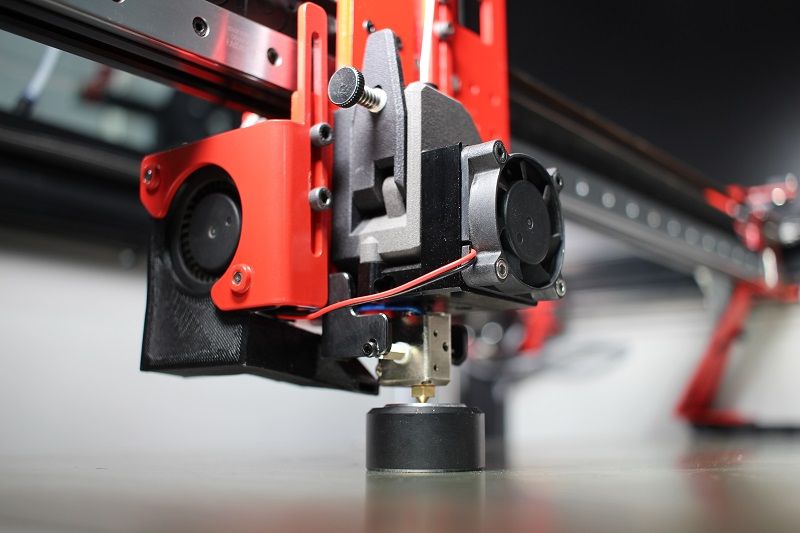

What used to be an optional upgrade is now the default printhead for all the Modix V4 3D printers. It consists of a custom extruder made by Bondtech and of a new hotend designed by Modix. In addition, the device has received an important upgrade.

Thanks to a double drive-gear system, the Griffin printhead ensures high flow rate, while the built- in heat-block made of nickel-coated copper enhances the compatibility with higher printing temperatures. Rigid mounting for the heat-block and premium constituent material make for increased reliability and longer service life.

Add to this easier nozzle replacements and overall compact and smart design enabling completely automatic calibration — and this becomes a highly beneficial offer.

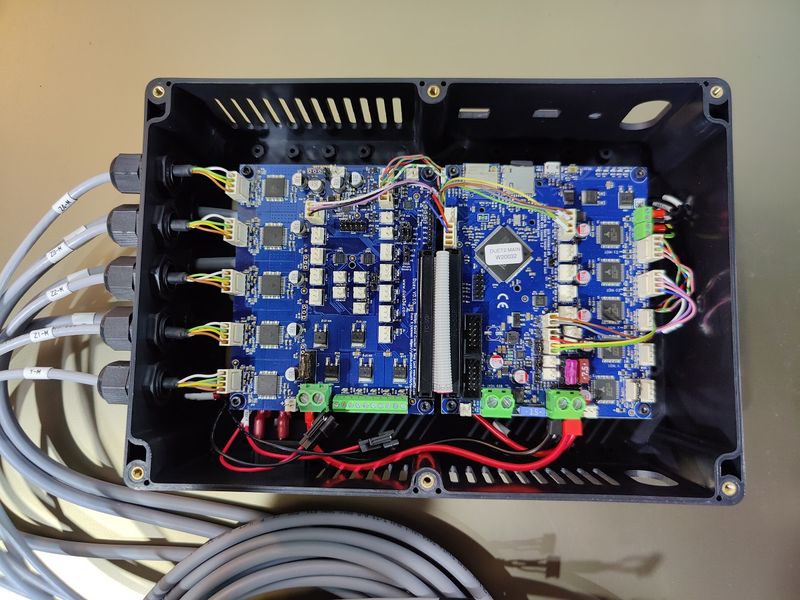

The Generation 4 is engineered with the integrated electronic expansion board — Duex 5, which was previously included only for the BIG-Meter and BIG-180X models.

With Duex 5, a dedicated stepper motor driver is allocated for each Z and X axis motor, which allows for a full set of automated calibration routines, such as automated bed tilt, bed leveling, gantry alignment, and Z offset calibration.

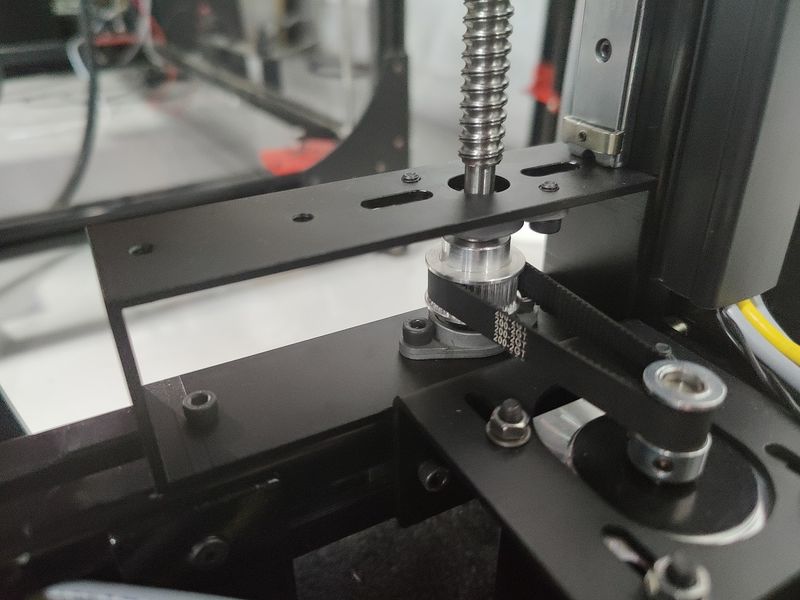

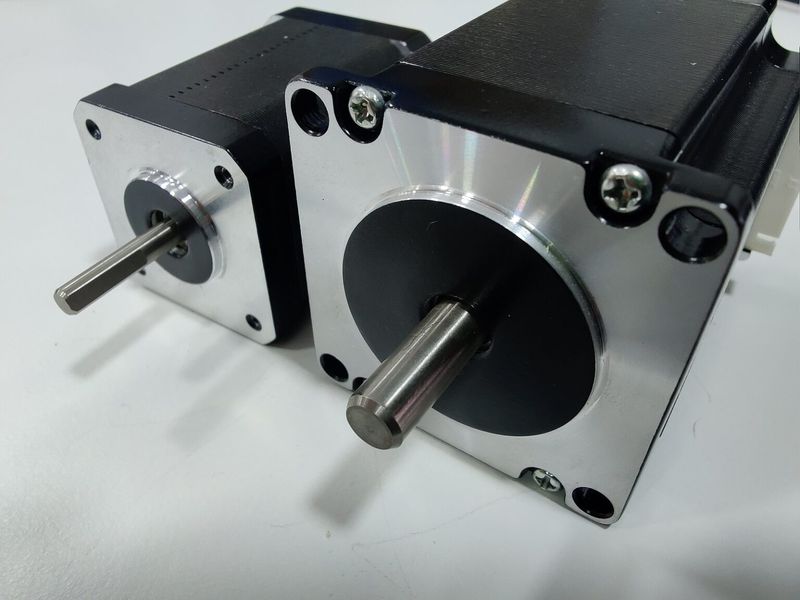

Due to more powerful Nema-23 motors (compared to previously used NEMA-17) as well as CNC machined brackets, the print bed of the upgraded printers is held firmly and thus provides a higher level of accuracy.

The above-mentioned improvement has also led to an increase in printing speed up to 250 mm/s, with travel speed of up to 350 mm/s. This has been achieved thanks to the stronger NEMA motors on the X axis and reduced weight on the Y axis due to the new IDEX setup. With changes like these, even the biggest projects will not be as time-consuming as before.

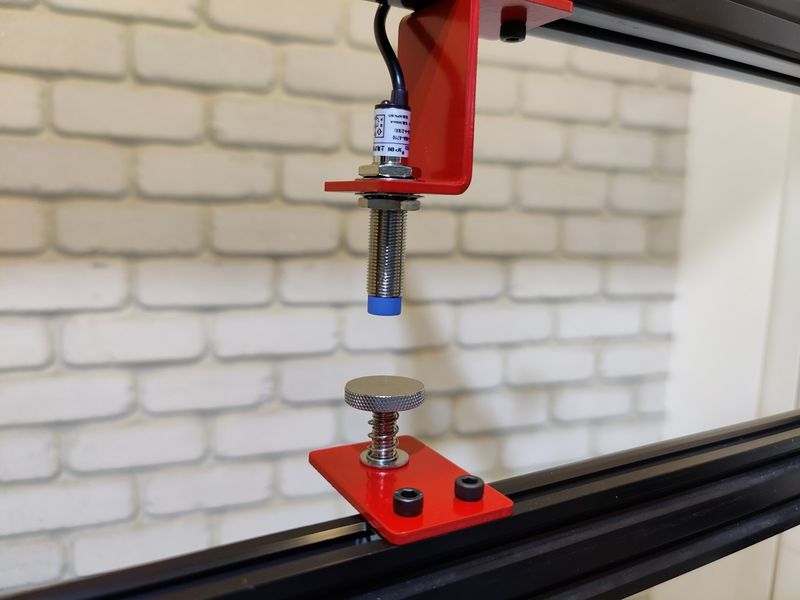

With the Generation 4, end-stop switches are upgraded to more accurate optical switches that ensure better repeatability and smoother print recovery after power outages.

This former optional add-on is now a new standard for the Modix 3D printers. The clog detector is equipped with a custom highly sensitive encoder capable of indicating such potential issues as hotend clogs, filament knots, material runout, and under-extrusion. When a problem is identified, printing is paused to save the project.

The new add-on serves as a drop-in replacement for the current filament runout sensor. To improve printer performance even more, it is recommended to purchase two units for IDEX configuration.

Another optional add-on has now become default for the Modix V4 machines. The crash detector prevents the printhead from crashing into the bed plate in some particular cases, for example, when the BL-Touch bed leveling probe fails and this failure is not being detected by the printer controller.

To improve user experience and make printer maintenance really smooth and easy, Modix decided to relocate the wires connectors on top of the print head. In addition, both top and back covers can be easily removed for maintenance, no mounting screws involved.

With the V4 upgrade, the PTFE tube now rests in a special roller guide. It provides the most relaxed position for the tube, which results in reduced friction inside it.

All the Generation 4 models are engineered with an emergency stop button ensuring immediate response in resetting the printer controller.

With the latest upgrade, the tallest models, like BIG-Meter and BiG-120Z, are now supplied with a new standard add-on, including a handy tilt screen ensuring easier access to information and commands, especially during system calibration, frontal secondary power switch for convenient operation in tight spaces, and secondary reset button for even better comfort of use.

The set is also available as an optional add-on for the rest of the Modix Generation 4 printers.

The Modix Active Air Filter (MAAF) comes as an optional add-on representing an external air filter device intended for cleaning of the printers’ build chamber from harmful sub-micron particles and gas fumes released during plastic melting. This procedure is held out constantly during the entire printing process, ensuring a risk-free working environment. In addition, the user can control the air flow speed for effective filtering in any situation.

Being a multi-layer filtering system, the MAAF includes:

The add-on is strongly recommended for every user who prints any plastic beyond PLA. Since the HEPA/Carbon combo filters last from 6 to 12 months, you can also purchase a spare filter set in our shop.

Modix have announced their proprietary line of filament, sales of which will begin in the new generation. This promises high-quality experience for the company’s customers using IDEX with engineering materials and the beginning of development of the company’s own ecosystem.

Modix continues to amaze its clients with ever-expanding capabilities of their professional-grade devices. The company’s 3D printers become more powerful with each upgrade and yet remain accessible to a wide range of users within various industries. With the mentioned changes, we can say it becomes really natural to finally get hold of such a machine and bring your production to a dramatic new level.

Update your browser to view this website correctly. Update my browser now

Write a comment