Developed by the South Korean company LugoLabs, the LUGO G3 is a dual-extruder machine carrying several in-house developed engineering innovations.

The lineup includes two versions, which are a basic and a high-temperature ones. Read the following overview to learn about their specs and features.

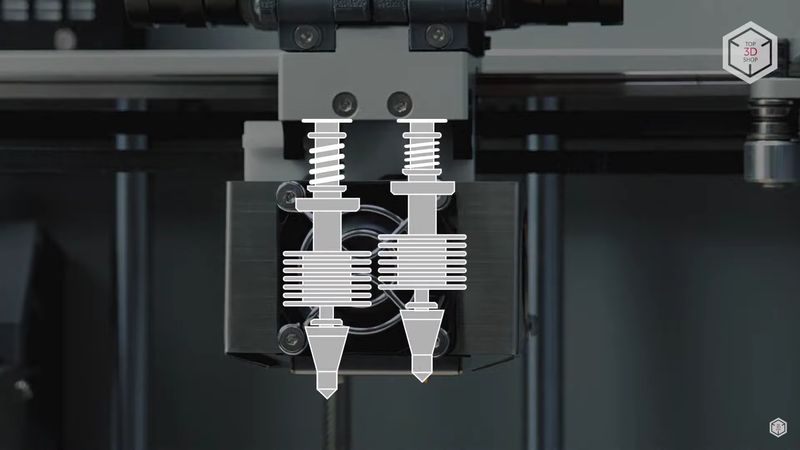

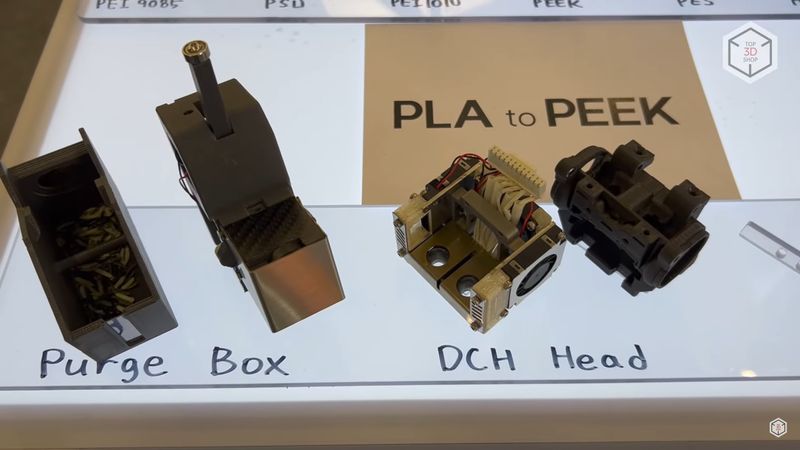

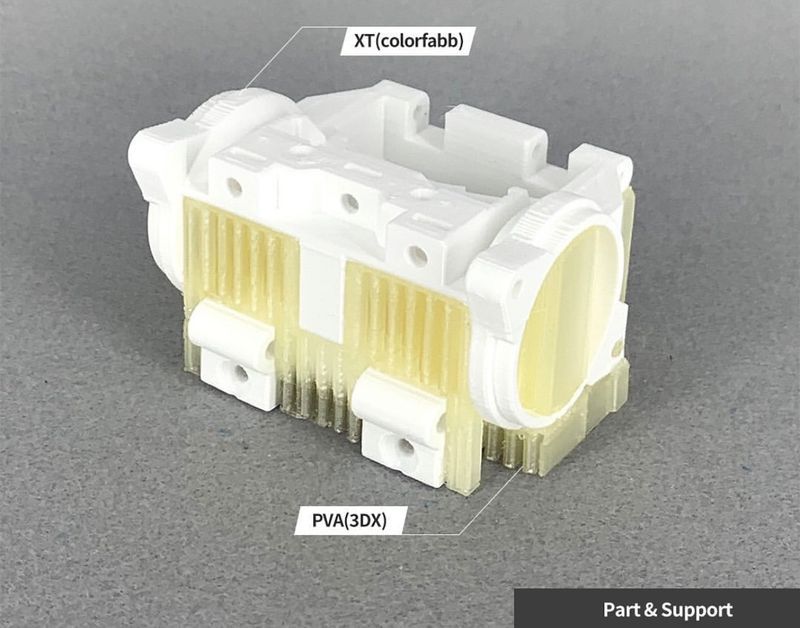

The printer is equipped with a proprietary extruder called DCH (Dual Cone-shaped Head) — its design eliminates the need for double calibration and allows for precise temperature control of each nozzle. This solution simplifies printing with two materials with different melting temperatures and expands the applications of the 3D printer.

The DCH comes with 0.4 millimeter nozzles with the maximum operating temperature of 285 °C. Another version of the printer, the G3 HT, can process high-temp materials with the extruder heating up to 400 degrees.

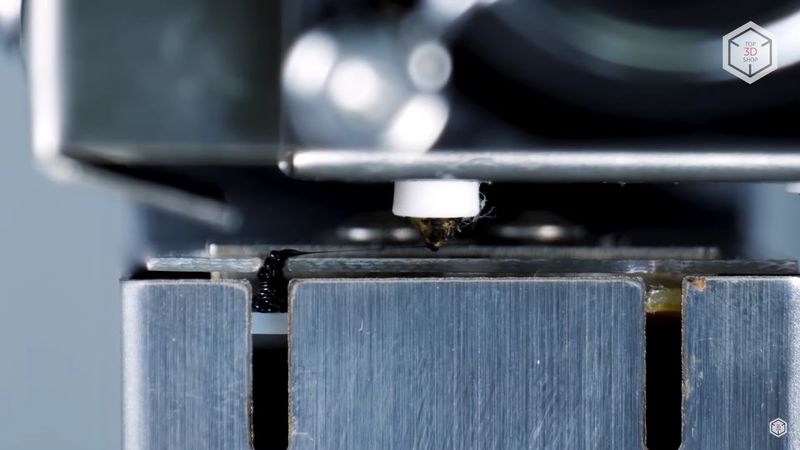

The unique Purge Box cleaning mechanism removes filament residue when switching between the materials. Conventional wipe towers usually formed for this purpose increase print time and material consumption, while the integrated nozzle cleaning solution solves both of these problems.

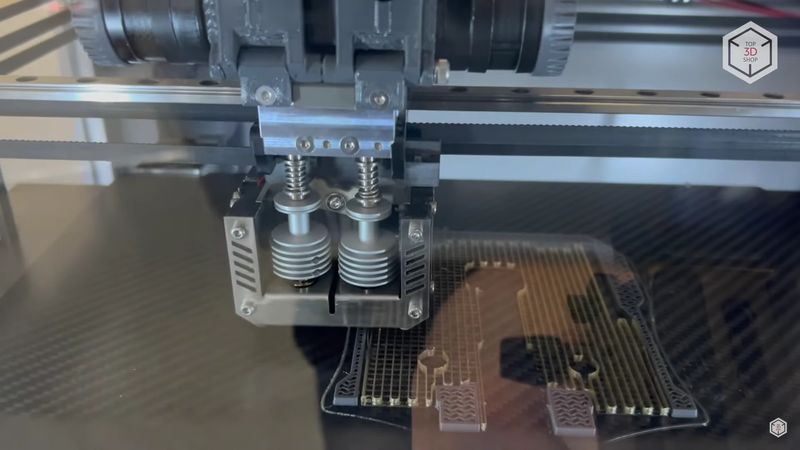

The LUGO G3 is equipped with a heated bed with a double-sided build plate. One side is coated with carbon fiber, and the other with PEI.

The enclosed-type 3D printer features an air purification system based on a HEPA 13 carbon filter.

The special sealed Fila-box compartment can store two spools of filament and keeps the humidity inside below 15–20 percent.

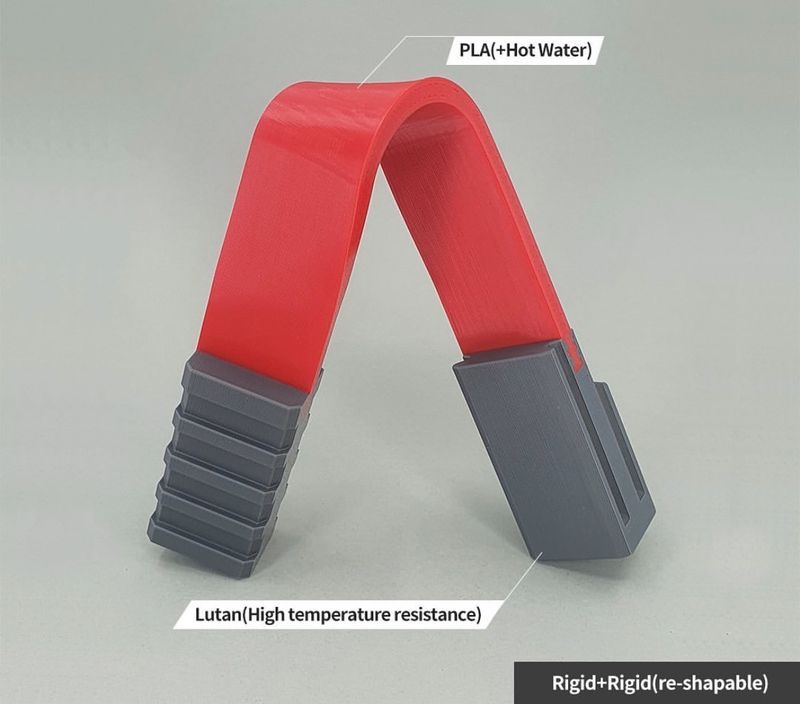

Compatible with a wide range of filaments, the LUGO G3 can process ABS, PLA, PETG, polycarbonate, polyamide, ASA, PBT, TPU, polypropylene, carbon- and glass-fiber composites.

The high-temperature model can also print in engineering-grade plastics such as PEEK, PEKK, and Ultem.

To prepare files for printing, the manufacturer recommends LUGO Cura — a proprietary version of the popular slicing software. Files can be sent to the machine via a USB connection, while the touchscreen grants access to the printer's settings in real time.

The Korean manufacturer LugoLabs has produced 3D printers for the domestic market since 2013 under the Former’s Farm brand. The LUGO G3 and G3 HT are professional devices that feature wide material compatibility and outstanding value-to-price ratio.

Remarkable innovations such as Dual Cone-shaped Head along with Purge Box bring the print quality and user experience to a completely new level. Furthermore, the high-temp version of the 3D printer adds to the already wide material compatibility, while the sealed filament compartment helps to store consumables in the optimal environment.

Update your browser to view this website correctly. Update my browser now

Write a comment