The Raise3D company has recently unveiled its Hyper FFF technology which establishes a new standard for industrial FFF printing. The technology successfully copes with one of the most significant challenges of the material extrusion process — the speed limitation.

This is Top 3D Shop, and in this article, we are going to tell you about the way to multiply your Pro3 series production volume without the slightest loss of quality. Read on to learn more.

As mentioned, speed has always been one of the limiting factors for FDM printing. When used for prototyping and small-batch production, FDM machines prove to be more efficient than traditional manufacturing methods, but they lose when it comes to large and even medium production volumes. Why not just increase the print speed? Unfortunately, it often happens that any further increase in speed leads to dramatic surface quality loss, dimensional inaccuracy, and poor layer adhesion because of vibrations caused by the fast-moving printhead.

Raise3D engineers found a solution to the problem by developing an algorithm that absorbs excessive vibrations every time the print head changes direction while moving at high speed. This algorithm is actually the core of the Hyper FFF technology and allows increasing acceleration up to 10000 mm/s², thus providing a speed boost of up to 200–350 mm/s.

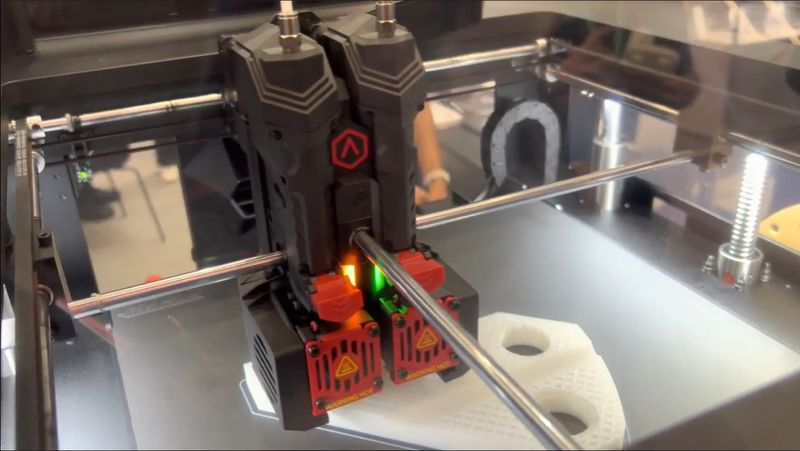

Raise3D at Formnext 2022

Increased print speeds pose a challenge for material engineers, as standard filaments do not have enough time to melt, which again means poor interlayer adhesion and part deformation. To avoid this, the manufacturer has developed a new line of Hyper Speed filaments, of which two most popular ABS and PLA materials are already available. New filaments feature better fluidity and melt and cool more easily than traditional thermoplastics.

Last but not least is the software, supporting the new technology. The dedicated Raise3D slicer ideaMaker has been updated with a new Hyper Speed mode and material profiles for corresponding filaments. The current software version to work with the Hyper FFF solution is 4.4.0 Alpha, which can be downloaded from the manufacturer’s website.

Now let us be more specific and see what implementation of the new technology the Raise3D engineers offer their customers.

For some items, package content may change. In case of any questions, please get in touch.

The Hyper Speed Upgrade Kit is a complete solution providing the user with all the benefits of Hyper Speed printing. Currently the kit is compatible with Pro3 and Pro3 Plus models only, but the manufacturer intends to expand the number of compatible devices and eventually make the technology available to all their industrial machines.

The box includes two high-speed hotends, an auto calibrator, two spools of PLA and ABS filaments from the new Hyper Speed lineup, and software upgrades. The Upgrade letter contains the activation code necessary to get the files needed to upgrade the firmware with Hyper Speed mode and to successfully install the hotends. The installation and calibration process does take some time, but you will be guided through it with the prompts on your printer’s screen, so it will not cause any problems.

Once you install and calibrate your new equipment, the manufacturer recommends recalibrating it every 2 or 3 months to ensure the best stability and printing results. The only thing left is to update the ideaMaker software, and your renewed Hyper Speed printer is ready to go.

High-speed printing and, as a result, reduced production times along with increased output is a highly demanded option in industrial 3D printing. The new Raise3D Hyper FFF technology aims to multiply the production volume without sacrificing product quality, which the company believes will be a milestone not only for Raise3D, but for the entire 3D printing industry.

Update your browser to view this website correctly. Update my browser now

Write a comment