In this review, we will take a deeper dive into the Farsoon Flight series of industrial 3D printers, which print with polymer materials using SLS technology.

Dr. Xu Xiaoshu, founder and chairman of Farsoon Technologies

Farsoon Technologies is a leading Chinese company that manufactures industrial laser sintering and fusion systems for 3D printing with fine metal and polyamide powders. The company was founded in 2009 by Dr. Xu Xiaoshu, using all the knowledge he acquired as CTO at DTM Corporation, later renamed as 3D Systems.

DTM was a pioneer in SLS 3D printing. With over twenty years of unique experience in the industry, Dr. Shu has become the world's leading expert in selective laser sintering (SLS) and melting (SLM) technologies, and has built a team of qualified specialists in all areas required in the development and production of industrial additive equipment.

Farsoon Technologies has offices in North America, Europe and China, as well as representatives around the world.

Farsoon Flight features include:

Flight technology, also known as Fiber Light, is a 3D printing process that utilizes a fiber laser that provides greater performance than diode and CO₂ lasers. The fiber laser is not only more powerful, but also has a longer lifespan compared to gas tubes.

The increased power allows processing a vast array of materials, including composite and high-temperature materials, and accelerates the sintering of each layer.

The Farsoon Flight 252 lineup of 3D printers is equipped with a 300 watt fiber laser, while the 403 series boasts a more potent 500 watt laser. The beam moves over a layer of material during printing at a speed of up to 15–20 m/s.

The Flight SS403P 3D printer is a standard model featuring the basic Flight series parameters, which are nevertheless quite impressive. Due to its increased scanning speed of up to 20 m/s, the machine provides extremely fast sintering resulting in accelerated manufacturing. Thus, the SS403P model is capable of producing two complete assemblies covering the area of 400 x 400 x 450 mm in a single business day. Furthermore, the machine can be pre-ordered with a high-cylinder option offering a larger build volume of 400 x 400 x 540 mm.

As for print quality, a high-precision 3-axis digital galvo system inherent to the series is characterized by improved accuracy with feature details of 0.3 mm. In combination with a robust and stable laser as well as even energy distribution to the material, the SS403P 3D printer can make strong and highly accurate parts with greater density in a really short time.

The Farsoon Flight HT403P 3D printer differs from the SS model in terms of the consistent print chamber heating temperature. In contrast to the original’s 190 °C, it can reach up to 220 °C. Both machines are engineered with a multi-zone heater and smart thermal control systems, which allows them to work with a wide range of demanding materials. Thanks to intelligent software with flexible settings and manifold handy functions, such as real-time continuous monitoring and surface temperature optimization, the printing process is fully controlled and brought to the highest quality level.

The Farsoon Flight ST252P is a powerful machine based on the new company’s technology, which is more compact compared to the 403P series in regards to its build volume: it is 250 x 250 x 320 mm in contrast to the latter’s 400 x 400 x 450 mm. Another slight difference is the scanning speed reduced to 15 m/s. Nevertheless, the given device is superior to the bigger machines in terms of its maximum build chamber temperature, which is able to achieve 280 °C, opening up new opportunities when dealing with high-performance materials.

Otherwise, the ST252P is not inferior to the 403P machines. The basic features of the Flight series are retained: a potent fiber laser with a smaller spot size and increased longevity, dynamic optical system, open parameters providing smart customization and precise machine control, user-friendly interface, multi-zone heater and comprehensive temperature control ensuring low risk of part’s deformation during printing.

The Farsoon Flight HT252P is similar to the previously described model in all aspects except for the build chamber temperature, which does not exceed 220 °C. Despite this limitation, it is a generally capable and efficient machine offering the best of the Flight series, including enhanced software potential expressed in multiple advanced functions, such as 3D visualization, automated diagnostic procedures, etc. Like any Farsoon device, the HT252P makes use of an open parameter system, which allows the user thoroughly control build settings through a clear, streamlined interface that comes in two modes — Production and Expert — depending on your skills and purposes.

With improved scanning algorithms, decent durability, and ability to effectively process small-to-medium-sized parts as well as batches of prints, which significantly speeds up the production cycle and reduces the cost per unit, the Farsoon Flight 3D printers guarantee a high ROI regardless of the model chosen.

The main areas of application of Farsoon Flight 3D printers are:

Given the opportunities that 3D printing provides when using various polymer, composite, ultra-strong and high-temperature materials, the list above can hardly be considered complete, because such equipment can be used literally in any industry.

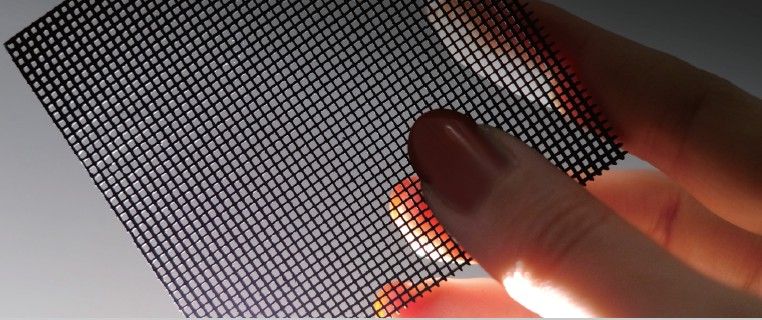

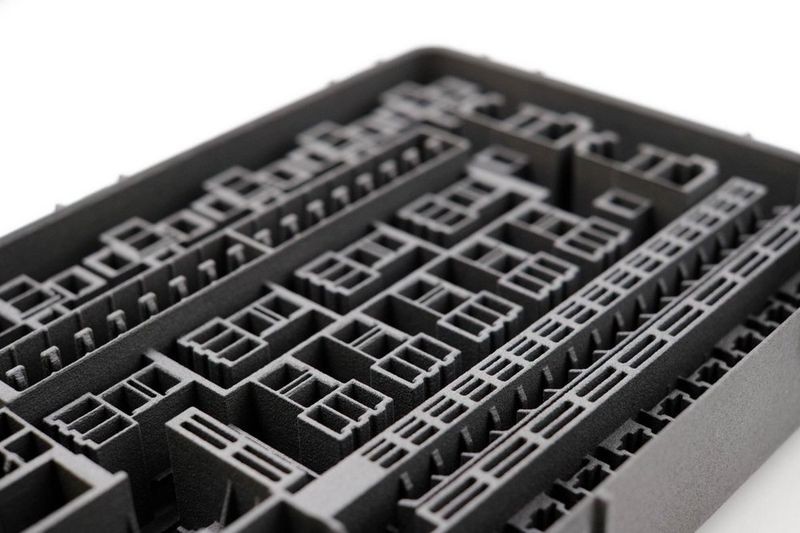

Lattice design. Minimum wall thickness of 23 µm. Material: FS 3200PA-F. Printed on the Flight HT403P

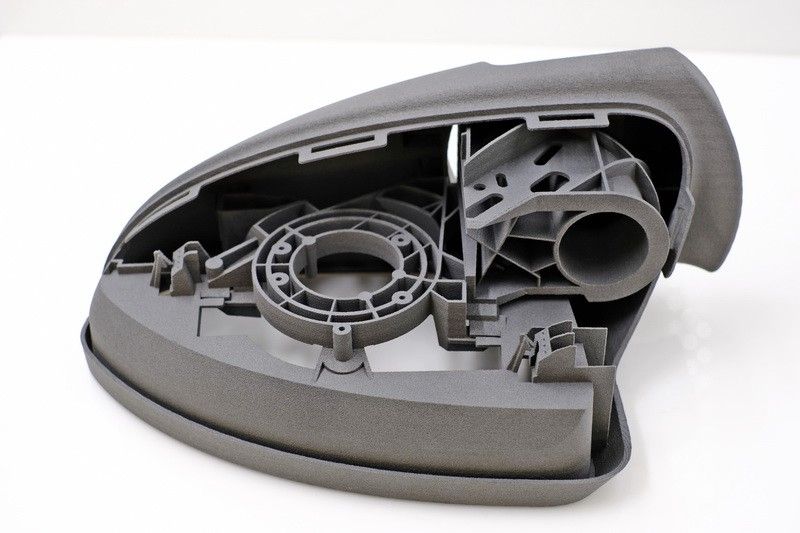

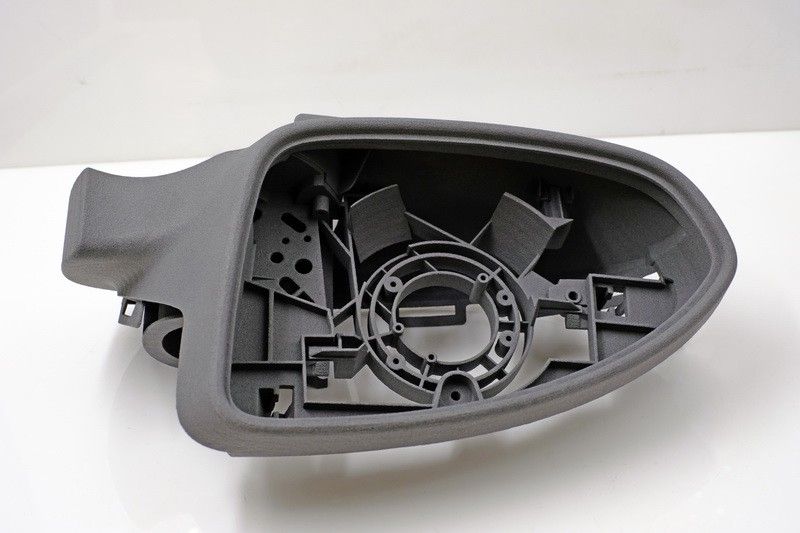

Rear view mirror housing. Material: FS6140GF

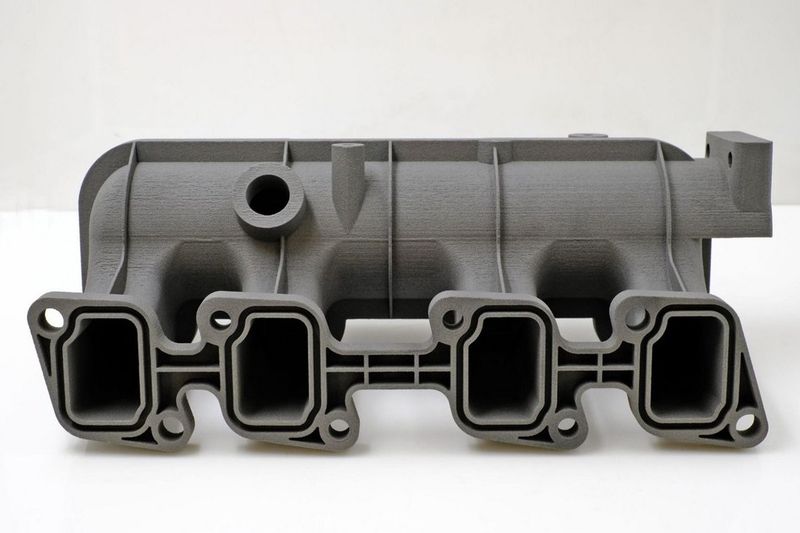

Radiator prototype

Engine cover prototype

Fuse box prototype

In a world where complicated and intricate designs drive industries forward, Farsoon’s Flight series can offer a leading edge to businesses in need of fast, reliable, and economically viable additive manufacturing. With a vast array of build volumes, available materials and ease of integration, Farsoon can deliver larger and more complex projects faster, simplifying the workflow for creating and producing new designs. In the long run, Farsoon technologies can provide the desired cost savings and limited production timelines needed to keep your business at the frontline of the market.

Update your browser to view this website correctly. Update my browser now

Write a comment