Selective laser melting, or SLM, is the technology behind most 3D printers using metals as consumable. DMLS, DMLM, LMF, LPBF, SLM are different names for the same printing method. Some terms have developed historically, while others are trademarks. Referring to the inventors of the technology from the Fraunhofer Institute in Germany, the most appropriate term would be LPBF — Laser Powder Bed Fusion. In our article, we are going to use the term SLM as the most common name for the technology today.

This is Top 3D Shop, and in this review, we will tell you about SLM 3D printing and the most prominent equipment based on this technology.

So, what is the essence of SLM as an additive method?

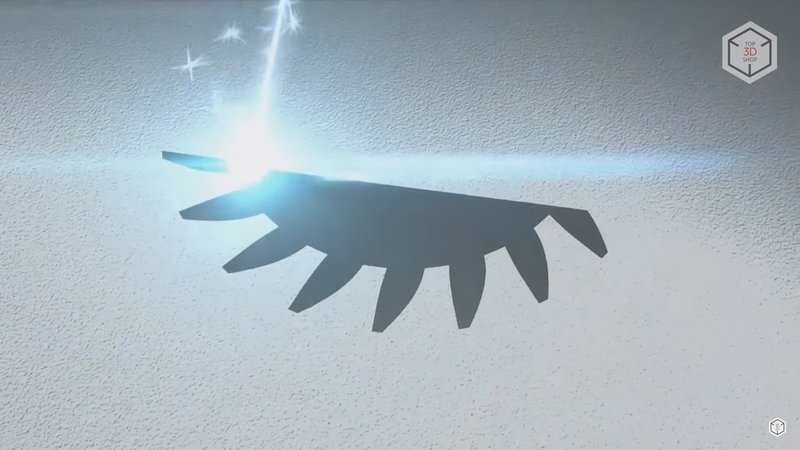

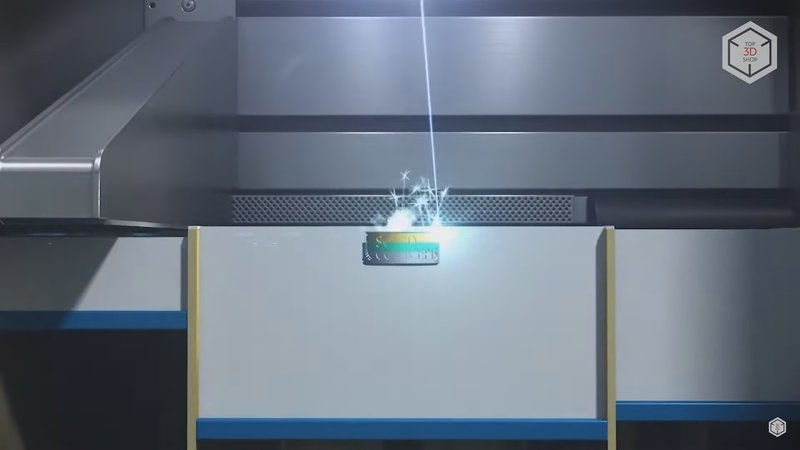

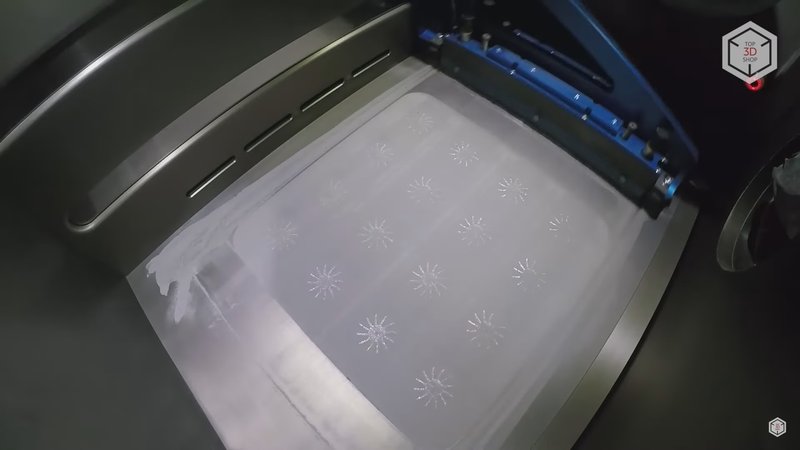

In short, potent lasers selectively fuse metal powder layer by layer. The required volume of powder is placed on a platform, which, after fusing a layer, is lowered to a predetermined height, equal to the layer thickness.

The next layer of material is applied on top and the procedure is repeated until the part is finished.

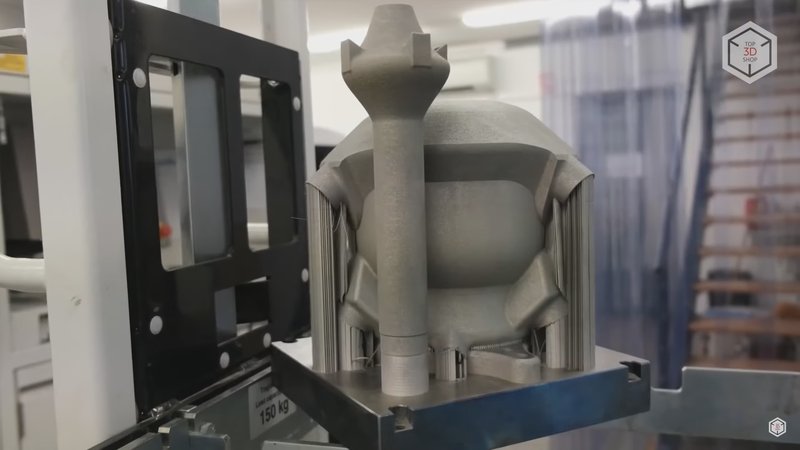

SLM refers to additive methods that do not require special support structures. On the one hand, the whole volume of powder in which the model is formed acts as support.

On the other hand, supports are needed since the difference in temperature between the melt zone and the surrounding powder can lead to certain deformations. In this method, supports are used to remove excessive heat from the work area.

Today, SLM 3D printers use both pure metal powders and metal alloy ones. The most common consumables are aluminum, cobalt-chrome, copper, nickel (Inconel), stainless and tool steel, titanium, and precious metals.

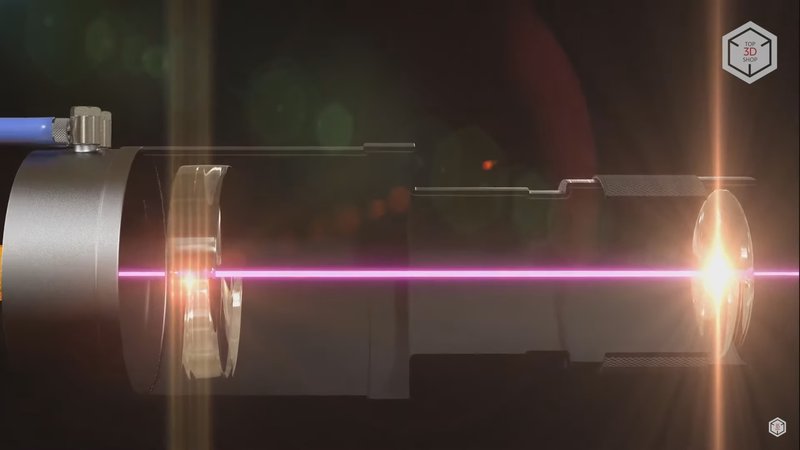

Compact budget-friendly SLM printers can be equipped with low-power lasers. Usually, the larger the size of the device, the more power and number of lasers it features. Some units are engineered with dozens of lasers 1kW each. As a result, the efficiency and productivity grow significantly, but so does the cost of the machine.

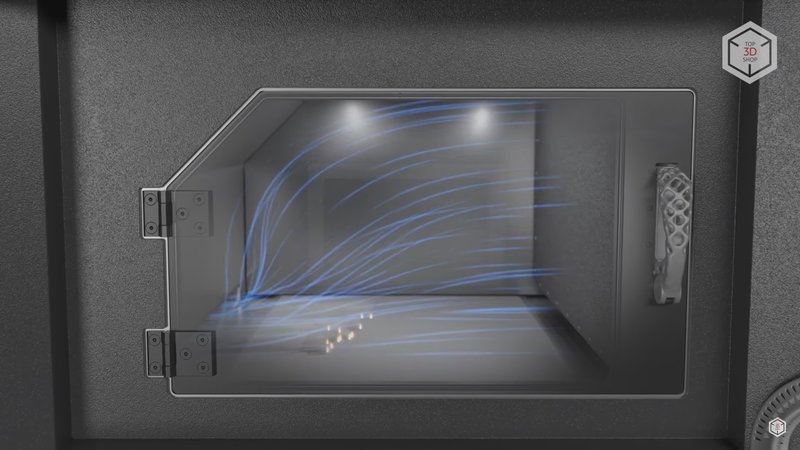

SLM 3D printers have an array of characteristics that should be taken into account when choosing proper equipment: power and number of lasers, diameter of laser spot, scanning algorithms and speed, layer thickness (usually from 20 to 120 microns), cooling system, etc.

When printing, the build chamber of an SLM printer is filled with inert gas — nitrogen or argon.

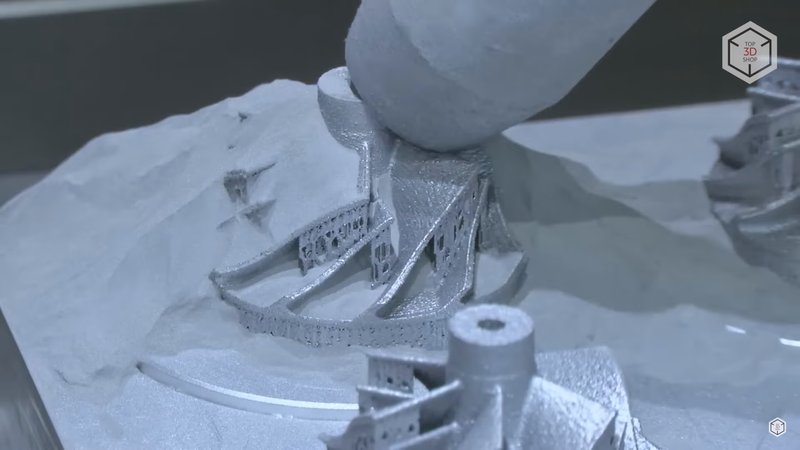

Upon completion of the process, the finished part can be removed from the build chamber after cooling. The latter can take up to several hours in case of large objects. The unused metal powder is collected, cleaned, and used for further printing.

Finished parts are removed from the platform mechanically. In some cases, special tools such as EDM cutting machines are used.

If a part requires support structures, you will subsequently have to remove them. Since SLM printers do not use additional materials to build supports, this can be a difficult and time-consuming process.

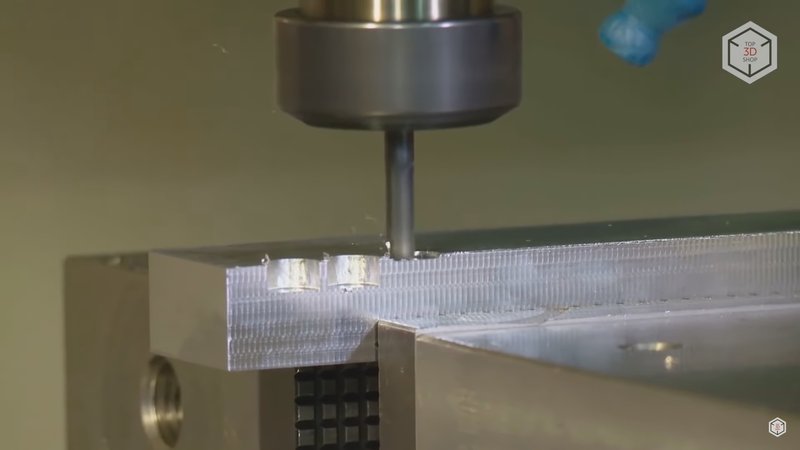

The surface of the finished part often requires post-processing. Mostly, it depends on the criteria for the final product.

Post-processing is also frequently applied to achieve high tolerance requirements, refine micro-parts, surfaces, and holes.

Like any other technology, SLM has its pros and cons.

The list of advantages includes:

As for disadvantages, SLM involves:

Now let’s talk about the strength and durability of SLM-printed parts compared to traditional manufacturing methods. Experts believe that there is no point in a direct comparison of these approaches, since in one case we deal with additive manufacturing, and in the other — subtractive manufacturing.

Items produced on SLM printers have finer microstructures when compared to cast parts. It provides them with higher tensile properties while cast parts are still stronger.

Overall, experts point out that SLM-produced parts can match and even surpass objects made with traditional methods in some aspects.

However, it all depends on the source materials, specific manufacturing and processing stages, as well as the features of a part in question.

The list of currently available SLM 3D printers includes dozens of brands and hundreds of models. For this overview, we have selected the most popular SLM machines that can be used for both single prototypes and mass production.

The Pro X DMP 320 is a high-performance SLM printer from 3D Systems. The device uses technology called Direct Metal Printing and features a build volume of 275 x 275 x 420 mm. The machine prints with various alloys of titanium, nickel, steel, and provides a minimum layer thickness of 30 microns. Due to its modular design, the system allows for really fast material changeover. The unit is fully automated and ready to work 24/7.

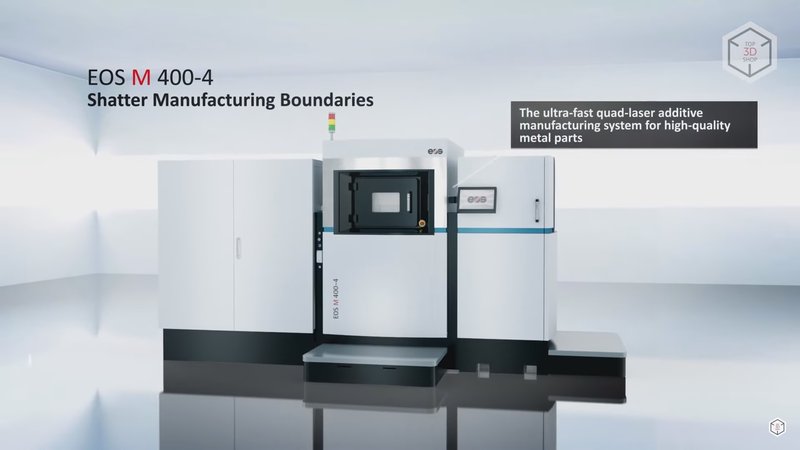

The EOS M 400 is an additive manufacturing machine employing a 1 kW ytterbium laser. Capable of producing items with maximum dimensions of 400 x 400 x 400 mm, the unit is ready to print in metal powders based on aluminum, nickel, titanium, and steel. The device features a modular construction, which simplifies the operation of the unit and upgrading of the entire system.

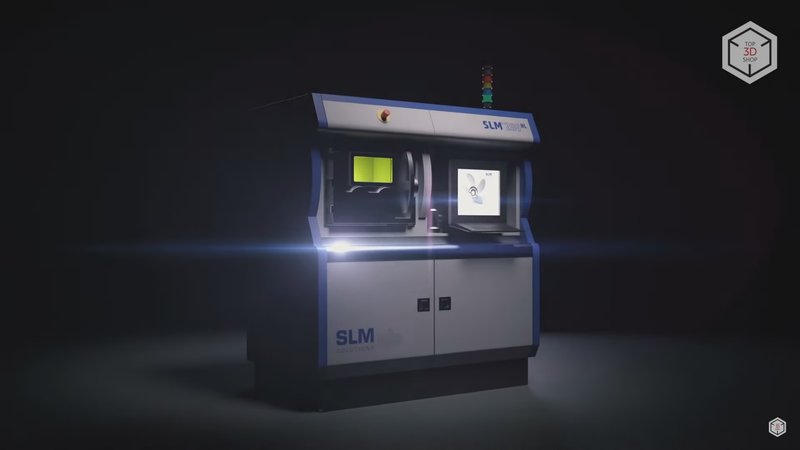

The SLM 280 2.0 is an industrial 3D printer made by the German company SLM Solutions. With a build volume of 280 x 280 x 365 mm, the device can print objects with the minimum layer height of 20 microns. The SLM 280 2.0 model can be equipped with one or two fiber lasers, 700 W each. Used for medium- and high-volume production of metal parts, the machine is compatible with a wide range of consumables, including pure metal powders and various alloys — aluminum, titanium, steel.

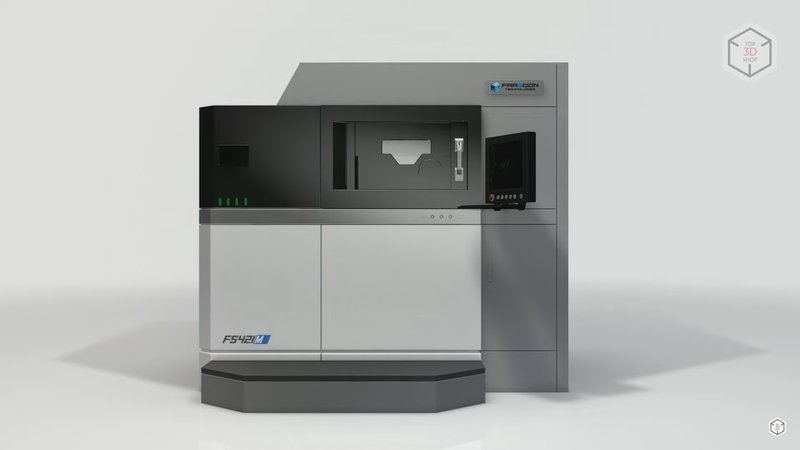

Due to the combination of key parameters, the Farsoon FS421M 3D printer is one of the leaders in its segment. The printer is equipped with a 500 W fiber laser and allows installing a second one. The dimensions of the build chamber are 425 x 425 x 420 mm, with the minimum layer thickness of 20 microns. These parameters are sufficient for the majority of additive manufacturing tasks. The automated system is ready for long-term continuous operation with a variety of metal powders.

The E500 from HBD is recommended for aerospace, automotive, and medical applications. With a build area of 430 x 520 x 520 mm, this industrial 3D printer can be used for the production of large-scale prototypes as well as high-volume manufacturing of parts from various metals and alloys, the minimum layer height being 30 microns. Depending on the modification, the HBD E500 can be equipped with two or three 500 W lasers.

The BLT-S310 and S320 are additive metal printing systems that meet the needs of diverse industries. The machines can work with a wide array of metal powders, featuring a build volume of 250 x 250 x 400 mm and the layer thickness from 20 to 100 microns. Depending on the modification, the printers are equipped with one or two lasers 500 W each. The 320 model is characterized by higher productivity; both units are engineered with advanced production automation systems.

The EP-M300 from E-Plus 3D is a powerful machine for efficient mass production. Its build volume is 305 x 305 x 450 mm, and the layer thickness ranges from 20 to 120 microns. The 3D printer can be equipped with one or two lasers of 500 or 1000 W each. The list of consumables includes metal powders based on titanium, aluminum, nickel, cobalt-chrome, copper, and various types of steel.

SLM 3D printing is used today in virtually all industries where traditional metalworking is applied, including aerospace, automotive, and medical spheres. What they all have in common is the need to rapidly produce efficient metal parts of higher quality at a lower cost.

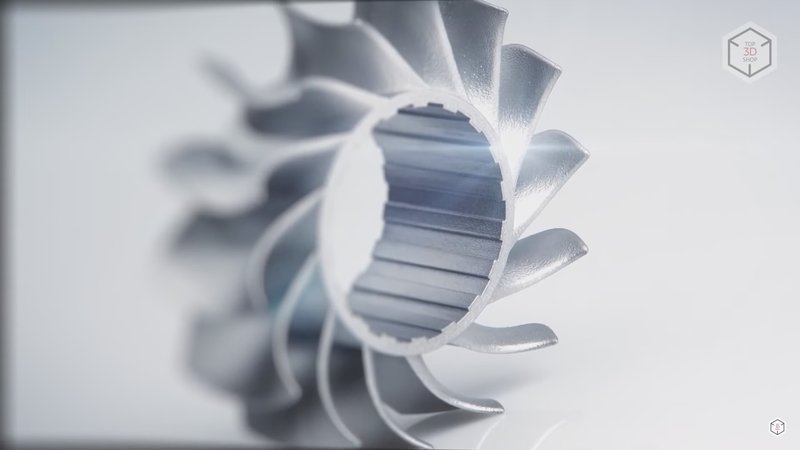

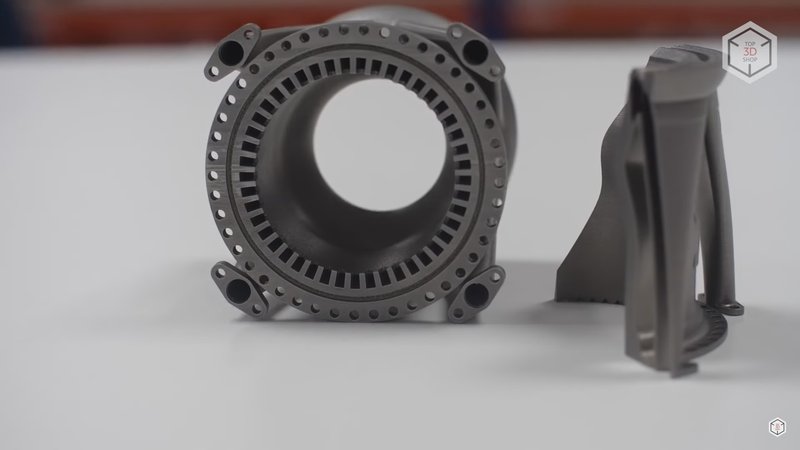

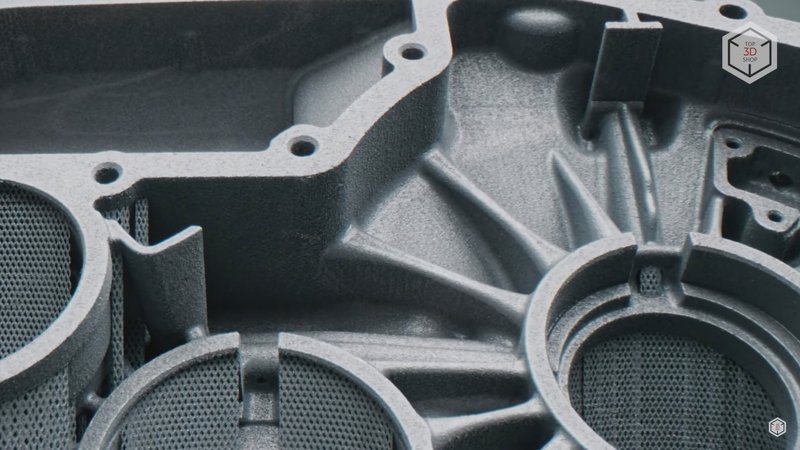

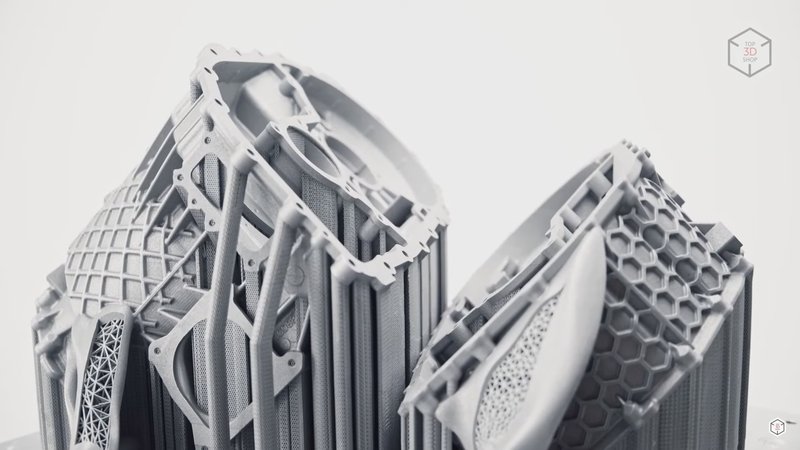

Although SLM is also widely used for faster and cheaper production of spare and replacement parts, the impact of the technology is particularly evident in the manufacturing of complex-shaped objects and the latest design solutions that would be impossible with other metal fabrication methods.

With SLM, multi-component parts can be printed in a single session, objects can have internal lattice structures to reduce weight and complex internal channels that cannot be made with traditional techniques.

Overall, SLM 3D printing also eliminates the need to maintain constant stocks of components and deliver parts over long distances.

In addition, it is a more environmentally-friendly method that uses fewer consumables and generates less waste.

Due to all above-mentioned advantages, SLM is a perfect AM method for a number of modern industrial applications implementing even the most complex projects with high technical demands that would be impossible through traditional technologies. With the properties acquired in the result of selective laser melting, the produced parts are great for many industries that are willing to bring their production to a completely new level.

Update your browser to view this website correctly. Update my browser now

Write a comment