Modern industries apply a wide variety of complex and even dangerous technologies, which require certain conditions alongside proper protection. When it comes to safe collection of metal flakes, combustible dust, impact-sensitive and other residual materials, a decent separation system will definitely come in handy.

This is Top 3D Shop, and in today’s article, we will tell you about special auxiliary equipment for additive manufacturing by the Ruwac USA company.

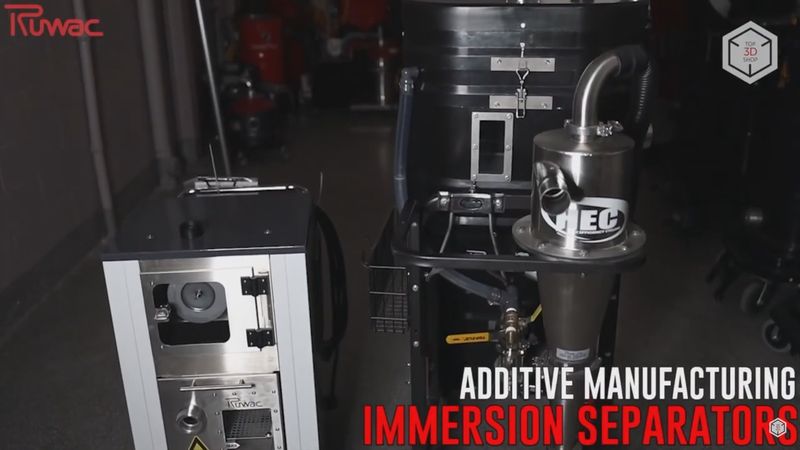

Ruwac USA develops and manufactures industrial vacuum cleaner systems, including immersion separators, dust collectors, and other filtration units.

The company’s current range includes a lineup of auxiliary equipment and accessories for additive manufacturing as well. Of particular interest are two series of immersion separation vacuum systems — MX200 and MX360 (formerly known as NA35-HD).

Ruwac immersion separators are used for collecting and separating particles of all kinds. They are an ideal solution for removing titanium, magnesium, and aluminum dusts.

For applications where additive manufacturing methods are used in mass production, such as in production halls, the manufacturer recommends the MX360 series.

The MX200 series of separators is designed for use in small labs and educational institutions, where 3D printing volumes are relatively low.

Characterized by low maintenance and safety, the equipment meets NFPA 484 standards for combustible metals, metal powders, and metal dust. The MX200 systems are equipped with an effective multi-stage filtration system, a durable powder-coated steel casing, and anti-static rollers.

The risk of explosion is eliminated thanks to the fact that explosive dusts enter the liquid medium — even hot gasses are cooled by the hydraulic separator.

To ensure exceptional durability, the body of the MX360 is made of dent-, crack- and rust-resistant carbon composite and equipped with antistatic rollers for mobility and ease of use.

Both series are equipped with TEFC brushless motors that provide 24/7 continuous operation and 15,000 hours of maintenance-free operation.

Designed for user’s convenience, Ruwac equipment requires very little maintenance and ensures hassle-free operation. All removable parts, such as the immersion tank or filters, can be taken out without using additional tools, and rinsed if needed.

The Ruwac MX361 is a high-performance vacuum system highly suitable for additive manufacturing and other industries, such as automotive and aviation part manufacturing. The machine safely collects and neutralizes combustible metal dust, such as aluminum, magnesium, titanium, zirconium, mixed metals, and other volatile dusts.

As for the Ruwac MX201, it represents a versatile vacuum system, which can be used in automotive, aerospace, gunpowder production, or additive manufacturing, including laser sintering and metal 3D printing. Like its MX361 counterpart, the machine efficiently filters combustible metal dust of different types.

Thanks to their portable design, advanced filtration, and 24/7 continuous operation, Ruwac immersion separation systems are highly suitable for constant and occasional use in laboratories and other places dealing with residual dust. The devices successfully combine high performance, low maintenance costs, and a long service life.

Update your browser to view this website correctly. Update my browser now

Write a comment