Safe and healthy working environment is essential for any company, regardless of its size or the industrial sector it belongs to. There are various factors that affect workplace safety, with poor air quality being one of the most hazardous as it is linked to diseases such as asthma, COPD, lung cancer, and others. There are different types of contaminants such as fine particulate matter, gasses, or VOCs (volatile organic chemicals) generated by various manufacturing processes. It is a legal duty of every employer to assess all potential risks and take comprehensive measures to ensure good air quality for their employees.

This is Top 3D Shop, and in this article, we will tell you about BOFA International, a company that provides efficient and cost-effective solutions to the problem of air contamination for numerous industries, additive manufacturing in particular.

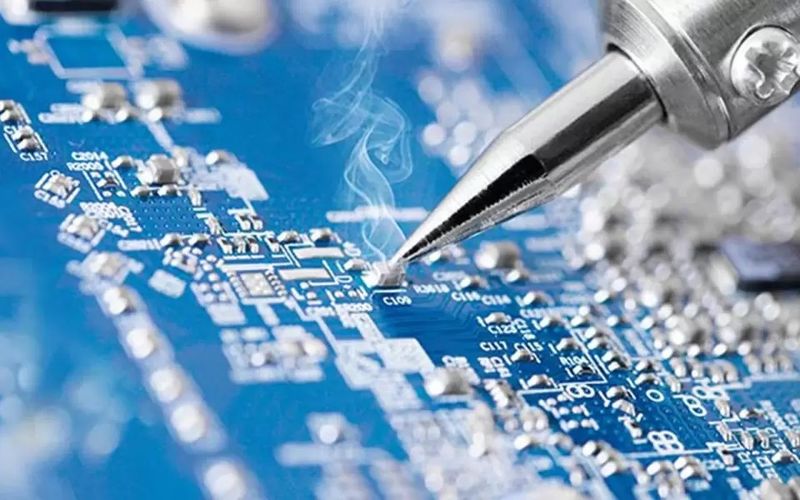

BOFA UK Ltd was founded in 1987 by Dave Cornell who became the only UK importer of a rudimentary Swedish air filtration system that protected PCB assembly line operators. At that time, people in the electronics industry were only starting to see the connection between employees’ absenteeism and exposure to fumes, so companies such as Rediffusion Simulation and Phillips Telecommunications that partnered with BOFA soon noticed the operators’ health improvement and increased productivity.

In 1999, the company launched its first L series of extraction units for the laser industry, and in 2003, the ADVANTAGE series of laser fume extractors was added to BOFA’s portfolio. The company was continually increasing its presence in the global market and in 2004, its name changed to BOFA International Ltd. This was followed by opening a fully owned Illinois-based subsidiary in the USA, BOFA Americas Inc in 2008, and in 2017, the company opened an office in Hamburg, Germany. In 2018, BOFA International reached revenues of £27m, and was acquired by Donaldson Company, Inc, a global leader in manufacturing industrial air filtration solutions since 1915.

Coming back to BOFA’s product timeline, the company continued to expand into new industries, and in 2007, the PrintPRO and PureBEAUTY series were launched, followed in 2011 by the DentalPRO and FumeCAB ranges. In 2014, BOFA entered the additive manufacturing market with its 3D PrintPRO fume extractors suitable for various 3D printing technologies, and in 2021, announced the AM 400 premium fume extraction solution for DMLS / SLM processes.

BOFA International has won a lot of awards, including two Queen’s Awards for Enterprise: in 2012, for International Trade, and in 2017, for Innovation with their world-first Intelligent Operating (iQ) system. In 2020, the company launched the BOFA Academy delivering free online training on fume extraction issues from the company’s experts.

Being a market leader in the field of fume and dust extraction, BOFA sees innovation as the key to successful business development and heavily invests in R&D. This results in a number of patented technologies that ensure exceptional efficiency of the company’s extraction solutions while reducing the overall cost. At the same time, BOFA provides enough flexibility to offer customized products ideally suited to various customers’ requirements.

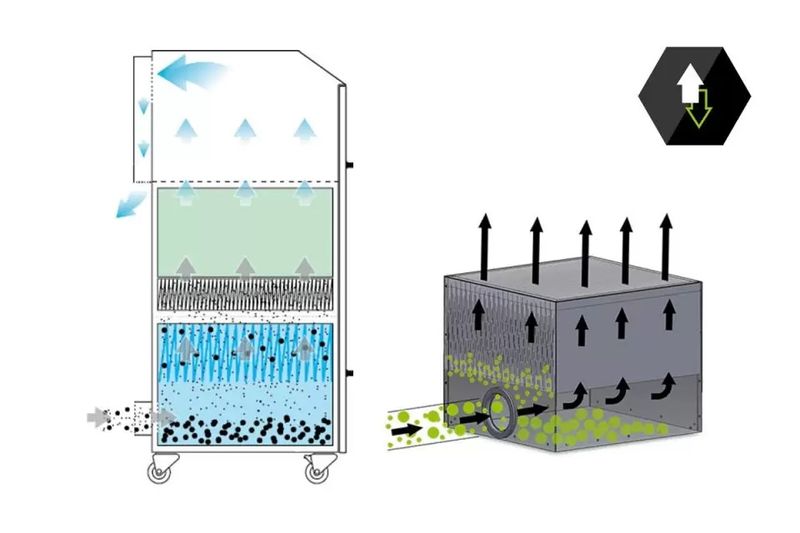

The Reverse flow air technology causes a drop in velocity and changes airflow direction, making larger particles fall out of the air stream into the drop-out chamber of the filter. This allows for significant increase of the filter lifespan.

The revolutionary Intelligent Operating system performs at two levels, providing operators with real-time information on system parameters and the current status. Additionally, the system keeps the log of analytical data, allowing users to evaluate the system performance and operating parameters and take immediate corrective actions as well as prevent future failures and reduce downtime. The data can be imported into a spreadsheet with the following graph creation. The ‘Black Box’ feature allows the user to retrieve the activity log and settings via USB connection in case of a critical failure.

The clear black-and-white LCD displays a number of real-time operating parameter values, such as airflow, either in m³/h or cfm. The operator can set the desired airflow rate, and the system will adjust the fan speed accordingly. Among other conditions monitored by the iQ system are pre- and combined filter condition, temperature within the motor housing in Celsius or Fahrenheit, and the actual motor run hours. Apart from that, the system provides a series of audible and visual alarms in case of any event requiring the operator’s attention, such as the need for filter replacement, hose blockage, or critical temperature increase.

BOFA’s more than 30-year experience in the development of air filtration systems ensures that all BOFA extractors are equipped with the best filters suitable for a particular industry and application. The combination of different filter types and the use of proprietary technologies provide 99.995% efficiency at 0.3 micron particle size. There are several filter technologies used by BOFA that make for reliable and cost-effective operation and guarantee clean air in any workspace.

Pre-filters are used for preliminary filtration of particulate to prolong the main filter lifespan and increase the overall extraction efficiency. The three pre-filter types installed in BOFA fume extractors are panel, bag, and patented DeepPleat DUO pre-filter that comes in three sizes. BOFA panel pre-filters have an F8 grade which means they keep 80% particles at 0.2 micron size and 95% particles at 1 micron. Bag filters come in a variety of shapes and are used in laser fume elimination. The unique DeepPleat DUO pre-filter employs the Reverse flow air technology to separate large dust particles thus significantly increasing the filter’s lifetime and reducing the cost of ownership.

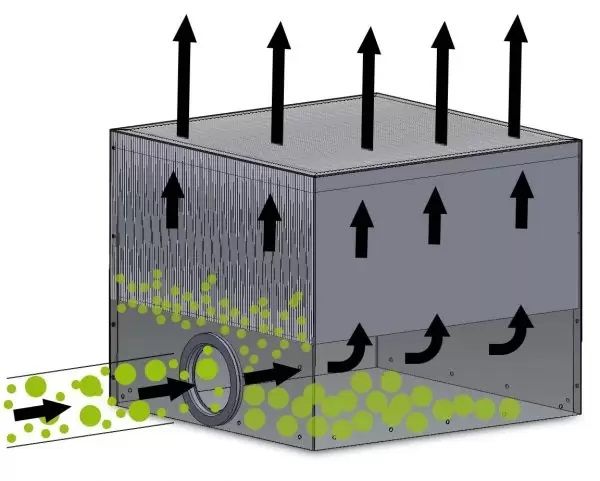

Inline filters are designed for applications that generate large amounts of particulate and usually installed between the source of contamination and the extraction unit. There are different types of inline filters used for various purposes.

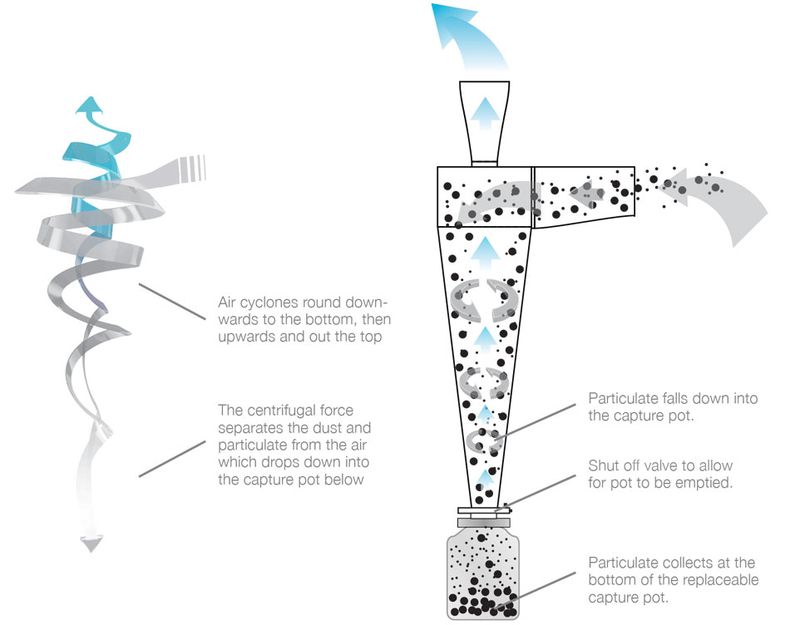

The BOFA Cyclone separator was designed specifically for the use with the AD Oracle iQ extractor in the laser marking industry. While common cyclones are efficient only with particles of 20 microns and larger, the BOFA Cyclone operates successfully at smaller particle sizes as well.

The BOFA range of ILF 300 / 600 / 1000 inline filter boxes for applications that generate a lot of dust and particulate allows protecting a more expensive main filter installed within the extraction unit and extending its lifespan.

BOFA’s Spark Arrestor and FireBOX inline filter systems were designed specifically for the industries with a risk of particulate catching fire.

BOFA applies HEPA filters produced by specialized filter manufacturers to ensure high quality and the use of the latest technologies for the most efficient filtration process. HEPA filters used in BOFA units feature mini pleats with a depth of up to 200 mm within each pleat and provide efficiency of 99.997% at 0.3 micron.

BOFA carbon filters effectively capture all contaminants and odors and keep the optimal balance between the air flow rate and the type, depth, and surface area of carbon for each particular application.

Credit: sodimate-inc.com

A comprehensive range of BOFA fume and dust extraction systems gives customers the opportunity to find the optimal solution for their industry and particular applications. The company’s specialists will help you select an appropriate system to suit your extraction needs. Moreover, they can tailor a customized solution for any specific requirements as well as provide assistance in proper installation and maintenance.

Let us have a brief look at the variety of industries that successfully utilize BOFA products and dwell on the solutions designed by company engineers for the additive manufacturing market.

The ADVANTAGE range has been around since 2003 and now it counts a large number of models that efficiently filter particulate and fumes generated by CO₂, solid-state YAG, or optical fiber lasers. The ADVANTAGE models incorporate iQ Operating system and advanced filtering with most filters made of flame-retardant materials.

Typical applications:

There are two series of BOFA solder fume extraction systems. The T-series includes systems for high pressure / low airflow soldering, and the V-series is designed for low pressure / high airflow electronics processes. The company’s solutions suit both for manual and automated manufacturing and range from compact single-operator units to multi-operator stations equipped with a variety of smart features such as iQ system, Reverse flow air technology, and Automatic flow control for utmost productivity and minimum downtime.

Typical applications:

BOFA’s PrintPRO series is designed for industrial printing processes to eliminate MEK (methyl ethyl ketone), ketones, and ozone. The specific carbon used in these models is tailored to avoid self-ignition on contact with MEK fumes. The PrintPRO models are also efficient in mailrooms for UV coating, hot melt glue binding, and polywrapping applications.

Credit: soyang.co.uk

Typical applications:

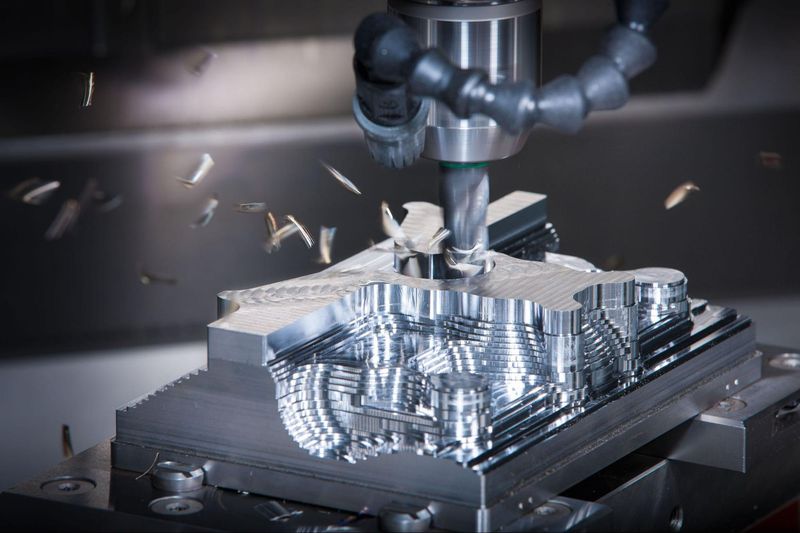

For mechanical engineering applications, BOFA developed the DustPRO range of extractors to remove dust and swarf that may cause serious health problems. The DustPRO machines are equipped with reliable brushless motors and high-spec filters and effectively remove particles of various sizes.

Credit: me.hawaii.edu

Typical applications:

Dental technicians constantly deal with processes that bear potential risk to their health. BOFA offers the DentalPRO under bench and benchtop systems designed to minimize those risks and create a safe environment in dental labs and offices. The machines feature sleek modern design and provide multi-stage filtration and digital speed control functions. They require little maintenance, which increases efficiency and reduces cost of ownership.

Typical applications:

BOFA FumeCAB models are ideal for use in the pharmaceutical industry. They are safe, easy to use, and suitable for clean room applications. The devices are equipped with a combined HEPA and gas filter and offer ESD-safe and conformal coating compatible options.

Typical applications:

BOFA 3D PrintPRO and AM models are designed by BOFA engineers specifically for the needs of various additive manufacturing processes, from home FDM printing to large-scale SLM applications. The machines filter fumes and dust generated by heated polymers, metals, and other 3D printing materials and return the clean air into the workplace environment. To ensure full compatibility of the 3D PrintPRO extractors with all 3D printer models, the manufacturer offers ‘Print your own connector’ option, providing STL files and a PDF instruction manual for five different connector sizes with adhesive or bolted mount options.

Typical applications:

In the table below you can see the most suitable AM applications for different extractor models.

| Metal / polymer powder bed fusion | FDM | VAT polymerization | Material jetting | |

| 3D PrintPRO 2 | ✓ | ✓ | ||

| 3D PrintPRO 3 | ✓ | ✓ | ✓ | |

| 3D PrintPRO 4 | ✓ | ✓ | ✓ | |

| 3D PrintPRO HT | ✓ | ✓ | ✓ | |

| AM 400 | ✓ |

The 3D PrintPRO models feature 3-stage filtration with the patented DeepPleat DUO pre-filter technology, providing extra-long filter life. The activated carbon filter has a large carbon bed and efficiently absorbs harmful fumes and odors.

The 3D PrintPRO 2 is the most compact machine in the series with the lowest airflow rate. It works best with small-format open-framed FDM printers with a build volume less than 0.03 m³. Featuring compact footprint, the device offers longer filter life and comes with a specially designed ‘stay-put’ arm to hang over the printer frame.

The 3D PrintPRO 3 is designed for enclosed or partially enclosed FDM 3D printers with the build volume not more than 0.2 m³, the model also suits for VAT photopolymerization processes. Due to the digital speed control function, the filter life is extended, and the filter change indicator will let you know in advance when it is time to replace filters, thus minimizing downtime. The 3D PrintPRO 3 can be equipped with optional features such as closed loop filtration for maintaining the temperature of the build chamber, VOC sensors, or remote start / stop function.

The next model in the range, the 3D PrintPRO 4 is a premium system scaled for higher airflow rates and longer filter life. It is used with large-format 3D printers and print farms for industrial applications, such as prototyping and small-batch manufacturing. Having the same features as the 3D PrintPRO 3 model, the device offers higher airflow rates, industrial-grade performance, and wide scope of application.

The 3D PrintPRO HT model, as the name suggests, is designed specifically for high-temperature printing up to 500 °C and is effective when used with printers with build volumes from 0.03 to 0.2 m³. The device features thermal insulation and advanced air management to provide efficient filtration in chamber environments up to 110 °C.

The latest AM 400 fume extraction system is made specifically for powder bed fusion processes, such as SLM or SLS, that take place in sealed environments in an inert atmosphere. The machine incorporates the company’s patented iQ Operating system and a number of smart functions. One of the key features of the AM 400 is a completely sealed removable filter housing that can be taken to a remote location for quick and safe filter change, which greatly reduces downtime and increases safety and convenience of operation.

Providing customers with comprehensive dust and fume extraction solutions for over 30 years, the BOFA International company is constantly engaged in extensive R&D work, introducing cutting-edge technologies and looking for new ways to increase efficiency of its products. Apart from a huge selection of various models specifically designed to meet the needs of different industries, the company offers tailored solutions and customer support at all stages, from selecting the right system to its maintenance and free online training at the BOFA Academy.

Update your browser to view this website correctly. Update my browser now

Write a comment