Being around for more than 30 years, 3D printing has come a long way from research and lab-focused machines to household items and readily available tools in your garage.

The fast pace of development allows people today not only to use 3D printers as a helpful tool for their hobbies, but to establish new businesses and manufacture high-quality products faster and at less cost than ever before.

Credit: hubs.com

So, what really changes when the industrial factor comes into play? What distinguishes industrial 3D printers from their consumer counterparts? How can you be sure that a particular 3D printing solution would benefit your business? Let’s figure it out!

There are several issues worth considering before you come to a decision. And to arrive at the best set-up, we may want to know the demands of the professionals operating 3D printing equipment from day to day. So what they need is to:

Credit: amfg.ai

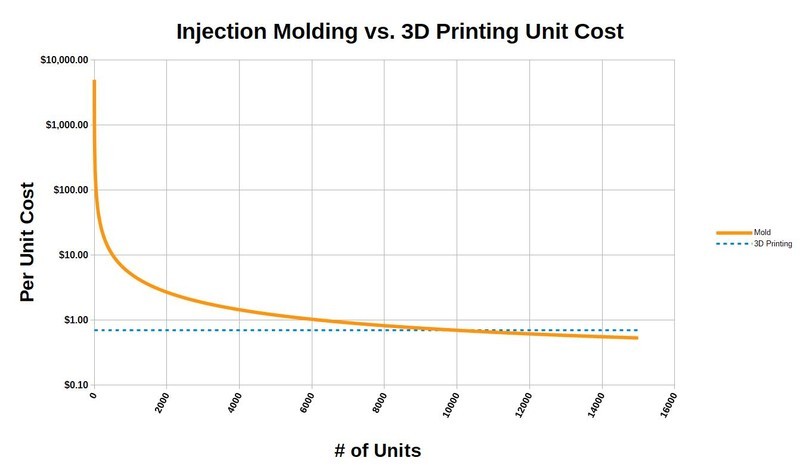

Not long ago the main technology for making plastic parts focused on injection molding. The appearance and development of additive manufacturing made rapid prototyping and low to medium-batch production accessible to a variety of industries. But what if your design is ready but the production costs are limited by the budget? Can 3D printing become a silver lining allowing for cost savings thus letting you keep under budget? In short, yes!

The chart below demonstrates the production volumes economically feasible in comparison with injection molding.

Credit: slant3d.com

With injection molding, the upfront cost should be taken into consideration, which is the cost of the mold, that is usually no less than a few thousand dollars. Besides, it takes pretty much time to cut the mold, while with 3D printing you can start production as soon as your design is ready without any advance payments. The cost per part is generally higher with 3D printing, but if the volume you’re going to print doesn’t exceed a few thousand pieces, it seems more cost-effective than injection molding, considering the cost of the mold.

Another important advantage of 3D printing, compared to injection molding, is the R&D freedom allowing for design changes at no additional cost (while each part’s design would require a new mold with conventional technology).

Industrial 3D printers normally have more spacious build volumes compared to entry-level devices. This comes in handy as you can print large objects or multiple smaller parts in one go, thus saving your time and money. Some large-format industrial machines boast enormous build volumes of 1 x 1 x 1 m and more.

Credit: etmm-online.com

Among other features that distinguish industrial 3D printers are high-quality hardware and cutting-edge technologies that ensure decent print speed along with consistent high-resolution printing with predictable results. Industrial machines manufacturers usually offer dedicated slicing software and a range of proprietary consumables to provide the best print quality possible.

The choice of materials used for 3D printing is determined by the technology your device is based on. FDM printers use spools of plastic filaments, while SLA involves liquid resins. The material used with SLS-based printers is polymer powder sintered by a laser. All these materials are utilized both in consumer and industrial 3D printing, the difference lying in the variety of materials supported by the printer. Entry-level models basically print with a few most common types that don’t require special equipment, and that is usually enough for most consumer projects.

Credit: ubuy.co.it

Industrial-grade machines require a much wider range of compatible materials to complete various complex tasks. Industrial FDM printers, for example, can work with high-temperature filaments, like PEEK or ULTEM, and also with carbon fiber or glass-filled filaments. We don’t usually mention metal 3D printing in terms of consumer models, but when it comes to industrial manufacturing this technology is a tremendous help. There are also 3D printers which use specific materials, like the Delta WASP 40100 Clay, which was designed specifically for working with ceramics.

Credit: amazon.com

Industrial-grade machines tend to include but are not limited to such features as automatic bed calibration, a filament runout sensor, an onboard camera, or print-farm compatibility. All of them increase the reliability of the process and help avoid emergencies and sudden failures while printing. Most printers use various technologies that aim at maximum automation starting with preparing the digital model and through the whole process of printing and subsequent post-processing. Some manufacturers offer complete solutions, like the Raise3D MetalFuse, including alongside the Forge1 metal 3D printer, the D200-E debinding machine and the S200-C sintering furnace. Such systems not only add to high performance and consistency but also minimize possible downtime.

Fused Deposition Modeling (or Fused Filament Fabrication) technology uses thermoplastic filament that is melted and deposited with a nozzle on the print bed layer by layer. FDM industrial printers are arguably the most affordable solution providing the lowest cost per part. They are perfect for rapid prototyping and even for production of end-use parts with simple designs, but manufacturing of intricate models with complex geometry is not their strong point.

Credit: 3dprintingmedia.network

The Fusion 3D EDGE is one of the fastest commercial FDM 3D printers. Utilizing the proprietary “F-Series” motion control system, the EDGE can reach the print speed of 250 mm/s still providing highly precise and accurate parts. The patented ANVIL print head heats up to 320 °C; the single interchangeable print tube, which comes in 0.4, 0.6, and 0.8 mm diameters, is made of surgical steel and is wear-resistant for use with abrasive materials such as carbon fiber or fiberglass.

Credit: fusion3design.com

The machine is ideal for professionals, fulfilling the requirements of large-scale production and multi-sized rapid prototyping. The Raise3D Pro3 Plus features a larger build volume (300 x 300 x 605 mm) compared to the original Pro3 model. The device has a heated print bed and a closed print chamber allowing printing with ABS-type materials. With the dual modular extruder being capable of reaching 300 °C, the Pro3 Plus can print parts with two materials in two colors. Auto bed leveling and an onboard HD camera add to the printer’s usability. Powered by proprietary ideaMaker software, as well as LAN and Wi-Fi connectivity, the Pro3 Plus is a powerful instrument for an industrial setting.

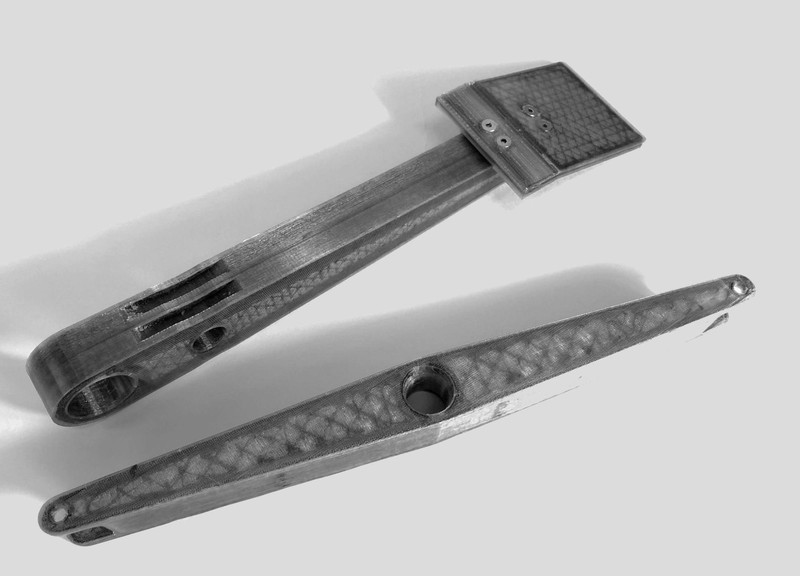

Designed specifically with carbon fiber composites in mind, the Raise3D E2CF utilizes IDEX technology — the independent dual direct drive extrusion system, ensuring faster and smoother printing. The Raise3D E2CF is aimed at engineers and designers in areas such as automotive, aerospace, healthcare, mechanical engineering, and basically the industries relying on the strength and durability of printed parts. With proprietary and third-party CF-filaments available, the E2CF can go a long way in terms of resolution, precision and repeatability.

Credit: intamsys.com

The Funmat Pro 610 HT is an industrial-grade FDM 3D printer specifically designed for printing with high-temperature filaments. The device features a fully-enclosed heated print chamber, a heated build plate and a high-temperature all-metal extruder with a dual-nozzle system that heats up to 500 °C making it possible to print with PEEK, PEKK, ULTEM, as well as with composites like carbon fiber and metal- or glass-filled materials. With the spacious build volume of 610 x 508 x 508 mm and the minimum layer height of 50 microns, the Funmat Pro 610 HT is able to print large parts with great precision and accuracy.

Credit: anisoprint.com

The ProM IS 500 is an industrial 3D printer combining Anisoprint Composite Fiber Co-Extrusion (CFC) and standard Fused Filament Fabrication (FFF) printing technologies. This machine has been specifically designed for printing high-temperature fiber-reinforced plastics. With a large print area of 600 x 420 x 300 mm, it is equipped with everything necessary to process carbon fiber, hard and high-temperature materials on an industrial scale. The Prom IS 500 supports up to 4 interchangeable print heads for printing both with standard plastic filaments and composites. The machine sports a 160 °C heated platform and the extruder with the maximum heating temperature of 270 °C, though it can be upgraded with an optional high-temperature FFF print head (400 °C), a high-temp extruder (400 °C), and a heated build chamber (160 °C).

Credit: anisoprint.com

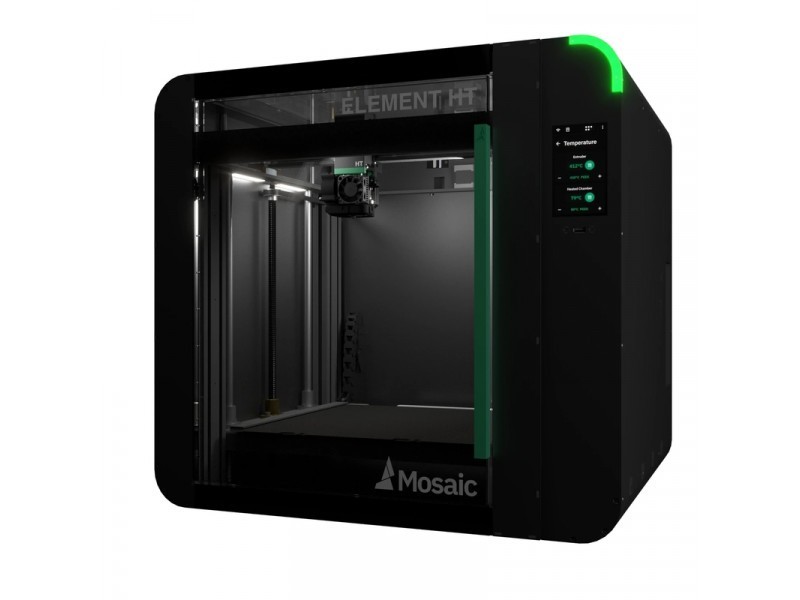

One of the most notable features of the Mosaic Element HT FFF 3D printer is the proprietary Series Enabled Multi-Material Extrusion (SEME) technology realized through the built-in Palette X filament splicer, which allows printing a single part with up to eight different filaments of various properties. The build chamber of 355 x 355 x 355 mm can heat up to 80 °C. Alongside the 500 °C nozzle temperature it enables working with high-temp industrial-grade materials, such as PEEK, Ultem 9085, and Polycarbonate. The minimum layer height of 20 microns provides highly detailed prints with smooth surface finish. The Element HT can perform as a part of the Mosaic Array complex solution for industrial automated 3D printing with minimum downtime.

Credit: mosaicmfg.com

American company IC3D has gained expertise in designing custom-built 3D printing equipment, and the IC3D Virago 700 is the company’s first commercial 3D printer. The machine features independent dual extruders with the maximum heating temperature of 500 °C that support simultaneous printing with different filaments, including industrial-grade materials such as polycarbonate, polypropylene, nylon, thermoplastic polyurethane, and fiber-reinforced composites. The Virago 700 sports a pretty large build volume of 600 x 700 x 785 mm and a heated bed platform equipped with a removable magnetic plate.

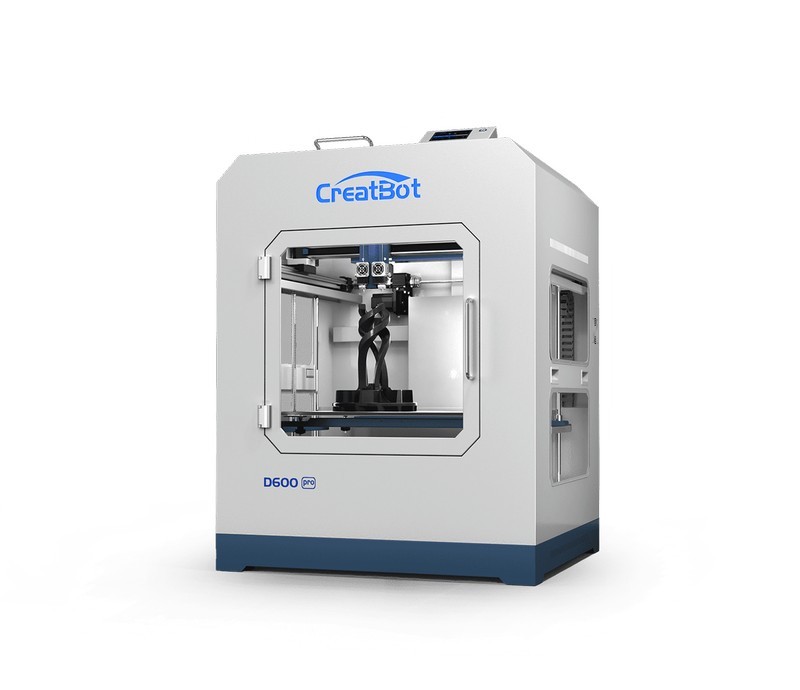

Credit: creatbot.com

Featuring a large build volume of 600 x 600 x 600 mm, the Creatbot D600 Pro has a surprisingly compact footprint which is great for limited workspaces. The device is equipped with dual extruders: the left one with a 260 °C hotend is for printing low-temperature materials, while the right extruder 420 °C hotend is capable of printing with high-performance materials like high-temp nylons, carbon fiber-filled thermoplastics and PC. Unlike the original D600 model, the D600 Pro sports a heated build chamber which can maintain the temperature of 70 °C.

Credit: creatbot.com

Size has recently become one of the main market revelations. More manufacturers continue to push boundaries when it comes to large-scale 3D printing. Automotive, aerospace, shipbuilding, plumbing, architecture and arts have been the main fields targeting large-size 3D printing, and it is the direction the market will always keep pursuing.

FDM (FFF) technology seems to be the leading area where build volumes over 600 x 600 x 600 mm (25 inches) are becoming a household staple and printing out car bumpers, pipes, boat hulls and human-sized objects in one go is a readily available option. Below you will find the list of really gigantic 3D printers with build volumes starting with 1 x 1 x 1 meters.

The Modix BIG-Meter is an industrial self-assembly kit. With the minimum layer height of 40 microns and the impressive build volume of 1,010 x 1,010 x 1,010 mm, it is capable of printing highly-detailed parts of virtually any size. The BIG-Meter is equipped with a number of useful features, such as an automatic bed leveling system, a filament run-out sensor, and a dual-zone silicone heater. The PEI print surface provides perfect layer adhesion and ensures hassle-free print removal. The list of compatible filaments includes PLA, ABS, composite materials, such as Carbon fiber, Wood, Copper, Brass, Magnetic, PHA, PVA , Hips, Nylon, TPE & TPU (flexible) Co-Polyester, and PETG.

Credit: @Shawn Hicks / Instagram

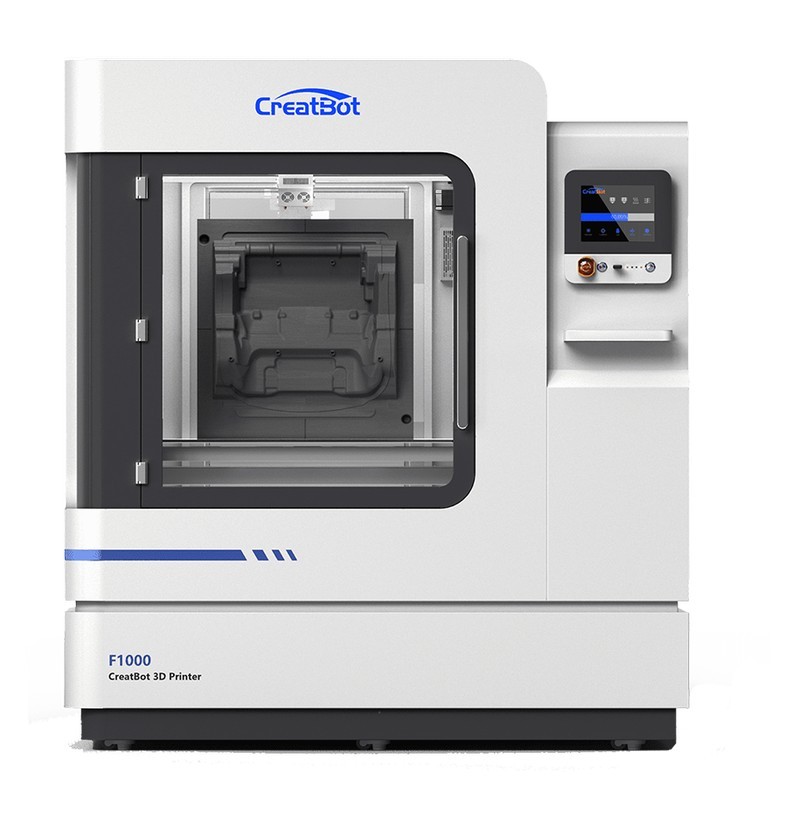

Credit: creatbot.com

The Creatbot F1000 is a large-format FDM 3D printer with a dual-extrusion system, providing multi-material and multi-color printing, and a build volume of 1,000 x 1,000 x 1,000 mm. The machine can print with a variety of high-performance filaments for direct application and is packed with all the features necessary for efficient 24/7 production of plastic parts with various materials on a large scale, namely a heated chamber, a filament drying room, an automatic bed leveling function, and an on-board camera. The intelligent power-off recovery and filament detection systems help avoid the risk of printing failure. The device is compatible with a broad range of engineering-grade filaments, including ABS, PLA, Carbon Fiber, PETG, Nylon, PC, flexible filaments and others.

Credit: creatbot.com

The Delta WASP 3MT Industrial 4.0 is an FDM professional 3D printer that can print with thermoplastics in both filament and pellet form. The minimum layer height is 100 microns for filament printing, and 500 microns when working with pellets. The device features a fully enclosed print area of Ø 1,000 x h 1,200 mm. Powered by an auto-feeding pellet tank and a pellet run-out sensor for reliable continuous printing, its extruders can process both technical and recycled materials. Wi-Fi connection for remote control via smartphone, tablet or PC and an integrated camera provide real-time monitoring. The Delta WASP 3MT Industrial 4.0 is equipped with a print-recovery resurrection system and a Free Zeta System, which lets you start a print from a pre-set height.

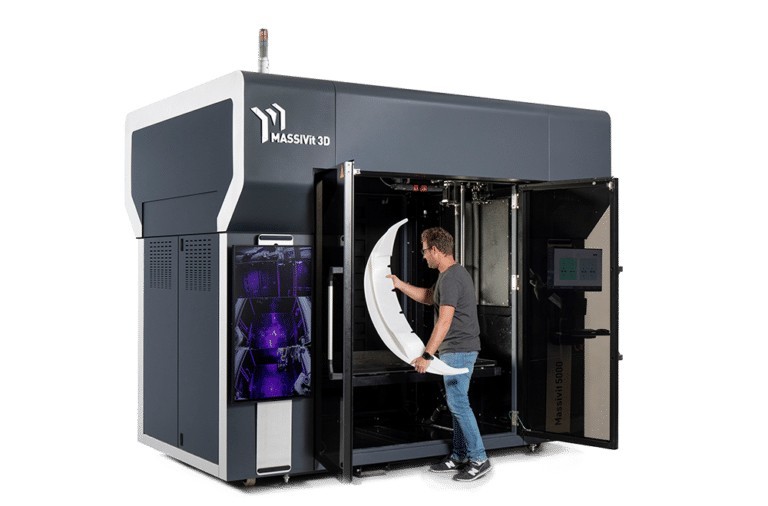

Credit: massivit3d.com

The Massivit 5000 is based on the unique Gel Dispensing Printing (GDP) technology that provides an incredibly fast printing speed of 300 mm/sec. The printer uses the proprietary Dimengel photopolymer acrylic gel as consumables, which ensures superb mechanical properties and fast curing time. The outstanding build volume of 1450 x 1110 x 1800 mm allows for the creation of extremely large models in one go. The Massivit 5000 features the dual material system and the Mold Mode designed for producing architectural elements, restorations or street furniture with concrete or plaster casting.

Credit: @massivit3dprinting / Facebook

Resin 3D printers are widely used by businesses when accuracy, precision and surface quality are at stake. Here the trend is also pointing towards larger build volumes and a more seamless transition from raw material to the final make on a scale as large as ever before.

The recent introduction of 4K and 8K monochrome LED light sources increased curing speed, build volumes and the overall print cycle of resin 3D printers.

In this sense, the industry is switching from small desktop machines to larger-format industrial devices without sacrificing print speed or resolution.

Credit: nexa3d.com

Nexa3D is the manufacturer of one of the world's fastest resin 3D printers. The proprietary Lubricant Sublayer Photo-curing (LSPc) technology and the patented structured light matrix deliver high-quality printing at unprecedented speeds making it full-fledged industrial equipment capable of manufacturing single models, small batches, and large-scale production.

With print speeds reaching 10 mm per minute, the NXE 400 is one of the world's fastest resin 3D printers delivering high print accuracy and surface quality at the same time.

With a print volume of 275 x 155 x 400 mm, this printer is a perfect tool for solving a wide variety of technical problems — from prototyping to serial production.

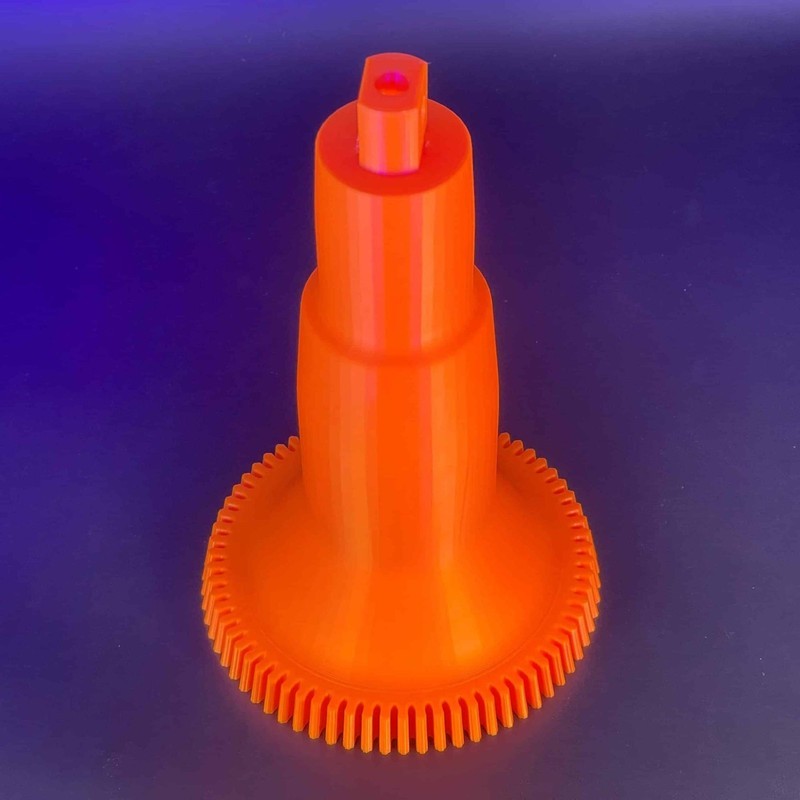

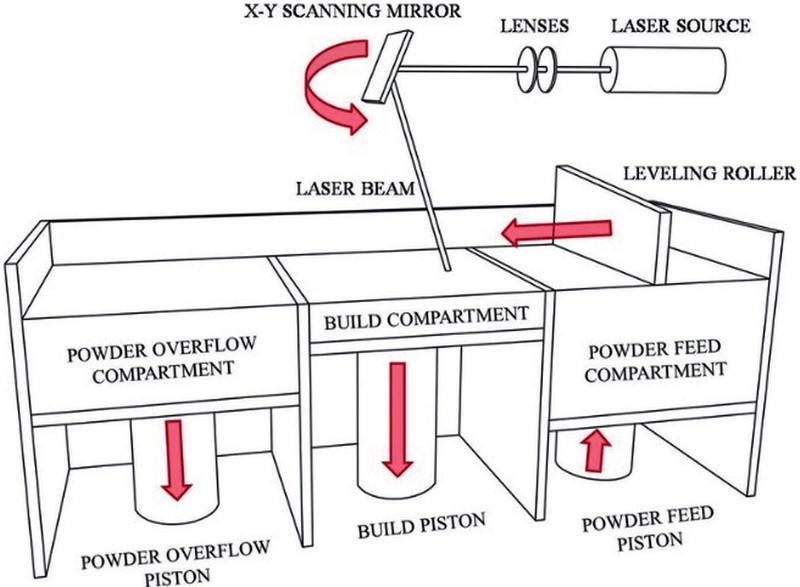

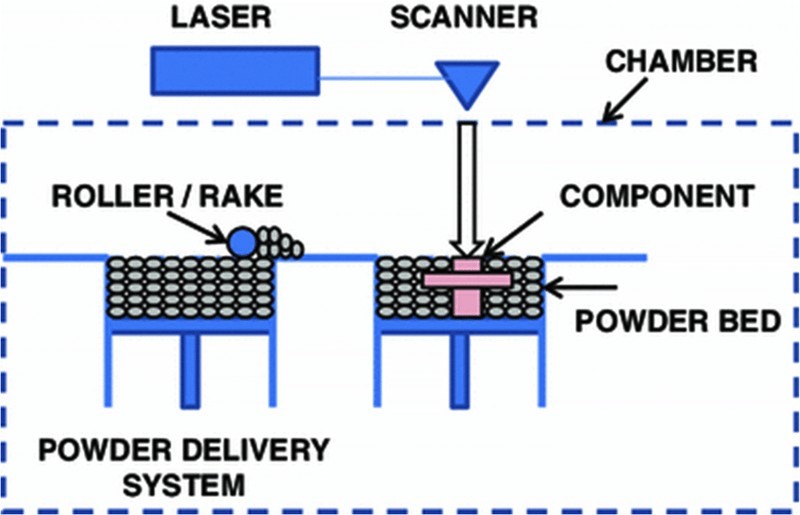

SLS, or selective laser sintering, was an industrial-grade technology right from the start due to the fact of utilizing lasers for melting raw material powder (available mainly for Nylon, TPA, FLEX, TPE). This type of technology usually features not quite large build volumes, but the precision and exceptional resolution together with layer binding properties make SLS one of the most sought-after technologies when it comes to manufacturing high-quality and intricate parts especially for functional use. When precision and high-impact materials come into play, SLS is an industry standard.

If you want to learn more about this technology and the best SLS-based printer models, read our Guide to Selective Laser Sintering and the comparative review of desktop and industrial SLS 3D printers.

Credit: sinterit.com

The Sinterit NILS 480 is an industrial SLS 3D printer which, according to the manufacturer, ensures the best ROI on the modern SLS technology market. The device features a large build volume of 200 x 200 x 330 mm and industrial print speed which allows printing the full bed in less than 30 hours. The automated systems for continuous printing and powder dispensing stand for high usability and efficiency of the NILS 480. Sinterit offers a wide variety of proprietary materials, as well as optimized profiles for all of them. Still, the NILS 480 is an open system, and you are free to use third-party powders with your own profiles.

The 403P Series is the flagship of Farsoon’s PLS (plastic laser sintering) printers. It comes in three different configurations, namely the HS403P, SS403P, and HT403P, the difference between them lying in the laser power, the scanning and print speed, and the maximum chamber temperature. The most powerful of the three is the HT403P; its maximum internal temperature of 220 °C allows for the use of FS6140GF and Ultrasint®PA6 high-temp powders. 403P Series printers are able to print accurate detailed models at high speed. The 8-zone heater and the intelligent thermal control system eliminate the risk of part deformation. The machines are a completely open system which means that the user has free access to all operating parameters and is not limited to proprietary powders only.

Credit: @sahassoftech / Instagram

Credit: tpm3d.com

TPM3D is a Chinese-based company specializing in industrial SLS 3D printers and consumables production. The P550DL is an industrial machine that combines easy operation and high-performance printing. The device is equipped with double 140W lasers and allows for the minimum layer height of 60 microns. The maximum internal temperature is 210 °C. The P550DL features a large build volume of 550 x 550 x 850 mm.

Metal 3D printing opens up new opportunities for many industries, as it allows creating functional complex parts, difficult, if not impossible, to make with traditional manufacturing methods, with mechanical properties none of the plastic materials can provide. Today there are a number of additive manufacturing technologies that use metal as printing material. We’ll briefly cover the most common of them.

Originally, FDM technology was focused on thermoplastics due to the low-temperature nature of processing such materials. However, there are several ways FDM can be effective in a metal printing industry.

One way of introducing metals into FDM 3D printing is infusing conventional thermoplastic filament (PLA, ABS, etc.) with small metal particles. Although such filaments are compatible with consumer FDM 3D printers, the resulting parts are basically plastic objects that resemble and simulate metal structures lacking the mechanical properties of all-metal objects. So, the solution is more decorative than practical.

But some manufacturers took this principle to another level, introducing sintering into the process which requires additional equipment. The sintering process removes the plastic binder from the printed part fusing the layers closer together.

However, this type of post-processing reduces the size and weight of the part; fortunately, the software successfully deals with this problem. Besides, the final part can turn out to be porous, which becomes an issue in certain applications.

Still, metal FDM 3D printers are widely used for various applications, as it’s, probably, the least expensive method of utilizing metal materials in 3D printing.

Credit: raise3d.com

The Raise3D MetalFuse is a complete solution including the Forge 1 metal FDM printer, the D200-E debinding machine and the S200-C vacuum sintering furnace. The system allows for efficient low to medium batch manufacturing of high-quality metal parts, comparable to full-metal objects in mechanical properties. The Forge 1 printer is equipped with two extruders with the maximum hotend temperature of 300 °C. The machine supports BASF UltraFuse 316L and UltraFuse 17-4 PH filaments that consist of 80–90% stainless steel and 10–20% resin binder. As soon as the part is printed, the excessive binder is removed in the D200-E catalytic debinding machine, and then the part is sintered in the S200-C to obtain the required mechanical properties.

Credit: raise3d.com

3D printing metal parts has never been simpler than with the Metal X. The FDM-based Atomic Diffusion Additive Manufacturing (ADAM) process prints using metal powder bound in a plastic filament. The latter is then removed in the Wash-1 debinder, and the metal powder is sintered in the Sinter-1 furnace. The resulting parts are solid metal, with the same strength and durability as metal parts that have been cast. The Metal X can 3D print with different metals, including stainless steel (17-4 PH), tool steel (H13, A2, D2), inconel 625, and copper. With the resolution of 50 microns and an attractive price, the Metal X is a powerful tool for industries relying on proprietary metal parts production on a limited budget.

Credit: markforged.com

Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the two most common additive manufacturing processes which utilize metal powders. Less common technologies for 3D printing with metals include laser or high-power electron beam additive manufacturing, as well as binder jetting where the process of 3D printing is implemented by applying and binding of the metal powder layer by layer.

The differences between SLM and DMLS relate to the method of binding the particles together. With SLM, the metal powder is melted down by a laser beam, while in DMLS, the powder particles are heated with subsequent sintering while avoiding the solid-to-liquid transition.

DMLS printers can produce objects void of residual internal stresses, which is crucial for the automotive and aerospace industries, as this can increase part strength and durability.

Credit: researchgate.net

SLM printers melt metal powder layer by layer. Temperature fluctuations can lead to internal stresses in the part, which can potentially affect its quality, although to a lesser extent than in casting, for example.

Credit: researchgate.net

These technologies, as the majority of industry-focused tech, require elaborate post-processing and higher power consumption, not always available in a consumer-focused setting.

SLM and DMLS printers work with a great variety of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt-chrome, and nickel-chrome used largely by such industries as automotive, aerospace, medical, and dental, while 3D printing with precious metals, such as gold, platinum, palladium, and silver is mostly used in jewelry.

Check out our Metal 3D printing overview to get a broader picture of how metals can benefit your business.

The FS721M is an industrial metal 3D printer produced by the Chinese-based Farsoon company. The machine offers a fairly large build volume of 720 x 420 x 420 mm and dual or quad (for the FS721M-4 modification) 500W laser system which allows fast printing of large-scale parts or batches of smaller-size objects. Such features as continuous powder feeding, optimized gas flow and integrated filter module are designed to achieve the uniformity of the part being printed to ensure its decent mechanical properties and industrial-grade quality. The printer supports a wide range of both proprietary and third-party materials, with even more to come.

Credit: xa-blt.com

The BLT S310 is aimed at industrial SLM 3D printing in the fields of aerospace, automotive, healthcare, engineering, and electronics industries, as well as at R&D purposes. The printer provides fast printing of high-quality metal parts. The intelligent powder saving function allows increasing the cost-effectiveness of the printing process. Among the supported material types are Titanium Alloy, Aluminum, High-temperature Alloy, Stainless Steel, High-strength Steel, Tool Steel, and Copper Alloy. The build volume of the printer is 250 x 250 x 400 mm.

Credit: xa-blt.com

While consumer and industrial-grade 3D printers often share the same basic technology and setup, there are several factors that bring in an edge to operating an industrial solution. And these factors are broken down to maintenance, spare parts and consumables security, as well as technical support. That is why the providers of industrial 3D printers invest a lot into making their products more accessible to particular industries, namely, proprietary software and material profiles, as well as corporate training that can form a team of professionals fully prepared to handle all of the aspects of a 3D printing workflow at a particular production facility. This allows for timely and professional maintenance, troubleshooting, and technical support required for reduced equipment downtime. An industrial 3D printing solution will always be paired with an elaborate plan on how to maintain the equipment, train employees and manage materials, all provided by the manufacturer.

The budget is essentially the thing that forms a business, and effective budget spending results in efficient manufacturing of quality parts. Industrial additive manufacturing equipment comes with a hefty price tag as the underlying technology making industrial goals a reality require sophisticated and high-precision solutions which are not cheap. The main benefit of paying more is acquiring a seamless workflow, minimizing R&D, maintenance and overall downtime at your business. In an industrial setting, the elevated equipment price will certainly bring down production costs in the long run by ramping up efficiency of your production base.

Update your browser to view this website correctly. Update my browser now

Write a comment