Industrial 3D printers have come a long way from enormous, overly complicated and expensive machines dedicated to narrowly specialized sectors to conveniently simplified multi-directional devices available to a wider range of users at increasingly affordable prices. This evolution opens up ample opportunities for major companies, smaller workshops, and even individuals when it comes to rapid prototyping and production of quality large-scale items.

Mingda is a China-based company that develops, manufactures, and supplies worldwide professional high-temperature 3D printers with multi-color and multi-material capabilities. Designed with a capacious build volume, high printing speed, and multiple quality-of-life features for user-friendly operation, the company’s devices provide impressive productivity for a wide range of uses, from complex prototyping to art design.

Let’s take a look at Mingda’s products, including their large-format FDM printers, proprietary filaments, and software, as well as application cases based on the manufacturer’s advanced solutions.

Founded in 2012 in Shenzhen, Mingda Technology Co. is a high-tech enterprise focused on additive manufacturing in terms of R&D and production. The company is committed to providing large-scale industrial 3D printing equipment and solutions for a wide scope of professional applications, such as rapid development and verification, small-batch manufacturing in automotive, medicine, injection molding, etc., production of complex prototypes and end-use parts, and more.

Since its establishment, the company has been guided by high standards and desire to change the world of digital manufacturing in their own unique way described as “with heart”. Pursuing a creativity-driven business philosophy aimed at continuous technology streamlining and innovation, the Mingda R&D team has succeeded in working on an effective automatic leveling system for their industrial-grade FDM 3D printers. The list of their achievements also covers a self-developed high-performance 64-bit motherboard for impressively fast and smooth operation, high-speed extruder making Mingda machines up to 5X faster than competing products, and intuitive slicing software delivering deep optimization of rapid 3D printing.

Currently, Mingda printers and materials serve as an effective means of rapid large-format additive manufacturing in workshops, factories, and other industrial facilities around the world. Due to their high-temperature functionality, user-friendliness, and reliable performance, the machines prove useful in a wide scope of fields, such as industrial production, medical treatment, aerospace and automotive areas, robotics, education and scientific research, molding and casting, design, customization, etc.

Given the above, it is no surprise that Mingda has become a trusted partner of many well-known brands, including Toyota, Bentley, Sony, Intel, General Dynamics, Boeing, NASA, SpaceX, and many others.

To their customers, Mingda offers industrial-scale FDM 3D printers, several categories of printing materials, such as general-purpose, engineering, flexible, and support filaments, as well as proprietary software with multiple handy features. Below, we will take a closer look at each of them.

Aimed at facilitating and accelerating mass production through automated leveling and self-checks, durable construction, Wi-Fi connectivity and remote control, Mingda 3D printing solutions enable convenient, reliable, efficient, and flexible multi-machine manufacturing, which makes them perfectly suited for both global enterprises and growing businesses. Represented by several models with their distinct features, these large-format machines are designed to speed up design iteration and productization.

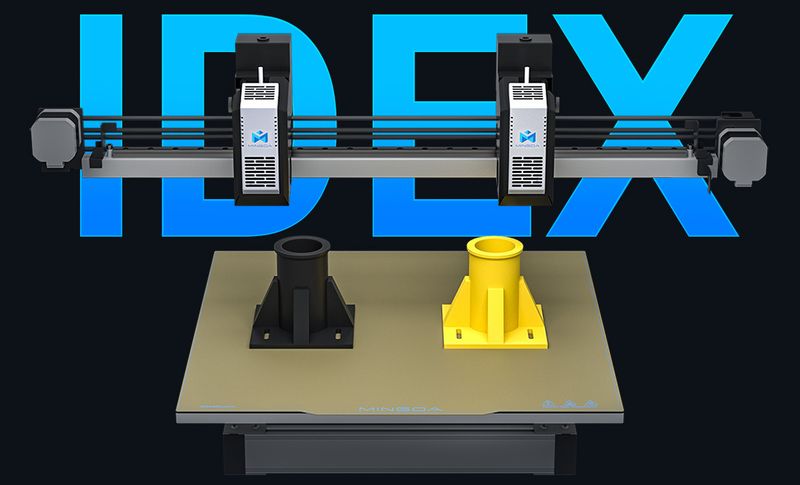

MD-400D

The Mingda MD-400D is the smallest of the company’s high-temperature FDM 3D printers. Nevertheless, it provides a capacious build area of 400 x 400 x 400 mm. Being an IDEX-based device, the MD-400D also stands out against its competitors due to a substantial workspace in the Duplicate and Mirror modes (400 x 400 x 400 mm and 320 x 400 x 400 mm respectively). This volume lets one produce a variety of items of different sizes, including fairly large ones, without the need of splitting them and in batches, which makes for a time-saving production.

As an IDEX 3D printer, the MD-400D offers four printing modes that make it both versatile and capable of tackling numerous projects, from printing with easy-to-remove and soluble support materials to effectively building complex models with overhangs, bridges, and hollow structures. Thus, with the Duplicate mode, one can print two identical models at once. The Mirror mode creates symmetrical models and saves significant time. The Dual-Color mode implies printing a single model in two colors, giving more creative freedom. Finally, the Support mode assists in printing complex structural models using both high-performance and breakaway filaments. This simplifies support removal, ensuring a smooth and successful printing experience.

Featuring flexible and precise extruder control, the machine can use a single extruder with the other one moved away or simultaneously and independently work with both if higher productivity is required. For example, check out how the MD-400D can double your productivity in the Duplicate mode without any loss in quality:

Like the other company’s devices, the MD-400D model comes with high-speed extruders with a flow rate of up to 40 mm³/s and the maximum print speed of 500 mm/s. Apart from this, Mingda has achieved an impressive acceleration of up to 10000 mm/s², which means only 0.02 s from 0 to 300 mm/s. As such, the manufacturer’s latest printers are generally 5X faster than competing machines, which significantly cuts production times with them.

The rest of the technical characteristics will be described below, since all Mingda 3D printers are built with similar principles.

MD-600D

The Mingda MD-600D is a professional high-temperature dual-extruder FDM 3D printer with an efficient build volume of 600 x 600 x 600 mm and impressive print speed. Along with the brand high-flow extruders, it comes with a robust metal construction with enhanced movement precision, fully automated leveling, intelligent algorithms improving print quality, and some other user-friendly features.

Built to accommodate both high-temperature and common hotends, the MD-600D model can reach the maximum temperature of 250 °C for the basic hotend and up to 350 °C for the all-metal one with a hardened steel nozzle. It allows the machine to reliably print with a wide range of engineering and composite filaments, including PET-carbon fiber, PET-glass fiber, Nylon carbon fiber, Nylon glass fiber, etc. ensuring high dimensional accuracy and surface quality of the printed parts. In combination with a quickly and evenly heated aluminum alloy platform with the maximum temperature of 110 °C, the printer ensures strong first layer adhesion.

Also, thanks to the dual-extruder design, the machine is capable of rapid multi-color and multi-material printing. It can print high-quality models with complex geometries and hollow structures by using water-soluble materials and filaments of different colors. For example, the following video shows how the MD-600D prints a two-color rotating vase with high precision and ease:

To ensure not only fast but smooth operation with rapid data processing and completion of 3D printing tasks, Mingda has developed a high-performance 64-bit motherboard powered by the 6-core CPU for their printers. With 32Gb of memory, one can quickly store, export, and print large files. For a better experience of interaction with the machine, it is equipped with a 7" IPS high-definition computer screen with a clear UI that features bright, saturated, and natural high-quality images from any angle and in addition saves electricity.

In terms of software, the model supports Cura, OrcaSlicer, PrusaSlicer, and specially developed Mingda Slicer. More information about the latter is available in the relevant section.

MD-1000D

The Mingda MD-1000D is a large-format yet accessible FDM 3D printer with an enormous build volume of 1000 x 1000 x 1000 mm. Similar to the other mentioned machines, it is made for a stable performance and comfortable user experience. To provide these, the device boasts a built-in filament detector, smart print resume function, hands-free auto leveling, efficient air filtration, Wi-Fi support and camera for remote monitoring, silent operation, and open material system making the choice of filaments literally unlimited.

Considering that the main distinguishing feature of the model is its build volume, here is the demonstration of the printer’s ability to produce spectacularly large models, such as this life-size 3D printed portrait:

In terms of print quality, the MD-1000D is designed with the Mingda self-developed vibration reduction technology that automatically compensates the vibrations during high-speed printing. The concomitant flow control mechanism allows precise management of the amount of filament, eliminating under- and over-extrusion, which leads to improved accuracy with finer details. Due to a flexible PEI platform with increased viscosity, the build plate provides strong adhesion, high-temperature resistance, and support of various consumables. It also aims to prevent model warping and allows for effortless removal of completed prints by simple bending.

Furthermore, the machine is equipped with closed-loop stepper motors featuring powerful feedback capabilities, faster speeds, higher precision, and lower heat generation. Crafted with an all-metal enclosed chamber and modular guide rail structure, Mingda 3D printers not only maintain a consistent printing temperature, but also ensure structural stability and precision of the printing process.

MD-600 Pro

As for commercial single-extruder solutions designed for industrial use with engineering-grade materials, Mingda presents two Pro models, both of them as equally large-format and easy-to-use as the previously described D series.

The MD-600 Pro 3D printer can be equipped with a standard or high-temperature hotend, with the maximum temperature range similar to the MD-600D — 250 °C and 350 °C respectively. Conveniently, they can be swapped quickly for different applications or filaments. Still, in contrast with the later model, the maximum printing speed of the machine does not exceed 200 mm/s, with the recommended one of up to 60—100 mm/s.

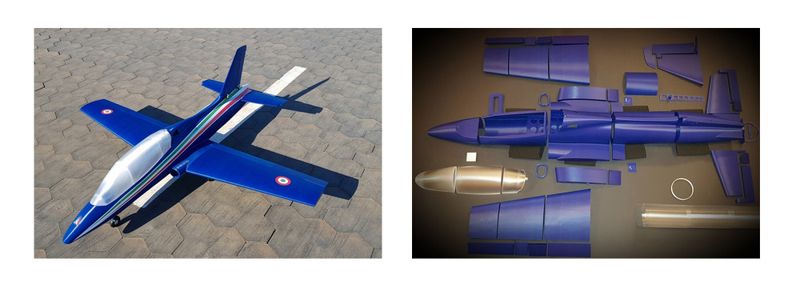

Alongside the outer dimensions that are optimal for any workspace, from an office to factory floor, the MD-600 Pro offers a generous build volume of 600 x 600 x 600 mm. By means of example, this video shows how to print large aircraft parts with the MD-600 Pro model:

Just like its dual-extruder analog, this fast-heating machine comes with a fully enclosed build area and temperature-controlled filament chamber, which allows it to produce top-quality parts with advanced materials, such as PETG, PET-GF, PET-CF, PA12-CF, HtPA-GF, HtPA-CF, and more.

Being a high-performance industrial device, the Mingda MD-600 Pro will become an efficient tool for application in multiple professional spheres, including production of prototypes, jigs and fixtures, molds and patterns, end-use parts, sculptures, etc. Read more on the topic in the “Applications” section.

MD-1000 Pro

The other Pro version, the MD-1000 Pro model, boasts a 1 m³ build volume and all the already-mentioned properties of the Pro series. Additionally, both machines are designed with an accurate linear guide rail structure, intelligent auto-leveling system, detachable magnetic build plate for easy print removal, and built-in UPS (Uninterrupted Power Supply) function, which cumulatively provide designers, engineers, and manufacturers with an easy-to-use, agile solution to produce fairly large items faster and cheaper, especially when it comes to functional prototypes, factory tooling, patterns, molds, and end-use parts. Or, for example, full-size sculptures like those in the video:

To deliver high quality products despite their large format, the MD-1000 Pro as well as its smaller counterpart comes with the innovative Baby step function used for precise leveling during the first layer printing process. Due to the control accuracy of 0.01 mm, the machines consistently provide a perfect first layer in combination with reliable leveling.

In terms of slicing software, the Pro series supports Cura, Reptier-Host, and Simplify3D. However, compared to the D series, these printers lack Wi-Fi connectivity and smart self-check functionality. Furthermore, they are equipped with a smaller 5" touchscreen in contrast to the 7" IPS high-definition one. For the rest, both series are distinguished by their advanced printing capabilities, thoughtful design, and user-friendliness.

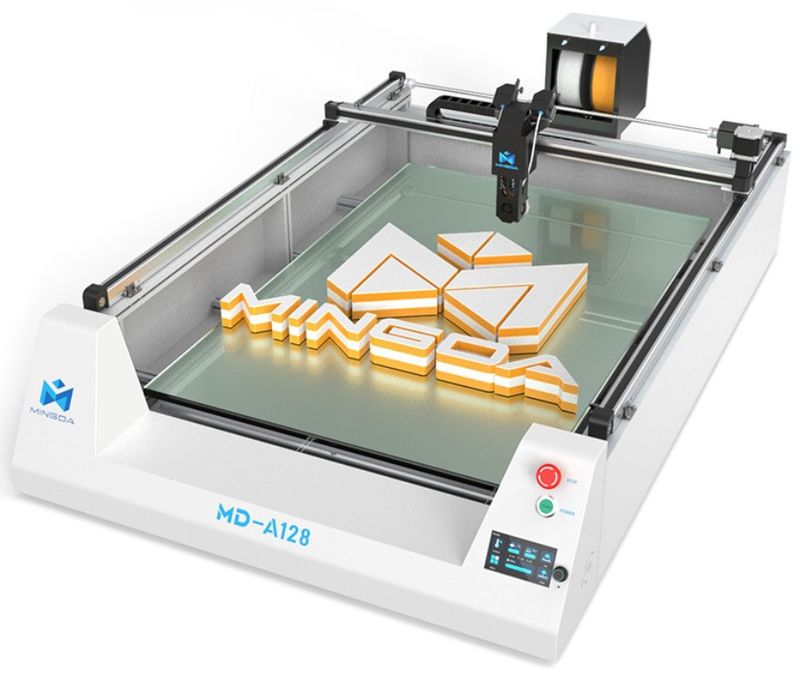

MD-A128

Last but not least, Mingda offers a large-format 3D letter printer primarily used for branding and advertising. The MD-A128 features a build area of 800 x 1200 x 100 mm and overall compact dimensions of 1054 x 1613 x 490 mm. Thanks to the trademark auto-leveling system (40 points) and self-developed powerful motherboard, the machine provides high positioning precision, time-saving, and the increased success rate of printing models. A stable modular structure leads to further quality improvement without shaking during the printing process.

Since the compatible nozzles from 0.6 to 1.2 mm ensure rapid flow, the MD-A128 boasts a decent print speed of up to 100 mm/s, which is 10X faster than traditional craft and essentially comes down to 2 hours for a single 3D printed illuminated letter.

Thanks to the 2-in-1-out extrusion system, the device is capable of smart color changing during the printing process to make your designs more vivid and eye-catching. As for preliminary design, one can enter a text in the dedicated software and generate a 3D model with one click, which makes the MD-A128 ideal for beginners. For further process simplification, the device is equipped with various quality-of-life features, from print recovery to the Baby step intelligent compensation function.

The printing process with the Mingda MD-A128 is demonstrated in the following video:

Mingda has a vast portfolio of their own 3D printing consumables that are developed to meet strict standards of modern industries and guarantee uniform parameters and consistent quality of printed products. Sealed in controlled, low-humidity conditions for safe storage and transportation, they ensure stable and even extrusion as well as good mechanical properties regardless of the time of use within their shelf life.

A wide selection of available materials for large-format 3D printing, from affordable general-use filaments to high-quality engineering-grade ones intended for demanding industrial applications, allows the user to choose a proper Mingda filament according to their personal specifications.

ABS-HF

Key properties: designed for high speed printing; high flowability, warp-free printing, higher dimensional stability, excellent impact resistance, improved interlayer bonding

Application: parts under high mechanical stress; strong prototypes and end-use parts; aesthetic models; electronic or appliances cases, suitcases and phones; precision fits, knobs, lids, and buttons; rigid models with snap-fit joints

ASA

Key properties: UV resistance, high impact and wear resistance, high heat resistance, high strength

Application: items for outdoor use; manufacturing aids and fixtures; end-use parts; production tools; functional prototypes

PETG-HF

Key properties: designed for high speed printing; excellent chemical resistance, easy to print, high stiffness and strength, good impact resistance

Application: parts in contact with salts, acids, and alkalis; functional prototypes and mechanical parts; waterproof applications; structural parts subject to mild stress; snap-fit joints; beverage bottles

PLA

Key properties: easy to print with excellent surface finish, wide range of color options, high stiffness and strength, biodegradable and environmentally friendly

Application: prototyping and design; architecture models; education and visualization; manufacturing aids; art and sculpture

ASA-Aero

Key properties: high heat resistance, low density

Application: aircraft, ship models; UAV models

PET-GF

Key properties: low moisture absorption, high dimensional stability, heat and chemical resistance, creep resistance, multiple colors

Application: automotive; end-use parts; jigs and fixtures; manufacturing tools; electronics

PET-CF

Key properties: HDT up to 150 °C, high stiffness, high dimensional stability, low moisture absorption, creep and chemical resistance

Application: automotive; aerospace; end-use parts; jigs and fixtures; manufacturing aids; electronics

PA12-CF

Key properties: lightweight, superior interlayer bonding strength, stiff and strong, high strength-to-weight ratio, lower shrinkage ratio, heat and wear resistance, chemical resistance

Application: manufacturing aids; automotive; aerospace; jigs and fixtures

HtPA-GF

Key properties: super abrasive resistance, high heat resistance, smart fiber reinforced technology, good printing stability, low moisture sensitivity, multiple colors

Application: heat-resistant insulating structural parts; wear-resistant parts

HtPA-CF

Key properties: high heat resistance (up to 180 °C), stiff, impact resistance, high wear and abrasion resistance, resistant to solvents and corrosive chemicals, low moisture absorption, high dimensional stability, easy to process

Application: structural and functional parts subject to high temperatures and aggressive environments

ABS-GF25

Key properties: low shrinkage, warpage resistance, excellent mechanical properties, strong interlayer bonding performance, no coating fiber on the surface of the printed part, multiple colors

Application: structural with high temperature resistance below 90 °C

ABS-CF20

Key properties: low shrinkage, warpage resistance, excellent mechanical properties, strong interlayer bonding performance, no coating fiber on the surface of the printed part

Application: structural exterior parts with a temperature resistance lower than 90 °C and with high rigidity requirements

HtPA-GF25

Key properties: super abrasive resistance, high heat resistance, smart fiber reinforced technology, good printing stability, low moisture sensitivity

Application: high temperature resistant, strong structural parts; wear-resistant parts

HtPA-CF25

Key properties: high heat resistance, stiff, impact resistant, high wear and abrasion resistance, resistant to solvents and corrosive chemicals, low moisture absorption, high dimensional stability, easy to process

Application: structural and functional parts subject to high temperatures and aggressive environments; high-strength and wear-resistant parts

TPU95A-HF

Key properties: high speed, elasticity, flexibility, good shock absorption, significant durability

Application: industrial seals, gaskets, sleeves or hinges; soft-touch multi-material models or handles; flexible-joined multi-material models; protective cases, shoe soles, non-slip surfaces; springs, seals and shock absorbers, wheels and rollers

TPU-75D

Key properties: elasticity, flexibility, good shock absorption, significant durability

Application: medical protective gear

PVA

Key properties: exceptional adhesion, excellent for 3D printing with more than one material, ideal as a support material, leaves a smooth surface on other materials

Application: for 3D printing complex geometry; facilitates printing large overhangs and cavities; ideal for 3D prints with moving parts

S-Multi

Key properties: rapid removal, safety and environmental protection

Application: for large overhangs and cavities; easy to remove and break-away; smooth and clean support interface

S-HTPA

Key properties: rapid removal, safety and environmental protection

Application: for large overhangs and cavities; easy to remove and break-away; smooth and clean support interface

Mingda also features an easy-to-use self-developed slicing software — Mingda Slicer that boasts intuitive controls, rich presets, and deep optimization for high-speed printing. Its integrated estimation engine gives accurate printing time and material use predictions for advanced planning and productivity. Optimized for industrial part slicing, this fast and precise program makes for a rapid and hassle-free start to 3D printing. Its key features are:

Mingda Slicer’s user-friendly interface makes for a simplified 3D printing experience, while its rich functionality streamlines industrial production and ensures successful, quality prints.

Due to their advanced functionality, high printing speed, sturdy build, high-temperature capabilities, and wide material support, Mingda 3D printers are ideal for an ample range of applications, such as rapid development and verification, small-batch manufacturing, design, production of complex prototypes and end-use parts, etc. With their user-friendly operation and a number of quality-of-life features, the machines will meet the needs of both professionals and hobbyists alike.

Let’s take a look at some cases of using Mingda solutions in different areas.

Speaking of the high-demand and high-competition automotive industry, large-format 3D printing is a powerful asset to simplify production with fast-paced, in-house manufacturing on-demand and in full scale, without numerous third-party supply chains. With Mingda 3D printers, it is possible to significantly streamline prototyping as well as make the whole process more affordable, efficient, and creative.

Application: jigs and fixtures, prototyping, end-use parts, customization

For example, this is how one can print large automotive parts with the Mingda MD-600D and MD-1000 Pro models:

Since developing aerospace products implies a certain cost and risk, Mingda solutions are a great way to optimize the production process in this sphere thanks to flexible prototyping and cost-effective production capabilities. Apart from this, industrial 3D printing allows one to fully control their supply chain and produce manufacturing tools in-house, which massively reduces development costs and lead times.

Application: jigs and fixtures, prototyping, end-use parts

This is the right task for the massive Mingda MD-1000 Pro:

For medical devices that require a high level of customization and flexibility, large-format 3D printing is a perfect opportunity to simplify the work with patients and increase the effectiveness of treatment.

Application: pre-surgical models, surgical guides, implants, orthopedic braces

In the video below, you can see how to print back braces with the Mingda MD-600 Pro for effective scoliosis treatment:

In the case of industrial 3D printing, one is capable of simplifying retooling processes with hands-free production and unlocking rapid tooling with fast lead times for full-scale jigs and fixtures.

Applications: jigs and fixtures, forms and molding, prototyping

Look at the Mingda MD-1000 Pro printing industrial-grade parts with ease and style:

Large-format Mingda FDM 3D printers can make construction more efficient, affordable, and cost-effective. Create forms and molds for complex designs or restoration projects in a simplified, reliable, and economical way.

Application: jigs and fixtures, forms and molding

From gadgets to sports equipment, customization and personalization are key trends in production of modern consumer goods. With an industrial-size 3D printer at hand, one will get a truly flexible manufacturing experience compared to traditional technologies.

Want to know how to print a whole design table in one go? We’ve got the answer:

When it comes to research and education, Mingda solutions let you create new designs and experiment with unparalleled simplicity and removal of common material restrictions.

Application: prototyping, forms and molding, end-use parts

From crafts to sculptures, true art endeavors require a flexible and creative approach, which can be achieved thanks to large-format 3D printing that eliminates the constraints of traditional production.

Large-scale sculptures are no challenge for the Mingda machines:

Modern trends inspire businesses to reach faster production speeds and facilitate manufacturing processes to achieve better results. So, when it comes to AM equipment, the priority today is a rapid, multi-functional, and above all reliable device with streamlined operation and precise control. Mingda has succeeded in creating such a solution through 12 years of bright ideas and continuous practice.

Now, the company provides increasingly productive, flexible, and environmentally friendly 3D printing solutions capable of fulfilling a wide scope of tasks in various industrial environments, including automotive, aerospace, healthcare, electrical industry, manufacturing shoes and sports equipment, design, research, and more. The implementation of Mingda machines and materials allows workshops, factories, and production facilities to optimize their performance, reduce costs and downtime as well as create a comfortable and safe environment for their employees. Thus, their price is fully justified.

Update your browser to view this website correctly. Update my browser now

Write a comment