Car manufacturing has long enjoyed the benefits of 3D printing. Being a process that creates three-dimensional objects from digital files, it in many cases is considered more flexible, time- and cost-effective compared to traditional manufacturing methods. Starting with prototyping and customization, 3D printing now allows creating fully functional car parts, from ducts, caps, and vents to even some mechanical pieces that are not inferior in quality and properties to conventional analogs.

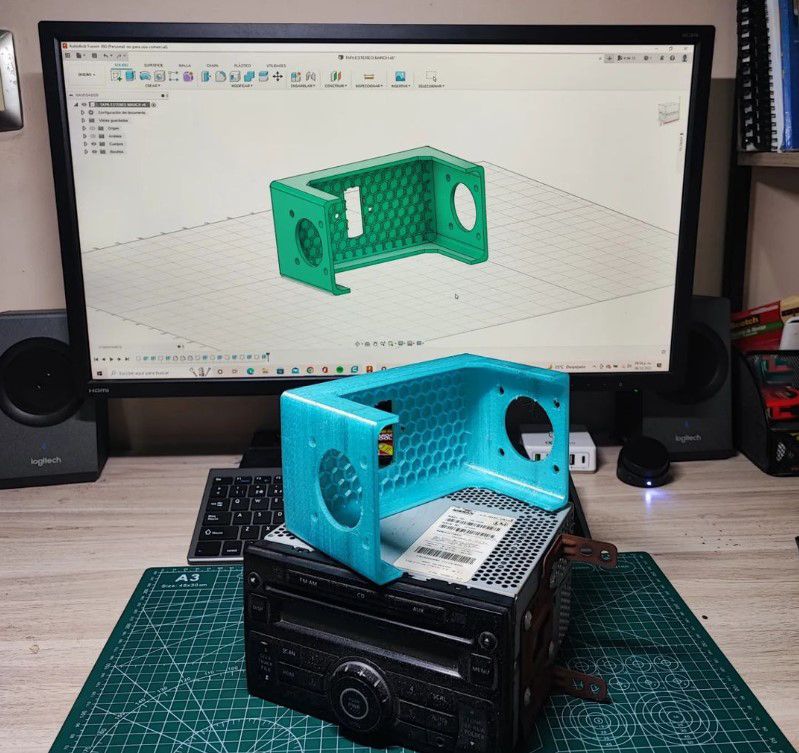

Given the current accessibility and affordability of additive manufacturing, the option to 3D print car parts is available not only to large companies but also hobbyists, enthusiasts, and small businesses, like custom body shops and smaller racing teams.

Credit: @futura_3design / Instagram

This is Top 3D Shop, and in this article we are going to explore the possibilities of 3D printing within the automotive industry. Let’s find out what resources, software, and devices are needed to make quality car parts for business or replacement purposes.

Credit: @wemakethingsreal / Instagram

The 3D printing process begins with a digital file, usually created using a Computer-Aided Design (CAD) program. The 3D model is then sliced into thin layers, which the printer reads and prints one at a time, building the object from the bottom up. Essentially, this technology provides greater creative freedom, easy adjustments, cost-effective manufacture, and fast implementation of an ever-growing selection of products throughout multiple industries.

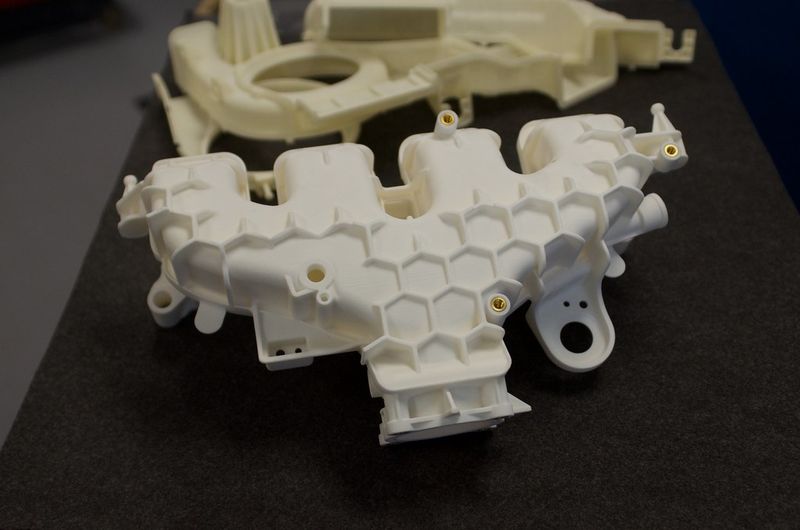

One of the most exciting applications of 3D printing is in automotive, specifically in the production of prototype, functional, and customized car parts. From intricate dashboard components to entire body panels, 3D printing allows for quick and cost-effective manufacture available to a wide range of users.

Usually, 3D printing is applied for making jigs and fixtures used for producing the cars themselves. These include alignment tools for precise positioning, symmetry check-ups, etc. Lately, manufacturers have also started using fully functional 3D printed components for their cars, like hubcaps, roof brackets for a roof retracting mechanism on an i8 Roadster by BMW, a turbo housing and titanium exhaust tip by Koenigsegg, and more. As for hobbyists, enthusiasts, and small services, 3D printing allows them to create customizations to vehicles as well as make spare parts.

Overall, the automotive industry is just beginning to realize the complete potential of 3D printing. As technology continues to evolve, we can expect to see even more exciting applications and efficiencies.

Now, let’s see why 3D printing is becoming increasingly popular when dealing with the production of car parts.

Credit: johnbiehler.com

Cost efficiency. 3D printing significantly reduces production costs by minimizing waste. It also lowers the inventory costs as parts can be printed on-demand.

Customization. With 3D printing, car parts can be personalized to fit specific models or individual customer preferences, promoting a higher level of product customization.

Speed of production. At every stage, 3D printing can significantly reduce the time it takes to produce car parts, allowing for rapid prototyping, risk-free testing, and quicker time-to-market.

Improved properties. Greater design freedom results in more efficient structures, which can either save weight or improve airflow. In combination with various materials ensuring specific characteristics, 3D printing provides quality car parts with increased performance.

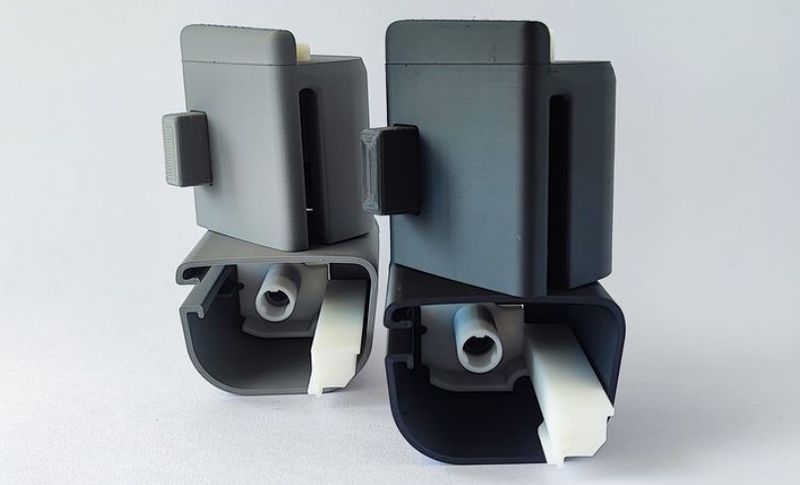

3D printing replacement car parts involves the same steps as the general process. Let’s now review the major factors to consider.

Credit: customcarsnow.blogspot.com

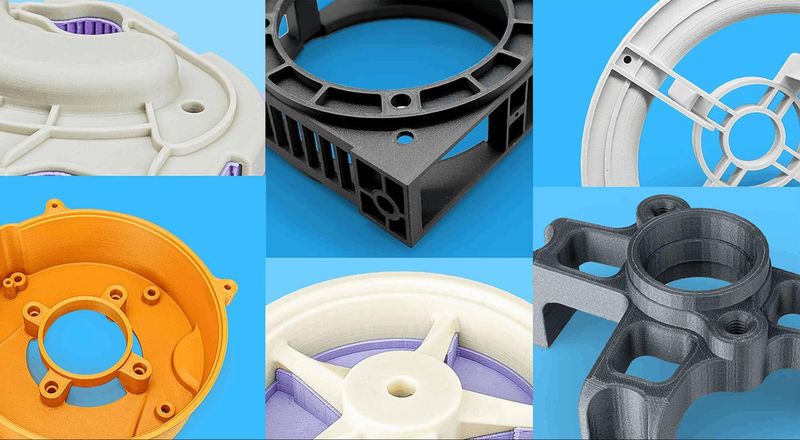

Various materials can be used for 3D printing car parts, including plastics, metals, and even composites. The choice of material greatly depends on the part’s function and desired properties.

Thus, PLA and ABS plastics are commonly used to make smaller, less significant parts, while nylon and carbon-fiber-reinforced filaments are great for components requiring more strength. For temperature- and pressure-resistant parts, such as engine components, metals like titanium or steel would be ideal.

For 3D printing, you need a digital design of the chosen part, which can be created using a 3D scanner, CAD software or downloaded from online platforms. At this stage, it is important to know the part’s function, its compatibility with the chosen material, and its fit within the car.

Once you have your file, it can be loaded into the 3D printer for further production. The model will then be sliced into layers and gradually constructed by the printer. Depending on the complexity of the part and the printing speed, this process could take anywhere from a few hours to several days. After that, the printed part may require some post-processing, such as cleaning or smoothing, before it can be used.

As we have already mentioned, one of the key features of 3D printing is its accessibility: you don’t have to be an expert to try to make something yourself. There are plenty of online sources with ready designs from other hobbyists, especially when it comes to popularly owned cars. Let’s take a look at some of them.

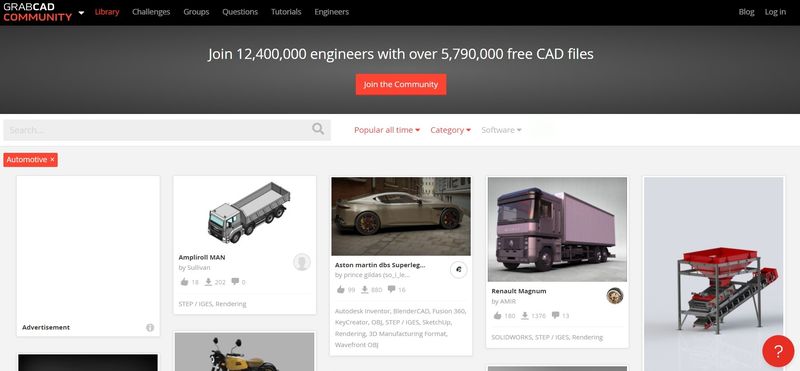

GrabCAD is a popular source for 3D models, including a wide variety of car parts. The site is free to use and offers an array of designs uploaded by its large community of engineers and designers.

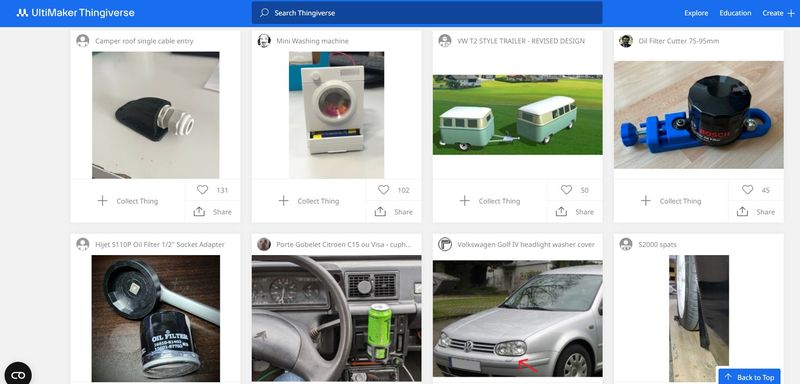

Thingiverse is one of the largest 3D printing communities on the web. It hosts thousands of 3D models, including a variety of functional car parts, that can be downloaded and printed for free.

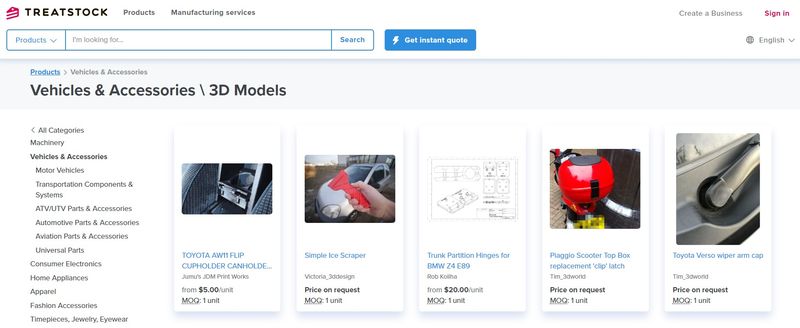

Treatstock is a 3D printing marketplace with reasonable prices that connects designers and hobbyists. It offers a variety of ready-to-print designs, including car parts.

STLBase is a search engine for 3D printable models. The source does not host the models themselves but aggregates them from other websites like those mentioned above.

If you have some skills and are willing to try designing yourself to make completely unique and fully customizable car parts, there is a good selection of software tools for the creation, optimization, and virtual performance testing of your models.

From straightforward CAD solutions to multiple simulation and modeling tools, there are quite a few options to choose from, particularly for advanced users. Despite fairly high subscription prices, some of them might offer a free trial or educational license.

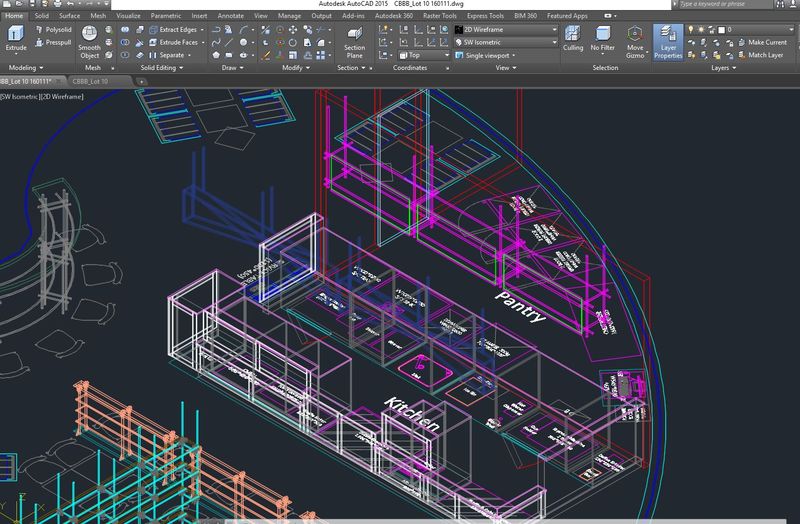

AutoCAD is a professional-grade CAD software that can be used to design or replicate car parts for both interior and exterior. Fairly difficult for a hobbyist, it is a versatile tool boasting rich functionality that supports a wide range of applications.

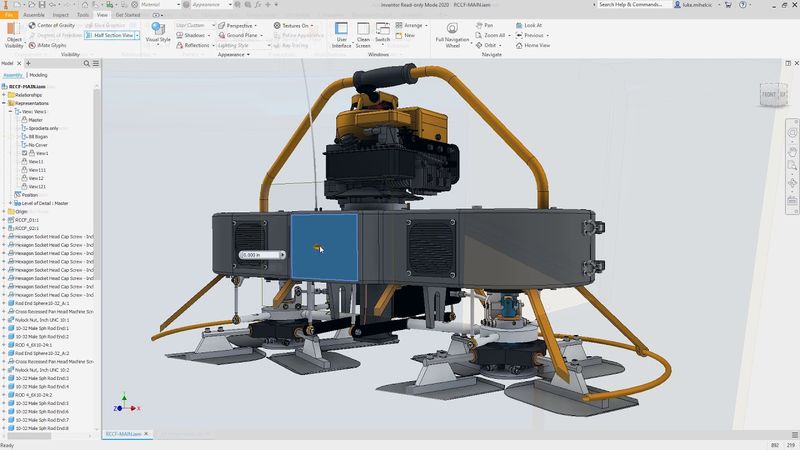

Inventor from Autodesk is a CAD software that is great for mechanical design, including car parts. Apart from advanced 3D modeling and simulation features, the program is compatible with Autodesk’s cloud network, which makes it great for teamwork.

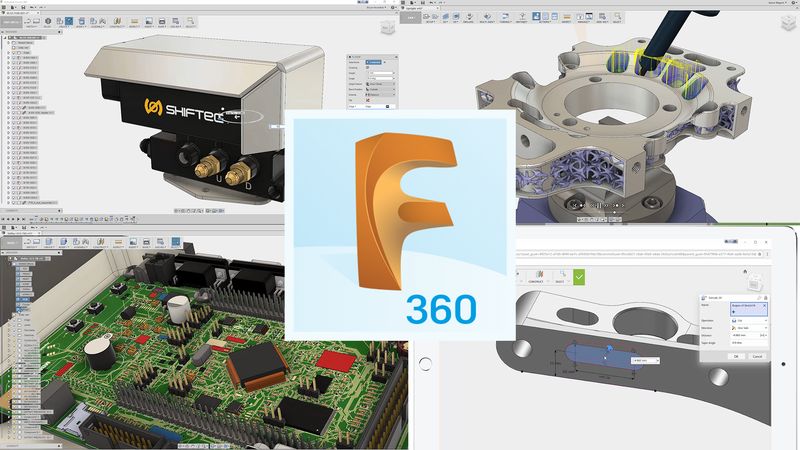

Fusion 360 is another product from Autodesk tailored for 3D engineering. Covering a wide spectrum of possibilities, like CAD, CAM, and CAE, it serves as a great tool for designing complex geometries. While the solution is mostly aimed at the needs of advanced hobbyists, some industry professionals will also find it useful.

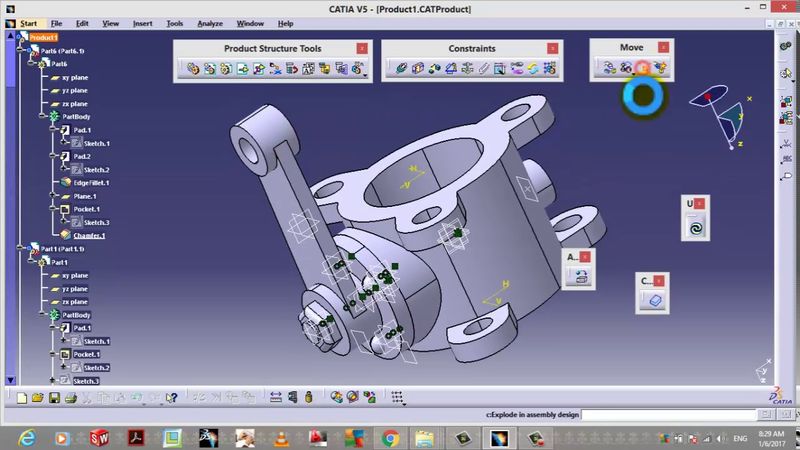

Catia is a powerful CAD software used by professionals in various industries, including automotive and aerospace. It offers parametric and non-parametric modeling as well as multiple advanced tools for 3D engineering and simulation.

Credit: japaneseclass.jp

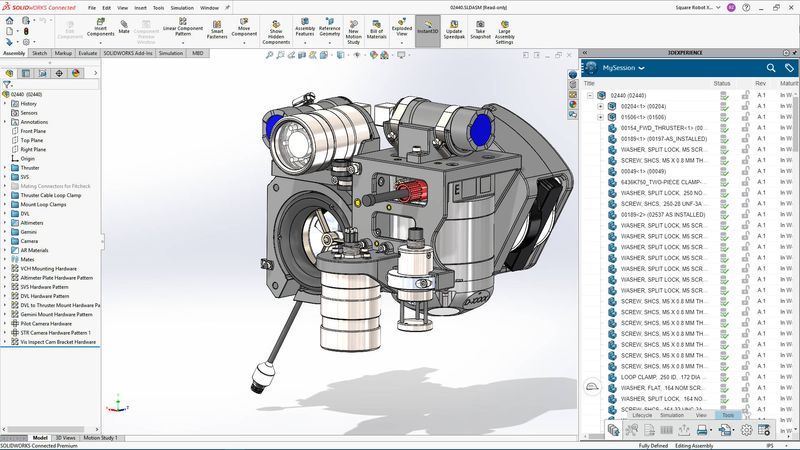

SolidWorks is a popular choice for 3D design in the engineering and manufacturing industries. It is an increasingly user-friendly solution with a clear interface that is well-suited for designing individual components, such as car parts.

Credit: javelin-tech.com

When it comes to 3D printing car parts, you will need a printer that can handle the size and material of the part you are going to make. Industrial-grade machines are often necessary for larger parts or those that need to be extremely durable, like metal engine components. For smaller parts or those made from plastic, a desktop 3D printer may suffice.

We have selected popular models with excellent features and specifications for you to choose from.

As the next generation of the popular Prusa MK3 line-up, the Original Prusa MK4 offers some major changes and sets a new print quality and reliability standard for desktop FDM printers. If you aim for an impressive speed and outstanding accuracy with a minimum layer height of 0.05 mm, this machine is the right place to start. One of the most prominent features of the MK4 is the extruder, or Nextruder, which is a smaller and lighter version of the one used on the previous models. Equipped with a load cell sensor that eliminates the need for manual adjustment, it ensures what the company calls “always perfect first layer”. The quick-swap nozzle design allows for easy replacement and maintenance. With hardware overcurrent protection, a printing resume function, and enhanced silent mainboard, the MK4 offers completely safe and convenient user experience.

What makes the printer a perfect choice for producing replacement car parts, apart from the excellent print quality, is the robust, easy-to-set-up, and flexible structure combined with an open-source nature. Thanks to the impressive material compatibility as well as handy add-ons, you can make just about any sizable item.

While the Qidi Tech X-MAX 3 might be slightly more costly for hobbyists than some other listed models, it offers generous build volume, industrial-grade print quality, and high performance. It is engineered with an actively heated build chamber for reliable printing with high-performance thermoplastics as well as a built-in circulation fan with an active carbon air filter for better results and safe environment. Thanks to the advanced CoreXY kinematics and silent stepper drivers, the X-MAX 3 can reach an impressive print speed of 600 mm/s while working quietly. The resonance compensation function allows reducing the impact of vibrations, ensuring high print quality without visible artifacts. In addition, the machine comes assembled and ready to work within 10 minutes after unboxing.

A spacious build chamber of 325 x 325 x 325 mm allows for printing fairly large car parts as well as batches of smaller items in the most time- and cost-efficient way.

The Raise3D Pro3 Plus is a professional dual extrusion FDM 3D printer offering extra-high build volume of 300 x 300 x 605 mm suitable for efficient production of just about any car part. To meet various project demands, the printer is equipped with interchangeable nozzles with 0.2–1.0 mm diameters and can print layers at 10 microns producing finely detailed objects with extremely smooth exterior surfaces and intricate shapes. The maximum operating temperature of 300 °C and a built-in cooling fan allow the machine to effectively work with a wide range of materials, including PLA, ABS, HIPS, TPU, PC, nylon, TPE, FLEX, PETG, metallic PLA, wood PLA, carbon fiber, and others. Featuring the auto bed leveling function and a removable flexible steel build plate, the Pro 3 Plus provides high-quality prints with a perfect first layer adhesion. A bundle of convenient functions, like EVE smart virtual assistant, adds to consistent printing.

Thanks to its robustness and rich functionality, the Raise3D Pro3 Plus is ideal for professionals seeking versatile, reliable, and high-performance 3D printing solutions.

Credit: @okm3d / Instagram

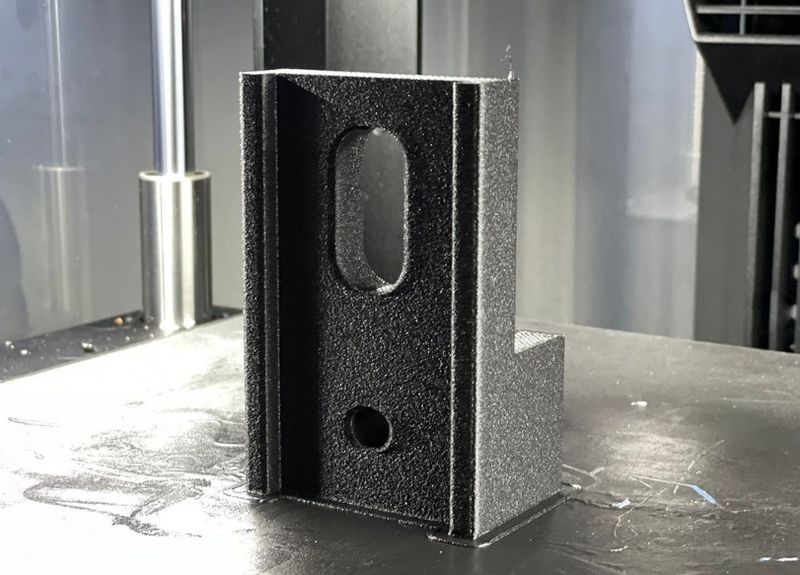

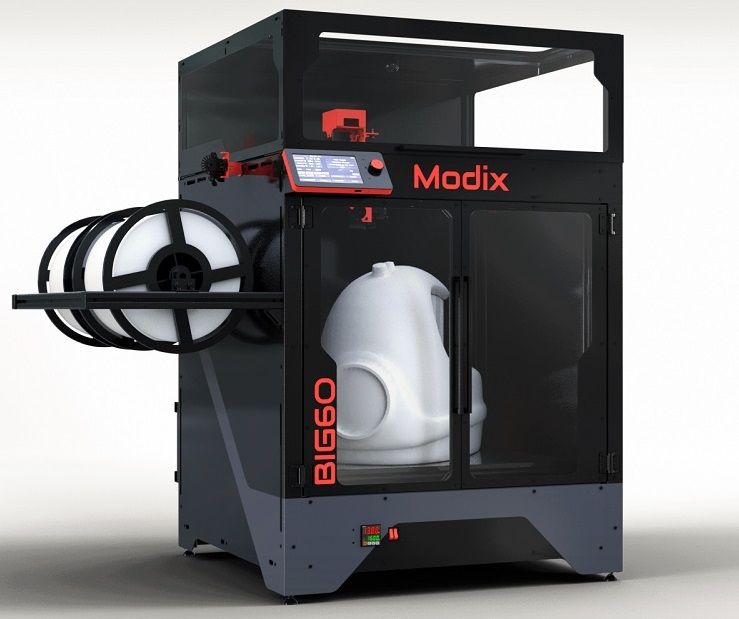

The Modix Big-60 V4 is a professional, self-assembly FDM 3D printer kit featuring a sturdy modular construction with future enhancements in mind. Being a part of the company’s Generation 4, it is relatively easy and fast to assemble as well as more reliable and accurate, with a number of handy improvements. For example, the Big-60 V4 offers automated calibration, stronger industrial components for much faster and more stable printing, improved wires management for smooth and convenient maintenance, built-in crash detector for additional safety, filament sensor, Wi-Fi connectivity, and more. To expand the sphere of application, Modix has also released a number of optional add-ons including IDEX for printing with independent dual extruder and water-soluble filaments.

Thanks to the improved extruder structure, the Modix Big-60 can reliably print with PLA, PETG, PVA, ABS, ASA, PC, Nylon, TPU, Woodfill, Carbon composites, and other specialty materials that will become an ideal base for a wide variety of car parts.

The Creatbot D600 Pro is a prosumer large-scale FDM 3D printer featuring a build volume of 600 x 600 x 600 mm and a dual direct-drive extrusion system with the maximum nozzle temperature of 420 °C. Combined with the heated ceramic-glass print bed and the hot air chamber, maintaining the constant temperature of up to 70 °C, this allows the D600 Pro to print with high-performance materials, like high-temp nylons, carbon fiber-filled thermoplastics, and PC. The precise auto bed leveling system using BLTouch sensor greatly adds to print quality, ensuring proper first layer adhesion. Apart from this, the printer is equipped with an in-house drying station, responsive touch screen, filament run-out sensor, power-off print recovery function, and effective HEPA Air Filtration system for a user-friendly 3D printing experience.

The D600 is widely used for prototyping, engineering, modeling, and small-scale manufacturing. Due to its rich and intuitive functionality, it is a solid option for automotive applications such as printing replacement car parts. In terms of price-performance ratio, there is no alternative on the market that comes fully assembled, factory-leveled, with the same set of features and at the same reasonable price.

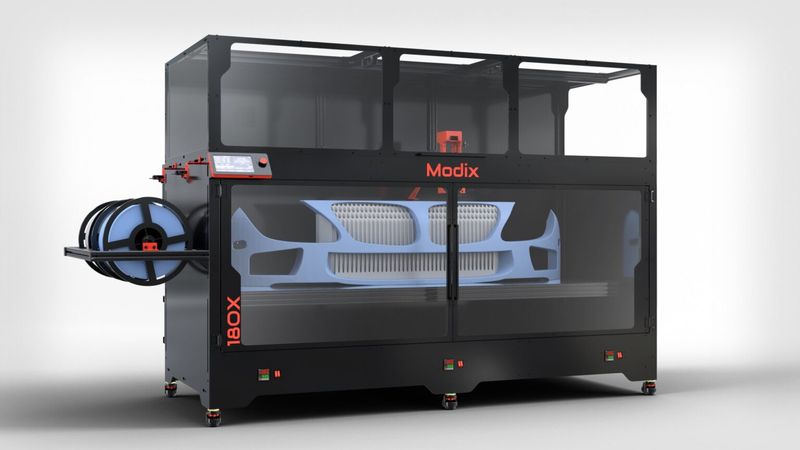

Just like the Big-60, the Modix Big-180X V4 is an industrial-grade self-assembly FDM 3D printer kit that provides the utmost degree of reliability and precision. Being a part of the company’s Generation 4, it boasts simplified assembly, redesigned key components, and a number of handy improvements. The key feature of the model is its wide build chamber (1800 x 600 x 600 mm) that is ideal for making full sized car body parts, just like a bumper prototype in the photo below. Unlike the majority of the V4 models, the Big-180X is supplied with an enclosure and casters by default. With fully automated calibration, an upgraded extruder with higher flow rate and easy nozzle replacement, integrated clog and crash detectors, increased print speed of up to 250 mm/s, easy access and convenient usage, the machine provides accurate and consistent outcomes alongside user-friendly operation.

Due to its advanced default functionality, wide material compatibility, and a number of optional add-ons, the Big-180X is great for producing strong and precise car parts. The only catch is that it is expected to be used by experienced makers.

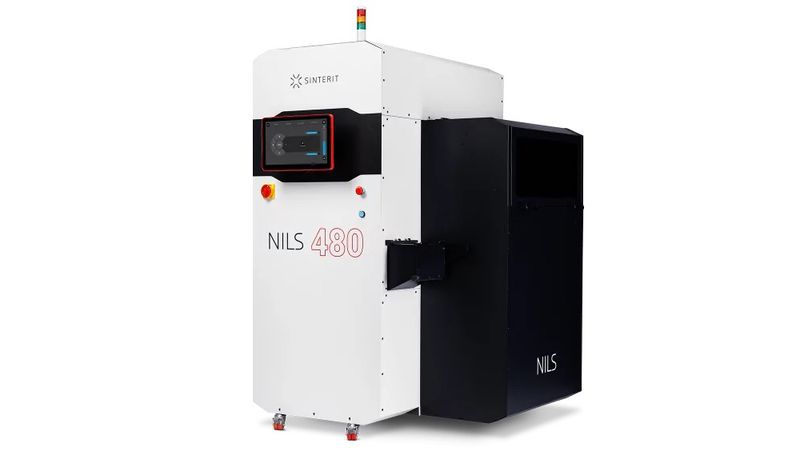

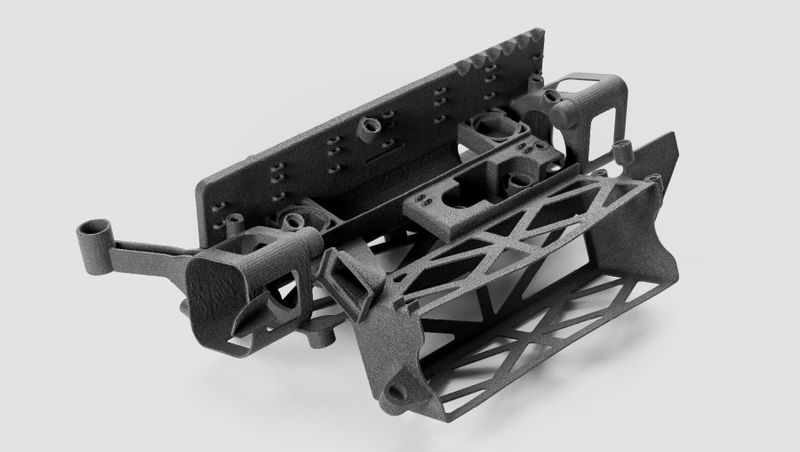

The Sinterit NILS 480, with NILS standing for New Industrial Laser Sintering, is a professional SLS 3D printer featuring reinvented productivity to ensure the best return on investment on the modern SLS technology market. Working with polyamide powders of various properties, it offers high-resolution printing alongside the ability to build complex geometries without supports. To meet the needs of automotive prototyping and manufacturing of functional car parts, it comes with a decent print area of 200 x 200 x 330 mm, built-in inert gas control system, automatic powder distribution and continuous printing capabilities. The revolutionary speed of 14 mm/h and outstanding powder refresh ratio of the NILS 480 make for optimal printing costs. In addition, the machine provides a complete slicing solution with many advanced functions, such as Auto Nesting ensuring the optimal arrangement of parts to be printed.

Although it requires specific working conditions and a certain level of skill, the Sinterit NILS 480 allows one to multiply their production in a smart and cost-efficient way. It is great for applications requiring high-resolution prints with intricate design and special properties.

Credit: jalopyjournal.com

As one of the most innovative manufacturing technologies, 3D printing has revolutionized the making of car parts, providing an accessible, cost-effective, and flexible method of production. Whether you are a car enthusiast looking to replace a hard-to-find part, or a manufacturer willing to streamline your production process, 3D printing offers a wealth of opportunities in a variety of forms.

Update your browser to view this website correctly. Update my browser now

Write a comment