3D printing, also known as additive manufacturing, is an innovative technology that creates three-dimensional objects from digital files. Its application spans various industries, including healthcare, aerospace, architecture, and more recently, small businesses.

In modern realities of rich opportunities and rapid advances, small companies and entrepreneurs must think ahead to remain competitive. With 3D printing at hand, it is now possible to bring even the most daring ideas to life in a cost-effective and efficient way.

Credit: @jenellstudio / Instagram

This is Top 3D Shop, and today we are going to elaborate on the advantages of 3D printing for small businesses. We also present a list of top models and essential criteria for choosing the best option for your specific goals and needs.

In contrast to traditional manufacturing methods, 3D printing is a game-changing technology that allows for the accurate and simplified creation of products with complex designs that were previously impossible to make. This opens up new opportunities and significantly contributes to your business’s expansion.

So, let’s start with some of the advantages that 3D printing can bring to small business owners and entrepreneurs.

Credit: phrozen3d.com

One key benefit is definitely cost saving. Traditional manufacturing methods often require expensive molds and prototypes. In the case of industrial production, high investment costs are offset by a large amount of products, while small businesses often struggle to compete with larger companies due to severe expenses. However, with 3D printing, it is possible to quickly and cost-effectively produce parts directly from a digital design, without sacrificing quality, which makes it a perfect option for those dealing with small batches of items of varying styles.

Thanks to the peculiarities of 3D printing, each item can be tailored to specific customer preferences, allowing small businesses to offer unique, highly personalized products — a feature that sets them apart in an overly competitive environment. What’s more important, this process does not require costly machinery or particularly advanced skills: 3D modeling software is now increasingly intuitive and comprehensive. Thus, 3D printing not only provides a high level of customization but also the ability to adapt to the ever-changing market.

Traditional manufacturing methods can be slow and costly at the design stage due to significant investment in tooling and molding. With 3D printing, ideas can quickly transform into physical prototypes, accelerating product development cycles. In addition, all the necessary adjustments will not take long, making for a comfortable testing experience. This speed to market can provide small businesses with a competitive advantage in the form of flexibility and time-saving, which eventually results in saving budget.

Choosing a 3D printer for your small business is not a decision to be taken lightly. Factors such as budget, ease of use, print quality, speed, and after-sales support should be considered before making a purchase.

Credit: 3dwasp.com

First and foremost, visualize your goals and business needs. This step is crucial for searching for the most suitable 3D equipment. If you plan to produce consumer goods with less time and more flexibility, focus on FDM devices aimed at high production speed and ease of use. However, for intricate designs with complex structures, fine details, and smooth surfaces it is better to pick up an SLA or SLS printer.

Also, despite the fact that most professional 3D printers are suited for multiple applications, always check out if a particular device satisfies your demands in terms of outer dimensions, controls, safety, silent and convenient operation, etc. Whether it is a commercial or home office, your work with the machine should be comfortable and helpful, not distracting or discouraging.

One of the decisive factors when it comes to workflow is the software powering your printer. Overall efficiency, turnaround time, simplicity of use, and many other aspects depend heavily on a software suite compatible with the machine. Proper solutions offer extensive functionality for small businesses, including one-click printing, intuitive UI, automated slicing procedures, Wi-Fi connectivity, cloud-based processing, remote monitoring, multiple device management, and more. These will surely boost the productivity of your business.

Knowing your purposes, it will be easy to choose a printer that supports required consumables, especially when your applications imply working with flexible, temperature-sensitive, engineering, or abrasive materials. Professional 3D printers frequently offer broader compatibility than hobbyist-grade equipment, from standard plastics and resins to specialized powders, metals, clay, ceramics, etc. Dedicated machines provide better outcomes, so choose carefully.

A printer’s resolution, also referred to as layer height, is a measurement expressed in mm or microns. It defines the thickness of each printed layer that affects the level of detail and surface texture of the final product. The lower this parameter is, the better.

For small businesses, print resolution usually varies between 20 to 100 microns, which is sufficient for most applications. Resin 3D printers provide the most accurate results for small, finely detailed items.

Last but not least comes build volume or available print area. It determines the maximum size of a single printed item or batch. Professional 3D printers normally have larger build volumes to meet the demands of small-scale production. It is possible to produce several parts of an item separately and assemble them afterwards, but this will likely impact the product’s final quality.

The printer’s physical dimensions and footprint are also worth consideration, especially for offices, labs, and workshops with limited space.

Choosing the right equipment for your business can be a daunting task, given the multitude of options available. We’ve decided to narrow the selection to several of the best 3D printers suitable for small businesses.

The Phrozen Sonic Mega 8K is an industrial-grade mono-LCD 3D printer with a massive build area of 330 x 185 x 400 mm, great print speed, and ultra-high resolution. The printer comes with a 15" monochrome LCD panel and can print layers at a minimum layer height of 10 microns. This makes for exceptionally accurate models with intricate designs and extremely smooth exterior surfaces. To add to the overall quality of printouts, the machine is equipped with a perforated print platform that ensures improved adhesion and time savings. As a nice bonus, the build plate is pre-calibrated before shipping allowing the user to start printing right after unboxing. Despite some potential complications with operation and maintenance, with the right approach the machine can work around the clock and efficiently produce top-quality models and parts.

With a machine like this, one can easily print large-scale items of any complexity at a professional level. Therefore, the Phrozen Sonic Mega 8K is perfect for businesses requiring large amounts of highly detailed, quality products and generous build volumes.

The Bambu Lab X1 Carbon has already gained popularity due to its capacious build volume of 256 x 256 x 256 mm, powerful printing capabilities, and a variety of advanced features, such as a filament cutter, Bambu Micro Lidar for auto calibration, spaghetti detection, active vibration compensation, power recovery function, and filament runout sensor. Based on the CoreXY motion system, the X1 Carbon allows for much faster printing than Cartesian 3D printers while not sacrificing print quality. If you plan to work with demanding materials, the machine features an all-metal hotend that can reach temperatures of up to 300 °C. With the abrasion-resistant hardened steel nozzle, it is also capable of handling carbon and glass fiber-reinforced composites.

For those new to 3D printing, the Bambu Lab X1 Carbon might be a bit expensive. Still, given the device’s advantages, it can be considered a good investment, especially with some extras. For example, an optional automatic material system (AMS) allows combining up to four different filaments in one project, making it possible to build multi-color or multi-material models. Plus, the X1 Carbon is supplied fully assembled, tuned, calibrated, and tested before shipping, so one can enjoy printing right out of the box.

Credit: @preischl3d / Instagram

As an industrial-grade FDM machine, the Qidi Tech X-MAX 3 boasts a generous build volume, professional print quality, and high performance. It is engineered with an actively heated build chamber for reliable printing with high-performance filaments. The resonance compensation function allows reducing the impact of vibrations, ensuring high print quality without visible artifacts. To provide better printing results and a safe working environment, the X-MAX 3 has a built-in circulation fan with an active carbon air filter. Thanks to the advanced CoreXY kinematics and silent stepper drivers, the device can reach an impressive print speed of 600 mm/s while working quietly, which is perfect for home businesses. In addition, the printer comes assembled and ready to work within 10 minutes after unboxing.

A spacious build chamber of 325 x 325 x 325 mm allows for making fairly large items as well as batches of smaller products in the most time- and cost-efficient way.

The Raise3D Pro3 Plus is a professional dual extrusion FDM 3D printer offering extra-high build volume of 300 x 300 x 605 mm suitable for efficient production of just about any product. To meet various project demands, the printer is equipped with interchangeable nozzles with 0.2–1.0 mm diameters and can print layers at 10 microns producing finely detailed parts with extremely smooth exterior surfaces and intricate shapes. The maximum operating temperature of 300 °C and a built-in cooling fan allow the machine to effectively work with a wide range of materials, including PLA, ABS, HIPS, TPU, PC, nylon, TPE, FLEX, PETG, metallic PLA, wood PLA, carbon fiber, and others. Featuring the auto bed leveling function and a removable flexible steel build plate, the Pro 3 Plus provides high-quality prints with a perfect first layer adhesion. A bundle of convenient functions, like EVE smart virtual assistant, adds to consistent printing.

Thanks to its robustness and rich functionality, the Raise3D Pro3 Plus is ideal for professionals seeking versatile, reliable, and high-performance 3D printing solutions.

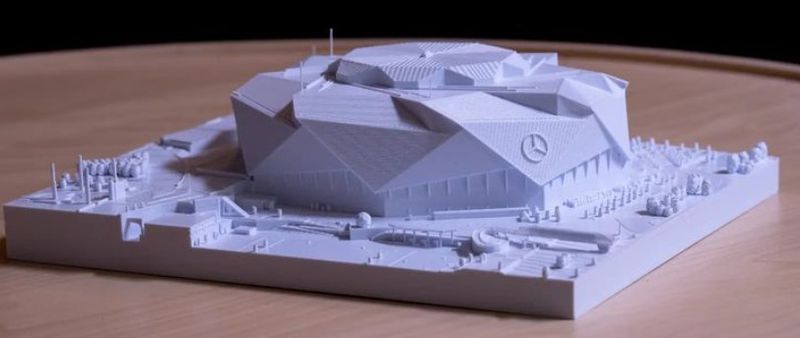

Credit: @architectural3dprint / Instagram

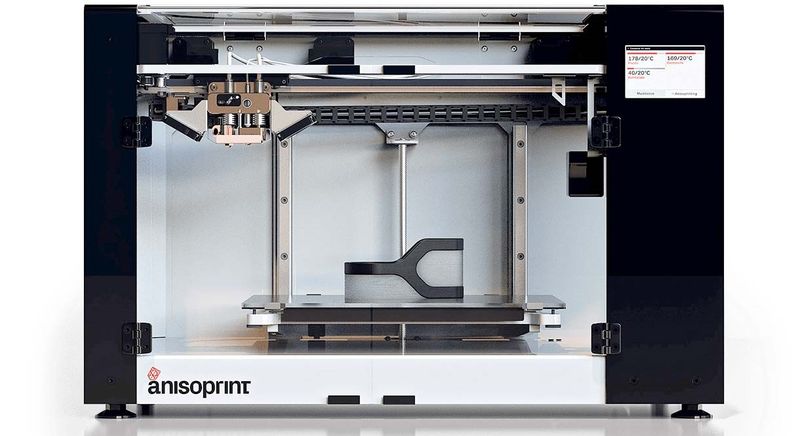

The Composer A3 from Anisoprint is a truly innovative 3D printer with a dual-nozzle system that combines the proprietary, patent-pending Composite Fiber Coextrusion (CFC) technology with standard FFF 3D printing. This professional device is equipped with an enclosed print chamber with a decent build volume of 460 х 297 х 210 mm that is more than enough for printing a single large item or simultaneous production of several smaller parts. When printing with the FFF print head, it can reach a print speed of up to 80 mm/s and 10 mm/s when using the CFC module. Each of the printer’s extruders comes with its own fan that effectively cools the model during printing, which reduces warping, stringing, and other issues. In terms of supported materials, the Composer A3 is compatible with a variety of thermoplastics that can be used with special reinforcing fibers. The list includes PLA, ABS, PETG, PA, TPU, PC, ASA, fiber-filled and glass fiber-filled filaments.

Thanks to its cost-efficiency, the CFC technology is widely used to produce lightweight and durable products with outstanding physical and mechanical properties, making the Composer A3 an ideal tool for certain small business applications. It is supplied in a fully assembled state, which makes for enhanced usability and a streamlined user experience.

Credit: @anisoprint / Instagram

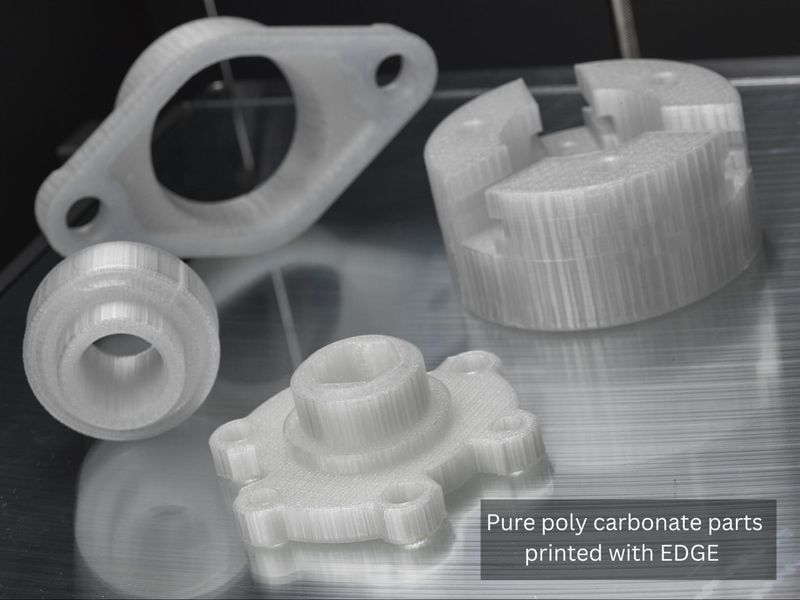

The Fusion3 EDGE is one of the fastest commercial FDM 3D printers. Utilizing the proprietary “F-Series” motion control system, the EDGE can reach the print speed of 250 mm/s still providing highly precise and accurate parts with smooth exterior surfaces, complex geometry, and detailed composition. The patented ANVIL print head heats up to 320 °C, which in combination with the printer’s enclosed design, multi-zone heated bed, and passively heated chamber allows for a wide range of materials with temperature-sensitive and engineering properties. Due to a wear-resistant interchangeable print tube that comes in 0.4, 0.6, and 0.8 mm diameters and is made of surgical steel, the EDGE can reliably work with abrasive materials such as carbon fiber or fiberglass. In addition, the device comes with a new mesh bed leveling system, remote management tools, intuitive software with optimized material profiles, door interlock function, and more.

Being an affordable high-performance 3D printer of industrial scale, the Fusion3 EDGE is a perfect tool for professional use in multiple spheres, including small businesses, rapid manufacturing, end-user production, and education.

If you are ready to work with professional 3D equipment, the Sinterit Lisa X will be great for small businesses. This compact SLS (Selective Laser Sintering) machine dealing with polyamide powders offers high-resolution printing alongside the ability to build complex geometries without supports. It features a capacious build volume of 130 x 180 x 330 mm and a nitrogen chamber for a wide range of materials. The revolutionary speed and outstanding powder refresh ratio of the Lisa X make for optimal printing costs. As for additional quality-of-life features, the machine provides fast cooldown of the printed models, simple material change, responsive display with clear interface, and a complete slicing solution with many advanced functions, such as Auto Nesting ensuring the optimal arrangement of parts to be printed. Apart from the basic set, Sinterit offers peripheral equipment to further enhance operation for smooth user experience and streamlined workflow.

Although it requires specific working conditions, the Lisa X allows one to multiply their production in a smart and cost-efficient way. It is suitable for businesses requiring high-resolution prints with intricate design and special properties.

Credit: @cadsolutions / Instagram

Credit: @binim_studio / Instagram

3D printing is capable of revolutionizing the entire manufacturing sphere, making for fast, consistent, and economic production of a vast range of items. Therefore, incorporating a 3D printer into small businesses can bring about countless benefits, including cost savings, customization, and rapid prototyping. With a wide selection of constantly evolving methods, growing quality, and user-oriented approach, modern 3D equipment can create top-notch products quickly and reliably. Consider your specific needs and choose wisely to reap the benefits of this transformative technology.

Update your browser to view this website correctly. Update my browser now

Write a comment