When you think about 3D printing, especially with respect to the consumer segment, the first technology to cross your mind is fused deposition modeling. That is not surprising as FDM printers are arguably the most affordable and easy-to-use devices in today’s additive manufacturing market. However, the oldest 3D printing technology is not FDM but stereolithography, or SLA, which remained the privilege of professionals for quite a long time but in the last decade has finally become accessible to consumers as well. Vat photopolymerization, more commonly known as resin 3D printing, is the general term that can be applied to three related technologies, namely SLA, DLP, and LCD, that use liquid photosensitive polymers (or resins) cured by a light source to build a solid object. If you want to learn more about resin 3D printing, read our guide on stereolithography.

Credit: @gazelle_3d_tech / Instagram

This is Top 3D Shop, and in this article, we will tell you about the best machines based on the oldest 3D printing technology. Read on and you will learn how to choose the right resin 3D printer for your particular needs and what tips and tricks you can use to make the best out of its capabilities for amazing flawless prints.

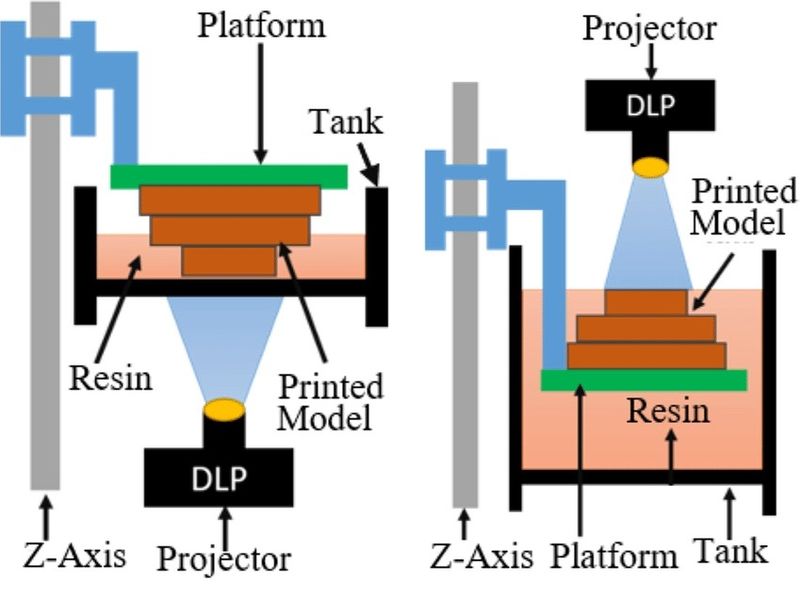

The three above-mentioned resin 3D printing technologies (SLA, DLP, and LCD) are based on vat photopolymerization process. The printing workflow looks as follows:

1. The resin tank, or vat, is filled with liquid photosensitive polymer (resin).

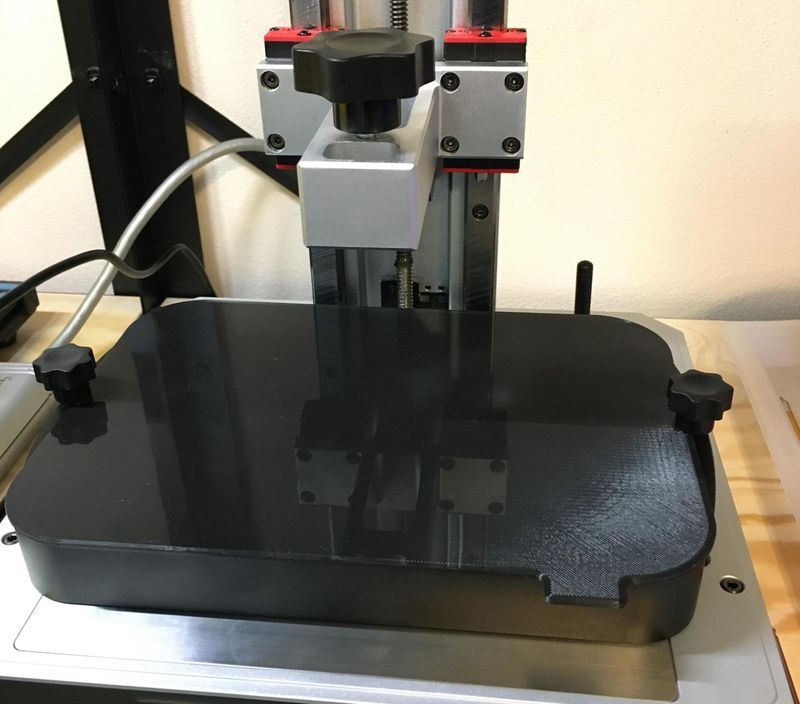

2. The build platform goes down into the vat until a thin layer of resin is left between the bottom of the vat and the print bed. (It is true for most consumer models employing the so-called bottom-up construction where the build platform gradually goes up during printing, and the model is built upside-down. In industrial top-down machines, the build platform stops at a single layer height under the resin surface to build the first layer, and then descends while the part is being built.)

Credit: researchgate.net

3. The light source cures the resin to build the first solid layer of the future part. And here we come to the difference between SLA, DLP, and LCD machines. SLA 3D printers use a laser beam to selectively cure a layer in a point-to-point manner. Such a method allows for incredible part quality but at the cost of print speed, compared to the other two. In DLP devices the whole layer is exposed to light all at once with a digital light projector used as a light source. LCD 3D printers are equipped with an LCD screen that serves as a mask for the light from an array of LEDs, transmitting the light only in required areas, curing the entire layer at a time.

4. Once the first layer is ready, the build platform goes up (or down) for a single layer height, and the second layer is being built.

5. The process continues until all the layers are built. The part now can be detached from the build platform and post-processed.

Credit: @volaux / Instagram

A resin 3D printer is a good choice if you are looking for uncompromised part quality, want to create isotropic watertight models with perfectly smooth surface finish, and are ready to spend a bit more money than on an FDM device. As long as resin printers are becoming relatively affordable, their popularity among hobbyists is constantly growing. In the consumer market, the most common type is LCD-based machines as they are the least expensive of the three. Still, even consumer LCD 3D printers can differ significantly in what they can offer to the user and, consequently, in price. To choose the right device that perfectly fits the bill and not to pay extra, it makes sense to define your printing goals and expectations beforehand. Below are some issues worth considering while making a decision.

An LCD screen is used as a mask for the light coming from an array of LEDs. Most LCD 3D printers are equipped with monochrome screens but some make use of RGB displays. The latter are cheaper but the downside is shorter lifespan and longer exposure time per layer, because the color pixels have lower light transmittance than those of mono LCDs. We recommend choosing a 3D printer featuring a monochrome LCD panel.

Credit: Miniac / YouTube

The print resolution shows how fine a detail your printer is able to produce. However, this parameter is determined not only by the LCD resolution but also by its physical size. If your device is equipped with a relatively small 2K LCD panel, it is perfectly capable of making highly detailed models compared to those built using a 4K or 6K printer with a larger size LCD. On the whole, all modern LCD printers from reliable manufacturers are able to produce parts of high quality that is fairly enough for most consumer projects. So, it is up to you whether you need a higher resolution LCD screen at a higher price.

Most consumer resin printers are equipped with rather compact build volumes, yet enough for most home-use needs. If your project implies building immense parts, you can consider buying a large-format resin 3D printer. Besides, you always have the option of printing separate parts of your model and joining them afterwards.

Resin 3D printing always requires a post-processing stage including a minimum of washing the part in isopropyl alcohol to remove the wet resin from its surface, and post-curing under UV light for complete polymerization. This can be done manually but some manufacturers offer full-cycle solutions including wash and curing stations for fast and convenient automated post-processing.

The Creality Halot-One Plus is a carefully balanced model from the manufacturer’s popular Halot-One series of affordable LCD 3D printers that offer high precision, decent build volume, quick setup, and increased accessibility. With the independently developed Integral Light Source ensuring over 90% light uniformity for higher accuracy of complex structures and print speed of 1–4 seconds per layer, upgraded 4K resolution, and numerous quality-of-life features, the printer is definitely worth your attention.

One of the main benefits of using the Creality Halot-One Plus is its advanced connectivity and remote control via Creality Cloud App, which offers abundant model resources, cloud slicing, monitoring, and one-click printing. Apart from the brand Halot Box slicer, the device is fully compatible with Lychee and ChiTuBox. The Halot-One Plus can be easily controlled via a convenient 5" touch screen. For safer operation, the printer is equipped with the air filtration system with activated carbon that effectively absorbs most of the resin odor.

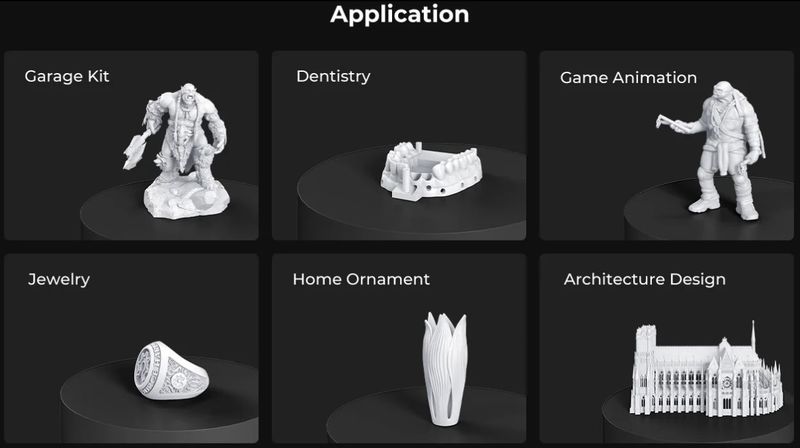

Thanks to its powerful light source, decent build volume of 172 x 102 x 160 mm in relation to the outer dimensions, and affordable price tag, the Creality Halot-One Plus can be used in a variety of personal and professional applications, such as the production of jewelry pieces, dental models, prototypes, tabletop miniatures, etc.

When it comes to medium-sized resin 3D printers in the budget segment, the Elegoo Saturn 2 is clearly the best choice in the category. With a powerful Fresnel collimating light source and 10" 8K mono LCD screen, the machine has an ultra-fine XY resolution of 28.5 microns and delivers highly detailed 3D models with a cure time of only 1–3 seconds per layer. In addition, this well-rounded printer comes with a generous build volume of 218.88 x 123 x 250 mm that lets one produce quite large models in one go.

The Saturn 2 is built with a dual linear guideway and non-slip hexagon socket leveling screws making for extra-steady and precise movement. Due to the build plate with sandblasted surface, the printer provides better adhesion, while PFA release liner ensures easier model removal and less release tension. The machine also comes with an activated carbon filter to absorb the characteristic resin odor. Another notable benefit is the printer’s universal material compatibility.

Credit: @philipp.kleinschmidt93 / Instagram

The Phrozen Sonic Mega 8K is an industrial-grade mono-LCD 3D printer with a massive build area of 330 x 185 x 400 mm, great print speed, and ultra-high resolution. With a machine like this, one can easily print large-scale detailed models at a professional level.

The printer comes with a 15" monochrome LCD panel and can print layers at a minimum layer height of 10 microns, with an XY positioning accuracy of 43 µm. This makes for exceptionally accurate models with complicated designs and extremely smooth exterior surfaces. To add to the overall quality of printouts, the machine is equipped with a perforated print platform that ensures improved adhesion and time savings.

For smoother user experience, the Phrozen Sonic Mega 8K is optimized to work with the ChiTuBox slicer and can utilize all of its features and new functions. As a nice bonus, the build plate is pre-calibrated before shipping allowing the user to start printing right after unboxing. Despite some potential complications with operation and maintenance, with the right approach the machine can work around the clock and produce top-quality models and parts.

The Elegoo Mars 2 is a mono LCD 3D printer that is capable of fast high-resolution printing with less maintenance involved. Being a truly budget device, it still offers a decent 2K HD resolution alongside rapid curing of only 2 seconds per layer, which makes for enhanced printing efficiency. Its 6.08" monochrome LCD with new light source structure boasts an impressive lifespan and provides stable performance during long term printing, thus saving your costs.

Thanks to a newly designed sandblasted build plate, the Mars 2 provides better adhesion. To guarantee a comfortable and safe user experience inherent to all brand products, the machine is equipped with an integrated air filtration unit. The printer’s solid metal construction with a compact footprint and decent build volume of 129 x 80 x 150 mm gives it a sturdy feel and makes it suitable for a wide variety of applications.

Credit: @tuffs105 / Instagram

The Elegoo Mars 3 is a professional MSLA resin 3D printer that offers a high-resolution printing experience at an affordable price. Engineered with a potent COB light source and efficient heat sink system, it is capable of creating highly detailed prints with just a 2.5 second per layer cure time and 0.035 mm XY resolution.

For its conveniently small footprint, the machine offers quite a large build volume of 89.6 x 143.43 x 175 mm. Overall, the Mars 3 stands out for its stylish and futuristic design with intuitive controls and simple maintenance, including easy bed leveling. Thanks to the solid linear rail, the machine provides smooth and silent operation, while the sandblasted build plate ensures proper adhesion and simple removal of the printed models. Thus, you are sure to get desirable results even with the most intricate projects.

Credit: @inky_john / Instagram

One of the most interesting 3D printers on our list is the fresh Elegoo Saturn 3 featuring innovative 12K resolution. With a 10" mono LCD boasting a stunning resolution of 11520x5120 and an XY resolution of 19x24 μm, the printer is capable of producing extremely detailed and intricate models at a decent printing speed of up to 70 mm/h.

In terms of its build volume, the printer is similar to the predecessor, the Saturn 2: the area of 218.88 x 122.88 x 250 mm lets one produce single large models or a wide variety of small-to-medium sized items in batches. To ensure over 90% light uniformity and overall print accuracy, the machine uses an effective combination of the powerful COB light source and Fresnel collimating lens. Furthermore, the build plate with a laser-carved surface provides excellent adhesion.

The printing efficiency of the Saturn 3 is further enhanced with the included lifetime license of the Voxeldance Tango software that offers several printing modes: static and dynamic, the latter including smooth and high-speed mode. As for the quality-of-life features, the machine comes with a USB plug-in air purifier with an activated carbon filter that eliminates harmful odor released during resin printing.

The Phrozen Sonic Mini 8K LCD 3D printer, as its name suggests, features a remarkable resolution of 22 µm and 1152 ppi and other impressive characteristics that make it stand out from other devices in the consumer electronics space. Apart from the 7.1" LCD screen and 18 cm Z-axis, which is great for small highly detailed objects, such as tabletop miniatures, the Sonic Mini 8K is built with reliable components ensuring high print speed, uniform light exposure, and stable operation with top-quality outputs. Considering the sphere of its application, the device offers a sufficient build volume of 165 x 72 x 180 mm perfect for single medium-sized models.

For its price, the Phrozen Sonic Mini 8K offers a solid foundation for LCD 3D printing exploration and small businesses. Thanks to its budget-friendliness, cost-efficiency, and ease of use, the machine is an excellent choice for entry-level makers.

Credit: @sigurddecroos / Instagram

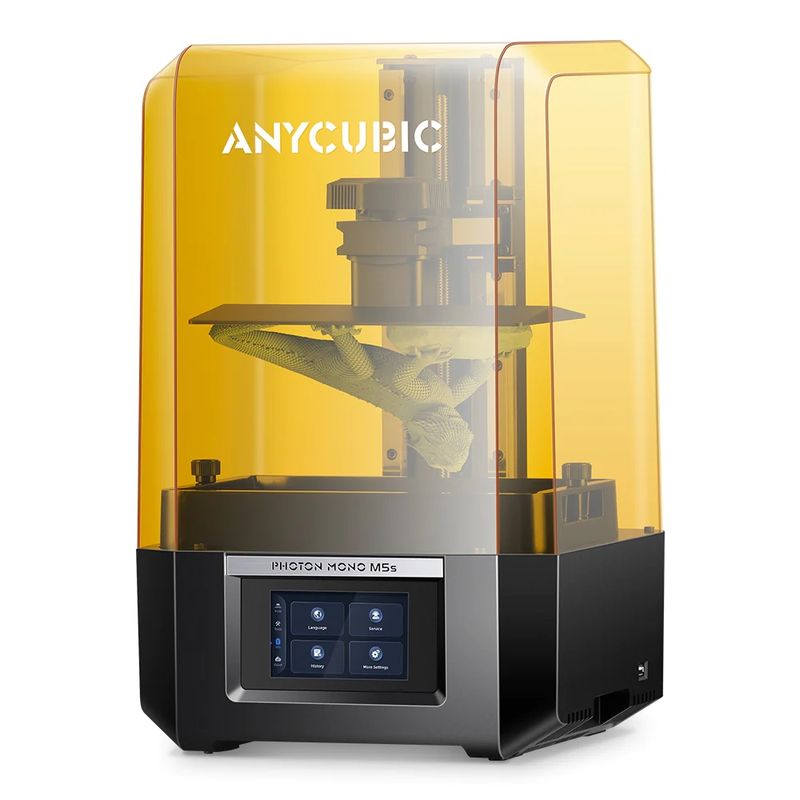

The Photon Mono M5s from Anycubic is a new 12K LCD 3D printer providing the best experience for beginners in 2023. Due to the 10.1" mono screen, achieving a 19-micron X accuracy, it is capable of printing details as precise as a hair thickness, which is great for complex models.

Despite its relatively compact dimensions, the printer offers a sufficient build volume of 200 x 218 x 123 mm. As for the print speed, the Photon Mono M5s is able to reach up to 105 mm/h with high-speed resins and an average speed of 70 mm/hr for standard materials. With a special high-speed vat film, the device ensures easy print release and higher print success rate.

Speaking of user-friendly characteristics, the machine comes as leveling-free, with a mechanical sensor automatically doing all the work, which eliminates the risk of poor leveling. In addition, the Anycubic Photon Mono M5s has a number of integrated smart functions dedicated to boost printing efficiency, minimize print failures, and reduce waste of resin and time. The list includes Auto Device Check, Resin Detection Mode, Print Status Detection, and Intelligent Mode for the updated Anycubic Photon Workshop 3.1 software.

Thanks to Wi-Fi connectivity and convenient Anycubic App, it is easy to remotely control the printing process with the Photon Mono M5s and get access to popular sliced models available in just one touch.

The Uniz NBEE is an LCD 3D printer primarily aimed at the needs of the dental industry. As the world’s fastest resin 3D printer, the device is able to achieve the record build speed of 280 mm/h, which allows it to produce up to 6 dental models in 5 minutes.

To ensure professional quality of the printed parts, the Uniz NBEE is equipped with a high-power collimated light source providing light uniformity of up to 95%, smart resin temperature control system maintaining optimal reaction temp, and an anti-collision high-performance server that boosts the print precision. With the patented liquid cooling, the system temperature will not exceed 40 °C, which prolongs the lifespan of the LCD screen to over 5,000 hours. Furthermore, the micro-stereo composite film is reportedly able to withstand up to 55 liters of resin before replacement.

Thanks to its build volume of 192 x 120 x 180 mm, high accuracy, and compatibility with 100+ resins, the Uniz NBEE will become a great tool for a wide variety of dental applications and streamlined production of aligner models, removable dies, surgical guides, crowns and bridges, brackets, and more.

The SuperMaker SLA1000 from the Chinese company Zongheng3D is a large-format industrial machine that is rightfully considered a record holder among SLA 3D printers in terms of build volume that reaches 1000 x 1000 x 600 mm.

To match this impressive capacity in reliability, the printer is engineered with a number of smart features enabling continuous production of high-quality parts at a fast speed. It can print layers at a minimum height of 50 microns, which results in complex models with perfectly smooth surface finish. Automated printing process is achieved through the customized software functions and intelligent control system of printing parameters, such as resin level control and adjustment. While printing, the device can maintain stable chamber temperature and humidity level, providing optimal conditions for impeccable results. With the built-in camera, the SuperMaker SLA1000 provides convenient remote monitoring of the printing process.

Considering its advanced characteristics, simplified operation, and high fault tolerance, the Zongheng3D SuperMaker SLA1000 can be used for a wide range of applications, such as rapid prototyping, product demonstrations, aerospace and automotive industries, architecture modeling and home decoration, consumer products manufacturing, and many others.

If you are new to resin 3D printing, our “tips and tricks” section will help you avoid print failures right from the start.

Credit: @unclejessy4real / Instagram

There are a wide variety of 3D printing resins of different colors and properties, like engineering-grade tough, rigid, flexible, or chemical and heat-resistant resins. There are also casting resins used to make mold patterns for creating molds in lost-wax casting, as well as medical or dental biocompatible resins for medical use. For consumer needs, regular, or basic resins are used most often unless your project has any special requirements.

There is one thing you should always remember when dealing with printing resins. While absolutely safe in its cured solid state, the liquid polymers and their fumes are hazardous when contacted with your skin or inhaled. So, it is absolutely necessary to wear protective gloves and use the printer in a well-ventilated room. Wearing a protective mask is not a bad idea either.

The printing process itself is pretty simple. You need a digital 3D model which you prepare using a slicer suitable for resin printing, like ChiTuBox or the program recommended by your printer’s manufacturer. If your printer does not come pre-calibrated, it is important to level the print bed thoroughly to ensure the proper first layer adhesion. Shake the bottle with selected resin material and pour the resin into the vat. Be careful not to overfill it, there is often a fill mark inside the vat. Now you send the print task to the printer, and it does the rest of the job.

When the part is ready, leave it in the printer for some time to drain the excessive resin. After that you can carefully remove the build platform from the printer and gently detach the model using the spatula which usually comes in the box. Now your part is ready for post-processing.

The short answer is yes. Resin printing can be fairly messy compared to the FDM process. Considering the fact that resins and solvents used for post-processing are toxic materials, you need to dispose of them with all necessary precautions after each printing job. Cleaning the resin vat is also necessary but not the easiest and most pleasant task to do.

All resin 3D printed parts need to be washed to clear off the uncured resin. To wash the part you need to submerge it into a container with a solvent (isopropyl alcohol is the most common choice) and scrub it with a toothbrush, for example, to remove all the remaining resin.

When the model is clean, you need to carefully remove support structures and cure the part under UV light, so that it could obtain the required mechanical properties. Leaving the part in direct sunlight also works, though the process will take a bit longer. The average curing time is 6–8 minutes, but it may vary depending on the type of the resin used, the power of the light source, and the part size.

Credit: reddit.com

To make post-processing easier and faster you can use one of the cleaning and curing stations mentioned before. They are usually two-in-one solutions and can wash and cure any resin parts of suitable size despite your printer brand.

Credit: @hobbydad90 / Instagram

Before applying paint to your resin model, it is a good idea to use a primer to smooth and even the surface. There are special model-making paints, but acrylic and water-based paints can work too, although they may require two or more layers.

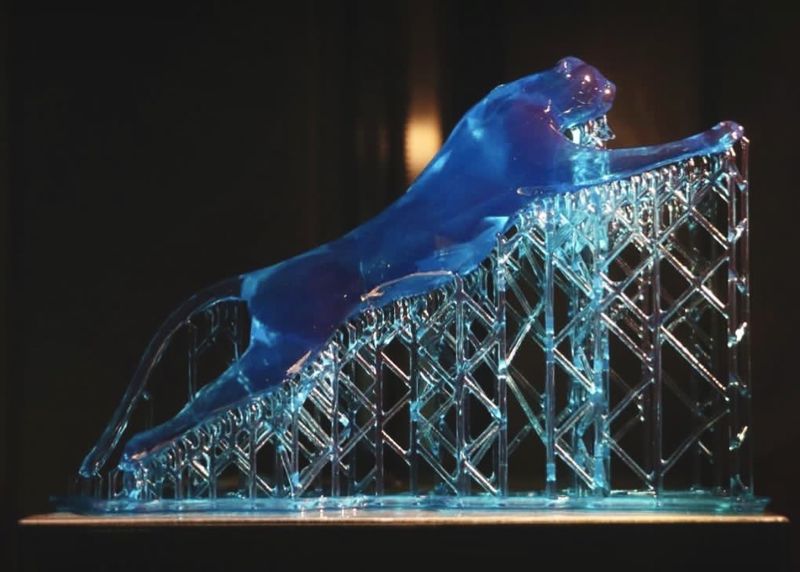

There is a special-purpose type of casting resins designed specifically for investment casting. These wax-like materials are used to build negative mold patterns which are used to create molds for wax-lost casting. Casting resins are widely used in jewelry manufacturing and in the dental industry. The 3D printed resin mold patterns burn completely leaving almost no ash or residue. Besides, the use of 3D printing allows for unlimited customization opportunities hardly possible with traditional manufacturing.

Credit: @novafab_ / Instagram

You can definitely mix resins of the same type using different colors and even brands. As for different resin types, it can be a good idea to mix, for example, basic and flexible resins to add elasticity to your model. But such mixtures require certain printing experience as you have to adjust print settings, such as exposure time, that can vary for different resin types. Anyway, you are free to experiment, and eventually you will realize what works best.

Uncured resin left in the vat can be reused for future prints unless it contains inclusions of even slightly cured material. The uncured resin should be collected and filtered after printing and kept in a UV-protected container.

Polymerized parts can not be melted and reused, as heated resin burns rather than melts and does not restore its initial properties.

Credit: @glimmsaum / Instagram

You can leave resin in the vat for several months if you are absolutely sure it is not exposed to any UV light. Cover the vat, or better the printer, with a UV-resistant cover. Yet, if you are not planning on using the resin in the nearest future, it is safer to filter it and put it into a UV-protected bottle for storage.

Credit: reddit.com

Stored properly, resin can keep its properties for a year or even longer, however, you may notice some quality degradation if you try using it after the expiration date. To prolong the lifespan of the resin, keep it in its original package in a cool dark place and never expose the bottles to direct sunlight.

As mentioned, liquid resin is not environmentally friendly and should be disposed of with special care. Never pour liquid resin or solvents into drains. To dispose of the liquid resin that can not be filtered and reused, you need to completely cure it to a solid state, either leaving it in direct sunlight for several days, or using UV light source. All objects that have been in contact with liquid resin, like gloves or paper towels, should be also exposed to UV light to make sure they do not have any residues of liquid resin. After that you may dispose of the cured resin as household waste.

Solvents used for washing resin parts should be poured into a container and disposed of as chemical waste according to your local regulations.

Credit: the3dprinterbee.com

There can be a lot of reasons for resin 3D print failures, and here we will name the most common ways to fix the problem and improve the print quality.

Credit: imgur.com

Credit: @fablab.ir / Instagram

Choosing the right resin 3D printer can seem overwhelming with the multitude of options available. However, by understanding what you need, considering your budget, and examining the top picks for 2023, you are sure to find a machine that matches your 3D printing ambitions. Whether you are a novice hobbyist or a professional seeking precision, there is definitely a resin 3D printer out there for you.

Update your browser to view this website correctly. Update my browser now

Write a comment