3D printing is becoming a more popular solution in the jewelry world. The new technology provides flexibility and creativity as well as adding many new possibilities to jewelry design

The speed of 3D printing allows the designers to produce several iterations a day: and this is the key to use all of the strong points of the technology. Reduced production time makes using 3D printing a competitive advantage in jewelry production.

After choosing this technology, one can make complex projects for each client, as well as produce interesting models. The tech can also be used for prototyping as a way to make sure that the end product would turn out exactly as planned.

Metal 3D printing is one of the most complex additive manufacturing processes. Since the result will be a wearable art object, it would require thorough polishing and tooling after printing. Adding jewels and other things will make things even more complex. Nevertheless, it can still be the easiest way to get what the designer has originally envisioned.

These days, jewelry 3D printing is often used by small workshops, since the technology is becoming more accessible and simple. Some provide the services of customizable printed jewelry, and these offerings are becoming even more widespread. Choosing the design online is a popular approach as well. Using 3D printers reduces the manufacturing time and increases the level of competition among the companies.

There are two main approaches to jewelry printing. One involves casting using investment patterns and is not far from traditional techniques. Another one is direct 3D printing that is just starting to pave its way into the world of jewelry production.

Investment patterns are the most popular way to print jewelry. It consists of 8 steps:

1. Making plastic/wax master pattern

Traditionally it’s done by filling a metal/silicone form with castable wax. Additive manufacturing allows one to print a mold or just directly print the prototype from castable resin.

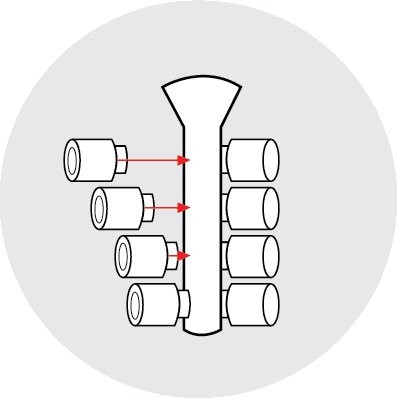

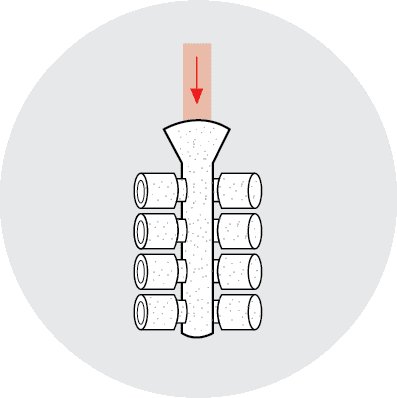

2. Producing a mold.

Molds are used in the cast tree (a sprue with several molds attached) for casting multiple parts at once. Some methods avoid this stage by printing parts and the tree at one step.

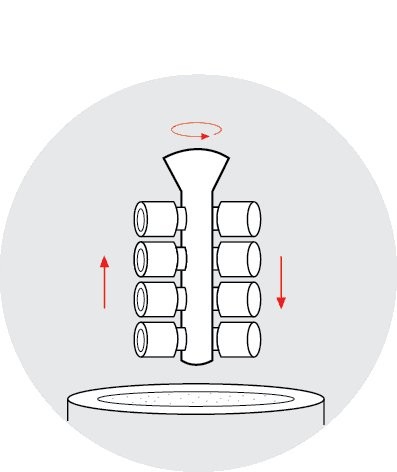

3. Making of a ceramic mold (also called an ‘investment mold’).

After the tree is complete, the whole system is dipped into suspension several times. After that the suspension coating is left to dry and harden, making a ceramic outer layer over the pattern.

4. Burning out.

The structure is placed inside the furnace and the initial mix of wax/resin melts off/burns away which results in a hollow shape.

Going from traditional methods of jewelry production (using wax models) to the methods that involve equipment that prints with plastic will require using higher-temperature furnaces. And this may stop many from shifting to 3D printing.

5. Pouring.

After material removal from the ceramic shell, the casting material will be poured in the investment mold and will stay there for cooling off and solidifying. The parts are often made from brass and will be galvanized in precious metals at the final stage.

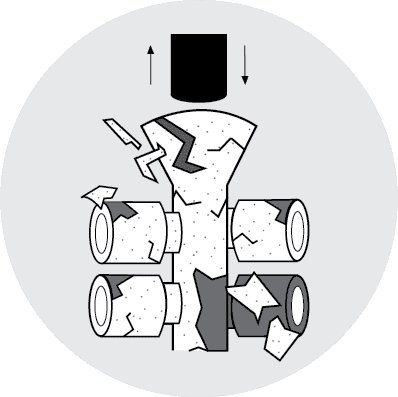

6. Destroying the shell.

The external ceramic must be destroyed. It’s usually done with vibrations.

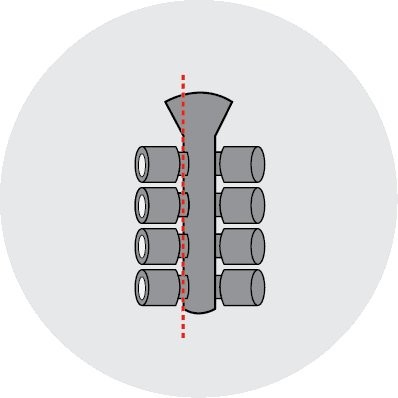

7. Cutting off the results from the sprue.

After full removal of the ceramic layer, separate cast products are cut off from the sprue that can be recycled.

8. Post-processing and final works.

After everything is done, castings go through traditional mechanical tooling and post-processing.

This method is good because there’s no need to use fine-powder metal, just any metal in its default form can be used.

01| 3D printing jewelry models based on investment casting molds

Investment casting models are usually made of highly fusible materials. The most simple example would be wax, since it starts melting at low temperatures.

3D printers by American company Solidscape are the most common high-precision wax printers that use the Drop on Demand technology. Another example are the devices by 3D Systems that use the Multi Jet Modeling (MJM) technology for 3D printing. It’s a lot like regular jet printing.

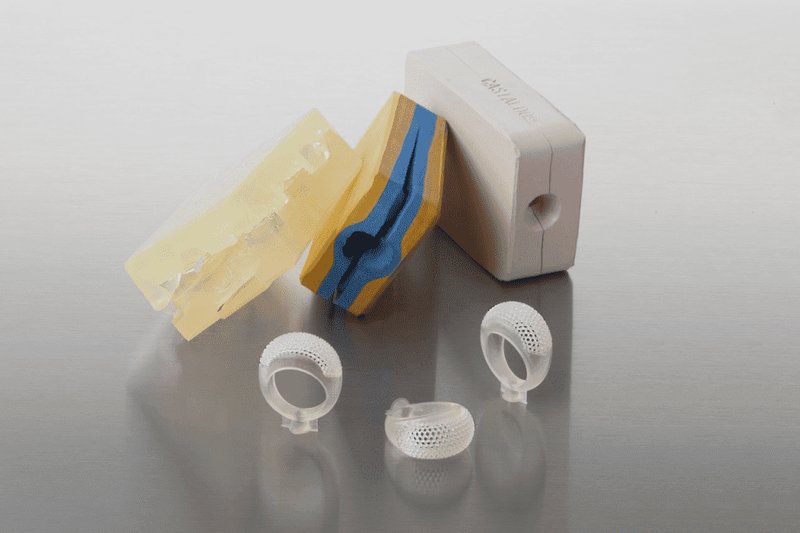

02| An example of an investment casting model

Evaporative-pattern casting models are usually made of plastic and are 3D printed from specialty resins using the SLA and DLP technologies.

03| An example of an evaporative-pattern casting model

Phrozen Sonic 4K by Taiwanese company Phrozen is a resin 3D printer that can be a great choice for manufacturing small jewelry, thanks to its 4K resolution allowing the precision of 35 microns across the XY-axes at 10 microns of minimum layer height.

04| An example of a 3D printed jewelry prototype made with Phrozen Sonic 4K

Evaporative-pattern casting models are usually made of plastic and are 3D printed from specialty resins using the SLA and DLP technologies.

Currently both technologies are used in the jewelry industry.

04| Examples of investment casting models

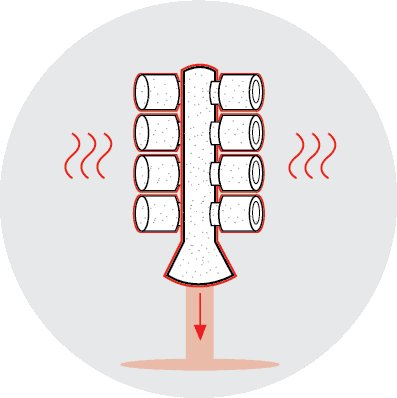

This means additive manufacturing of the end-use jewelry products from metal. This approach is significantly less popular since it’s much more expensive compared to casting with investment or evaporative-pattern casting models. Nevertheless, it offers a wider range of abilities.

Direct 3D printing consists of sintering the particles of metal powder with the help of a laser and using melting methods for the powder layer. The technologies are now called Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). The list of available metals depends on a model of the 3D printer but there’s a wide selection of metals.

Not all metal 3D printers using the SLM and DMLS technologies are capable of handling precious metals. The Farsoon 3D printers can handle such materials.

05| Directly 3D printed jewelry products

Direct metal 3D printing of jewelry products is the most non-standard and expensive way to manufacture jewelry but it offers the shortest production cycle. Extensive tooling and post-processing are necessary after printing.

The jewelers from all around the world use various methods and technologies to do their job. CNC tooling and 3D printing can be useful for them. Let’s compare the advantages and disadvantages of each approach.

As can be seen here, the choice between the CNC machines and 3D printers depends on what product one wants to manufacture. Those who want to produce relatively simple shapes such as rings and bracelets, can find the CNC machines enough for their tasks. 4- and 5-axis CNC machines can do a lot of what 3D printers can offer. Moreover, solid wax that is used for tooling is cheaper than specialty castable 3D printing resins. But if one wants to make something small and delicate with a high level of fine details, they can use the whole potential of the DLP and SLA 3D printers.

Update your browser to view this website correctly. Update my browser now

Write a comment