Modern technological equipment increases not only production speed and profitability, but also the quality of products. Modernization of production benefits the economy, improves everyday comfort for consumers, and supports future professional and industrial use of these products, which in turn drives industrial standards and economic growth.

High-tech industries need trained specialists for every stage: design, launch, production, quality control, and even operation of the finished products. Training such specialists with broad technological knowledge and focused skills has become a key priority for leading public and private educational institutions. Regular schools now add extra programs to help students choose a specialty early and build a foundation for technical careers.

In this article, we describe how we equipped and installed a 3D printing lab for a local school.

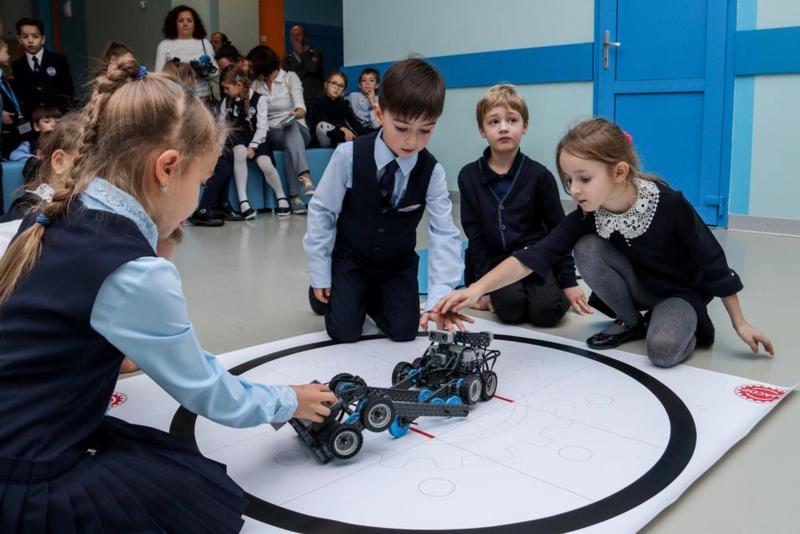

This school teaches students who show creativity and strong abilities in technology. It uses special programs and modern equipment to give students not only general education, but also initial skills and competencies for working with real-world production in any form.

Students regularly participate in competitions and events in biology, ecology, art, history, geography, mathematics, astronomy, social studies, and physical education. They can also take additional courses to deepen their interests.

The school prepares students for life and work in a high-tech world. After graduation, they already have a broad base of knowledge and practical skills, so they can continue training in chosen professions and apply their talents more easily. The result is a society that receives motivated, properly trained specialists.

Alongside the general education program, the school offers several supplementary technology-focused tracks:

Bio-Insight: Research and experimental work in biological labs and wildlife studies.

IT-Insight: Creation and exchange of IT cases, developing clear algorithms in programming languages.

3D-Insight: Project and creative activities using 3D graphics and design.

Energy-Insight: Study of the region’s energy systems, with clear models of processes and electrical engineering logic.

Robo-Insight: Design and programming of robotic systems and components.

Liberal arts: Courses in humanities and social sciences.

These additional programs include robotics, mechatronics, 3D prototyping, and 3D design — especially relevant in an era of rapid technological progress.

The school already has an extensive technical base, including:

7 computer labs

5 mobile computer labs

445 computers, 5 laptops, and 90 tablets

80 touchscreen panels

Robotics lab

3 3D classrooms

3 digital labs

25 voting systems

5 teleconference systems

50 document cameras

Fiber optic internet

A print office with a printing complex, risograph, and laminating machine

5 scriptoriums

6 classrooms with interactive projectors

Astronomy classroom with a planetarium dome

Electronic shooting range

80 multifunction printers

Laser machining system for wood, metal, and glass

3 fax machines

1 camera

The school also includes specialized classrooms, laboratories, workshops, gyms, two swimming pools, sports fields (including a soccer field), and more.

Our task focused on 3D printing equipment. We supplied and installed:

Several Epitum FDM 3D printers

A Formlabs Form 2 resin 3D printer

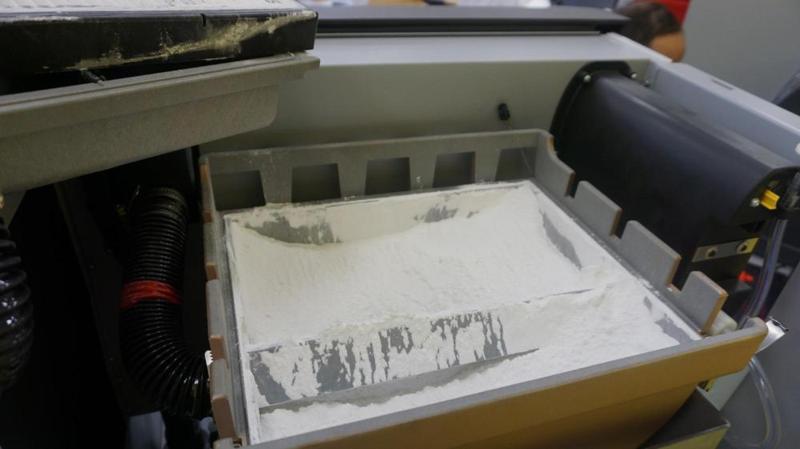

A full-color 3D Systems ProJet 260Plus

All related peripherals and service equipment

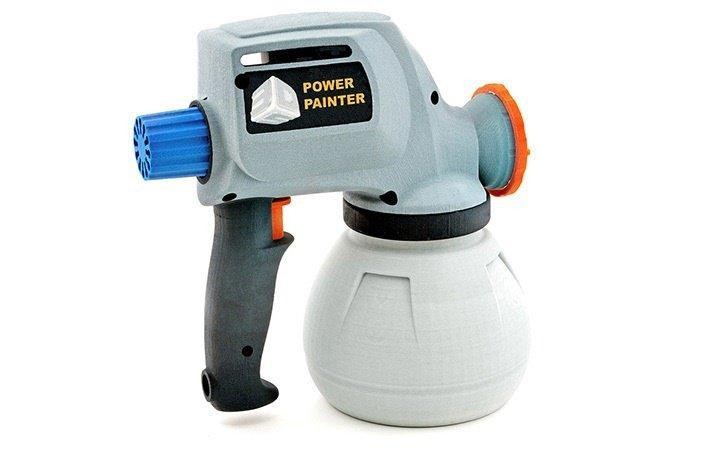

The ProJet 260Plus is a compact, full-color inkjet 3D printer that uses gypsum-based material. During printing, the machine deposits binder and color components, which allows it to produce parts in 64 CMY colors.

3D Systems ProJet 260Plus is one of the most compact and affordable color 3D printers from a trusted, well-known manufacturer. This gives the school confidence in its reliability and maintainability.

Key advantages:

The most affordable full-color 3D printer in its series

High printing speed: 3.5 layers per minute

64 colors

Compact size: 74 × 79 × 140 cm

Low cost of consumables

Strong, durable models

Excellent print resolution

Bright white base color

High color accuracy and rendering

Low cost per printed unit

In education, clarity, color, and memorability are critical. Full-color 3D prints provide exactly that for visual aids and student projects.

Teachers will use the ProJet 260Plus both to teach 3D printing, prototyping, and modeling and to produce visual aids for other school subjects. This way, the 3D lab supports multiple disciplines at once. An important advantage is that the package includes didactic materials and manuals suitable for lessons on many topics, not just standard technical documentation. For educators, this kind of teaching material is extremely valuable.

Why it was chosen

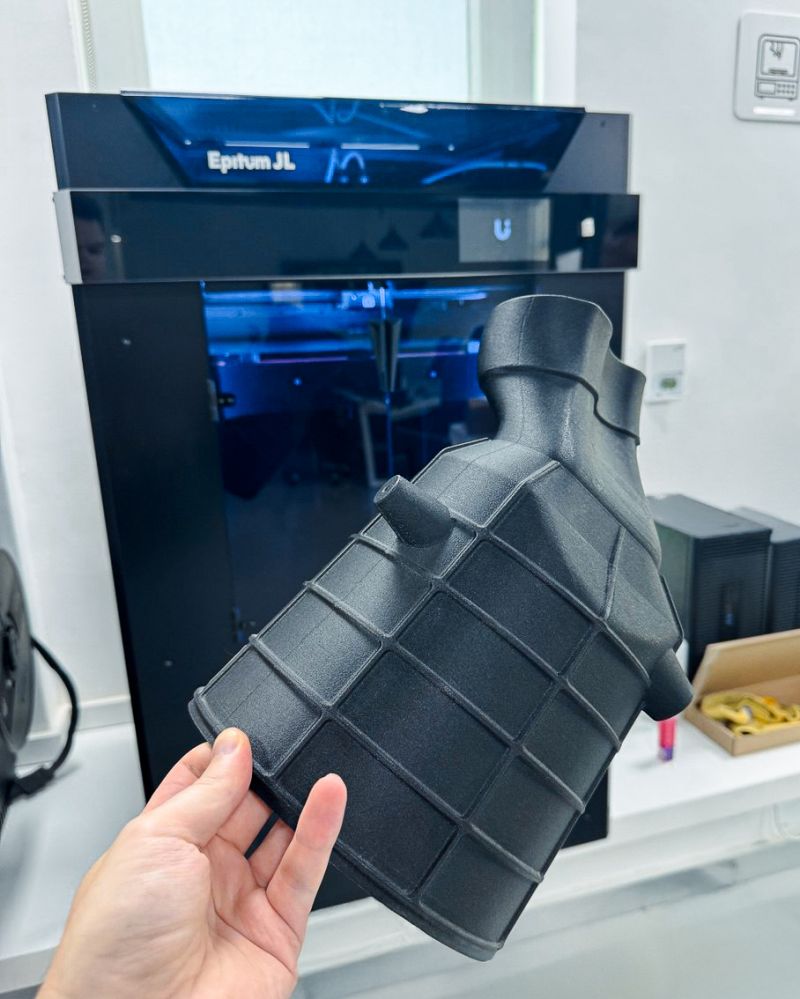

The school needed modern, reliable FDM machines for everyday educational use. The Epitum desktop FDM 3D printer matched that need. It suits prototyping and product visualization and often appears in enterprise environments. The school integrated five units to give students a solid base in FDM skills.

Key features:

Dual-material printing via JetSwitch printhead:

5 s tool change in normal mode

0.25 s in draft mode

Supports two-color printing or soluble support material for complex geometry

High precision (up to 1 micron) with a rigid frame and precise mechanics

Built-in material profiles, light indicators, and first-layer control

Automatic bed leveling in about 50 seconds

Compatibility with most common filament types

Network operation as a 3D farm using Polygon X software from a single computer

Teachers will use the Epitum printers to show students how modern FDM/FFF 3D printing works in practice. Students will learn:

How to prepare models for printing

How to manage slicing profiles and materials

How to operate and maintain current-generation FDM equipment

These skills help students understand additive manufacturing workflows they will later encounter in universities and industry.

The Formlabs Form 2 is one of the most recognized and widespread desktop stereolithography printers in the world. It builds parts by curing liquid photopolymer resins with a laser, achieving far higher accuracy and surface quality than most affordable FDM printers.

The school selected the Form 2 as a proven, reliable SLA machine. Many users still consider it a benchmark for desktop stereolithography, even after the release of more modern and larger models from Formlabs and other brands. This stability and mature ecosystem make it ideal for teaching.

Students will use the Form 2 to learn resin-based 3D printing. This knowledge will help those who later enter:

Jewelry and small precision product design

Dentistry and dental modeling

Any field that requires highly accurate, dimensionally critical prototypes and parts

Before schools had 3D printers, teachers could rely only on:

Standard visual aids from specialized stores

Custom orders from third parties

Hand-made teaching models

This limited what teachers could show in class, especially when teaching updated or experimental programs that standard aids didn’t cover. Few could predict which materials and tools they would need in the future.

With the introduction of 3D printers, teachers can now prepare and print exactly the visual aids they need — or assign this task to students. Students, in turn, gain practical experience in 3D modeling and 3D printing while creating useful materials for their own lessons.

Naturally, training children in prototyping and 3D printing requires access to real 3D printers.

We assembled the main 3D printer directly in its future workspace: the modeling and prototyping classroom, where we had already installed other machines such as the Epitum 3D printer, the Formlabs Form 2, and CNC equipment.

In addition to the 3D printer, we set up its proprietary post-processing station for cleaning printed parts.

On site, we:

Assembled the printer and checked all mechanical components

Configured the system, connected it to the network, and loaded the first batch of consumables

Switched the machine on and verified that it operated correctly under working conditions

We expect this equipment to help the school train future engineers, developers, and scientists, giving them their first hands-on experience with modern technologies.

Training young specialists remains one of the main priorities in education, because industry cannot advance without ambitious, technically competent workers, and the economy directly depends on industrial development and the overall state of society.

Many educational institutions connected with production processes have already modernized, are in the process of modernizing, or are planning to modernize their technical base. Their goal is to ensure high-quality growth in learning outcomes and keep pace with technological progress.

At Top3DShop, you can:

To create a modern, well-balanced set of such equipment for your organization, contact Top3DShop. Our specialists will create a detailed equipment plan based on your requirements, help you choose the right devices, prepare all necessary documentation, deliver and install the equipment, and provide ongoing support and service.

Update your browser to view this website correctly. Update my browser now

Write a comment