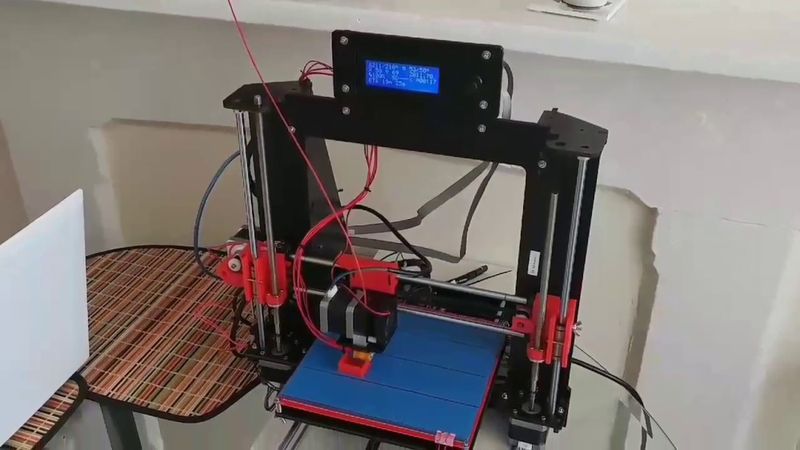

There are currently a great many FDM 3D printers available for purchase. They can be divided into two large categories — open-framed printers and enclosed printers. In this article, we will consider the differences between these categories and explain why it is better to opt for a printer with a closed chamber.

Any purchase should be economically justified, and 3D printers with a closed chamber are usually more expensive than their open-framed counterparts. So in what cases it is worth taking an enclosed 3D printer?

First, such a 3D printer is worth purchasing if you intend to work with engineering plastics, which have high shrinkage (more information about shrinkage, delamination and why it is bad you can read in the next section), for example, ABS, HIPS, Nylon, PC.

Secondly, if you are going to install a 3D printer in a garage or a workshop, where there may be dust or drafts and temperature fluctuations.

And thirdly, if near the place of the installation will be children or pets.

Now we will analyze these factors in more detail.

Plastic heated to a liquid state has a bit lower density than in a solid state. With the same mass, the volume of liquid plastic will be slightly larger than that of hard plastic. Accordingly, during the printing process, when the materials hardens, its volume will decrease. This process is called shrinkage and is believed to interfere with 3D printing.

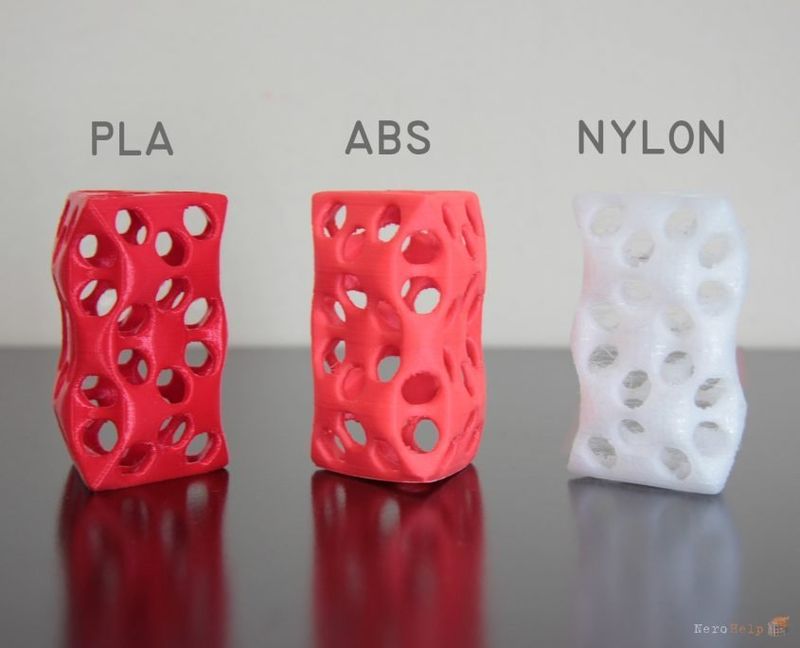

Different plastics have different shrinkage.Materials such as PLA or PET-G, which are widely used for printing decorative products, virtually don't shrink when cooled. But “engineering” materials (ABS, HIPS, Nylon), on the contrary, have significant shrinkage.

The most common problem caused by plastic shrinkage during hardening is delamination, that is, a disruption of the connection between layers. The result is the splitting of a print or separation from the print bed.

In plastics of low shrinkage, the delamination process hardly occurs — they can be printed using open-frame printers. That's why beginners who buy open 3D printers are advised to start with PLA when getting acquainted with 3D printing.

A different situation occurs when printing with engineering plastics. To avoid the delamination process, uniform cooling of the plastic is necessary during printing. To achieve this when working with an open device, it is necessary to place the printer in a closed room without air drafts, which is extremely difficult in real use conditions. If you print in an ordinary apartment, opening doors and windows leads to inevitable drafts. When printing with engineering polymers, an unpleasant odor is emitted from the heated plastic, which leads to the need for ventilating the room.

Drafts cause uneven cooling of the printed part and, as a result, uneven shrinkage of the material. The latter leads to inevitable delamination.

This problem can be avoided by using an enclosed printer. Some manufacturers (for instance, Picaso 3D) install in their enclosed models special air circulation fans to ensure a uniform temperature inside the printer’s chamber.

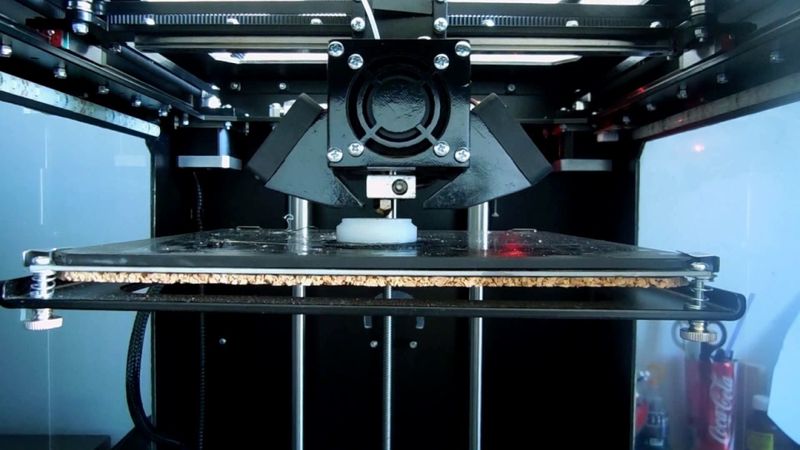

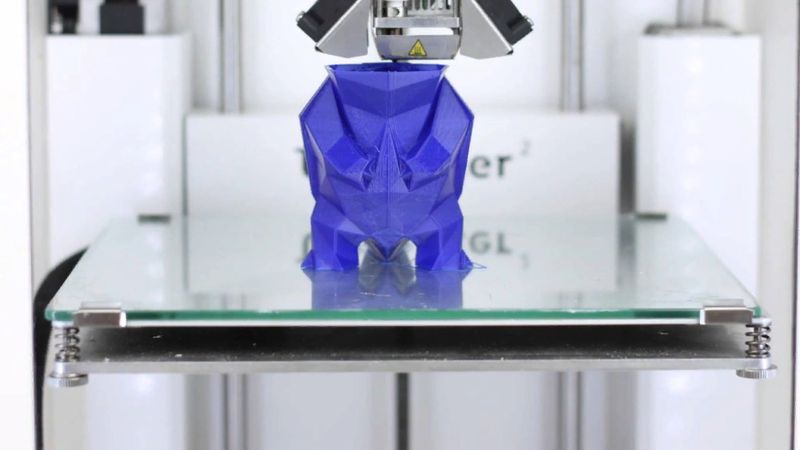

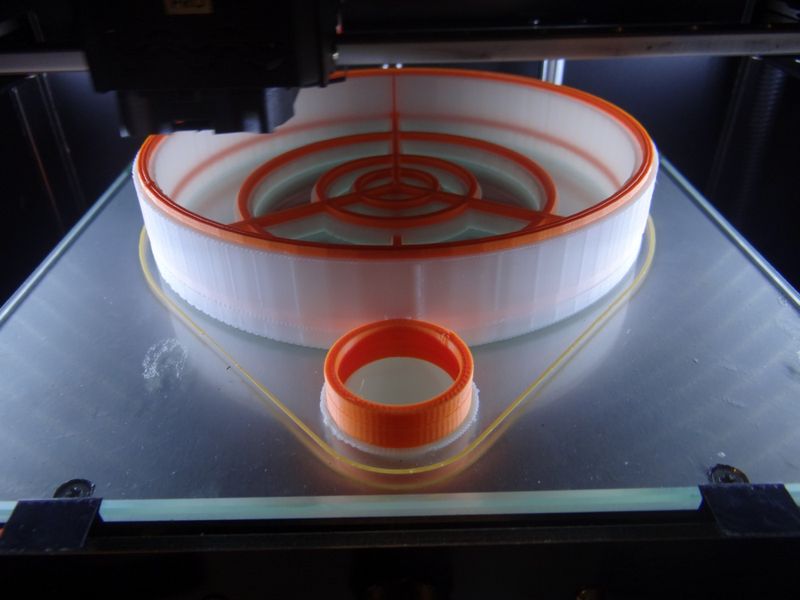

When printing with high shrinkage plastics (such as Nylon or PC), in addition to a closed chamber, a thermal camera is recommended. In this case, manufacturers install additional heaters to maintain a constant temperature inside the chamber during printing. Below is an example of printing the same part from materials of different shrinkage. Pay attention to the gap between the lower model corners and the table surface.

Many 3D printers are quite noisy during the printing process. Even if they have silent motor drivers, it doesn't prevent fan noise. If you buy a printer with a closed chamber and silent drivers, noise during printing is hardly noticeable. And given the fact that printing of some parts can take tens of hours, this is an important advantage when buying such a printer for home use.

As mentioned above, printing with engineering plastics can cause an unpleasant odor. Some manufacturers equip their printers with special filters to get rid of it. For example, the Raise3D Pro2 printer is equipped with a HEPA filter absorbing 91% of particles during printing.

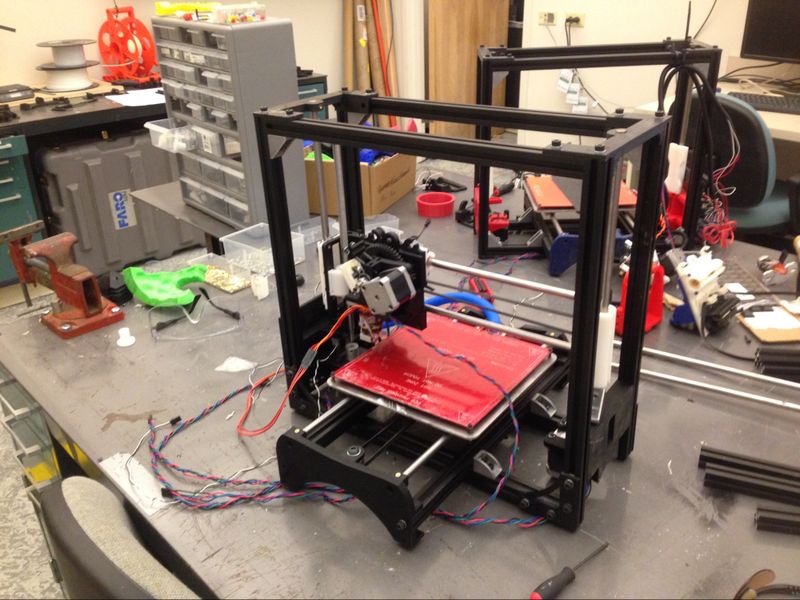

Plastic doesn't like dust in the process of printing. Neither do bearings moving along the rods. If the bed is covered with dust, the material will stick. It's hardly necessary to explain how this will affect the adhesion of the model to the build plate itself. The filament should also be kept clean as the accumulation of dust in the extruder is obviously fraught with unpleasant consequences.

Of course, there shouldn't be much dust in the apartment, but if a 3D printer is located at an industrial site, workshop or garage, there is a high probability of dust getting into the print area, damaging printed parts and increasing wear of rods and bearings. Besides, there is a high likelihood of foreign particles or tools getting into various parts of the printer.

If you are buying a printer for a workshop, it is best to acquire one with a closed chamber.

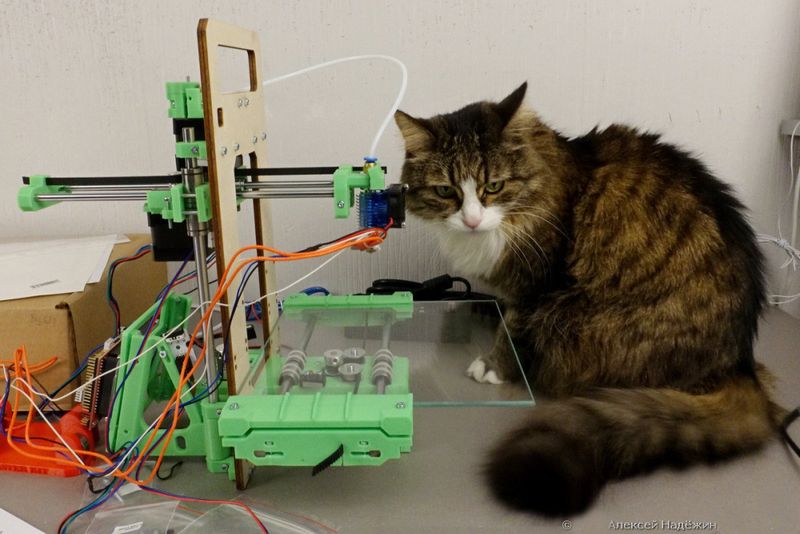

A printer contains three sources of danger for young children and pets. First, these are high voltage components; secondly, moving parts; and thirdly, heating elements.

It’s not a lot of fun if your child or pet receives an electric shock, gets injured by a moving extruder or gets a burn by a heated build plate.

So, if you have small children or pets, buying a 3D printer with a closed chamber will help preserve their health — and spare your nerves.

Below are presented three models of 3D printers, two of which, in our opinion, are ideal for both home and workshop use. And the third one is perfect for workshop and small production.

These are popular and well-proven printers, with serious support and service from manufacturers.

SPECIFICATIONS

A Russian-made printer equipped with two print heads using JetSwitch technology which allows you to switch from printing with one material to another within five seconds and without building an additional nozzle cleaning tower. Temperature control is also available both inside the chamber and on the hot end of the print head. This prevents delamination when printing with engineering plastics. The possibility of heating the nozzles and the bed to high temperatures allows printing with engineering plastics.

SPECIFICATIONS

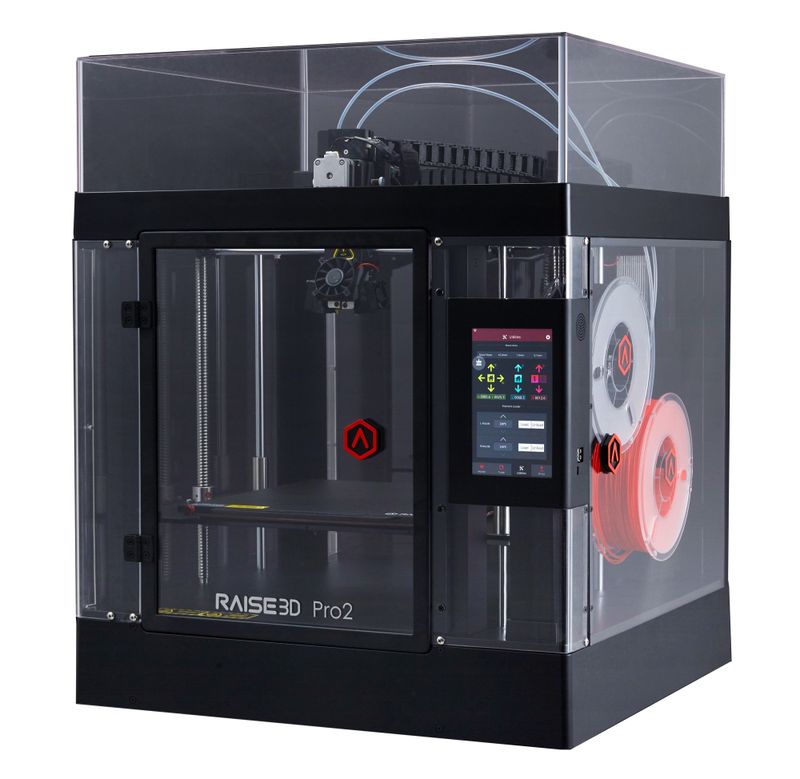

An enclosed printer equipped with a HEPA filter to protect you from plastic fumes during printing. Allows you to print with engineering plastics in your apartment without producing any unnecessary odors.

SPECIFICATIONS

Designed specifically for printing with engineering plastics, this printer has a closed chamber with good thermal insulation. The large build volume allows you to print big parts without separating and subsequently connecting them. Temperature control inside the chamber allows you to print with refractory durable plastics.

Printers with a closed chamber will allow you to avoid a lot of problems: to get rid of delamination when printing with engineering plastics, protect printed products from possible dust and rubbish in the workshop, protect people and pets from the threats that arise during 3D printing.

If you are a beginning maker, if you don't have small children and pets, and you are going to print with PLA only, then you may as well consider buying an open-frame printer. The cost of such printers is usually much lower.

In case you plan to print with engineering materials and buy a printer for your workshop, or use it in an apartment with pets or young children, it is better to decide on an enclosed model.

Thinking of acquiring a 3D printer for your home or workshop? Contact Top 3D Shop, and we will help you choose the right 3D printer model for your requirements.

Update your browser to view this website correctly. Update my browser now

Write a comment