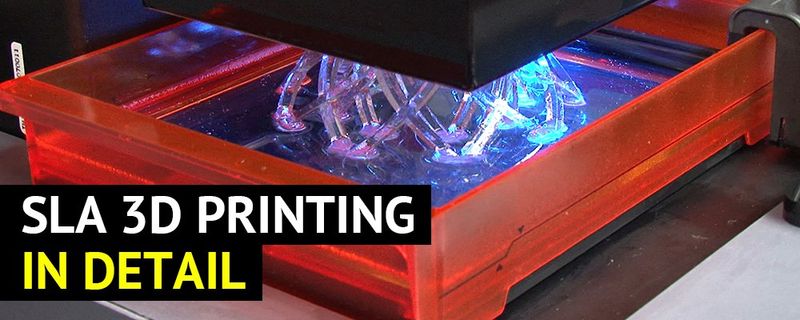

Stereolithography is the first additive manufacturing technology that was patented in 1986 and soon became commercially successful. That is not surprising as the new method made revolutionary changes in the field of rapid prototyping, allowing for more complex designs while offering outstanding part quality and significant time and cost savings. First SLA 3D printers were used only for industrial applications as they were fairly large and pricey. But the technology development has been underway and today, manufacturers offer quite a number of affordable desktop devices perfectly suitable for consumer needs.

Credit: jellypipe.com

This is Top 3D Shop, and in this article, we are going to delve into stereolithography 3D printing and discuss in detail its peculiarities, benefits, and application fields. We will compare SLA with other popular additive manufacturing technologies, so that you can decide what is best for your business. Read on to learn more.

The “stereolithography” term was introduced by an American engineer and inventor Charles (Chuck) Hull who developed the first 3D printer prototype based on this technology in 1983. Before that, in the 1970s, Dr. Hideo Kodama from Nagoya Municipal Industrial Research Institute, Japan was developing the same mechanism of light curing of photosensitive polymers into solid objects. In 1980 Dr. Kodama filed a patent but he could not provide the full specification by the one year deadline. About the same time, French engineers Alain Le Mehaute, Olivier de Witte, and Jean Claude André were working on their own SLA process, and in 1984, just three weeks before Hull, they filed a patent for their invention, but the application was abandoned.

Credit: asme.org

So, the first patent defined as “Apparatus for production of three-dimensional objects by stereolithography” was obtained by Chuck Hull in 1986. In the same year Hull co-founded the 3D Systems company that developed the first commercial SLA 3D printer, the SL-1, in 1987. The machine was a commercial success in the industrial field, but it was not until 2012 when the first relatively affordable desktop SLA 3D printer hit the market, having started the new era of consumer SLA.

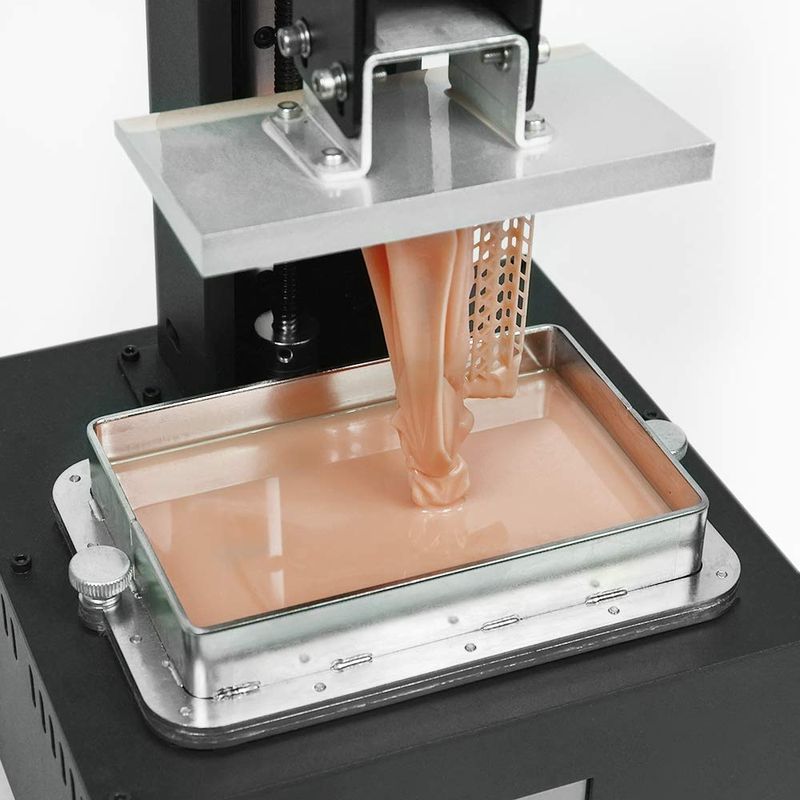

SLA, which is the acronym for stereolithography apparatus, is the type of vat photopolymerization technology that uses a tank filled with liquid photosensitive polymer which is selectively cured by a UV laser beam to build up a solid three-dimensional model in a layer-by-layer manner. The process is also often called resin 3D printing.

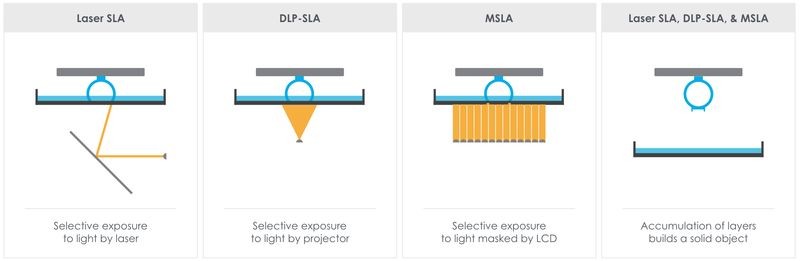

Apart from SLA, there are two more types of vat photopolymerization technology which are DLP and LCD resin 3D printing. Both technologies utilize the same process of selective curing liquid polymers with the only difference in the light source used for layer solidification.

Credit: theorthocosmos.com

DLP (digital light processing) devices employ a light projector, while in LCD (liquid crystal display) machines, also known as masked SLA (MSLA), an LCD matrix serves as a mask to transmit the light from an array of LEDs in the required areas. Both DLP and LCD technologies have the speed advantage over SLA, as they cure the entire layer at once, opposed to point-by-point curing by a laser beam. However, SLA generally boasts smoother surface finish. As all the three technologies are fundamentally similar in workflows and use the same materials, all of them are often referred to as stereolithography, or simply SLA 3D printing.

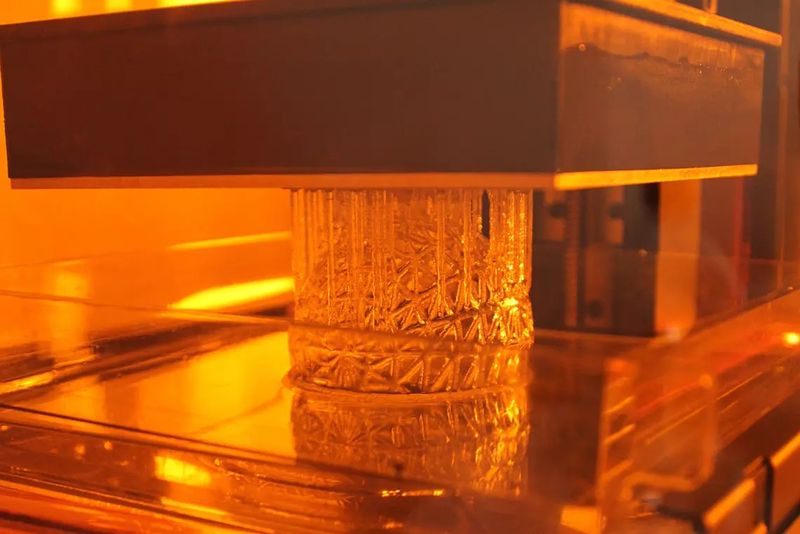

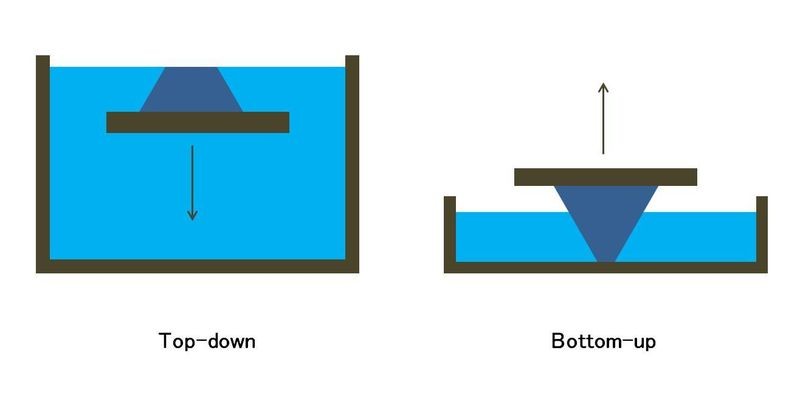

There are two main types of SLA printers, namely bottom-up and top-down constructions. In bottom-up printers, the build platform goes down to the height of a single layer from the bottom of the vat, and the first layer is cured by the light source through the vat transparent bottom. Then the platform goes up and the next layer is cured. Each time the platform rises, the cured layer has to be detached from the bottom of the vat, and this peeling step restricts the possible build size, as a part too big can deform or detach from the build plate because of the jerks. The bottom-up design is used mainly in desktop devices as it is less expensive in production and easier to operate.

Credit: instructables.com

In the top-down construction, the build platform starts from the surface of the polymer in the vat, just lowering under it for one layer height, and then gradually descends while the layers are cured by the light source placed above the vat. Such design allows for larger build volumes and the use of fewer support structures, and it is typical of industrial-grade machines.

SLA devices print with liquid photosensitive polymers, or resins, that are solidified when exposed to UV light. SLA printing resins are thermosetting polymers which means they harden irreversibly and can not be softened again. Resin printing allows for dimensionally accurate parts with fine details and smooth surface finish. The models generally feature heat resistance and high stiffness. On the downside is low elongation at break which means the parts are rather brittle. They can also change their properties under prolonged UV light exposure and can not be recycled and reused.

Credit: amazon.com

All resins can be divided into categories according to their properties. We will have a brief look at the main categories of printing resins, their strong and weak points, and best applications.

Standard resins print very stiff, though brittle parts with a high level of detail and smooth surface finish. They are perfect for non-functional prototyping and model making due to their affordable price. If you need a transparent part, you can use clear resin which has similar properties as standard resins.

Credit: @3dpop.impresion / Instagram

Engineering resins can be tough, durable, flexible, or heat-resistant. All types of engineering resins are designed specifically to meet certain requirements, like very high tensile strength of the tough resin which can be used for functional prototyping. Durable resins, conversely, have low tensile strength but are flexible and impact and wear-resistant. They are good for assemblies with low-wear moving parts. The heat-resistant and flexible resins are used for manufacturing models that are exposed to high temperatures or torsion correspondingly.

Credit: @wanhao3dp / Instagram

Dental and medical resins are widely used in the healthcare industry.To be certified as biocompatible all materials undergo biological evaluation according to ISO 10993. Class I biocompatible resins are used to produce non-invasive medical equipment, for example dental surgical guides, reusable medical instruments, or dental models. These materials imply short-term contact with the body and can be sterilized in an autoclave. Class IIa biocompatible resins can be used to produce invasive medical appliances that can be in long-term contact with the human body. These materials find a use in dentistry to make patient-specific products, like retainers or temporary crowns.

Credit: @alien_milling / Instagram

Castable resins are used to produce mold patterns for investment casting. Instead of melting, like traditional wax patterns, castable resins burn out cleanly leaving no ash or residue. Jewelry manufacturing greatly benefits from the use of this material.

Credit: @lacebyjennywu / Instagram

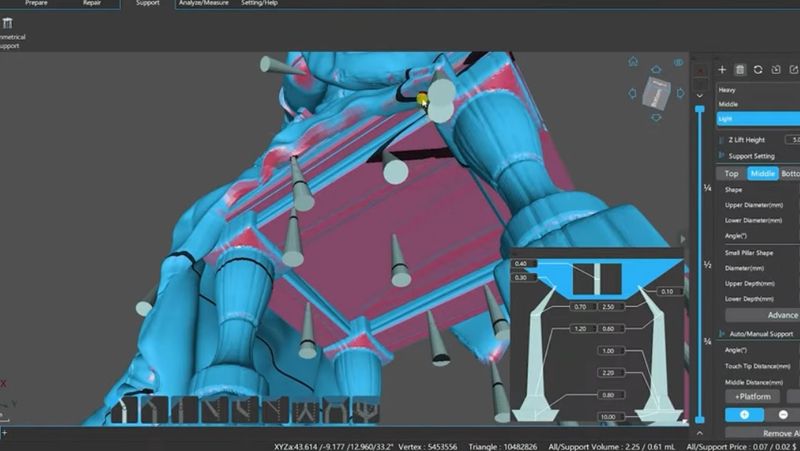

Once you have a CAD 3D model you are going to build, you need to export it to special slicing software that prepares your part for printing. Slicers for resin printers differ from those for FDM printing and there are not so many of them in the market. Still, apart from proprietary slicer software offered by printer manufacturers and designed for optimal compatibility with corresponding machines, there are a number of third-party slicers for those looking for something more.

The main difference between FDM and SLA slicers is in the slicing process. While FDM software generates G-code files, SLA slicers produce stacks of images corresponding to each layer with curing instructions.

Credit: CHITUBOX / YouTube

Slicers for resin printing generally allow you to scale, rotate, clone, mirror, infill, and hollow your models, as well as automatically generate support structures with further editing if necessary. They can also arrange parts to help you efficiently use the build space.

If you decide to choose a third-party slicer, be sure it is compatible with your computer operating system as well as your 3D printer. Another important thing is price. There are several free powerful slicers with advanced functions and easy-to-use operation, for example ChiTuBox, Lychee Slicer, or Z-Suite. But if you are looking for utmost functionality, you can always upgrade to the Pro version.

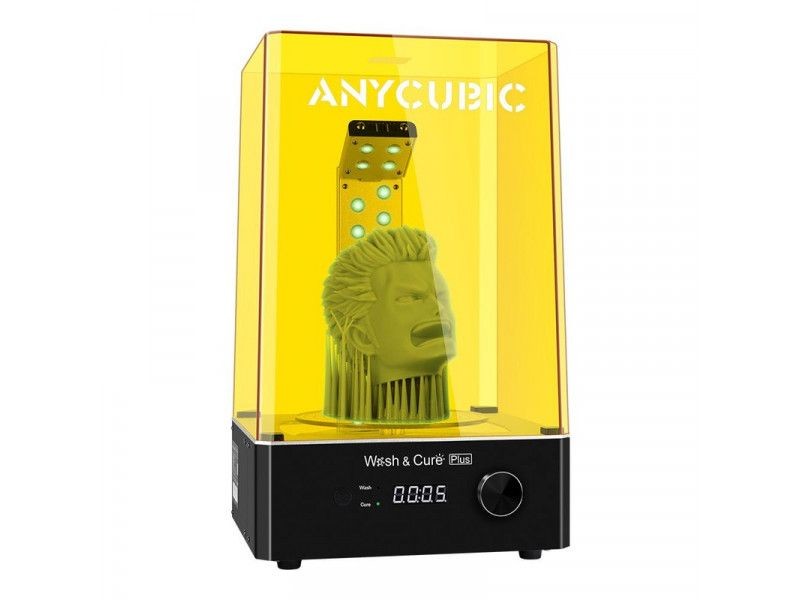

In resin 3D printing, post-processing is generally a necessary step that can not be omitted. Minimum post-processing usually includes washing the parts to clean the wet resin, and removing support structures. Apart from that, the model is often post-cured in a UV chamber to obtain optimal mechanical and physical properties. Some manufacturers offer complete solutions, like the Anycubic Wash & Cure Plus which combines washing and curing functions and allows for fast and easy post-processing of your models.

To achieve flawless look and feel of your resin parts you can employ different post-processing techniques like sanding, polishing, applying mineral oil finish or clear acrylic paint for UV protection. Hobbyists will like the possibility to paint their resin 3D models.

SLA printing is known for building incredibly detailed and accurate parts. However, there are certain printing parameters that can affect the quality of the printed models. Below are some of them.

Layer height determines the surface quality of the part. The thinner the layer, the smoother the surface finish. Some resin 3D printers are capable of printing layers as thin as 10 microns. The downside is the increase in overall printing time.

Exposure time shows how long a single layer is exposed to light. The average value is 6 seconds but some devices can make it faster. Too short exposure time can lead to undercured areas and model deformation. For the bottom layer it is recommended to increase the exposure time to ensure proper adhesion to the build plate.

Lift speed parameter refers to bottom-up oriented devices and shows how fast the build plate goes up between layers. If it moves too fast the part can be damaged because of the peeling step. So you need to find the right balance between speed and part quality.

Credit: @unclejessy4real / Instagram

Part orientation can also influence its quality to a great extent. The improper orientation may lead to an excessive amount of support structures, part shrinkage, and appearance of visible layer lines on the surface of the model.

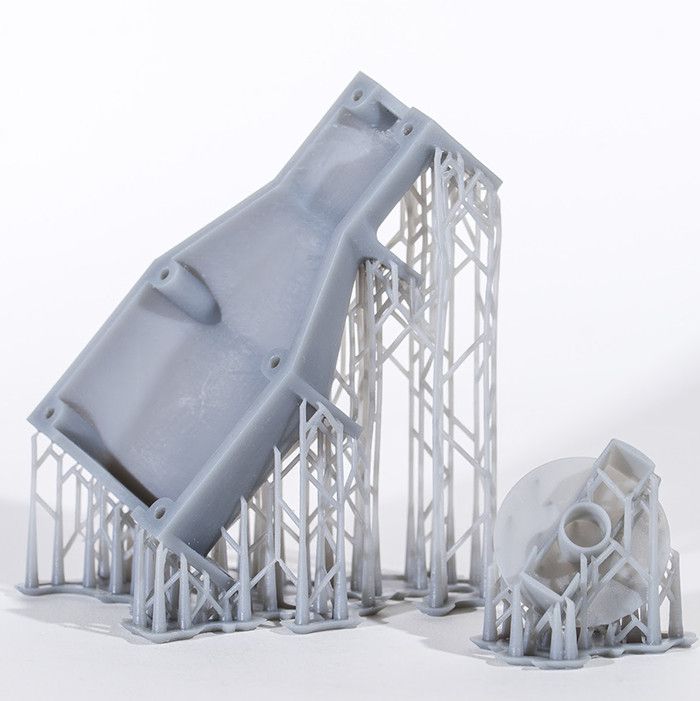

Building support structures is necessary for most SLA printed models. Supports are created with the same material as the model and are manually removed after printing.

Credit: shapefy.in

Curling in SLA printing has the same origin as warping in FDM. To prevent curling, it is better to avoid large flat printed areas and use support structures alongside proper part orientation.

Resin 3D printing with proper settings is supposed to produce a solid object with strong layer adhesion. Yet, sometimes layer separation, or delamination, can occur due to such factors, as:

Credit: reddit.com

Resin 3D printed parts are highly isotropic which means their tensile strength does not differ in XY and Z directions. During the printing process the cohesion across layers is formed by chemical bonds which results in homogeneous isotropic models with predictable mechanical properties, great for a lot of industrial applications.

Credit: facfox3d.com

SLA 3D printed parts are watertight which allows for their use in engineering applications requiring fluid or airflow control. This characteristic is especially important for automotive and medical industries as well as for part design validation of consumer products.

Resin printing is one of the most accurate 3D printing technologies. High level of accuracy is possible thanks to the use of a heated resin vat and an enclosed build chamber which provides consistent printing conditions. Besides, SLA printing, unlike other additive manufacturing technologies, does not require high temperatures, which means the part does not undergo thermal contraction and expansion. These factors ensure highly accurate repeatable prints, which is extremely important for dental, medical, jewelry, and other applications requiring precise accurate models.

HIgh resolution with the minimum layer height of 10 microns, provided by some resin 3D printers, allows printing models with extremely smooth surface finish and a high level of detail. Such parts do not require complicated post-processing which greatly adds to time saving and cost-efficiency of the manufacturing cycle.

Credit: protocam.com

The constantly growing popularity of SLA leads to the development of new resins with various properties to meet the requirements of many industries and consumers. We have already described the most popular SLA printing materials and their applications, and the list continues to expand all the time.

Due to its high precision and accuracy, resin 3D printing is widely used for fabrication of medical appliances and patient-specific devices, reducing production time and costs and eliminating the risk of human errors. Biocompatible certified resins are a perfect material for making various dental products, such as bridges, retainers, surgical guides, as well as custom hearing aids in audiology.

In jewelry, resin printing is used as a bridge to investment casting, allowing for the creation of intricate customizable designs of any complexity. Mold patterns printed with castable wax-like resins burn out cleanly leaving no ash and making the process of mold creation much easier than ever before.

Resin printed models can also be used for design and size verification with the client which allows for any level of customization at no additional cost.

Credit: @noktamodel / Instagram

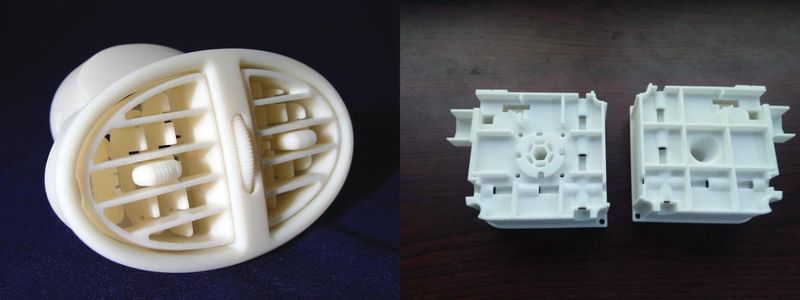

The use of engineering-grade materials expands the capabilities of resin 3D printing, allowing engineers to create functional prototypes in considerably short times compared to traditional methods. Used for rapid prototyping, proofs of concept developing, and testing, resin 3D printing makes for a highly efficient product development cycle with great customization opportunities.

In manufacturing, resin 3D printing is widely used to produce custom tools and molds, as well as small-to-medium runs of end-use products with different mechanical and physical properties, reducing lead times and production costs.

With the appearance of affordable consumer resin 3D printers, model making has become more popular due to such benefits of the technology as high resolution and the marvelous look and feel of printed parts.

Credit: @cf_prints / Instagram

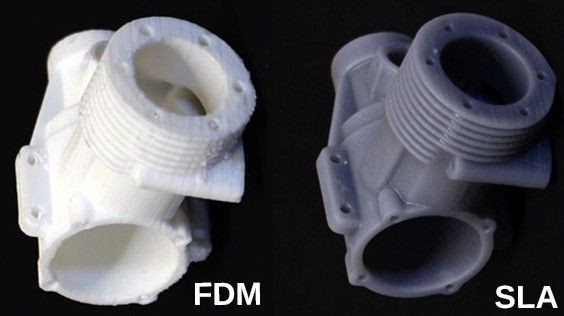

Both resin and FDM (Fused Deposition Modeling) 3D printers have their strong and weak points, and the choice of the technology depends mainly on your printing goals. FDM machines and printing filaments are generally less expensive compared to SLA, while the latter deliver higher precision and level of detail as well as much smoother surface finish of the printed parts. FDM models are usually stronger, as resins used in SLA printing normally have low elongation at break. But with the development of new material types this difference is becoming less explicit. Both technologies require building support structures but resin parts generally need more post-processing steps apart from removing supports, whereas for FDM models it is not obligatory.

Credit: vexmatech.medium.com

As for the print speed, SLA 3D printers can be slower than FDM devices as it takes considerable time for a laser beam to cure a layer. But when it comes to DLP and LCD technologies that cure an entire layer all at once, they may surpass FDM printers in terms of speed.

SLS (selective laser sintering) technology features some obvious advantages over other popular 3D printing processes including SLA, which are the ability to produce fully functional durable parts with engineering-grade thermoplastics, and support-free printing. SLS machines can build models with incredibly complex geometries and moving parts. Another advantage of SLS is the recyclability of unsintered printing material that can be collected and reused for future prints. Comparing SLS technology to resin printing, we can see that SLS models, though fairly detailed, still lose in resolution and have rougher surface finish.

SLA (left) vs. SLS (right) / Credit: 3dspectratech.com

While there are quite a number of affordable consumer resin 3D printers in the market, SLS remains solely professional technology offering sizable, expensive machines for industrial use.

With the appearance of first compact devices in the price range of under $5,000 in 2012, resin 3D printing has become more versatile and affordable for both consumer and professional needs. Today the user can choose between large and expensive industrial machines and compact desktop printers. Let’s find out what other components, apart from the price and size, which are pretty obvious, make these two types different.

Build volume is significantly larger for industrial SLA printers, reaching 1 meter and more in length in some cases. Desktop devices are usually equipped with compact build volumes, which are enough, though, for most consumer and a lot of industrial applications.

Credit: fiverr.com

Structure of the two printer types is usually different. Industrial printers mostly use the top-down approach which allows for larger build volumes but requires the vat to be completely filled with resin, which makes changing the material more difficult.

Accuracy of industrial printers is generally higher than that of compact devices which results in more consistent predictable results.

Material range is wider for industrial machines, including engineering-grade resins with various mechanical and physical properties. However, most resins have the same curing wavelength of 405 nm, so you can try using professional materials with a consumer printer. (Although engineering resins are usually more expensive and require more serious post-processing, so their use in consumer printing is not justified).

The evident advantages of compact resin 3D printers are their compact size, mobility, and affordable price alongside fairly high print quality.

Update your browser to view this website correctly. Update my browser now

Write a comment