Hi everyone! This article is intended to help those wondering, which 3D printer to choose for business. We will consider some examples of real companies, their personal experience and selection criteria — what they were guided by when choosing 3D printer for their business and how they assess its role in production.

3D printing is a versatile tool used in a variety of industries. In this article, we will talk about the examples of various possibilities of building a business with a 3D printer.

The examples will vary, beginning from doing business with the help of 3D machine at home and ending with large enterprises implementing 3D technologies to optimize their processes. We will also touch on companies, which build their entire business on the use of 3D printing.

All the examples given in the article are based on using 3D printing in business by companies and individuals, some of whom are our clients.

The application of a 3D device can emerge as the basis of a new idea for a small business; it can also increase the productivity of medium and large enterprises.

The majority of users start with printers based on FDM technology, as this is the most affordable and sophisticated 3D printing method. Still, in some fields of application, stereolithography is more preferable. We are going to analyze which printer is better suited for various purposes.

In all cases, we have tried to add the cost of equipment, materials and finished products to make it easier for you to draw up a business plan for the usage of a 3D printer. But keep in mind that, in addition to buying equipment and consumables, for doing business based on 3D printing you need to possess some skills in modeling, printing and post-processing of finished products.

If you are already an entrepreneur or art director of a successful company, you may consider expanding your business by offering customers collections of products in limited editions, with unique design elements and techniques. For instance, it can be shoes, accessories, bags, fashion items, parts for various devices or souvenirs printed on a 3D device.

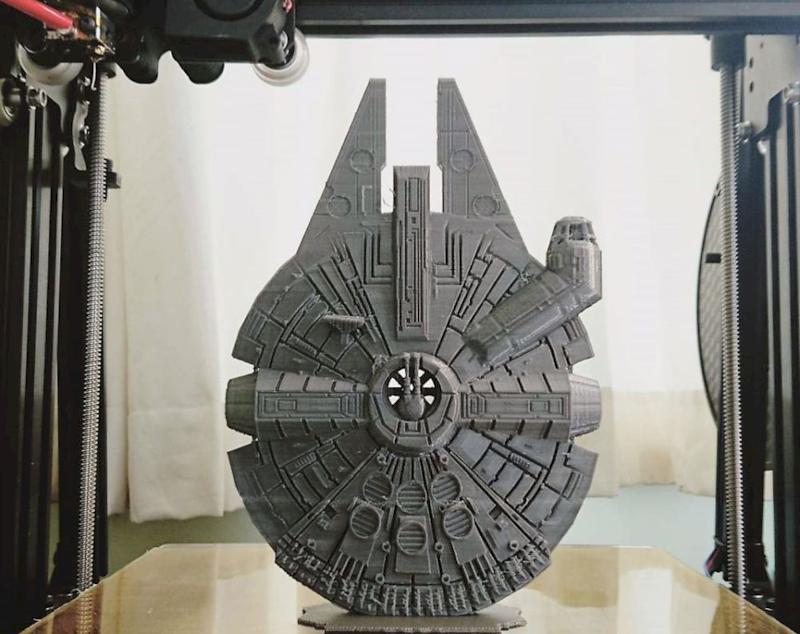

Case: Making costumes and props for cosplay

One of the St. Petersburg cosplayers, Ilya Nikonov, uses 3D printers to organize business at home.

Ilya and Nastya print elements of costumes and sceneries for themselves and to order.

According to Ilya, cosplay is a hobby that additionally brings money during the festival season. The audience of cosplayers is growing, especially in the last couple of years.

How much you can earn

Revenues from 3D printing to order will depend on a number of factors such as a customer base, the skills of a user and willingness to improve them, other abilities. Take, for example, a large order, such as a multi-element costume for cosplay which includes not only printed elements but their processing, painting and the connection with the fabric base. Its production can take several months, but it can also earn you thousands of dollars.

Taking into account the price of materials and the cost of post-processing but without considering the time spent, let’s say that the prime cost of the costume is about $250.

Ordering such a product in a 3D printing studio will cost more than $2000. If you offer such an order for price 3–4 times lower than that of studio, though with longer terms (for instance, Ilya with Nastya created the costume in the picture above in about one and a half months; specialized workshops with plenty of equipment would make it in a week or two), the possibility to find a client will be much higher.

What 3D printers are suitable for this task?

For printing costume elements, FDM machines with a large print area are best suited. You can use a smaller device to print details by parts and glue them, but this will greatly delay the production time and increase the workload.

Larger details such as breastplates and helmets are better to be printed as a whole.

The presence of two printheads will also be useful for printing with two materials, one of which is designed for soluble supports. It will greatly reduce the volume of manual labor and speed up the process.

In this case, it is preferable to buy Picaso Designer X Pro. This device works well with two materials.

If you work in a successful company, you can refresh your approach to prototyping by means of a good desktop printer, forgetting about expensive manual modeling. Thus, in the automobile market segment, they no longer resort to the production of clay models, replacing them with those printed through the given devices, which results in significantly reduced costs.

What printers are suitable for this

When printing prototypes of serial products, quality plays a crucial role, so you should choose from professional 3D printers.

Case: Full Power

Full Power is a company producing accessories for backpacks and travel clothing.

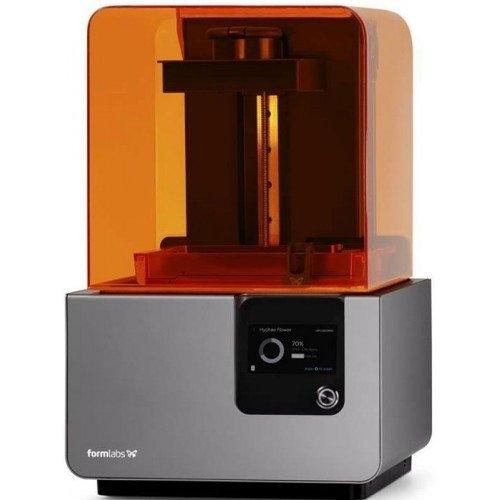

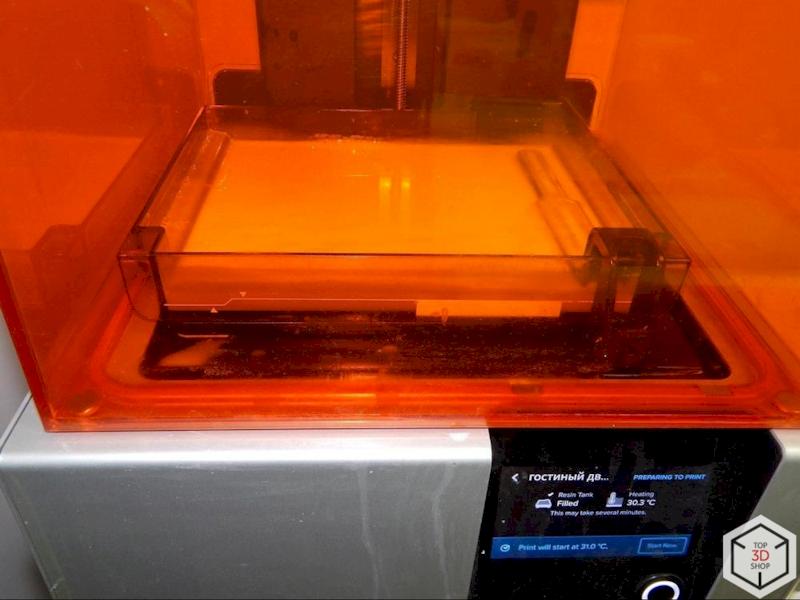

They use 3D printing as part of their business idea to make a prototype of the finished product according to the model developed. The company prints prototypes via the Formlabs Form 2 device which was chosen for its reliability.

3D printing allows of checking the compliance of models with the intended characteristics, dimensions and appearance as well as assessing the functioning of products.

Finished models are manufactured with the help of an injection molding machine.

The printer used is Formlabs Form 2.

Formlabs Form 2

Another suitable option is Flashforge Hunter.

Read more about the Full Power case in our article.

How much you can earn

The prime cost of materials for SLA printing is $0.32 to $0.36 per gram. The cost of 3D-printed parts made by this technology when ordered from an outside printing studio will be much higher per gram of the finished product, excluding post-processing. Thus, printing with your own device one element of accessories can save you quite a few bucks. At the prototyping stage, such elements are manufactured constantly and in large quantities, which allows you to quickly recoup the purchase of equipment and make a profit.

Case: REC

The founder of REC Dmitry Miller shared the secrets of his business.

What the business is built on

The main clients are manufacturing companies. To work with private customers is harder, though they may offer interesting and profitable orders as well. The printing is mainly implemented through FDM technology. Architectural models are printed with PLA; elements of cosplay use ABS.

What equipment is suitable for this

You can start this business without a printer and start-up capital. There are quite a lot of 3D printing studios, and if a novice businessman finds a useful field of the application, it will be enough for him to take orders and place them in these studios, receiving a certain сommission for his services.

If a businessman wants to immediately immerse himself in 3D printing, Dmitry recommends taking a single-extruder device, as it is easier to learn the basics of printing on this machine than on a two-extruder one.

Besides, Dmitry does not recommend starting a business with 3D printers of marginal (and most well-known) Chinese manufacturers, as during operation there occur many problems, and it is very difficult to ensure the proper quality and timing of orders. When choosing a printer, consult with experts or conduct some research beforehand in the online community of 3D print workers: study the reviews, pros and cons of different models.

Anatomical model of human heart

How much you can earn

Although 3D printing is not the main business of the company, the monthly income from this direction is $2-3000. The bulk of the money goes to the salary of a contractor. The rest is spent on materials, maintenance of the equipment, experiments and partial payment for the premises rent.

Chokolama.ru

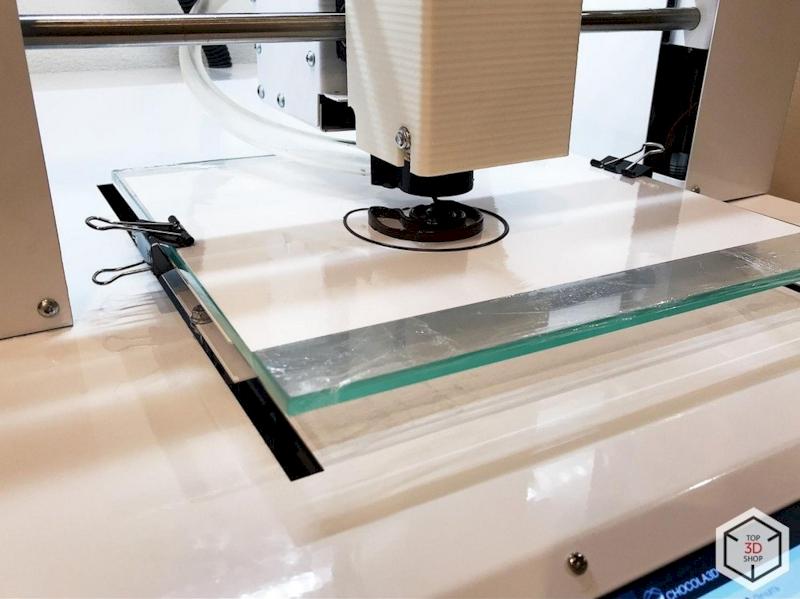

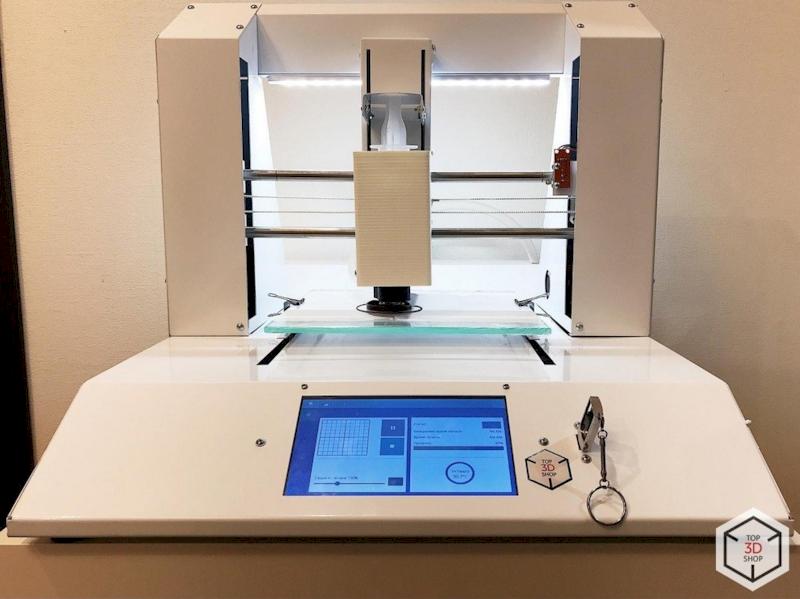

Chokolama.ru is a confectionery company that builds their business with Chocola3D printer. The device is used for printing chocolate logos, toppings and decorations.

The printer was chosen for its characteristics and price/quality ratio.

At the first stages there were difficulties, but eventually the business idea of 3D printing with chocolate proved a success. Now the process of creating a chocolate figurine brings pleasure.

What 3D printers are suitable for this

The range of 3D food printers is not too wide, but their number is gradually growing. The most elaborate of them are devices for printing with chocolate.

Chocola3D printer

Read more about chocolate printing in Chokolama.ru in our article.

How much you can earn

The cost of good chocolate for casting is less than $17 per a kilogram; the cost of products made of it can be tens and hundreds times more expensive, depending on each specific order — on the imagination and appetite of the customer.

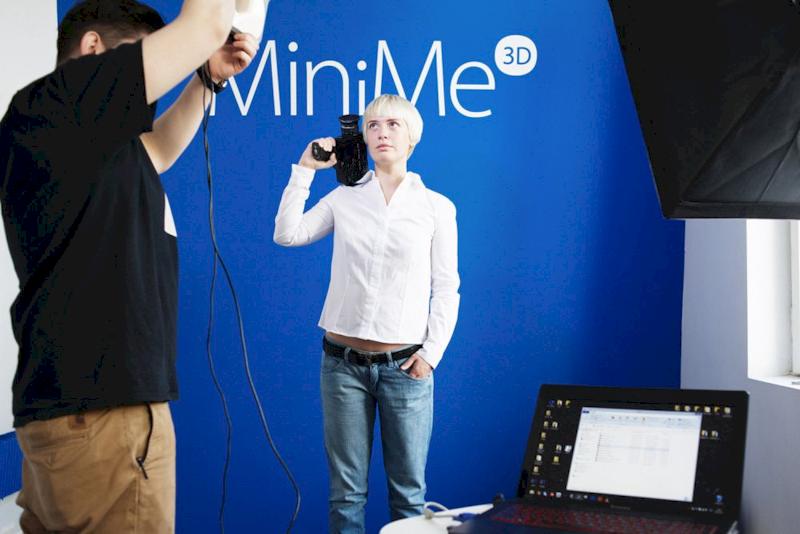

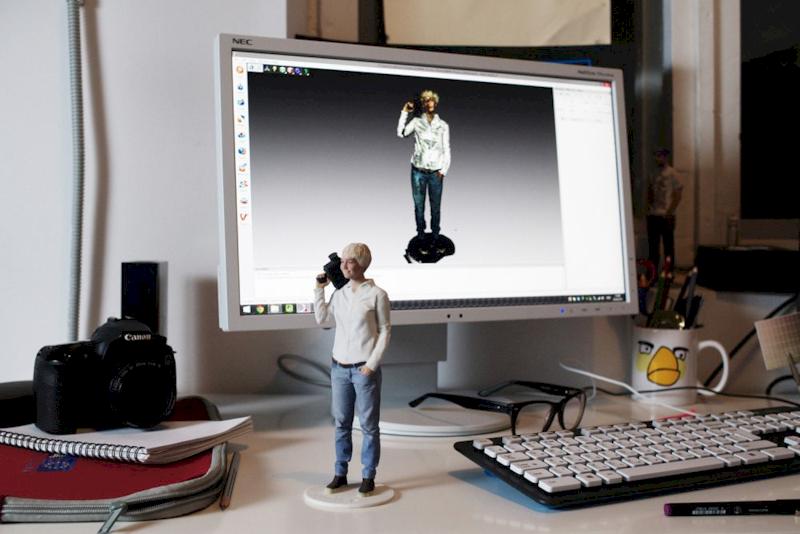

Creating 3D models of people is a relatively new business. Ruslan Akhmedov and Vitaly Malykhin, the founders of MiniMe, share the secrets of their business.

What is the business built on?

The business is based on scanning people and printing their reduced-size gypsum copies. A person is placed on a circular rotating stand and scanned with a hand-held 3D scanner. The scanning process takes about ten minutes. The main requirement is to keep the client fixed.

During the scanning, a 3D model of the client is automatically created on the computer. The resulting model is transferred to a designer working remotely. He corrects the shortcomings and paints hair. The model processed by the designer is converted into a file for printing.

What equipment can be used?

A hand-held scanner produced by Artec can be used for scanning. In addition, you can use a rotating stand, professional studio lighting and specialized software for processing resulting scans.

For printing, the company rents a 3D device powered by CJP technology. It is located in another place to save rental costs. This printer is normally used by architects when designing buildings.

3D Systems ProJet 860Pro

Instead of a manual scanner, you can use specialized systems to scan people, which will significantly increase the speed of work and the number of completed orders. These include products such as Tardis, TELMAT SYMCAD III, VITUS.

How much you can earn

The studio offers three formats of printing figurines: 20, 35 and 50 centimeters tall. The price of such figurines varies depending on the studio making them. However, it is safe to say that a 20cm tall figurine would cost about $200-250. In spite of the high cost of finished products, the company does not lack orders — clients come every day. Most often, these are families who want to capture their children and elderly parents.

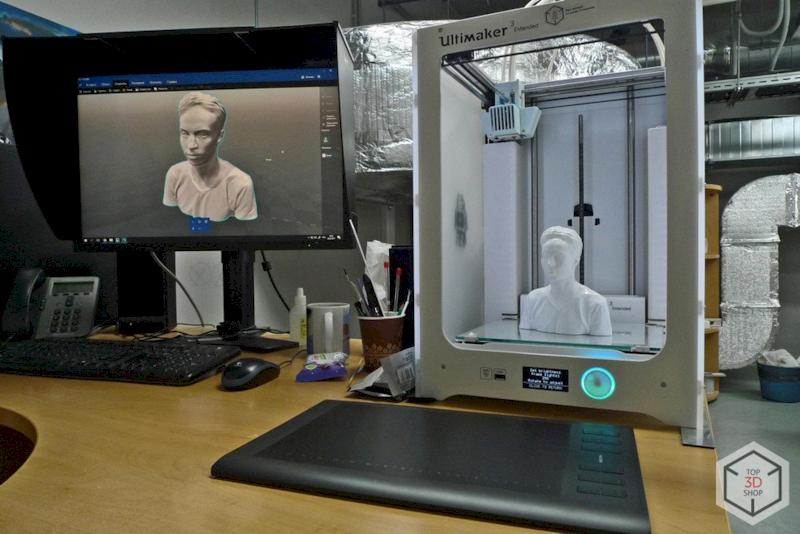

Case: Erarta Museum

A 3D printer provides the Erarta Museum with additional business opportunities. The machine is used for printing of souvenirs copying the items exhibited in the museum. Visitors can buy a figurine of the sculpture they like.

The device chosen was Ultimaker 3 Extended. The printer is designed by a well-known European manufacturer that has proven itself. It was necessary to print with two materials due to the complex geometry of the models, which required soluble supports.

After models being scanned, printed is the master-model, then a series of souvenirs made of polymer materials is cast.

Ultimaker 3 Extended 3D printer

Read more in our article.

How much you can earn

The prime cost of printing via FDM technology is about $0.07 per gram of material. Then check out the souvenir prices in your local museum. The difference between the costs and the return is easy to imagine.

Case: Studio 911

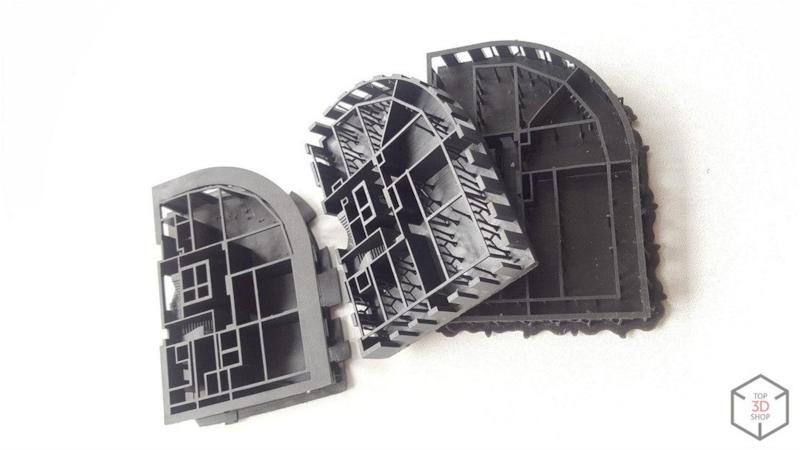

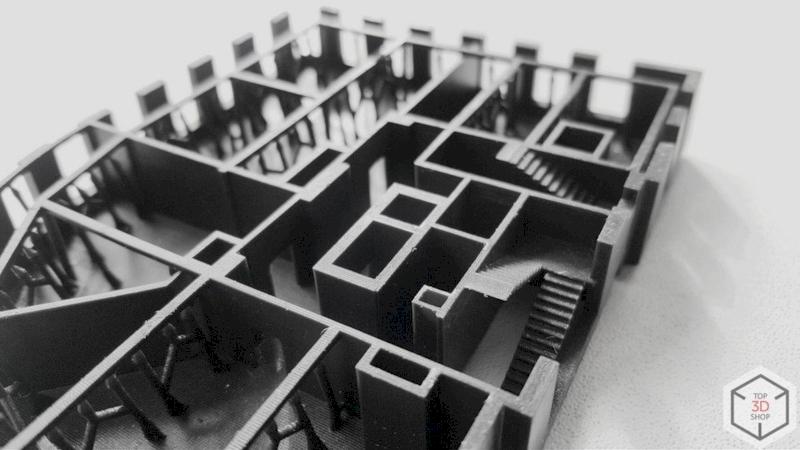

The layout workshop Studio 911 implements its business ideas with the use of 3D printers working on different technologies — FDM and SLA. The workshop produces architectural, urban planning, interior and other models in scales from 1:10 to 1:2000.

Five Picaso 3D Designer X printers are used to print large layouts with the help of FDM technology. The choice of this model is due to its characteristics and the place of production — the proximity of the manufacturer allows of directly communicating on the maintenance, warranty and repair issues.

To print small and detailed layouts, the Formlabs Form 2 SLA printer is used.

Form 2 was chosen for its user-friendly software, good assembly quality, and nice design.

For more details, see our article.

How much can be earned on it

The prime cost of printing via FDM technology is about $0.07 per gram of material and from $0.32 to $0.36 per gram for SLA printing.

The cost of 3D-printed parts in architectural layouts when ordered from an outside printing studio will be about $0.57 (FDM) and from $3.25 (SLA) per gram of the finished product respectively, excluding the assembly and additional work. Comparing these figures, you can see how the part cost can be reduced.

It should be added that the use of a model workshop with the own 3D printers allows you to reduce the share of manual labor and orders from subcontractors (as well as production time) and increase the number of orders per unit of time.

Case: Setl City

Setl City is one of the leading manufacturers in Russia. The 3D printer has increased the company's business capabilities by building models to be printed with regard to the distribution of internal space. Models are used by architects in the design of houses and for presentation purposes.

The company chose a printer that works on stereolithography technology — Formlabs Form 2. The technology on which this printer works provides better quality than FDM. This model was chosen for reliability, reputation, and characteristics.

Read more here. The profit from using SLA printing technology instead of ordering such a print from a third-party organization is obvious from one of the previous cases.

What is the business built on?

Business can be built on the production of aligners — transparent trays for everyday wear which correct malocclusion and serve as a modern replacement for braces.

The essence of the technology is simple: the dentist takes a cast from the patient's jaws, then this cast or its three-dimensional scan is sent to the center of aligners production where they are made and subsequently sent directly to the patient or their treating orthodontist. A patient has to undergo the whole course (which is usually delivered in full), constantly wearing and gradually replacing the trays. The shape of aligners is precisely calculated to shift the teeth to the correct position.

Until recently, aligners were only manufactured abroad, but at the moment dental clinics began to buy the equipment and software to make aligners by themselves.

What equipment should be chosen?

The Formlabs Form 2 stereolithographic device can be used for 3D printing of dental casts.

The forming of aligners on the printed casts is made on a thermoforming device, for example, Scheu Dental Biostar.

Having some start-up capital for renting out premises and buying the equipment, you can open your own ATC, where you will provide 3D printing services to order and 3D scanning, offer equipment for purchase, conduct educational programs for buyers who do not have experience in 3D printing.

In many areas of Russia, this market is completely free, and you can become one of the first to occupy an additive niche in your region.

Case: Top 3D Shop

As an example, read about how we created Top 3D Shop.

We started as a small shop of 3D printers, bringing the devices for our money and selling them through ads. Now we supply equipment in industrial quantities, provide services in a huge volume throughout the country, conduct courses and workshops as well as organize a large-scale exhibition and conference Top 3D Expo 1–2 times a year.

How much you can earn

After 7 years of successfully doing business, we have reached a turnover of $13,000,000.

To sum up, we would like to say that you can find an excellent use for 3D printing in business, offering prototyping services, producing exclusive art objects, printing 3D souvenirs. You can specialize in 3D rendering, graphic design, modeling and assembly, and even combine 3D printing with other technologies, for example, casting silicone.

You can get the necessary knowledge, choose and buy a 3D printer for business in Top 3D Shop — our experts will help you with the choice of an optimal set of equipment, materials and software.

Update your browser to view this website correctly. Update my browser now

Write a comment