Hi everyone!

My name is Vasiliy Kiselev and I am the founder and CEO of Top 3D Shop. Today I would like to tell you how I built and expanded my business without any entrepreneurial knowledge and experience.

We entered the market about six years ago and for the last four years we’ve been holding a dominant position in personal and professional 3D segment (3D printers and 3D scanners).

People often ask me about the recipe for success of our initially small company, and I decided to write a small post about it.

I’ve always had a disposition to engineering disciplines, that is why after graduating from technical college, I landed a job in one of the energy companies through an internship program. I combined work with pursuing a degree in gas and steam turbine engineering at the Polytechnic University and knew nothing of entrepreneurship.

My job was to provide support in construction of energy facilities. It was routine, mundane and mostly consisted of paperwork. The only benefits were experience, stability and private health insurance plan you rarely use at 25.

Career advancement in such a company is very rare and unrequired. You can hold your position in years without getting a single chance for promotion or raise in pay.

Working for a customer company gives some knowledge in project management but the workflow itself doesn’t juice you up at all: you can see mud and dirt outside the window and inefficient paperwork turns you into a zombie.

I felt the need for a new occupation, source of knowledge and additional income. I was desperate for change and the only thing left to do was to make up my mind about the field I wanted to evolve in.

At the beginning, I started working in event management. My colleague and I helped organize weddings in our free time.

This allowed me to gain a lot of experience in working with contractors. I also learned a lot about organizing a small business and dealing with money within that business.

All of this was happening while I was still on my main job. The side hustle paid off but the desire to radically change something wouldn’t go away.

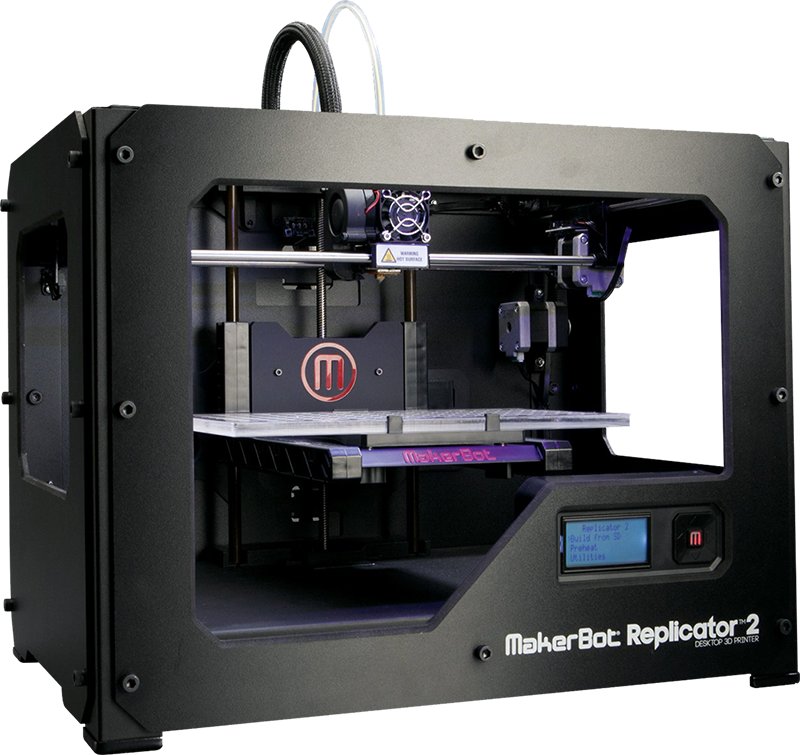

The changes I longed for were set in motion completely by accident. One day I was looking through the news feeds and came across a piece of news about the release of the legendary Makerbot Replicator 2 3D printer. It was 2012, the topic was fairly new and not very popular but it still caught my interest.

After watching a couple of videos and reading several feature articles on foreign websites, I took an extraordinary interest in 3D printing.

It was genuinely impressive: imagine sudden realization that this is the future that will walk past you and become the present unless you take notice.

I immediately felt the desire to own this miraculous machine and find out about the status of 3D printing in Russia.

After Googling for some stores, going through Avito and Yandex Market, I realized that there wasn't a single company in St. Petersburg that was engaged in selling this type of equipment. Not a single trustworthy company in such a huge city. A whole new, empty market that was engaging and interesting on top of everything else.

All I had to do in order to start was study the demand and find the means to get things rolling.

For my first try, I ordered MakerBot Replicator 2 on Ebay. This was the same printer I heard about in the news.

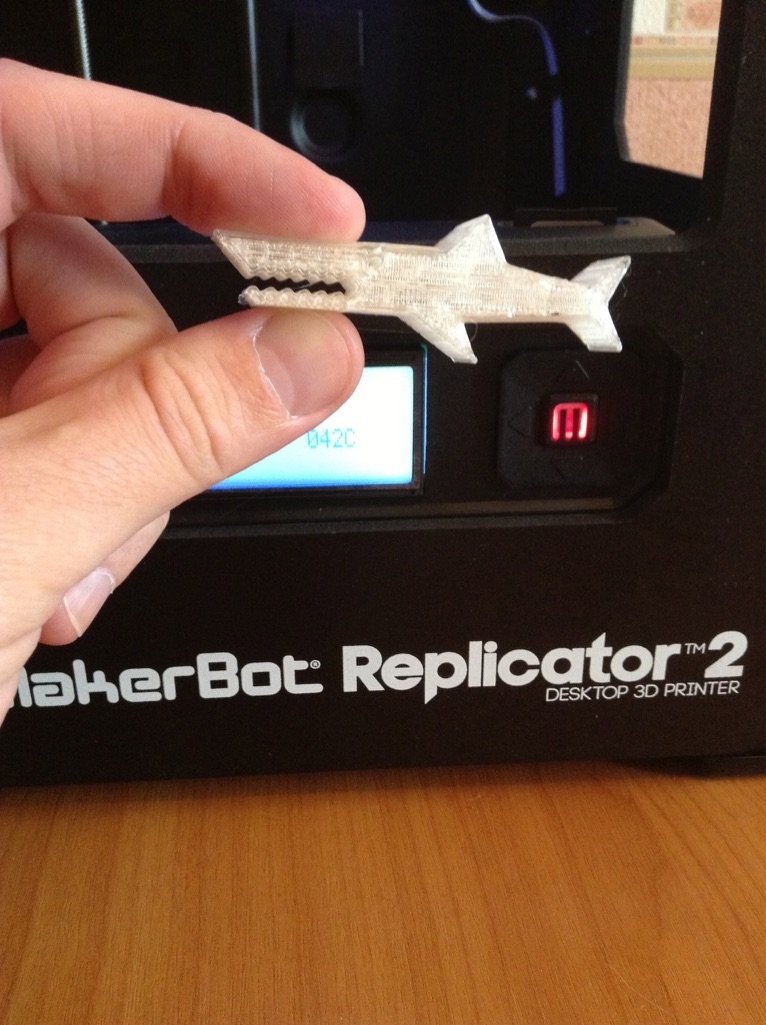

The first “take” - first object created on the first 3D printer I bought

After creating accounts and posting offers on several bulletin boards, I devoted my time to video lessons on constructing and coding websites. I used tutorials offered by Linda.com. My offers almost instantly got responses, which only confirmed that I had made the right choice. Without thinking twice, I registered the domain.

The first 3D printers I ordered with my own money were sold in a matter of days - they literally went off like hot cakes.

As you can imagine, there was no office at the beginning, the first clients had to come directly to my place for demonstration and purchase. That was horrible.

Of course, I wasn't 100% confident in success, since there was no similar companies in my hometown, the media provided no useful information, the market was just emerging and I didn’t have any entrepreneurial experience.

But it was obvious that the demand was growing, and therefore, in order to make things more civilized, it was decided to register a legal entity.

By that time, I completed my first website, which seems pretty laughable now when I remember it. I also prepared a Google Ads account and involved a colleague from work into the business - the same colleague with whom we used to organize events. He liked the idea and invested his savings (around $30,000 USD) into the project.

We acquired more printers, rented a coworking space and hired a couple of new staff members - a sales manager and a maintenance engineer.

At first I had to combine everything: my old job, my studies, organizing the business, hiring staff, searching for suppliers, logistics and a bunch of other little things. Everything had to be done simultaneously. It was difficult at first, but at the same time I managed to get a kick out of it.

The first sales motivated to work even more and I felt no fatigue. I had to acquire competencies I had never thought about before and look into things that were completely new to me.

Luck and hard work are two important factors for a successful start. Both are equally meaningful. Without hard work, patience and a fair share of perfectionism, even the greatest luck won’t help you develop a business.

Knowledge of business dealing was sorely lacking. Creating a sales department, financial planning, organizing purchases and warehouse management - all these fundamental issues had to be resolved on the go.

And you keep asking yourself: “Am I doing this right?”

Because there’s no one else to ask.

I was always tormented by the desire to compare my company’s business processes to others, just as small, but successful.

I learned how to deal with this thanks to a business school called “UP”. Even now, this business club continues to help aspiring entrepreneurs like I was back then.

The meetings held by the school were attended by owners of large companies and top managers of corporations, who shared their best practices and provided a lot of useful information on organizing the business at an early stage.

In particular, this is where I got the knowledge of how to organize our sales department, for example, creating an incentive program, working with various legal entities, marketing and much more. This was a really rewarding experience.

We analyzed many cases, including mine. By the way, no one believed that we would succeed as an equipment vendor. Everyone kept saying that we would get devoured by “box movers” - retail chains, and that the only area we should concentrate on was service (3D printing, 3D scanning and modeling). But I was sure we were in the clear, since the equipment itself s complex and requires expertise, and a single transaction can take up to several months.

Despite criticism from the club’s skeptics, my business model continued to work.

After some time, when it was obvious that we were making great progress, a distinguished and experienced investor who was also a senior executive in a large retail company proposed to become our mentor and co-founder, receiving 25% of the shares without investing any funds. At this point, I almost made a fatal mistake.

Knowing about his success and experience, I was just about to accept, but my partner opened my eyes and I saw the absurdity of the situation.

The lack of foresight and strategic thinking gave rise to self-doubt. It seemed that an experienced mentor would definitely bring success and contribute to our development.

Now, over the years, it seems ridiculous. But in reality, giving a stranger a quarter of the shares for nothing is an unforgivable mistake.

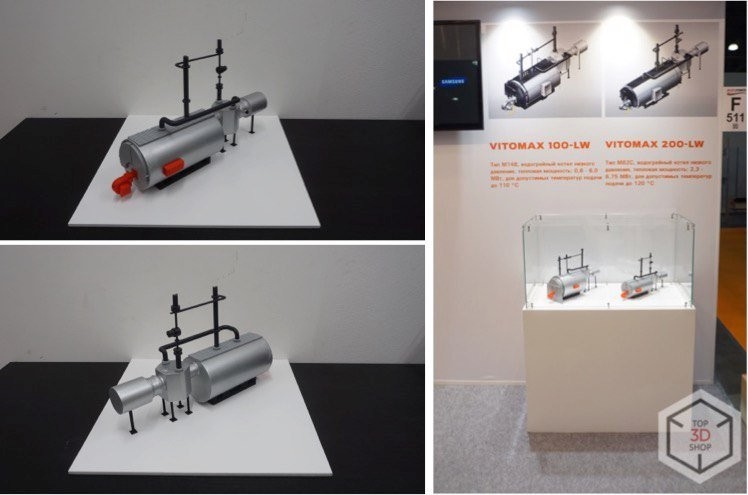

In the same year, we left the coworking space for an office and almost immediately began conducting heavy activities on all fronts and taking part in various expositions. One of the first expositions we attended was 3D Print Expo, the largest exhibition for additive manufacturing at the time.

When I realized it was time to expand our sales geography further, there was a need for a new brand name, corresponding to our growing competencies, memorable and conspicuous.

At that time, I already knew the prospects for the development of the product grid and knew what customers associated with the 3D hypermarket. That’s why I was out to find domains that had 3D+shop or store in their name.

All the short names were already taken or worth a bunch of money to buy. However, I was lucky and came across a free name top3dshop. And even though the words “top” and “shop” may seem too regular and so overused that naming professionals classify them as not recommended, this name worked out and didn’t interfere with business. It even corresponded with the purpose of our venture.

We started to actively promote our new website and even now, it proves to be effective every day.

After working at such an intense pace and realizing that the business keeps growing faster and faster, we decided to go all-in: I quit my job and made an absolute commitment to running the company and my partner invested another $70,000 USD to organize business processes in the office and purchase more equipment.

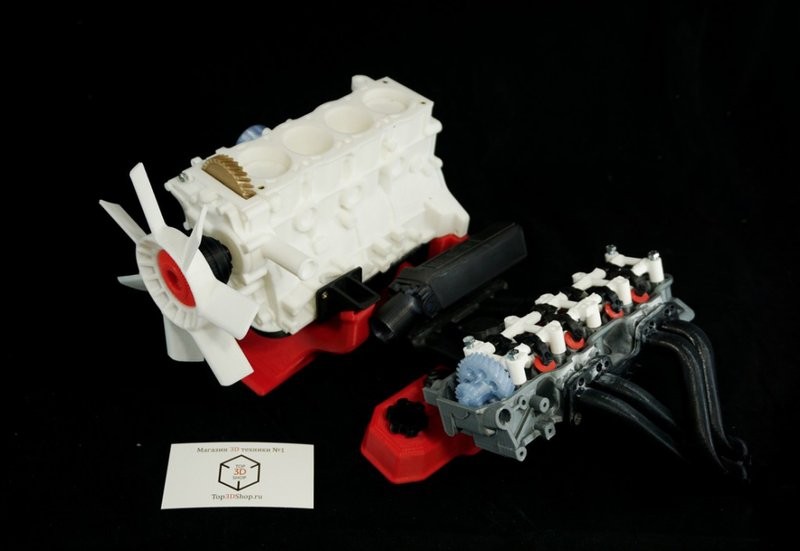

The first shipment of our product

For the next 6 months after I quit my job the revenue reached $150,000 / month and I focused on growing sales even further.

Quitting the job wasn’t easy. Salary, stability, benefits package - all these things made it really hard to leave my job. Corporations have a great way to brainwash young specialists into being satisfied with their current position, though it doesn’t offer more than a stable low salary and a social package, unless you’re a top manager.

After leaving my job, I became more confident that I had made the right choice. Constant presence in the office and the ability to devote as much time as needed to the business helped a lot.

And again: hiring employees, dealing with suppliers, procurement, promotion, monitoring all the services we offered and the delivery schedule of new equipment, as well as jumping into the intricacies of the 3D technologies. All of it was done in order to become adept at dealing with additive manufacturing, pass this knowledge to employees and control their training.

We used our own profits to grow and develop. We didn’t have the opportunity to raise funds to get a cool new office and hire expensive directors. We clearly set the expenditure patterns and established certain limitations to bring spendings under control. This gave me an incentive to acquire more skills, develop and learn to achieve my goals while working under harsh conditions.

All the profit was invested into the business and new equipment, it came to the point that employees made more than me.

Dealing with suppliers isn’t as simple as may be imagined. Some already had their own distributors in Russia and they only wanted to keep working with them directly.

Others demanded that we concentrate exclusively on their products. We had to negotiate with everyone to become an authorized dealer. Many lengthy negotiations led to us visiting the headquarters of potential suppliers for personal meetings. Paris, Stuttgart, New York - all these trips were not in vain; they allowed us to become official dealers of such companies as MakerBot, 3D Systems, David Vision Systems, Artec 3D and many others.

Not all meetings were strictly official. For example, Bre Pettis, founder of MakerBot Industries and at the same time a famous video blogger and creative artist turned out to be a really cool guy. He’s the kind of guy you always have something to talk about and have fun hanging out.

Bre Pettis’ DeLorean

Direct cooperation with manufacturers bore fruit: we were able to offer competitive prices to our customers without a decrease in margin. This became one of the key factors that contributed to the rapid growth of the company. In 2015, our revenue was 6 times higher than in 2014.

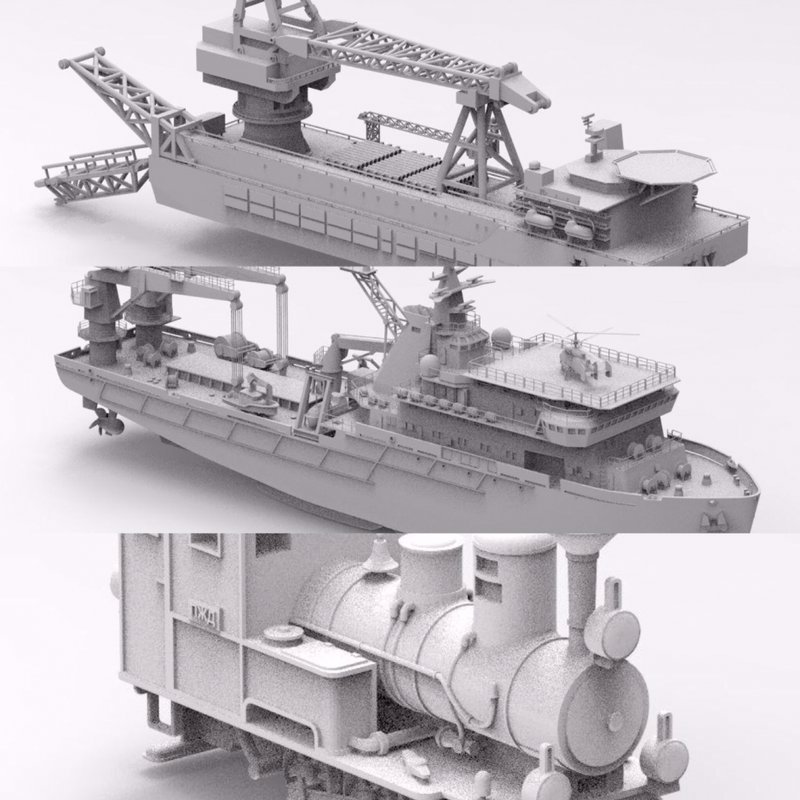

Another factor that had a considerable impact on our growth was the model that was the most obvious option for me but really unique at that time - we didn’t just sell 3D equipment, we provided maintenance and all the related services: 3D printing, 3D scanning, modeling.

Later on, this list became even longer: we started offering casting, prototyping, mold making, metal and plastic milling. We individually focused on every service. For every type of activity we opened a special department with specialists.

Other companies either sold equipment or provided services, but often the same people performed the duties of engineers and managers in the same company. Our organizational model turned out to be more effective.

Of course, we chose some unsuccessful directions. For example, 3D figurines manufacturing that was taken up by many companies fell short of expectations.

We were smart enough not to invest in our own equipment for manufacturing and we even managed to sell such equipment to the interested companies. That’s why we can’t call it a pure failure. We not only got the invaluable experience, but also benefited from the venture.

With the growth of the company, this truth also became apparent: the success of the enterprise depends on people and automatization of routine tasks.

We have grown enough to employ our own Сhief Operating Officer and Chief Commercial Officer for the constant work with sales plans and allocation of funds. Every day we work on automating our business processes. Now we have a great and capable team, as well as our own program for training specialists. We published about 15 courses on products and processes with mandatory testing. We train people who want to grow and earn. This is a very important element of success, especially for the companies that work in new fields such as additive technologies.

I am personally responsible for marketing, development strategy, increasing revenue and development in new directions. I also monitor the quality of training and customer feedback.

In 2019, our company employs more than 100 professionals in their respective fields. We already work in such areas as CNC, dentistry, jewelry, and robotics.

We’re not just hiring new employees, we’re enhancing the performance by helping each employee to improve in their field.

The structure includes several departments: sales, services, logistics, content, accounting and maintenance, as well as tender managers and specialists. Since we are a retail and manufacturing company, the salary comes mainly from the bonus part. There are, of course, fixed salaries, but most comes from the percentage of the profit.

After 2-3 months of work, a skilled manager can make 3-4 times the fixed salary and close important, long-term deals. The average salary of ordinary employees amount to 50-120 thousand rubles, depending on the held position and performance.

We don’t set limits for our managers and give real opportunities for earning, therefore, we have almost no turnover.

Now we pay special attention to automatization. We have implemented and synchronized a large number of services that will help work faster and more efficiently, receive feedback from customers and quickly respond to all criticism.

The red tape in our company is almost non-existent. All paper documents in our office exist to keep in with the law. Contracts, invoices, acts and so on. All agreements and requests exist only in electronic form. The speed of decision making and problem solving is something we can be really proud of.

Last year, we successfully began to master completely new directions for us: besides additive equipment, we started working with CNC machines. This year we will begin to actively expand into dental and jewelry fields, as well as educational robotics.

Update your browser to view this website correctly. Update my browser now

Write a comment