This case study features our client with their first Chocola3D 3D printer.

Chocola3D prints chocolate and any foodstuffs that have a paste-like consistency.

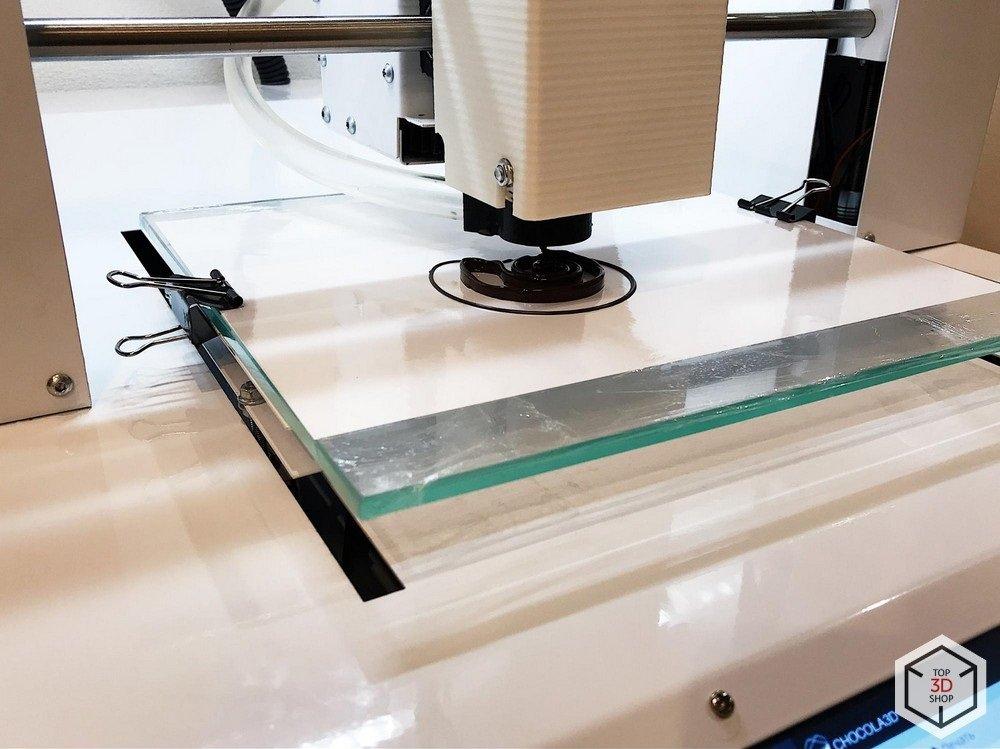

The client chose this 3D printer for its print quality, competitive price, and large print area. While few chocolate printers were available, this newer model stood out: “We’d been researching what printers were on the market and found that there weren’t all that many to choose from. The Chocola3D grabbed our attention, as it is a newer model and has a fairly large print area in comparison with the other printers. We were impressed by the print quality we saw in the demonstration photos and videos.”

Chocolate 3D printing was harder than expected, but the results were rewarding once mastered.

Learning the printer was easy, but mastering chocolate took time. Its sensitivity to temperature caused visual flaws until settings were fine-tuned. Now, the full printing process runs smoothly.

3D printing lets the client offer personalized items like names, logos, and dates — ideal for B2B gifts and custom cake toppers.

Even the most complex chocolate shapes can now be made in any quantity. Before 3D printing, special silicone molds would have to be made to order, or each individual item would be carved by hand. These approaches are incomparable with printing in terms of time and cost.

The printer’s job is to produce all manner of chocolate shapes, company logos and words in 2.5D and 3D. These are standalone edible souvenirs and various elements of cake decorations.

“Our throughput is around 15 to 20 items a day, depending on their shape and size. We’re pleased with that and we plan to scale up in the near future.”

Additional photos available below:

The client uses 3D printing to grow its business, showing how additive manufacturing benefits the food industry.

Explore more 3D printing solutions at Top3DShop.

Update your browser to view this website correctly. Update my browser now

Write a comment