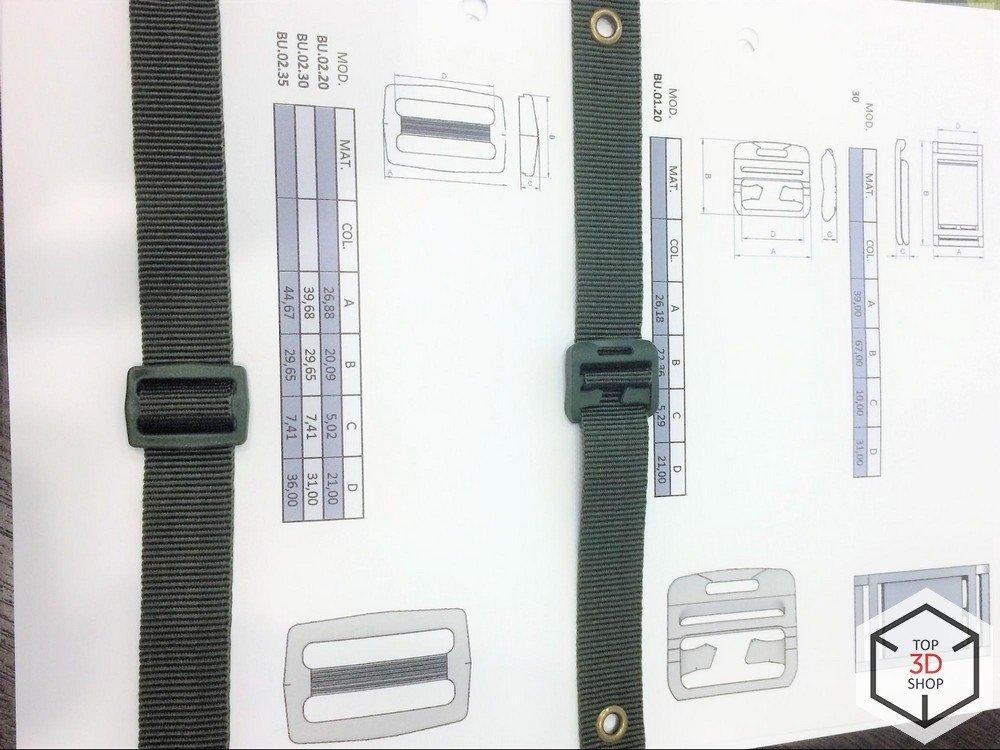

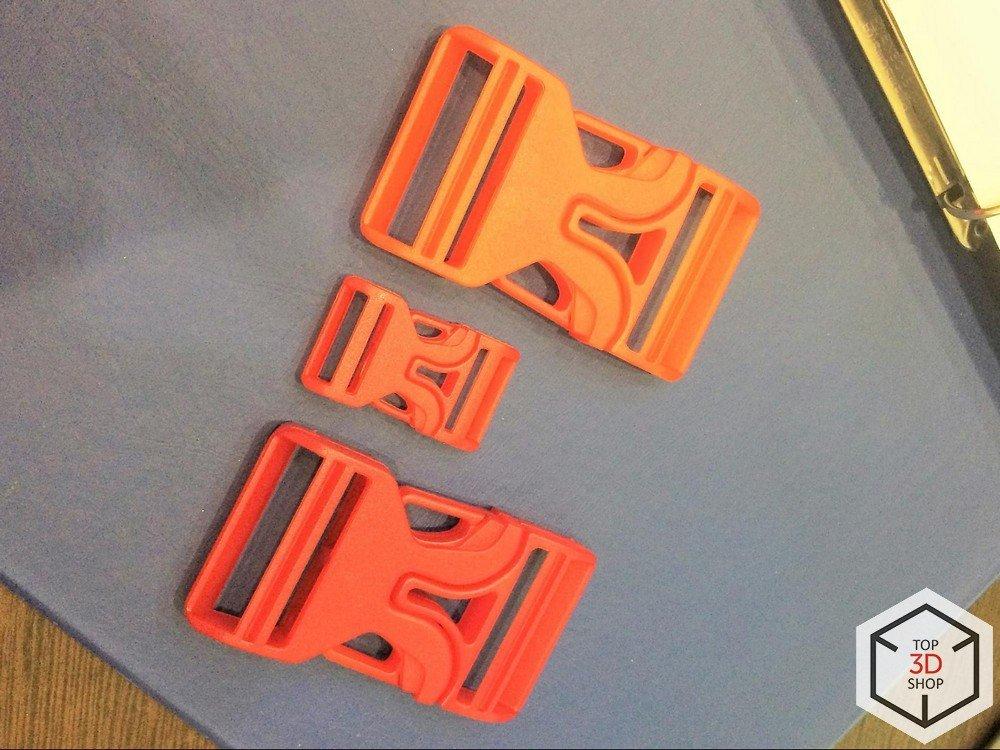

The client designs and manufactures plastic products, specializing in fasteners for outdoor clothing and equipment:

Belt fasteners for knife sheaths and gun holsters

Backpack buckles and fasteners

Jacket fasteners

They also produce custom plastic parts to order.

The Form 2 is one of the best-known SLA printers on the market and serves as a benchmark in its category for print quality and reliability.

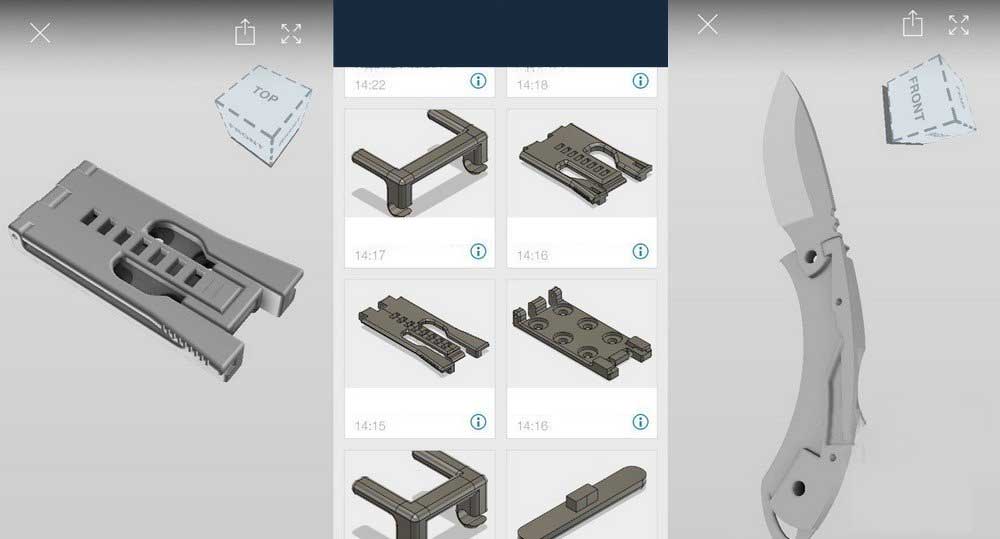

The client creates 3D models of fasteners in Fusion 360 and uses the Form 2 to print prototypes before investing in injection molds.

The workflow looks like this:

Design parts during the day.

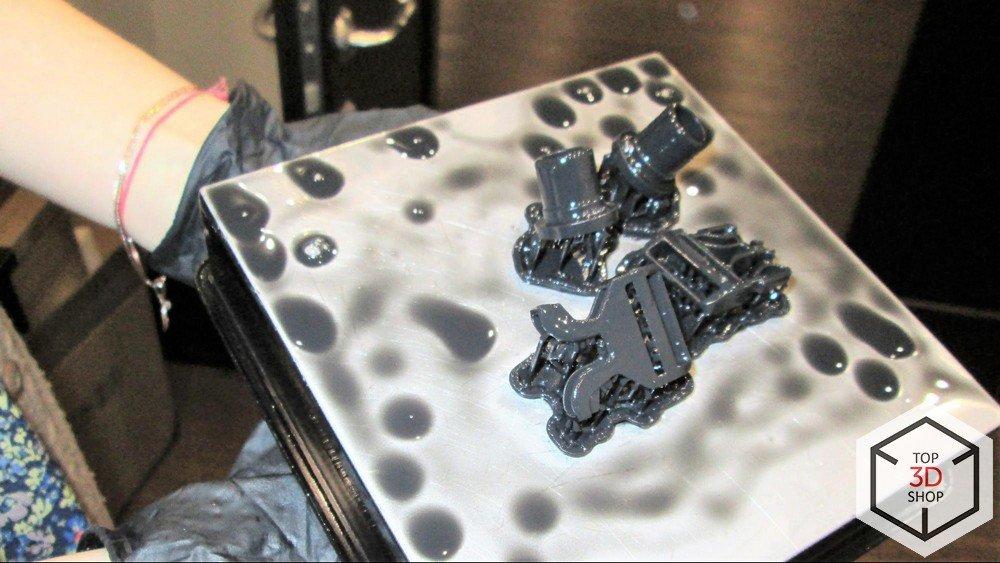

Send models to the Form 2 for overnight printing.

Inspect physical prototypes the next day.

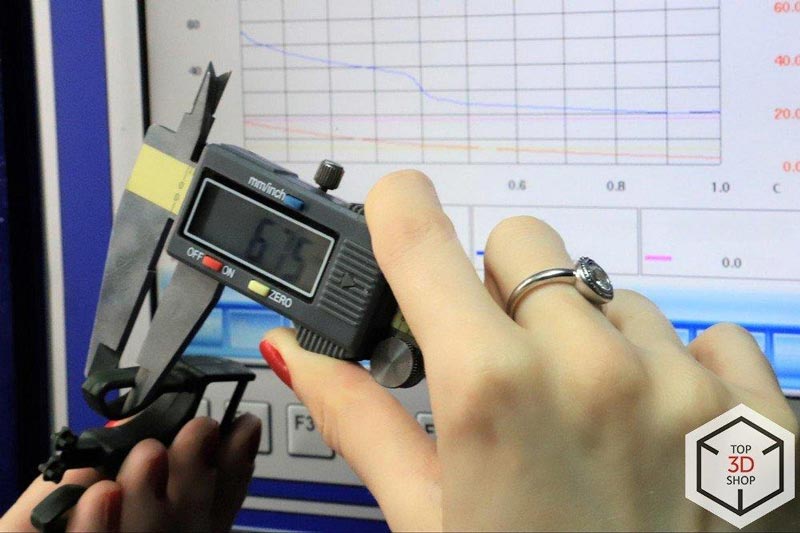

Detect and correct design flaws (dimensions, clearances, ergonomics, appearance).

Repeat, or send the order to the injection molding factory.

3D printing lets the manufacturer:

Validate fit, function, and appearance of digital models in real-world use

Check compliance with design specifications and dimensions

Iterate quickly before committing to expensive tooling

The major benefit for fastener production is the speed of getting a working prototype from a CAD file, which reduces the risk of costly mold changes later.

When selecting a printer, the client prioritized reliability above all else. The Form 2 has a strong reputation for stable operation, consistent quality, and a mature ecosystem of materials, which made it a good fit for continuous professional use.

Before 3D printing:

Prototypes were made by hand.

These handmade samples went to tooling manufacturers, who then created molds and started production.

This process was:

Slow

Expensive

Prone to inaccuracies in shape and proportions

With the first wave of 3D printers, the industry moved to FDM prototyping. Later, SLA printers like the Form 2 largely replaced FDM for this type of work due to higher accuracy and better surface quality.

High precision and tight tolerances

User-friendly interface and workflow

Ability to mix compatible resins within the Formlabs ecosystem

Proven reliability in professional environments

Resin is expensive, and a heavily used printer consumes cartridges quickly.

The resin tank (bath) is also consumable and needs periodic replacement during intensive use.

For this client, the Form 2 delivers two key benefits:

Time savings – turning an idea into a physical prototype takes hours instead of days or weeks.

High accuracy – SLA offers much tighter tolerances and better surface quality than FDM, so parts often require no manual surface finishing after printing.

Owning a Form 2 in-house eliminates the need to outsource printing:

No waiting for third-party service queues or delivery

Immediate iteration on designs

The total cost of ownership is well justified for constant professional use, though it may be relatively expensive for hobby use.

You can purchase the large-format resin 3D printers from Top3DShop with free delivery, training, and expert advice on choosing and using the full range of consumable materials.

Update your browser to view this website correctly. Update my browser now

Write a comment