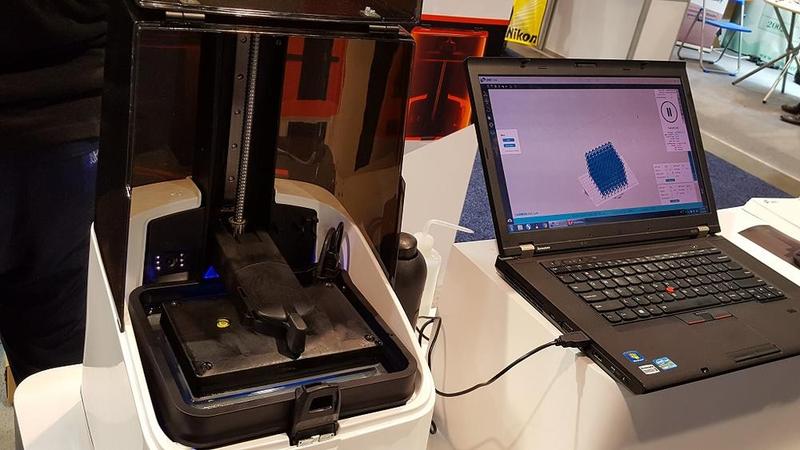

Hello everyone! In this article, we are going to talk about the Uniz brand and their 3D printers – desktop resin printers preferable for professional use. They support UDP – the new technology that allows to print up to 100 times faster.

Read this article if you want to learn more about the Uniz 3D printers and their abilities.

Source: kickstarter.com

Despite being registered in San Diego, California since 2014, this is a typical Chinese company with a factory in China. Their tech support still has language barrier issues. But the path of Uniz growth is still unusual, if only because of the fact that they had two successful crowdfunding campaigns on Kickstarter:

2016: the campaign to fund the SLASH 3D printer. The initial goal of $50,000 was met in the first day. It was surpassed and the campaign has raised around $572,000.;

2018: the campaign to fund 3D printers with the proprietary UDP technology has raised around $258,000 surpassing the initial goal of $30,000

The success of both campaigns is due to the brand’s revolutionary LCD screen’s liquid cooling solution. It allowed to print significantly faster without changing the fundamentals of the LCD printing technology – decent price and high resolution.

Source: kickstarter.com

Source: prnewswire.com

Uniz product line includes:

FDM 3D printers

Accessories and replacement parts for 3D printers

3D printing materials

Customer support

Source: kickstarter.com

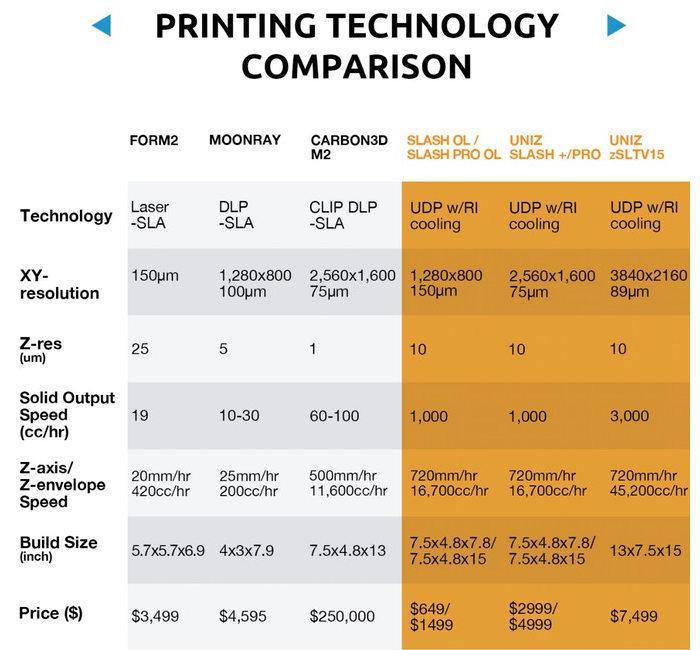

What makes Uniz 3D printers stand out? The main reason is fast printing with very high resolution that is typical for resin printers.

Inexpensive 3D printers work slowly due to complicated methods of printing. FDM/FFF and resin printers print on a layer-by-layer basis, which prolongs the process. FDM printers also use a highly precise system for moving print heads and SLA printers use mirrors (called galvanometers) that position the laser. Both systems make the devices more expensive and slow.

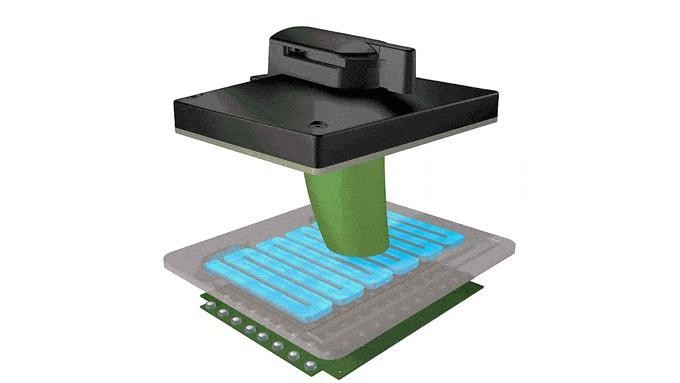

Uniz used another method – projecting each slice of the model to a transparent window on the bottom of the resin tank through LCD screen.

Photo-polymerization is an exothermic chemical reaction which generates a lot of heat on a thin separation interface. High speed printing can generate the temperature of up to 250-300 Celsium and damage the film and the LCD screen. The printer can’t work faster without solving this problem.

Source: kickstarter.com

Uniz solution was the usage of liquid cooling for the LCD screen, which allowed to take away heat and print large objects with high speed. Before the SLASH printer, speeds of around 1000 cm3 per hour were only possible on large industrial printers, but now you can print with that speed right with your desktop device.

But Uniz didn’t stop there and developed the new line of 3D printers that could print with special resins using the proprietary layerless Uni-Directional Peel (UDP) technology. Using the special resin and technology that eliminated the up-and-down motion typical for resin 3D printers allows to print with very high speeds and resolution and produce very smooth surfaces. The latter is especially important for medical printing. Special resins for UDP printing have different purposes: for high resolution printing, for high strength printing, for very smooth surfaces and for transparent models.

The zSLTV printer with the se-UDP technology holds a special place among Uniz printers. Its technology uses vertical placing of print plate and placing the finished parts in the resin tank. It’s necessary for printing very large objects, which usually either detach from the print plate or deform under their own weight.

Source: kickstarter.com

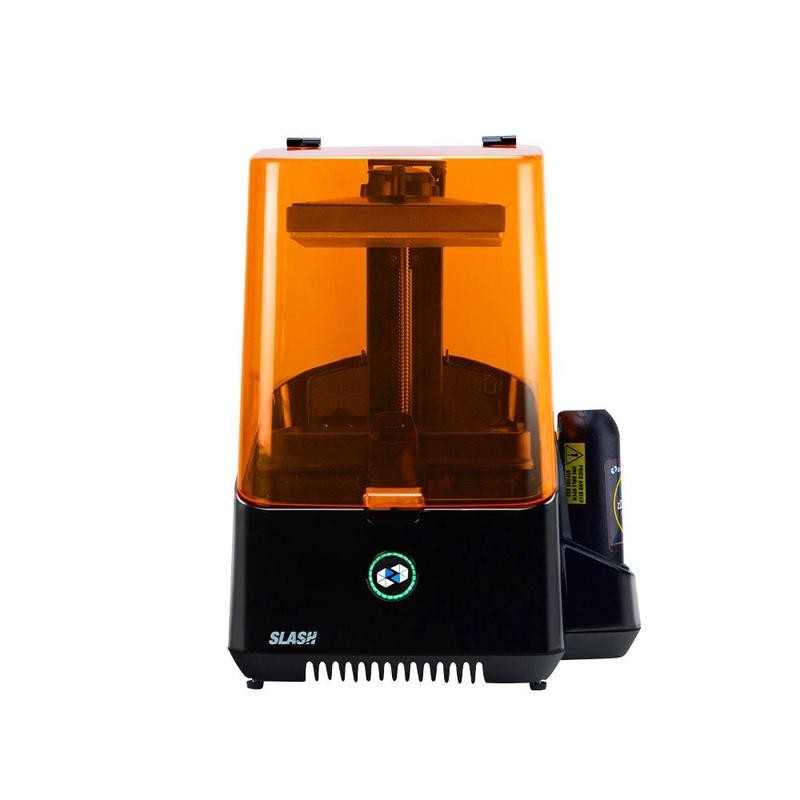

The SLASH is no longer produced and sold. The SLASH 2 3D printer with 4K LCD screen has taken its place. The shortcomings of the first version were addressed and corrected.

SLASH 2 is a high-speed 3D printer that works using the LCD technology. Its main feature that made it known over the globe is a liquid cooling system,. It allows the device to work with industrial-grade speed and precision, but still be affordable to general audience. Easy to use software that supports different mobile and desktop platforms and cloud integration allows the users to work with the device without issues.

Other useful features include the automatic resin level control in the tank, file support for objects larger than 1GB and the ability to control multiple printers. SLASH 2 allows the user to choose the parts that will be printer at high or low resolution, balancing the speed and the quality. SLASH2 uses special resin tanks that are designed to withstand 1000 hours or 300,000 layers of printing.

Specifications

Source: uniz.com

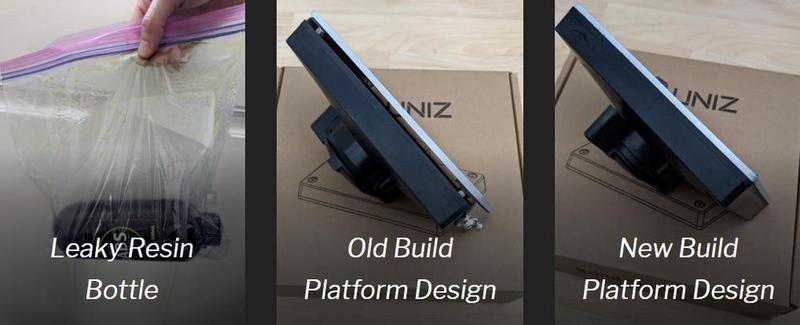

The SLASH PLUS is the continuation of all the successful things from the first SLASH printer and refining its design. Compared to SLASH this printer has a redesigned resin tank for better level control. The previous version’s tank suffered from resin links. The build plate was also redesigned and doesn’t suffer from getting resin on it. The UV source produces the light more evenly and the case is now more robust and stiff.

Like all other Uniz 3D printers, this device uses a liquid cooling system for LCD screen, but here it’s even more effective thanks to using an additional fan. These changes allows the printer to work at the speed of 1000 cm3 per hour.

Specifications:

Source: uniz.com

The SLASH PRO is a version with a doubled size of the Z-axis and the ability to print using the UDP technology with the speed up to 700 mm per hour. Uniz thinks that the model will be popular among shoe manufacturers for printing full size models. This printer is also able to work with third-party resins.

Specifications:

Source: uniz.com

This printer is identical to the SLASH PLUS but is also able to print using the UDP high-speed technology.

Specifications:

Source: top3dshop.ru

This unique printer is designed for creating especially large parts that can’t be printed in a regular 3D printer due to the deforming or detaching caused by its own weight. To avoid the problem Uniz decided to print the parts while being already completely submerged in resin and placed the print plate on the side. This decision allowed Uniz to design the printer with a very large (for the devices of this type) build volume of 330x190x381 mm. The liquid cooling system was also redesigned – it now uses the refractive index matched materials, which improves the precision of printing.

Source: kickstarter.com

Moreover, this printer has all of the abilities of its ‘siblings’ – the printing speed of 3000 cm3 per hour, liquid cooled LCD screen, the support for >1GB files and UDP (se-UDP) technology. Uniz targets the printer for aerospace and automotive manufacture.

Specifications:

Source: uniz.com

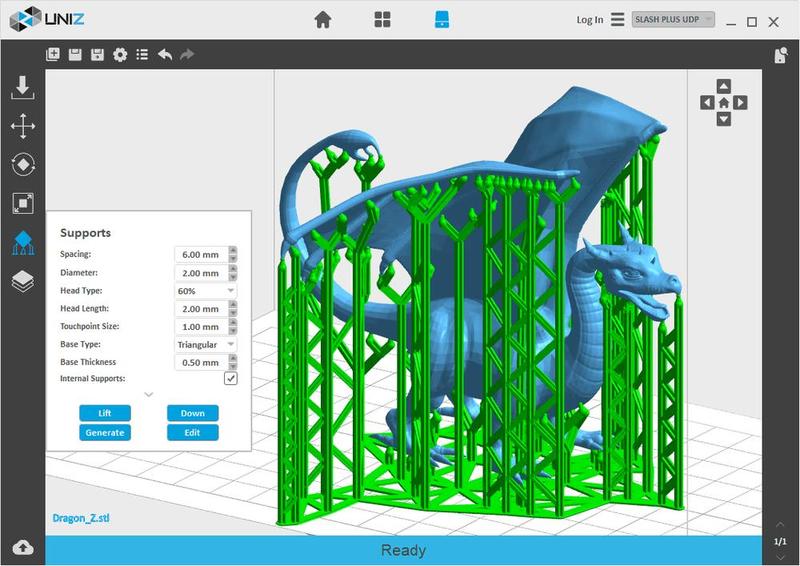

The UNIZ Software Suite package consists of two applications:

UNIZ Desktop allows to:

Use proprietary vector-based high-speed slicing algorithm

Customize Z-resolution profile (changing resolution at some points for optimizing printing speed)

Automatically find and repair mistakes in a model

Create additional supports in just one click

Work with large parts

View and send to print the models saved in the cloud

Control multiple printers simultaneously

UNIZ App allows to:

Load models saved locally or in a cloud

Control multiple printers from anywhere you want – control, start, cancel and pause printing

Source: ryang3d.com

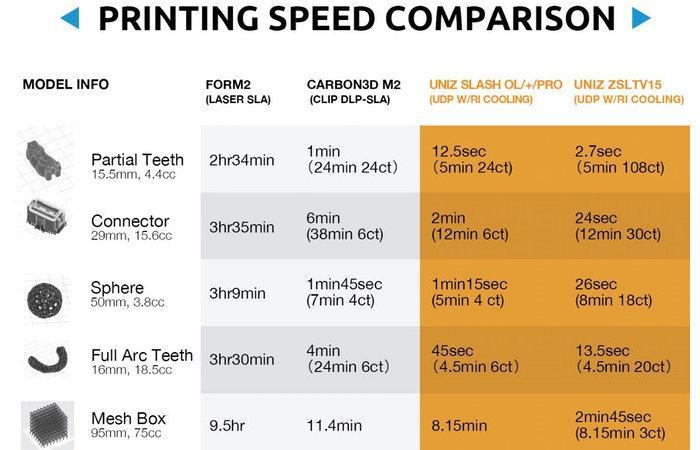

Resin 3D printers provide the best printing quality possible today. Customers can find the model that suit them the best – there’s a wide range of printers with different resolution, build volume and prices. The comparison table below lists the 3D printers similar to the most popular Uniz model – SLASH PLUS.

|

Printer |

Build volume (mm) |

Resolution (microns) |

Price |

|

100 x 75 x 203 |

XY: 30 — 70

Z: 5 — 200 |

$4,595.00 |

|

|

120 x 68 x 150 |

XY: 63

Z: 13 — 50 |

$3,999.00 |

|

|

Formlabs Form 3 |

145 x 145 x 185 |

XY: 25

Z: 25 |

On request |

|

192 × 120 × 200 |

XY: 75

Z: 10 — 300 |

$2.849.00 |

|

|

120 x 68 x 170 |

XY: 31

Z: 10 |

$1,399.00 |

|

|

190 x 120 x 200 |

XY: 85

Z: 10 |

$1,399.00 |

|

|

120 x 68 x 210 |

XY: 47

Z:40 |

$575.00 |

Source: 3dprint.com

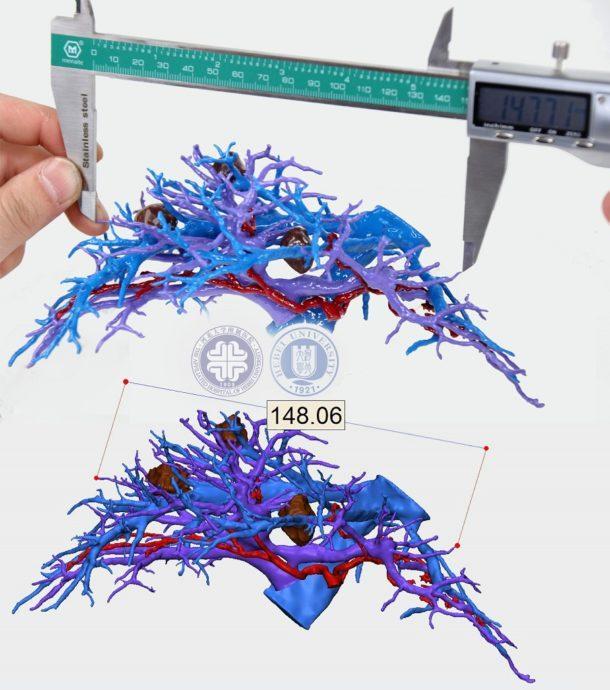

"3D printed medical models are making their way into hospitals around the world as medical professionals recognize their value. Patient-specific anatomical models offer physicians the opportunity to physically touch and examine complicated internal structures, understanding the extent and precise locations of issues to be addressed through medical procedures. Patients also benefit from the models, which can be used to inform them of specifics of both condition and treatment. [...] Other improvements have been in focus for research in China, as a team of researchers led by Professor Cheng Shujie from the Affiliated Hospital of Hebei University are now introducing precise 3D printed liver models that reproduce complex anatomies at a much lower cost than had been previously available. "

Source: 3dprint.com

"3D printed models showing the entire liver, including internal tissue and structures, have shown demonstrable benefits for physicians, chief among them increased surgical safety, reduced intraoperative hemmorrhage, and fewer post-op complications, as the Hebei-based team pointed out. "

Source: 3dprint.com

“At the first time in the world, the team led by Professor Cheng Shujie from the Affiliated Hospital of Hebei University spent less than 4 hours on parallel printing of the entire internal structure and the surface of the liver under the layer thickness of 0.1mm with high speed photosensitive resin by using two high speed LCD-SLA 3D printers equipped with liquid cooling system. Then after one precise match by applying the improved traditional transfer molding technology, they completed the manufacturing process of patient-specific medical models with high transparent resin. As the internal structure of the liver was printed at once, malignant tumors can be seen clearly in the model. Compared with the measured distance from the 3D computer model, the errors of the measured distance of the printed model and its adjacent blood vessels are all less than 0.7 mm in every direction. With the premise of decreasing printing time drastically and improving the printing accuracy, it has further lowered the cost of model production, which has greatly increased the surgery efficiency and accuracy.”

Source: ryang3d.com

"There are definitely some pros to owning a UNIZ SLASH, but it is certainly not without its cons. Plagued by design flaws, poor design decisions, iffy customer support, underdeveloped “features,” and more… somehow the SLASH printers do still seem to work, when they work. "

"The printer’s built-in wifi capability has never worked properly, but plugging it in to a computer’s USB port seems to work fine. "

Source: ryang3d.com

"From some online discussions (especially on the Facebook Users Group) there were plenty of other issues with this machine for many people, including an issue with the liquid cooling system which caused what are being called “cooling lines.” In other words, parts would come out with visible vertical lines on them… which is pretty undesirable. Also due to the high suction forces and unfortunate plastic printer chassis, some folks have experienced twisting. Even one of my brand new, unopened resin bottles, leaked. Again however, I have not used the original SLASH that extensively… I only have a few small test prints, and a couple contract prints that went through it. "

Source: ryang3d.com

"After waiting a couple months, I reached back out to UNIZ to ask about the stretch goal rewards. They gave me some BS excuses about why the stretch goals were not sent (basically referring to their confusion when I had them refund my orders), but they did eventually send out what was promised. Unfortunately UNIZ decided to send me the old build plate design which features screws for adjusting and a large air gap that resin can easily get into, but not get out of. My SLASH came with their sealed build plate design, so this seemed odd to me… but I decided to just accept it. I also experienced a few leaky bottles of resin (due to a bad bottle design), and was eventually able to get UNIZ to replace these wasted bottles of resin with their updated bottles that do not leak as easily.

The initial releases of the UNIZ software definitely seemed like it came from the same company. I found the UNIZ software to be somewhat clunky, but it got the job done. More on the software later though…"

Source: ryang3d.com

"After having already worked with Carbon’s M1 at my day job, I was blown away at the concept of being able to have a 3D printer that is just as, if not more, powerful than a Carbon printer on my desktop for a small fraction of the cost. With this campaign, UNIZ was releasing a line of new improved SLASH printers, and planned on introducing a pricing structure which included the possibility of buying software limited machines for a lower entry cost. The software limited machines would be limited to lower resolution printing, and possibly other limitations, and could be unlocked later for an additional (and pretty steep) fee. UNIZ seems to think they are Tesla or something here, and I am definitely curious how this is panning out for them… "

"Once unpacked, the printer fired up, but when testing the LCD screen, I discovered that the LCD screen was not working (no image or logo would display). Not a promising start, so as much as I did not want to deal with their support team, I reached out to UNIZ about the issue. They responded relatively promptly, and after confirming the issue, they surprised me by offering to send a full replacement printer (they didn’t even ask me to return the first one, so now I have it for parts!). "

Source: ryang3d.com

"So aside from the various flaws and nuances I discovered with this new 3D printer, I have continued to use it every once in a while. I have not been using UDP (high speed) mode at all due to the technology’s current limitations, but the natural peel (standard speed) mode does seem to work relatively reliably. "

"While UNIZ’s own resins do seem to work best for me so far, I have begun testing third-party resin from Monocure (their Rapid line of resins) which do seem to also work. UNIZ’s resins are a bit on the expensive side, especially when compared to third-party manufacturers such as Monocure. "

"…UNIZ SLASH has plenty of potential, and UNIZ is continuing to develop new printers and software today. "

Source: 3dprint.com

"[…] The company introduces Uni-Directional Peel (UDP) 3D printing technology. […]" Company CEO Dr. Houmin Li explains:

"Uni-Directional Peel (UDP) results from over 2 years’ of dedicated effort by the UNIZ R&D team. By reducing the up-and-down peel to one-directional peel action and using conventional materials, RI-matched cooling, improved light-engine, evolved resin formula, UDP pushes SLA printing speed to the physics limit (14800cc/hr envelope speed or 650mm/hr z-axis speed) without the help of pure oxygen or exotic separation material. This is a revolutionary solution provides speeds more than 100x that of conventional desktop 3D printing technologies such as FDM and laser-SLA.”

Source: 3dprint.com

“The new 3D printer lineup includes:

SLASH OL — With OL standing for online, this LCD SLA 3D printer is designed for beginners, with demos running live all day at CES.

SLASH Pro — Targeted toward shoe manufacture, the taller version of the Slash can fit an adult shoe shape.

SLASH+ — This upgraded version of the original SLASH 3D printer is more stable, with better accuracy.

The zSLTV-M and zSLTV — These two industrial SLA 3D printers feature larger build volumes and a horizontal orientation. The smaller of the two, the zSLTV-M (M for mini) has a 315 x 180 x 412 mm build volume and is available via Kickstarter; the larger zSLTV, with a 521 x 293 x 651 mm build volume, is a newer devleopment without a firm price yet. “

Source: 3dprint.com

Houmin Li further explains:

“To further explore the physics limit of 3D printing and scale-up the UDP technology, we designed zSLTV series industrial 3D printers. zSLTV is equipped with the world’s first side-exposure-UDP (se-UDP) technology. The key idea behind se-UDP is that any material has a limit of specific-strength, which means a material will eventually break by gravity when it is long enough. The as-printed photopolymer resin unfortunately has quite low specific-strength and posing a low limit on the longest structure that can possibly be printed using top-down approach. In order to counter the gravity induced break limit, we implemented the submerged side-exposure design using floatation force of the uncured resin to defy gravity on the printed parts, thus enabling reliable and accurate printing of ultra large structures at UDP speed which is over 700x faster than conventional FDM and laser-SLA technologies,”

“Next, we developed refractive index matched cooling tech, which is a key technology UNIZ patented to achieve UDP speed. As described in our previous campaign, to print at super-fast speed, the extensive amount of heat generated during exposure must be removed via convection. However, the cooling structure design and coolant of choice must not affect printing quality. So UNIZ implemented a refractive index matched cooling system in which the cooling channels and coolant are electromagnetically uniform to the excitation wavelength, thus artifacts caused by the cooling system are greatly minimized.”

Source: 3dprint.com

"Target industries for the newest introductions from UNIZ include automotive, which can benefit from the large build volumes possible on the industrial 3D printers, as Dong Zhao pointed out, while dental, jewelry, military, aerospace, and prototyping applications can see great use of the speed and resolution from the various machines available. "

Source: 3dprint.com

Time-lapse of the full SLASH OL print job, the green circle acts as a progress bar:

Source: uniz.com

Uniz 3D printers are great for experienced users. The brand had two successful crowdfunding campaigns on Kickstarter to finance their research and development of their technologies. Uniz continues to refine their 3D printers and software for experienced and seasoned 3D printing enthusiasts.

There are some expected side effects of being a fast growing company such as design issues, software problems, lack of customer support and strange policy of paid functions unlock. But despite all of that, it’s clear that the brand is on the right path of growth among the very competitive market of resin printers.

Source: uniz.com

The LCD screen cooling system doesn’t work perfectly. After some time it will deform the screen which will lower the printing accuracy and physically damage the screen.

The experts at Uniz are aware of this issue and has released a guide that describes the pressure release process and how often it should be done. But the workaround is still a complex manual job. We could only hope that in the future the issue will be controlled automatically.

We recommend buying Uniz 3D printers as a rather inexpensive way to try high speed resin printing.

You can order professional high-end Uniz 3D printers at Top 3D Shop and get the best customer support.

Update your browser to view this website correctly. Update my browser now

Write a comment