FLUX is a young Taiwan-based company specializing in development of laser cutting and engraving machines. With its world’s smallest Beamo model and the recently launched professional HEXA, the company offers comprehensive solutions for various production needs, from hobbyist making to mass manufacturing for small businesses.

This is Top 3D Shop, and today we are going to review the FLUX Beambox series represented by two models of CO₂ laser cutters and engravers, namely the Beambox and Beambox Pro.

The Beambox is the first model in the FLUX family of laser cutters and engravers. This smart machine was designed for versatile applications, be it consumer projects, education, or a small business. A wide range of compatible materials both for cutting and engraving, a number of professional features, and ease of use make the Beambox a popular choice for those looking for a reliable device at a reasonable price. The machine was soon followed by its Pro version featuring a more powerful laser and a larger working area (and, consequently, bigger size).

Let us have a look at the key features of the Beambox series.

The Beambox models are equipped with a CO₂ laser tube with 40 / 50 W (for the Beambox Pro) power operating at the 10,640 nm wavelength. The power is enough to cut through up to 10 mm (12 for the Pro version) thick material in one pass.

The internal closed-loop water cooling system prevents overheating of the machine components during operation. In case the temperature gets too high, the machine will pause to prevent damage.

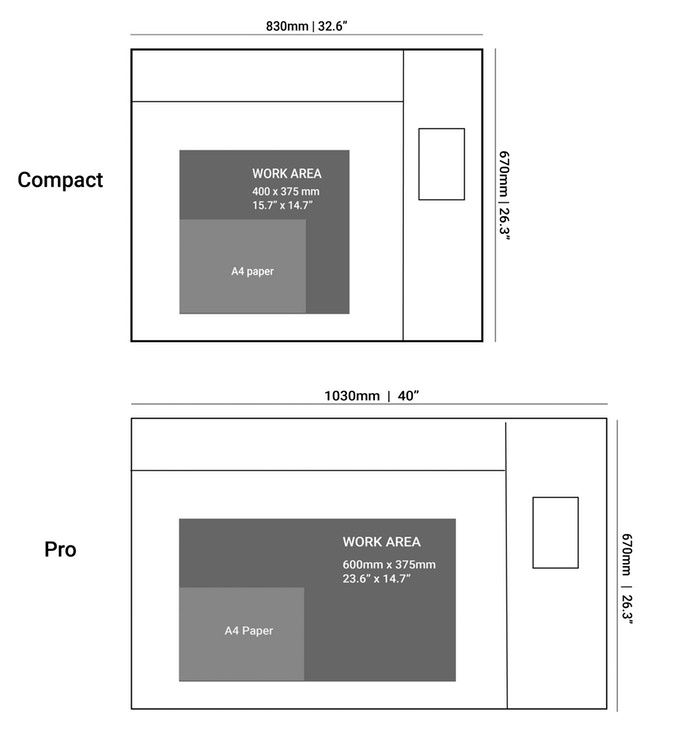

Both models boast an 80 mm working height and a spacious working area of 400 x 375 mm for the Beambox and even 200 mm longer for the Pro model. This is quite enough for most consumer and professional projects.

The built-in HD camera allows for the live preview of the working area so that you can line up your design with the material and get the expected result.

To extract the hazardous fumes, the Beambox cutters are equipped with an efficient ventilation system with an exhaust fan. The air pump helps keep the working area clean while cutting and keeps the focusing lens from dust.

FLUX pays a lot of attention to safety, equipping their machines with a number of features preventing any potential hazards. In case the lid is open during operation, the device is immediately put on hold and resumes working when the lid is closed. Besides, there is an emergency power switch you can use if something has gone wrong.

Like the other FLUX cutters, the Beambox series features rich connectivity options, including Wi-Fi, Ethernet, and USB connections. The free proprietary Beam Studio software is compatible with different raster and vector file formats and provides a variety of editing tools. You can also control your Beambox via a mobile app called Beam Go which is a mobile version of the Beam Studio software.

The package contains the FLUX Beambox / Beambox Pro and an accessory box with all the additional tools. Here is the full list of items you will find in the box:

For some items, package content may change. In case of any questions, please get in touch.

Once you take the machine out of the box, it is almost ready to work. What you need to do first is install the acrylic cover, fixing it with a washer and a nut on each bolt, and put the two dampers into the holes on the front edge of the device.

Now plug in the power cord and the USB Wi-Fi dongle into the corresponding sockets.

The next step is attaching a vent hose to the exhaust port on the back side. Take the other end of the hose outside to remove smoke and fumes. The video below will help you with the installation.

Turn the Beambox on and set up Wi-Fi connection, selecting Network > Connect to Wi-Fi on the touchscreen.

Do not forget to fill the water tank with distilled water so that the cooling system can operate properly. To do this, you need to unscrew the back lid and open the water tank with a small wrench. Fill the tank with distilled water using a supplied funnel.

Then check the water level by selecting Maintenance > Pump on the touchscreen. Add some water to the tank if necessary.

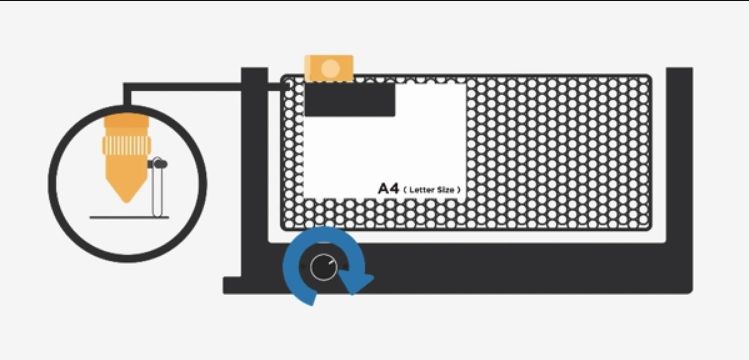

There are only two more steps left to complete the preparation. The first one is to adjust the focus by putting down the plastic probe and rotating the adjustment knob on the platform.

It is recommended to check the focus before each new job to ensure precise operation.

And finally you need to calibrate the built-in camera, following the instructions of the Beam Studio software. Go to Menu > Machine, select your Beambox, choose the Calibrate Camera option and run the calibration process.

Once it is done, you are ready to start.

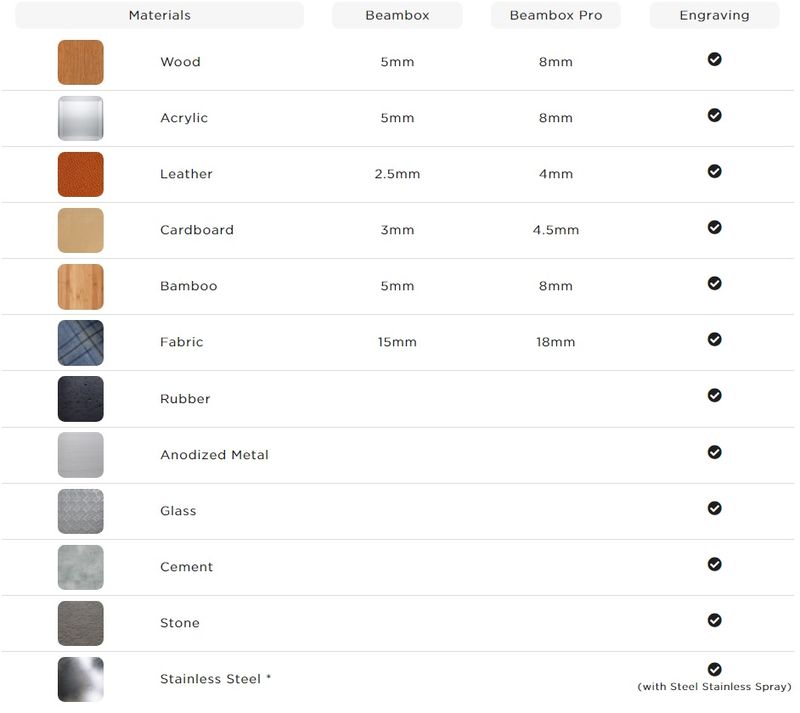

The Beambox series machines are compatible with a lot of different materials for cutting and engraving. In the table below you will find the list of materials and the maximum thickness that can be cut through in one go.

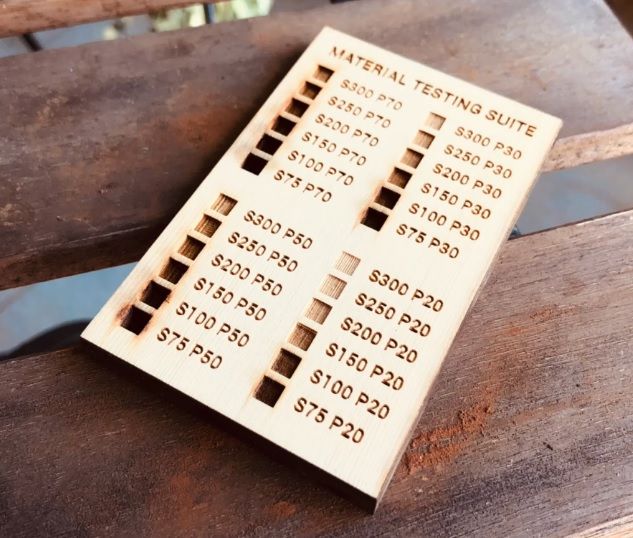

The best way to start working with a new type of material is to use the preset offered by the Beam Studio software and then adjust it according to your experience. Apart from that, you can run a test file for any new material and then use these charts as references for your next projects.

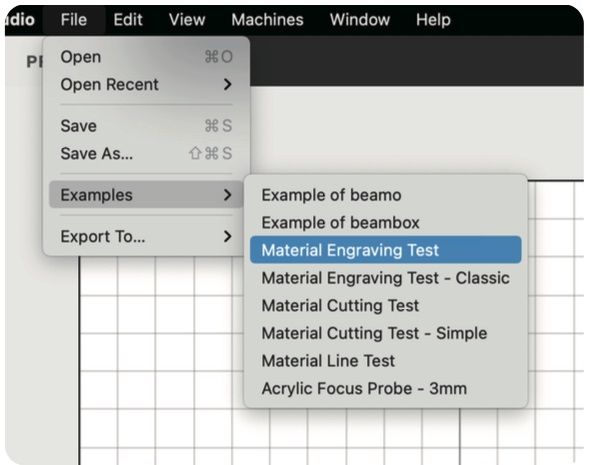

You will find test files with various power and speed parameters for both cutting and engraving in the Menu > File > Examples > Material Engraving Test.

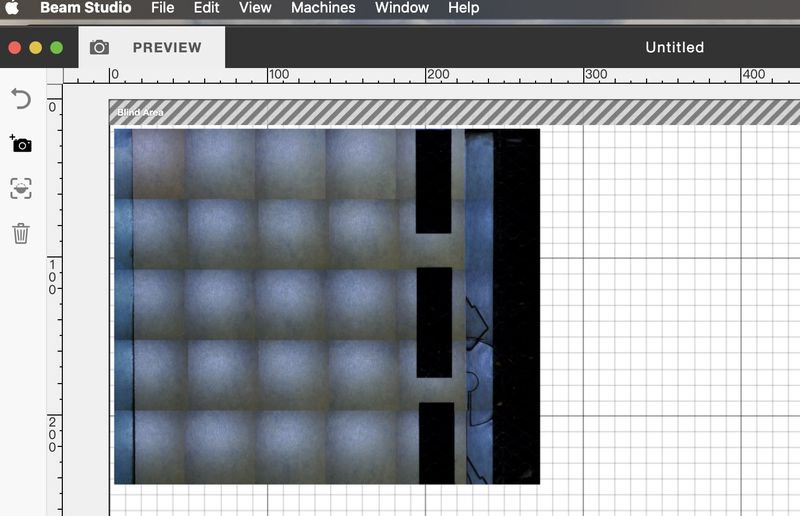

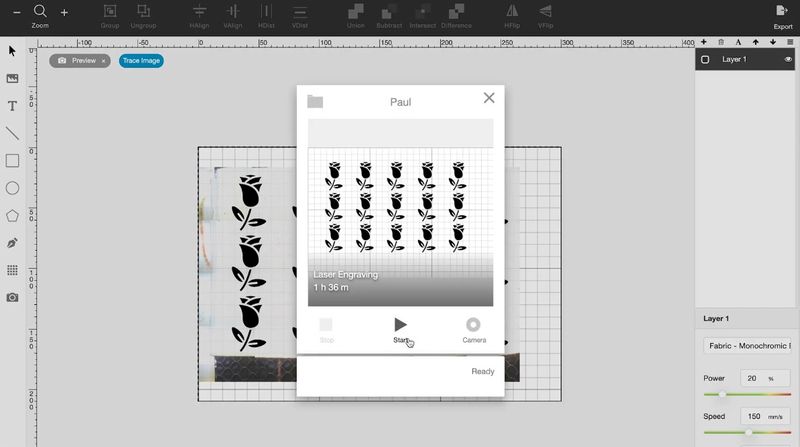

The Beambox laser head is equipped with a built-in camera used for the live preview of the working area. Tap the camera icon and drag the cursor to the areas you want to see, and the camera will take a series of shots to show you the preview of the chosen area. You can now place your design exactly where it should be and press the start button.

The camera allows for the use of another interesting function called Smart Trace. You can put a drawing of a simple pattern onto the working area and take a picture of it while in the Preview mode. Then you need to adjust the Threshold value, set the power and speed parameters, and cut or engrave your design on the material of your choice.

To expand the capabilities of the Beambox machines and provide more flexibility in the use of items to be engraved, the FLUX offers an optional rotary add-on which allows engraving on round and cylinder-shaped objects, such as glasses, balls, tumblers, and so on. The FLUX rotary module is easily installed and can hold objects of up to 30 cm in length for the Beambox and 50 cm for the Beambox Pro model.

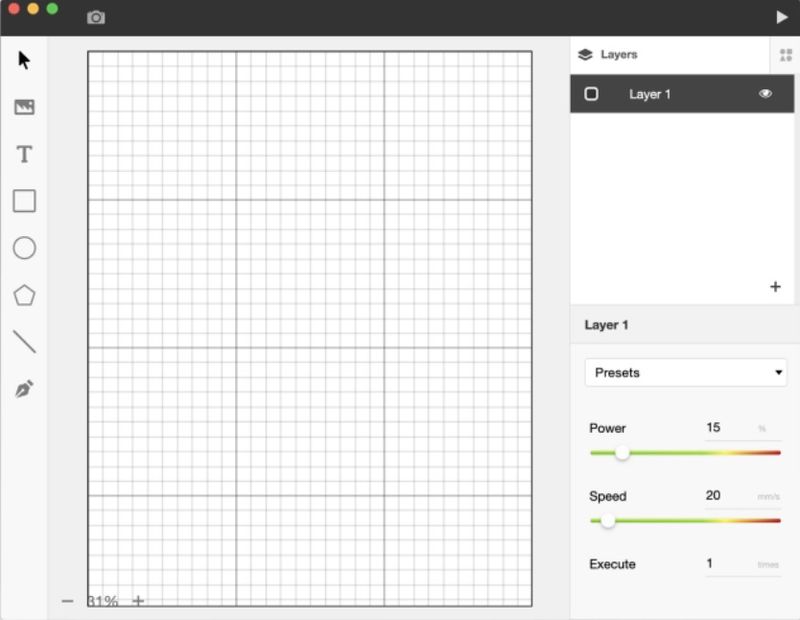

You can download the proprietary Beam Studio software from the manufacturer’s website. It is free and compatible with Windows, macOS, and Linux systems. Beam Studio supports various file formats, such as JPG, PNG, SVG, DXF, AI, and PDF, and provides you with all the necessary designing and editing tools, like different shapes and free-form drawing, text editor, and more. You can align, rotate, center, or flip the objects, as well as use the Array function allowing you to easily make a number of copies of your design and place them for cutting in a single job.

The engraving resolution defines how detailed your design will be, and can be set depending on your goals. Choosing higher resolution for your project always means longer processing time.

Thanks to the layering support, you can set different cutting parameters for each layer of your design, and the machine will process them in turn, so you can combine cutting and engraving in a single job.

Beam Studio is compatible with a number of popular design software, including Adobe Illustrator, Adobe Photoshop, Affinity Design, Autodesk AutoCAD, SketchUp, SolidWorks, Sketch, Corel Draw, and Rhinoceros. You can use any of them for your complex artwork projects and then send them to Beam Studio.

The Beambox series machines are extremely popular with creators all over the world. Many of them have turned their hobby into a side business, and you can find a ton of such examples on Etsy or other similar platforms. Here are some inspiring cases of people’s experience with the Beambox and Beambox Pro devices.

Willow Creative, a digital artist and costume designer creates cosplay costumes and props. In her work she combines a lot of different techniques, such as 3D printing, foamcrafting, and more. The video shows the fantastic result of her work with the FLUX Beambox.

Credit: @ross.mcsweeney / Instagram

Ross McSweeney is a hobbyist designer and creator. He makes wooden moving toys, paper art boxes and other amazing things using the FLUX Beambox. Now he sells his unique design files on Etsy.

Credit: 10po.co

Tenten Tenpo is a brand of accessories by a Singaporean artist, crafter, and maker, Denise. She uses the Beambox Pro in her work and says, “It allows me to create art using a material / technique that is usually reserved for bigger commercial businesses. There's a lot more freedom and independence in having a nifty laser that fits in the corner of my home-based workshop”.

The FLUX Beambox series laser cutting and engraving machines are highly versatile tools that significantly expand your creative capabilities and allow turning your hobby into a business. You can choose between the Beambox and Beambox Pro versions according to your project size and budget, with either model featuring high performance, wide material compatibility, and a whole bunch of opportunities.

Update your browser to view this website correctly. Update my browser now

Write a comment