Wouldn’t it be great to add a unique touch to your smartphone case? Or start a morning with a nicely customized cup? How about a handmade wooden box with personalized design for a very special gift? All these options are reality with the right tool that requires no particular skills, only the power of imagination.

This is Top 3D Shop, and today we are going to introduce you to FLUX — the company famous for high-performance laser cutters and engravers that are powerful yet accessible to everyone. With the whole product ecosystem, FLUX has a lot to offer.

FLUX Inc. was founded in 2014 in Taiwan by a team of young specialists in industrial design, software programming, hardware engineering, and other fields.

Credit: @fluxinctaiwan / Instagram

In the same year the team raised more than 1.6 million dollars in a Kickstarter project, the Delta all-in-one desktop device combining functions of a 3D printer, 3D scanner, and laser engraver. The machine was shipped to 64 countries and got several awards, like CES Innovation Award 2016.

In 2018, the company launched their first CO₂ laser cutter, the Beambox, followed by the Beambox Pro version, and in 2019, the world’s smallest laser cutting machine, the FLUX Beamo. Then, at the end of 2021, FLUX launched their flagship called HEXA.

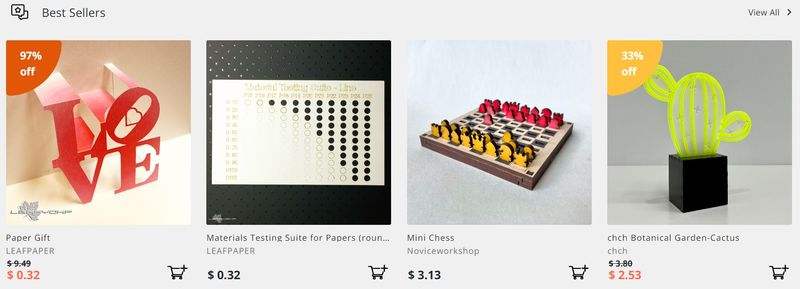

In 2022, the company also established an open e-commerce platform for laser engraving enthusiasts — Design Market. There, you can find digital creative projects from designers from all over the world. Moreover, the company commits to assist users in practicing design, thus ensuring everyone enjoys the wonder of creation.

Today the FLUX company has more than 100 local resellers in the US, Europe, Japan, Australia, and other countries, and offers comprehensive laser cutting and engraving solutions for businesses, education, and hobbyists.

Overall, the company produces to date four devices varying in terms of size, power, and functionality. Their basic differences can be learned from the table below:

|

Beamo |

Beambox |

Beambox Pro |

HEXA |

|

|

Dimensions |

615 x 445 x 177 mm |

800 x 670 x 250 mm |

990 x 670 x 250 mm |

1110 x 670 x 273 mm |

|

Weight |

22 kg |

40 kg |

48 kg |

58 kg |

|

Work area |

300 x 210 mm |

400 x 375 mm |

600 x 375 mm |

730 x 410 mm |

|

Camera preview area |

300 x 195 mm |

400 x 360 mm |

600 x 360 mm |

730 x 395 mm |

|

Power |

AC 110V/220V |

|||

|

Max. engraving speed |

300 mm/s |

900 mm/s |

||

|

I/O |

Wi-Fi, Ethernet, USB |

|||

|

Laser |

30W CO₂ laser |

40W CO₂ laser |

50W CO₂ laser |

60W CO₂ laser |

|

Wavelength |

10640 nm |

|||

|

Cutting thickness (varies by material) |

0–5 mm |

0–10 mm |

0–12 mm |

0–10 mm |

|

Operating system |

Windows, macOS, Linux |

|||

|

Supported files |

JPG, PNG, SVG, DXF, AI, PDF |

|||

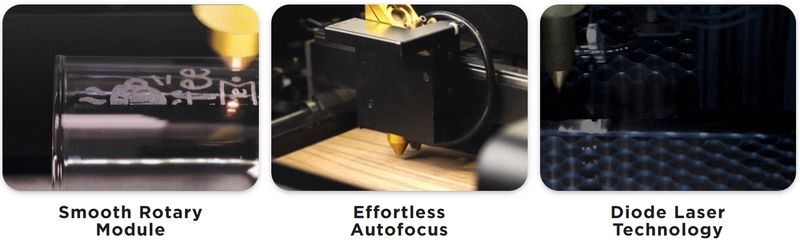

The FLUX Beamo is the most compact laser cutter and engraver in the world that is nevertheless equipped with a high-resolution laser, HD camera, and various safety mechanisms. This allows the machine to produce high-quality products with personalized design and work with an impressive range of materials, from wood to glass. Due to its small footprint and completely safe enclosed construction, the Beamo is perfect for professional, personal, and school use.

Compared to other devices from FLUX, this model has the smallest working area of 300 x 210 mm. Its 30W CO₂ laser is relatively inferior to those of the more powerful engravers developed by the company, but it is potent enough for the majority of common home crafting tasks and efficient processing of even transparent materials.

In addition, the company provides several attachments for the Beamo (see further below) to expand the device’s capabilities and improve your laser cutting and engraving experience.

Credit: @horohorodesign / Instagram

The FLUX Beambox is a professional laser cutter and engraver with a number of smart features making it a powerful yet user-friendly device. Just like the Beamo, it is engineered with an HD camera for convenient positioning, sensitive touchscreen with clear interface, and comes with an integrated software that primarily aims at accessibility and ease of use. Thanks to this focus, the machine is suitable both for aspiring and seasoned crafters.

The cutting and engraving capabilities of the Beambox cover more projects due to the enlarged working area (400 x 375 mm) as well as increased laser power of 40W. The latter allows the machine to cut through up to 10 mm of certain materials (twice that of the Beamo) with impressive accuracy. Still, these changes lead to larger dimensions and weight, so the device might not fit into some home interiors, which will not be the case with professional workshops.

Credit: @moiras.casket / Instagram

The FLUX Beambox Pro was until recently the most powerful laser cutter and engraver from the company. Similar to the Beamo and original Beambox, this model boasts an efficient CO₂ laser (50W) smaller than the width of a human hair, integrated HD camera with a smart preview function, and intelligent safety mechanisms, including manual shutdown with a single switch and air assist system for the lens.

Apart from the built-in ventilation devices, such as a powerful air pump and exhaust fans ensuring protection against potential ignition of the processed material, smoke, and fumes, the Beambox series offers premium laser efficiency through high-quality rails and other durable components. The Beambox Pro version provides a large working area of 600 x 375 mm for unrestricted professional and household use. The maximum cutting thickness can reach up to 12 mm depending on the material, which is the best performance for the FLUX machines in this aspect. However, this power also implies an increase in dimensions.

Credit: @bitsnatoms / Instagram

The HEXA model is the latest addition to the FLUX family that represents by far the most effective laser cutter and engraver with exceptional performance. It brings the company’s machines to the new level, especially in terms of maximum engraving speed, which is three times higher compared to the standard 300 mm/s achieved by the previous devices. Nevertheless, HEXA retains the brand accessibility with the intelligent electric elevation platform offering automatic height adjustment and built-in cleaning slot for smooth operation at all stages.

Another valuable upgrade concerns the working area that reaches 730 x 410 mm, which is 33% larger than Beambox Pro and provides even more creative and business possibilities. The high spec 60W laser tube with optional 1.5" focus lens allows easily achieving 1000 DPI resolution and boasts an increased lifespan of 10000 hours. With this high-stability laser and overall durable structure, the machine can cut through dozens of materials 10 mm thick in one pass.

Furthermore, the company provides several handy add-ons for the HEXA (see below) to expand the device’s capabilities and improve your laser cutting and engraving experience.

Credit: @feinschliff_laserdesign / Instagram

The Beam Air is an external filtration system consisting of four highly effective filters and a brushless motor with powerful air intake. It serves as an enhanced protection against harmful fumes and particles that generate in the working chamber of the FLUX devices during laser cutting and engraving processes.

This universal add-on can be connected to any of the above mentioned machines. Due to its smart operation mode, the Beam Air will turn on and off automatically, synchronized with the laser cutter. Moreover, the amount of air ventilation can be easily regulated with a special knob.

With a compact footprint and simple yet elegant design, the Beam Air will decorate any workshop.

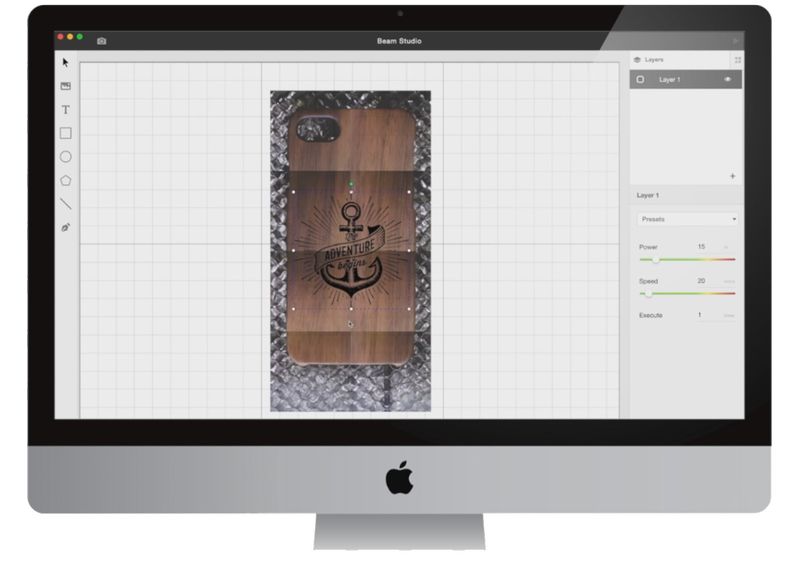

The Beam Studio is a highly intuitive software solution from FLUX providing all the necessary tools for smooth and easy laser cutting and engraving. The program features not only high compatibility, but also various design functions suited for the needs of both beginners and professional creators.

Among the opportunities within the Beam Studio, there is a real-time preview of the current project, drag-and-drop interaction, auto alignment, design distribution, quick color adjustment, advanced functionality for multi-layer projects, preset recommendations for different materials, pre-made test patterns, etc. In addition, the program comes with a clear interface with universal icons.

The Beam Studio supports many file formats, such as SVG, PNG, JPG, DXF, PDF, and AI. The program is available for free on Windows, macOS, and Linux with no limits and a web-version (Chrome or Safari are recommended).

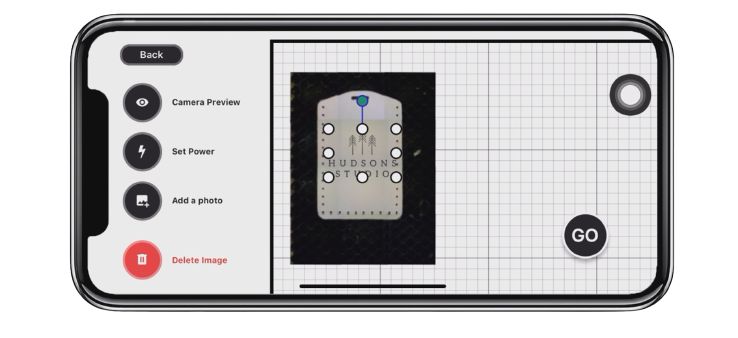

The Beam Go makes working with the FLUX laser cutters and engravers even easier. With this mobile application, the user can turn any drawing into a digital engravable design. Thanks to the unique image rendering algorithm, all one needs to do is to take a photo and upload it to the app.

The main advantage of the Beam Go is that the user does not need any expensive tools or third-party software to convert an image or digital drawing to an engravable file. Plus, the program features a live preview function through the laser cutter’s built-in camera as well as user-friendly touchscreen controls.

The Beam Go is available for free on iOS and Android devices.

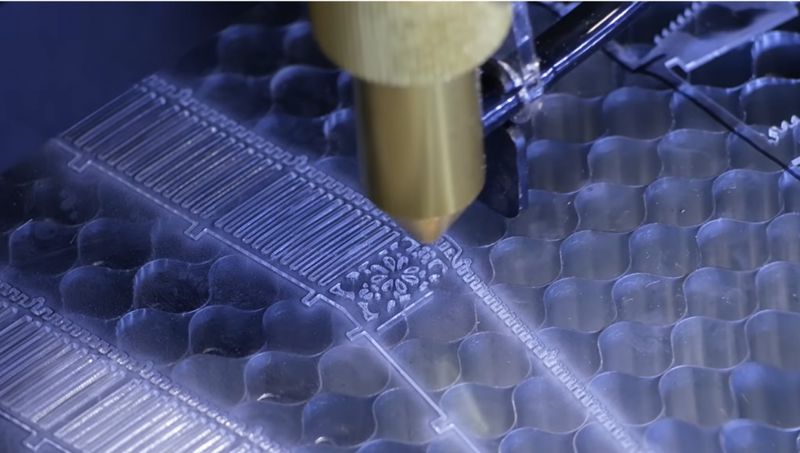

The TIKTOK earring collection by Majyo Majyo is entirely made from digital wastes by using the Beambox laser cutting technology. This is a perfect way to turn scraps of electronic components into stylish and environmentally friendly accessories with the thought of the future of our planet.

These clocks are just one example of creative works by the Taiwanese studio Clay Workshop. They are famous for making both aesthetic and functional products from eco-friendly materials, such as so-called ‘Paradise Soil’ extracted from the silt. Due to the excessive development of the cement industry and fish farming in the region, the studio decided to help the situation by using natural components obtained through cleaning the affected reservoir.

The Beambox laser engraving technique allows the studio to combine wood and Paradise Soil as well as processing the latter directly. Due to these advanced possibilities, the list of goods by Clay Workshop includes paper-weights, clocks, ornaments, and much more.

Another Taiwanese studio MK Design specializes in loft-style works with a personal touch. Their handmade furniture pieces and decorations are popular among consumers and corporate team buildings. The entire studio design, including the furniture and lighting, is created by the owner and his father themselves, which inspires many customers to explore craftsmanship.

The owner Mr. Wong chose the Beambox as the engraving tool because of its intuitive software, multi-computer control, and high compatibility of file formats. All these features enable the studio to provide their clients with highly personalized products in a quick and easy yet quality way.

Luke Towan is an Australian miniature artist and popular YouTuber who creates highly detailed railroad and architecture models. For his works, Luke uses the Beamo laser cutter due to its camera alignment function, which is of great help when it comes to working with precise details.

For example, for this 1:87 Iron Bridge model the artist took 1 mm acrylic sheets and combined all the miniature parts into a splendid work of art.

FLUX has successfully built a whole ecosystem of laser cutting and engraving devices effectively working in combination with supportive mechanisms and comprehensive software solutions. The company’s defining feature is accessibility that allows users of all levels to benefit from professional equipment with powerful capabilities.

Most importantly, FLUX is actively developing its technologies by crossing boundaries set by their previous products. Featuring great technical characteristics, the company’s machines provide high performance as well as broad creative, business, and educational prospects coupled with a reasonable price.

Update your browser to view this website correctly. Update my browser now

Write a comment